Providing Professional Overall Planning and Integrated Layout Design Solutions for Slaughtering and Processing Plants

An efficient, compliant, and sanitary slaughterhouse starts with a scientific and meticulous layout design. Leveraging over 15 years of industry experience and more than 300 successful projects, NPW offers comprehensive layout design services, from initial concept to final commissioning. We do more than just sell equipment; we deliver integrated solutions designed to maximize your return on investment.

Three Scientific Steps to Construct a Superior Processing Facility

1.In-depth Demand Alignment and Analysis Our journey begins with listening. Through in-depth communication with you, we will precisely capture the project’s core:

- Capacity Goals: Clarify your production scale (e.g., 300 BPH compact line, 3000 BPH standard line, or 10000+ BPH large-scale fully automatic line).

- Site Blueprint: Analyze your site conditions (dimensions, structure, water, electricity, and sewage interfaces), and propose optimization suggestions.

- Products and Certifications: Determine processing categories (chicken, duck, pig, cattle, etc.) and target market certification requirements (e.g., HALAL, HACCP, CE, USDA).

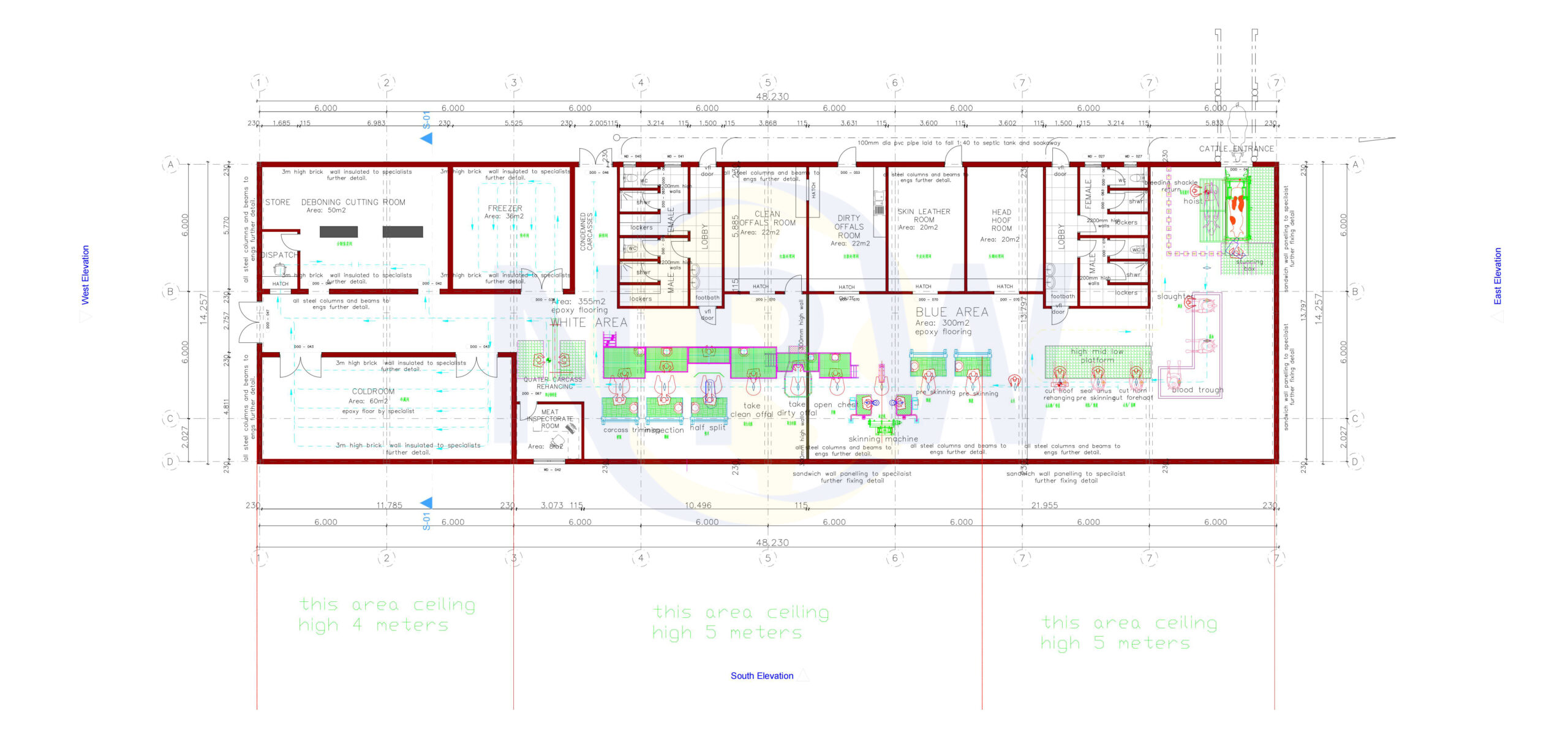

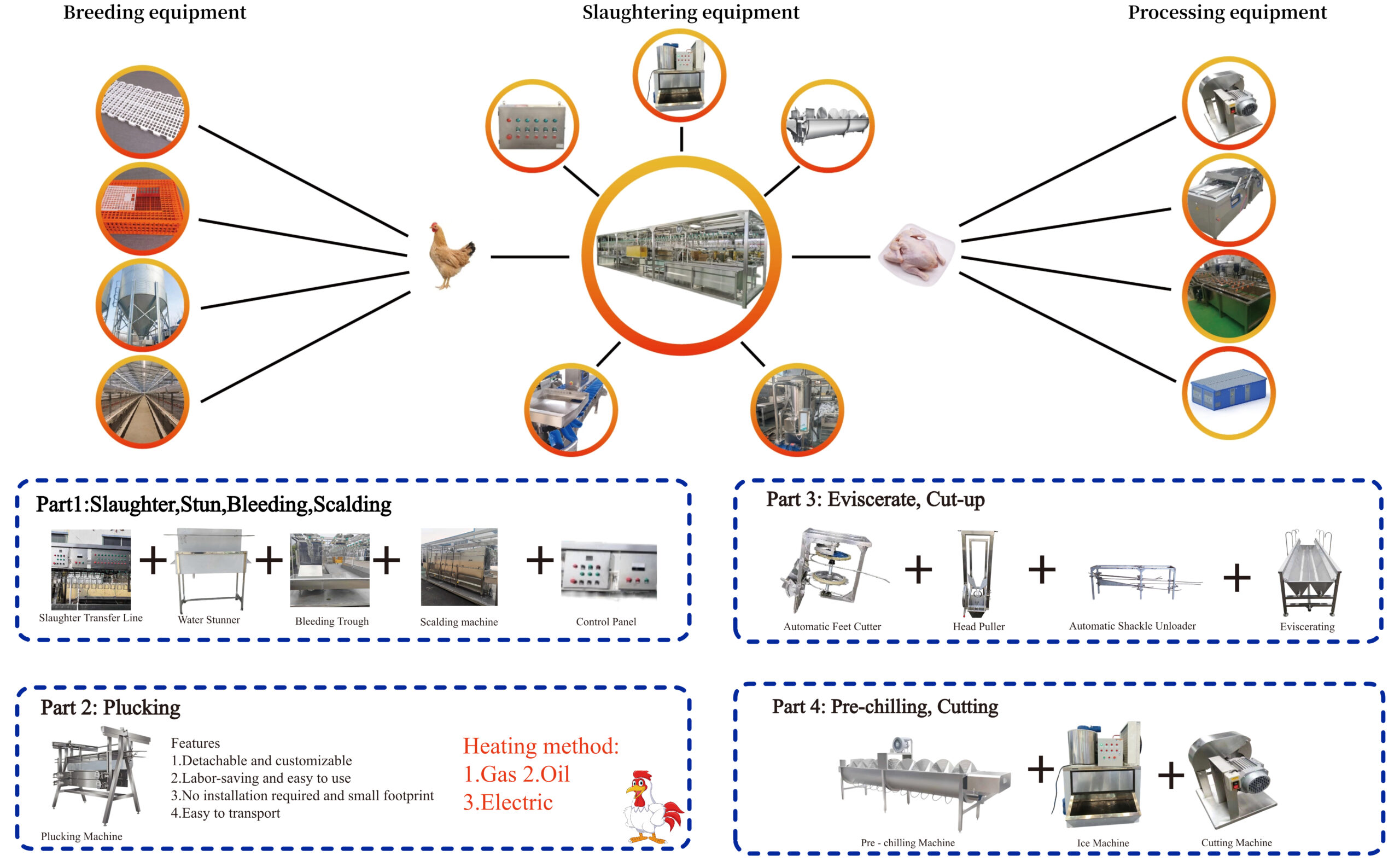

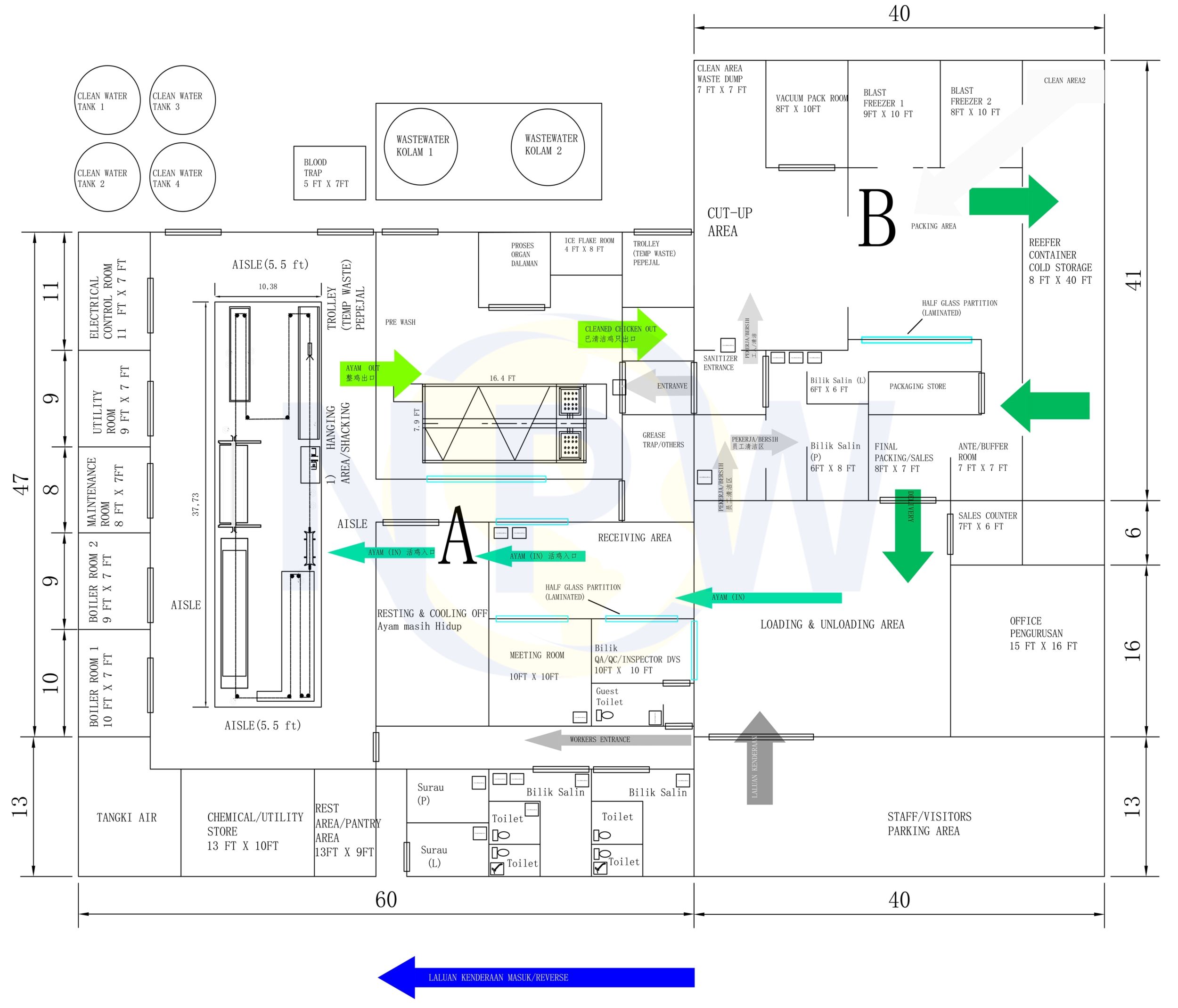

2. Conceptual Design and Process Planning Building upon the in-depth analysis, we meticulously craft an efficient production blueprint for you:

