T-Rail Heavy-Duty Metal Carriage

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

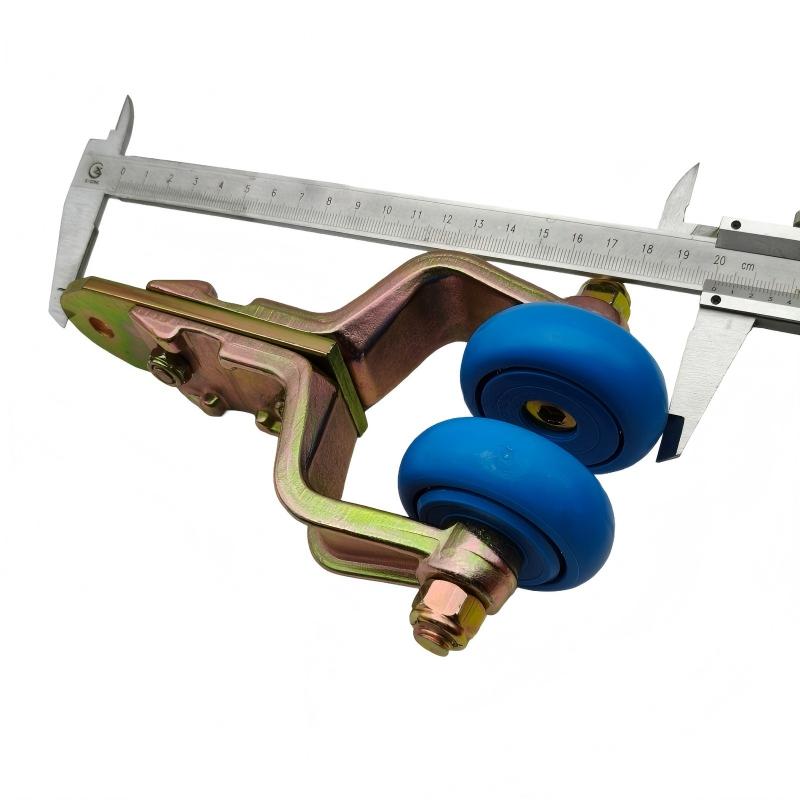

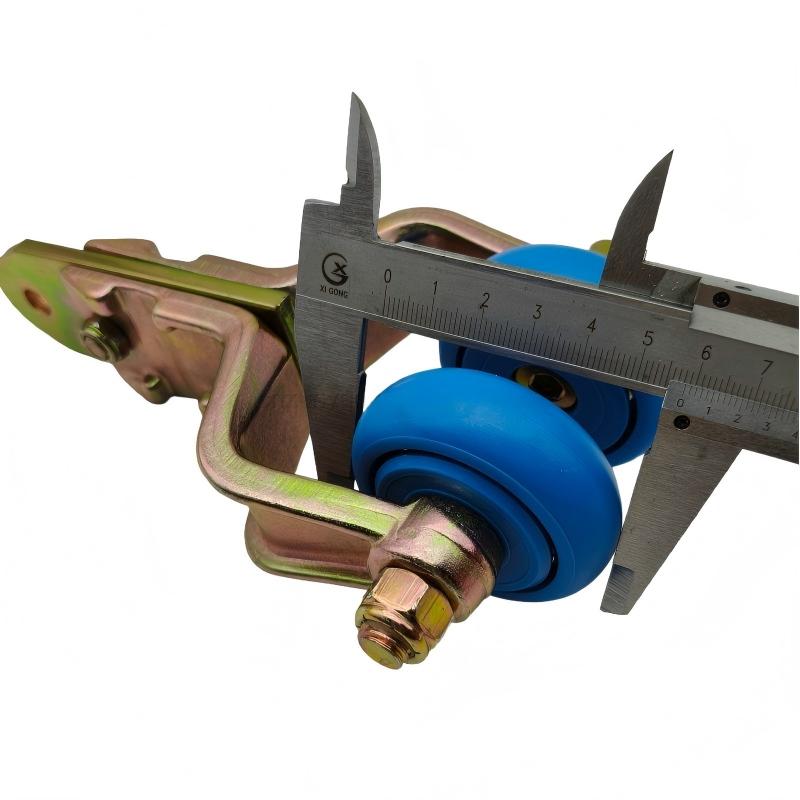

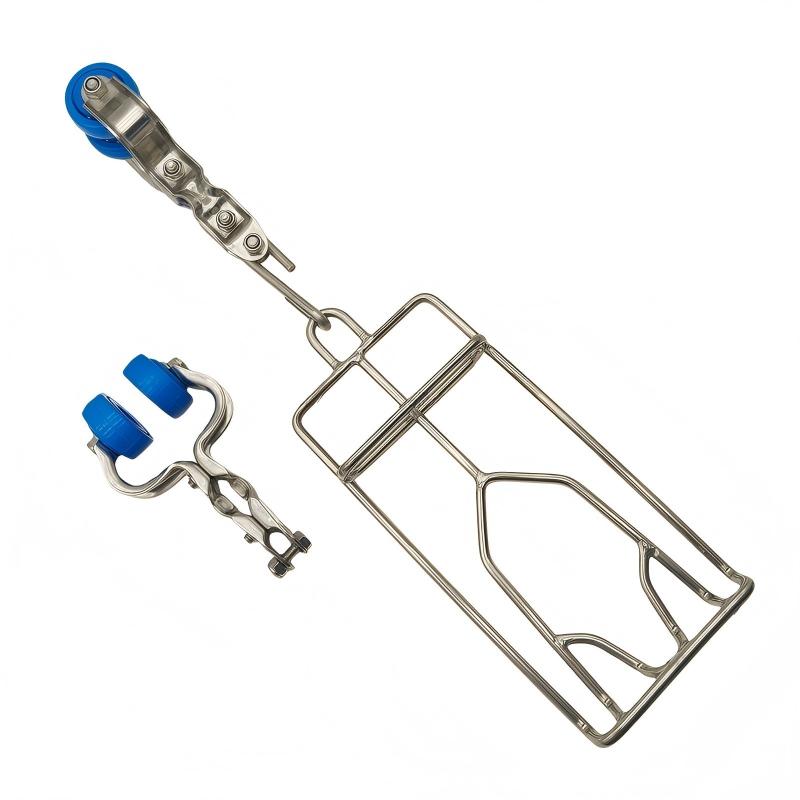

Product Name: T-Rail Heavy-Duty Metal Carriage (Hot-Dip Galvanized Steel / Stainless Steel Versions)

Product Positioning

A core load-bearing component for T-rail conveyor systems, specifically designed for high-load, high-intensity poultry slaughter lines. This product offers metal carriage options in two materials: hot-dip galvanized carbon steel and food-grade stainless steel (e.g., 304/316). Precision-manufactured to match standard T-shaped steel guide rail systems, it provides a robust, durable, and flexible high-performance solution for the conveyance of heavy poultry carcasses, high-frequency operations, and demanding hygiene environments.

Core Features

- Dual Material Options, Tailored to Need:

- Galvanized Steel Carriage: The main body is made from high-quality carbon steel with a hot-dip galvanized surface finish. It offers excellent rust and corrosion resistance with high cost-effectiveness, making it an ideal economical choice for most general-purpose and humid environments.

- Stainless Steel Carriage: The entire unit is manufactured from austenitic stainless steel. It provides superior corrosion resistance, can withstand high-strength chemical cleaning agents and prolonged damp conditions, fully meets the highest hygiene standards for food processing, and offers an extremely long service life.

- Heavy-Duty Structural Design: Features a reinforced structure with precision welding/casting processes, resulting in high overall rigidity and exceptional resistance to deformation. Optimized to withstand the continuous loads from heavy-duty hooks, multiple hanging carcasses, or tooling fixtures.

- Precision T-Slot Guidance System: Equipped with high-precision, wear-resistant alloy steel or stainless steel guide wheels (or sliders) that achieve precise engagement with the T-rail groove. Ensures smooth, accurate, and wobble-free operation even under heavy loads, providing a stable foundation for automated stations (e.g., cutting, weighing).

