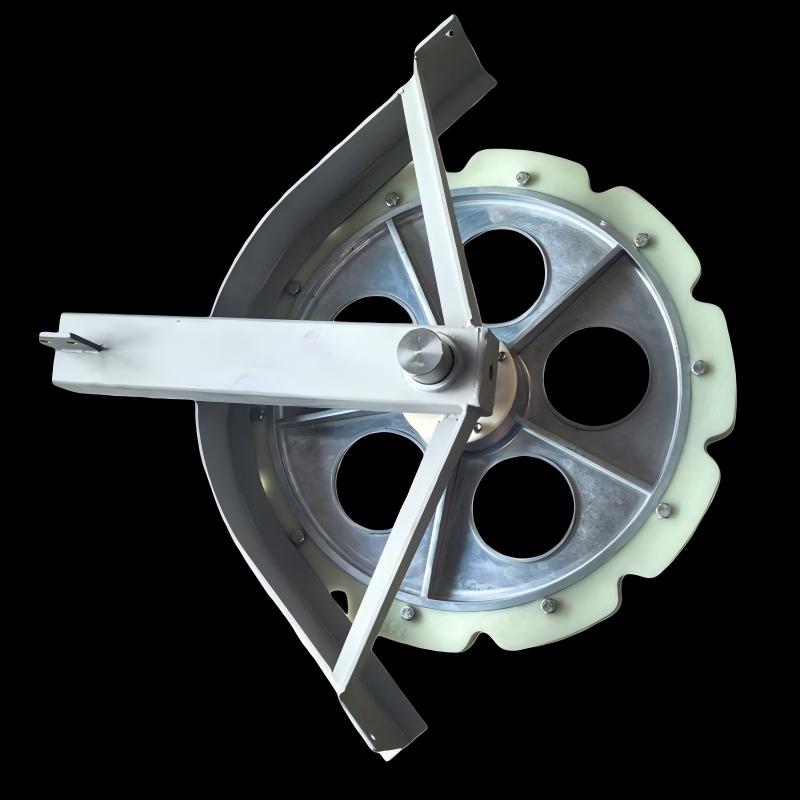

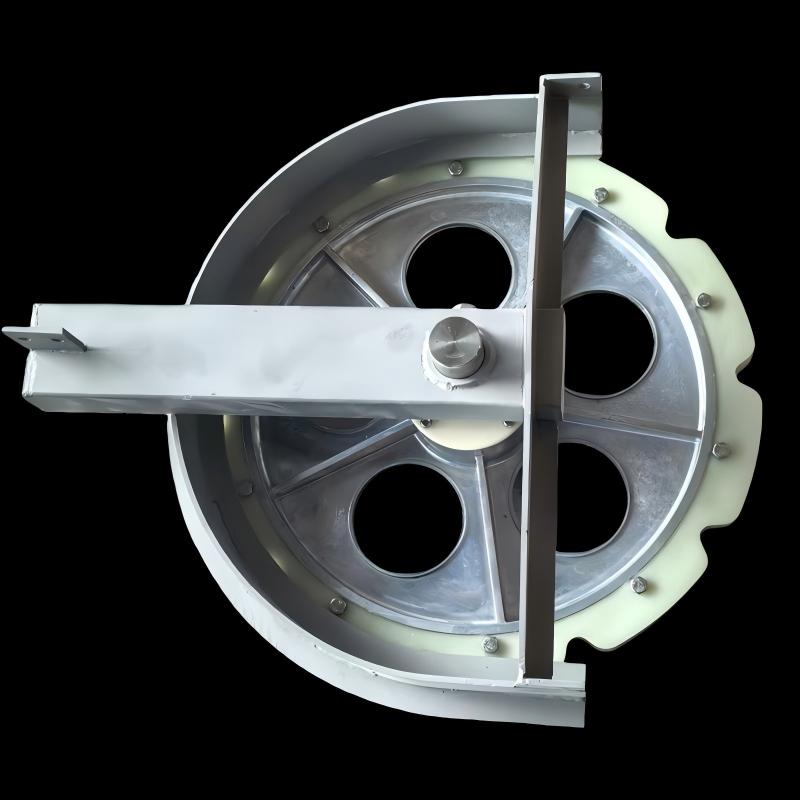

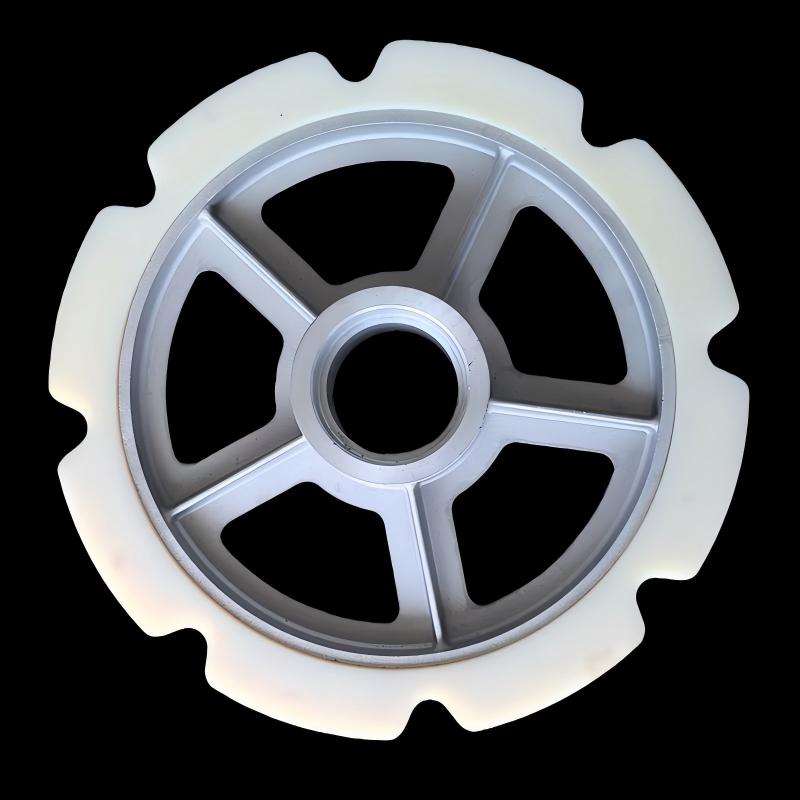

T-Type Guide Chain Bracket for Poultry Slaughter Line

Designed specifically for poultry slaughter overhead conveyor lines, this T-type guide rail support frame is constructed from food-grade 304 stainless steel. It is available in two standard guide wheel diameters (385mm and 485mm), each with 90° and 180° standard turning angle models.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Product Overview

Designed specifically for poultry slaughter overhead conveyor lines, this T-type guide rail support frame is constructed from food-grade 304 stainless steel. It is available in two standard guide wheel diameters (385mm and 485mm), each with 90° and 180° standard turning angle models. It is used to support and guide the smooth directional change of the conveyor chain in both horizontal and vertical planes.

Product Features

- Food-Grade Material: Full 304 stainless steel construction, corrosion-resistant and easy to clean, compliant with food production hygiene standards.

- Precise Guidance: T-type rail design ensures accurate chain running trajectory, minimizing shaking and derailment risks.

- Multi-Angle Adaptability: 90° angle for right-angle turns in production lines; 180° angle for U-turn return sections.

- High Load Capacity: Reinforced frame structure with single-point load capacity exceeding 150kg.

- Modular Design: Standardized interfaces for easy installation and maintenance, compatible with mainstream slaughter line equipment.

Specifications & Models

| Model | Guide Wheel Diameter | Turning Angle | Suitable Chain | Approx. Frame Dimensions |