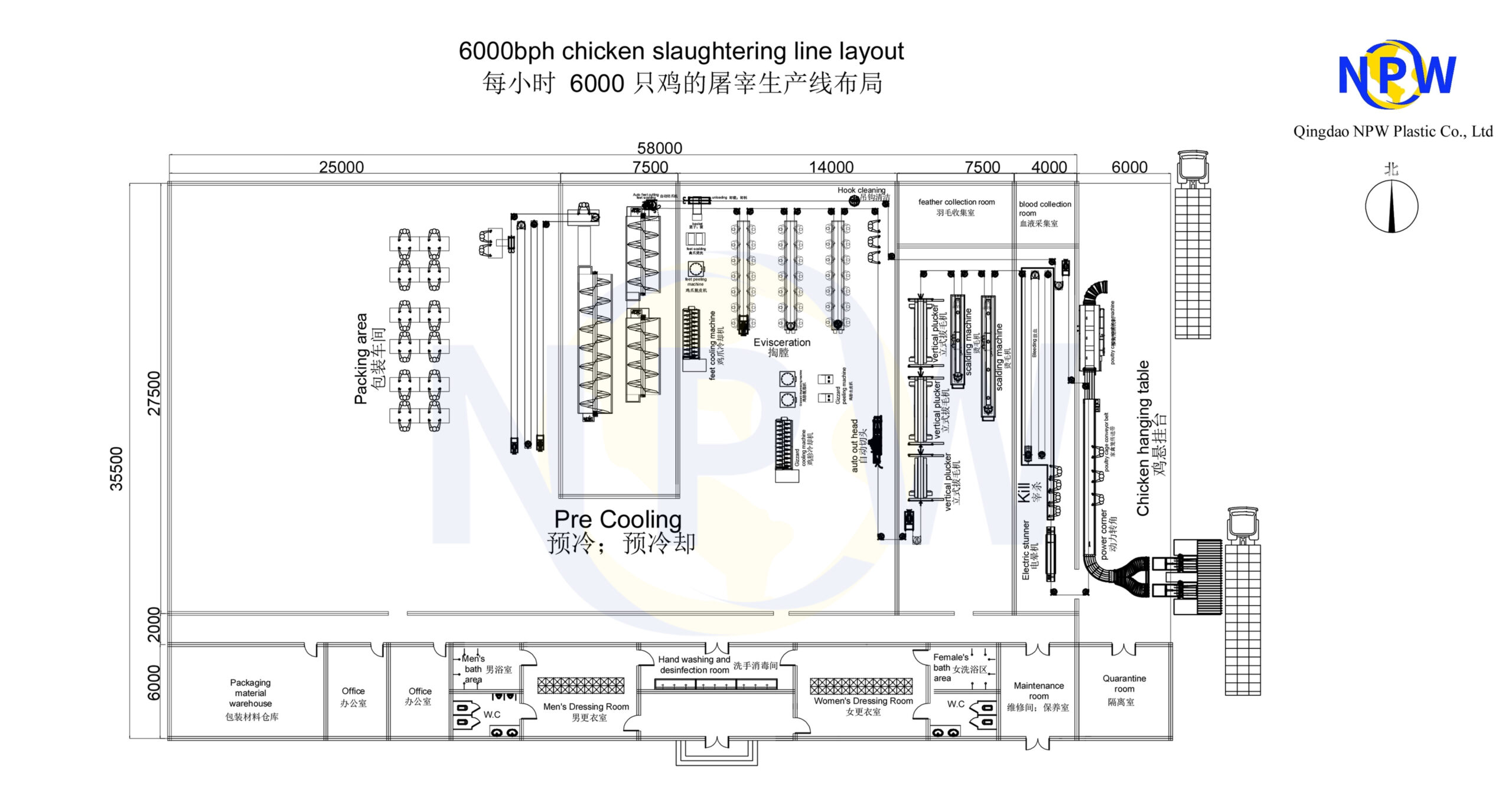

- Process Flow Design: We detail the complete process flow diagram, from live animal receiving, stunning, slaughtering, initial processing, all the way to final packaging. Our design ensures the shortest possible movement lines, strict separation of personnel and material flows, and the complete elimination of cross-contamination.

- Optimized Equipment Configuration: Based on your capacity requirements and specific process workflow, we precisely select and strategically position each piece of equipment from NPW’s comprehensive product range, conducting preliminary operational simulations to verify efficiency and compatibility.

3. 3D Visualization and Detailed Design We enable you to “foresee” your future factory before project commencement, thereby completely eliminating potential design flaws:

- 3D Solid Modeling: Create a complete three-dimensional model of the workshop, intuitively presenting the internal spatial layout, precise equipment positioning, and operator activity zones.

- 2D Construction Drawing Set: Provide a comprehensive set of 2D construction drawings, meticulously detailing all critical dimensions, utility interfaces (water, gas, steam, etc.), and electrical wiring points.

Four Key Advantages of NPW’s Layout Design

Successful Design Case Studies at a Glance

Case A: Middle East 500 BPH Halal Compact Poultry Processing Line

- Challenge: The project site had limited space and required strict adherence to Halal production standards.

- Solution: NPW provided a modular design solution, achieving high equipment integration and clear functional area zoning.

- Outcome: The production line was successfully commissioned within 90 days and passed all relevant certifications.

Case B: Asia 6000 BPH Modern Chicken Slaughter Line Upgrade Project

- Challenge: Renovation of an existing aging factory, requiring a significant increase in production capacity without interrupting current operations.

- Solution: Adopted a phased construction strategy, re-planned the entire process workflow, and introduced NPW’s efficient vertical defeathering line and advanced spiral pre-chiller.

- Outcome: Successfully increased production capacity by 200%, while achieving a significant reduction in energy consumption.

Commence Your Customized Engineering Planning Immediately Claim Your Complimentary Preliminary Facility Layout Proposal!