- High-Strength Connection & Drive Compatibility: The carriage body incorporates reinforced connection points for rigid, reliable linkage with galvanized drive chains or other transmission mechanisms. This guarantees efficient, synchronized power transmission during starts, stops, and acceleration, with no lag or disengagement.

- Key Comparison with Nylon Carriages: Compared to nylon carriages, this metal carriage offers absolute advantages in ultimate load capacity, overall structural rigidity, resistance to physical impact, and high-temperature tolerance. Nylon carriages are characterized by light weight, ultra-quiet operation, self-lubrication, and lower initial cost, whereas the metal carriage focuses on maximized durability, reliability, and adaptability to extreme production conditions.

Product Advantages

- Exceptional Load Capacity: Easily handles single-point loads far exceeding those of nylon carriages, suitable for large poultry or high-density processing lines.

- Extremely Long Lifecycle: The metal material itself resists aging, and the galvanized or stainless steel finish provides strong corrosion protection. Under normal use, its lifespan can reach several decades with low maintenance costs.

- Strong Environmental Adaptability: Particularly the stainless steel version, which can withstand frequent high-temperature/pressure washdowns and strong acid/alkali disinfectant environments without risk of rust contamination.

- Easy Maintenance: The structure is sturdy and durable. Primary maintenance is limited to guide wheel bearings, and the design allows for quick inspection and replacement.

Typical Applications

- Main conveyor lines and lift/lower sections in large slaughterhouses

- High-load bearing points in overhead chain systems

- Conveyor lines in pre-cooling and cooling rooms requiring frequent high-pressure washing and disinfection

- Stations integrated with automated cutting, grading, weighing, and other heavy-duty equipment

We can recommend the most suitable galvanized steel or stainless steel material solution based on your specific load requirements, environmental corrosiveness, and budget. Customization services are available to ensure precise compatibility with your existing T-rails and chain systems.