|---|---|---|---|---|

| TGL-385-90 | 385mm | 90° | #80 / #100 | 450×450×280mm |

| TGL-385-180 | 385mm | 180° | #80 / #100 | 800×450×280mm |

| TGL-485-90 | 485mm | 90° | #100 / #120 | 550×550×320mm |

| TGL-485-180 | 485mm | 180° | #100 / #120 | 950×550×320mm |

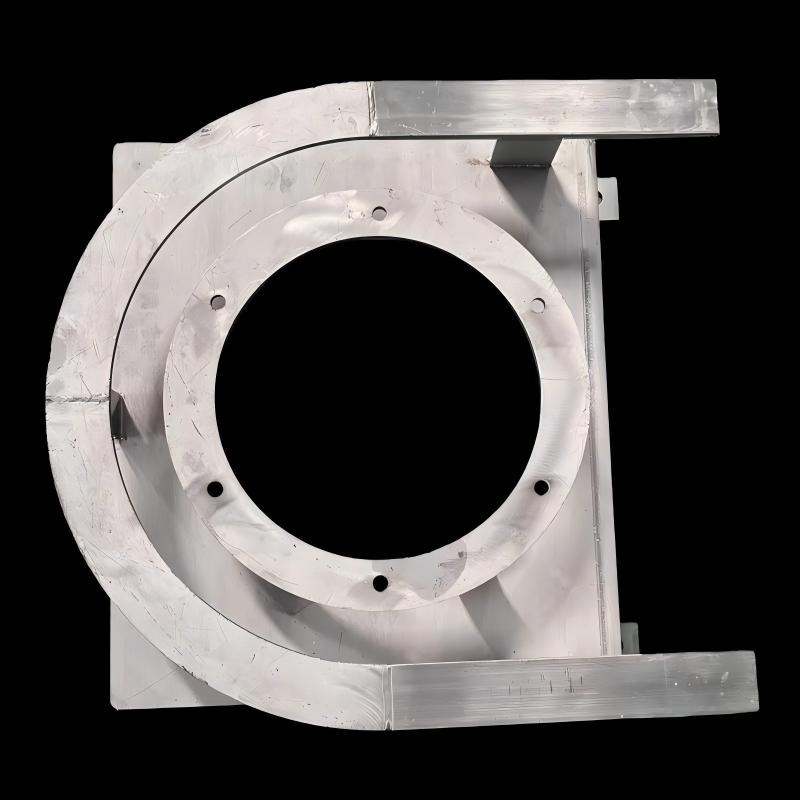

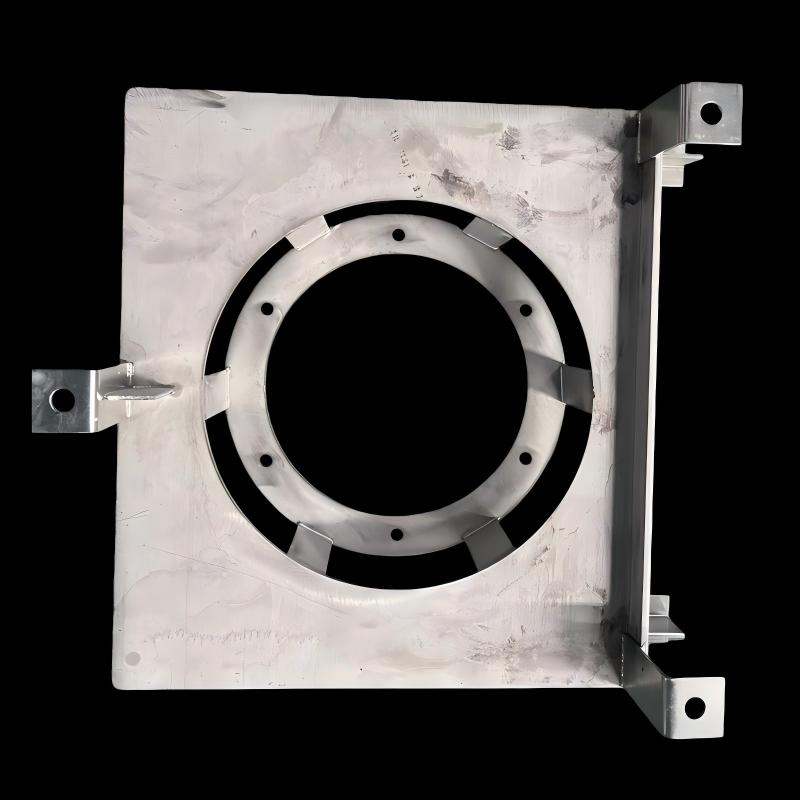

Material: 304 Stainless Steel (rail thickness 3mm, frame pipe 50×50×2mm)

Surface Treatment: Mechanical polishing (Ra ≤ 0.8μm)

Bearing Type: Fully sealed double-sided dust-proof bearings

Installation Method: Top suspension or side bracket fixing

Application Scenarios

- Horizontal turning stations in slaughter line overhead conveyor systems

- Chain guidance devices at elevator inlets/outlets

- Corner support for evisceration lines, pre-cooling lines, grading lines

- Retrofitting and upgrading of existing production lines

Installation Instructions

- Determine the installation position according to the production line layout.

- Secure the bracket to the building structure using expansion bolts.

- Adjust the bracket’s levelness (tolerance ≤ 1mm/m).

- Install the guide wheel and check its rotation flexibility.

- Mount the chain and debug the running trajectory.

Quality Assurance

- Load Test: 1.5 times full load static pressure test for 24 hours with no deformation.

- Precision Standard: Angle deviation ≤ 0.5°, flatness deviation ≤ 1mm.

- Service Life: ≥ 10 years under normal operating conditions.

- Warranty Period: 18 months (12 months for bearing components).

Packaging & Delivery

- Each bracket is individually packaged in a wooden crate with an accessory kit.

- Standard models are kept in stock for quick shipment.

- Custom sizes and angles are supported (drawings required).

Precise Guidance · Durable & Reliable

Providing stable turning support solutions for your slaughter production line!