Sheepskin Hair Removal Machine

The Sheepskin Hair Removal Machine, also known as the Animal Hide Dehairing Machine, is a specialized equipment designed for efficient hair removal from various animal hides including pig skin, cattle hide, and sheep skin. This versatile machine is essential for leather processing facilities, tanneries, and meat processing plants that require clean, hair-free hides for further processing or leather production. Engineered with precision and built for durability, this hide dehairing machine combines mechanical efficiency with ease of operation. The robust construction featuring high-quality bearings and gear systems ensures reliable performance in demanding industrial environments. With its customizable capacity and dual voltage options (380V/220V), this machine adapts seamlessly to various operational requirements and electrical standards worldwide. The compact design (1600×900×1800mm) makes it suitable for facilities with limited space while maintaining impressive processing efficiency of 20 pieces per hour. Whether you’re processing pig skins for culinary applications, cattle hides for leather production, or sheep skins for specialty products, this machine delivers consistent, high-quality results.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Core Advantages

High Productivity

Designed for maximum efficiency, this machine processes up to 20 hides per hour, significantly improving throughput compared to manual dehairing methods. The automated operation ensures consistent processing speed, allowing facilities to meet high-volume production demands while maintaining quality standards. This high productivity translates directly to increased profitability and reduced processing time.

Easy Operation

The machine features an intuitive control system that requires minimal operator training. Simple controls and straightforward operation procedures enable staff to achieve optimal results quickly. The user-friendly design reduces the learning curve and ensures consistent performance across different operators and shifts, minimizing operational errors and maximizing efficiency.

Versatile Multi-Species Application

Unlike single-purpose equipment, this dehairing machine handles multiple animal types including:

- Pig Skin: Efficient hair removal for culinary and industrial applications

- Cattle Hide: Thorough dehairing for premium leather production

- Sheep Skin: Gentle yet effective processing for specialty leather and wool products

This versatility makes it an ideal investment for facilities processing multiple species or those looking to expand their product range.

Customizable Configuration

Understanding that every facility has unique requirements, this machine offers customization options including:

- Processing capacity tailored to production volume

- Voltage configuration (380V/220V) to match local electrical standards

- Dimensional adjustments for specific space constraints

- Specialized features for particular hide types or processing methods

Robust Construction

Built with painted steel construction, the machine offers excellent durability and corrosion resistance. The metallic color finish provides both aesthetic appeal and protective coating against harsh processing environments. This robust build ensures long-term reliability even under continuous heavy-duty operation.

Premium Core Components

Equipped with high-quality bearings and precision gear systems, the machine delivers:

- Smooth, consistent operation

- Minimal vibration and noise

- Extended service life

- Reduced maintenance requirements

- Reliable performance under demanding conditions

Technical Features

Compact Yet Efficient Design

- Dimensions: 1600×900×1800mm

- Space-efficient footprint suitable for various facility layouts

- Optimal height for ergonomic operation and maintenance

- Easy integration into existing processing lines

Flexible Power Configuration

- Dual voltage options: 380V/220V

- Adaptable to different regional electrical standards

- Energy-efficient operation

- Reliable performance across voltage variations

High-Quality Mechanical System

- Premium bearing components for smooth rotation

- Precision gear system for consistent power transmission

- Durable construction for long-term reliability

- Minimal wear and tear under continuous use

Efficient Processing Capacity

- 20 pieces per hour standard efficiency

- Customizable capacity based on specific requirements

- Consistent output throughout operational hours

- Scalable for different production volumes

Application Scenarios

This hide dehairing machine is ideal for:

Leather Processing Facilities

- Tanneries requiring clean hides for leather production

- Specialty leather manufacturers

- Premium hide processors

- Export-oriented leather facilities

Meat Processing Plants

- Integrated slaughterhouse operations

- By-product processing departments

- Hide preparation for sale or further processing

- Multi-species processing facilities

Agricultural Processing Centers

- Farm-based hide processing

- Cooperative processing facilities

- Small to medium-scale operations

- Custom processing services

Industrial Applications

- Gelatin production facilities

- Collagen extraction operations

- Industrial hide processing

- Specialty product manufacturing

Operational Benefits

Enhanced Productivity

- Process 20 hides per hour consistently

- Reduce manual labor requirements by up to 60%

- Minimize processing time per hide

- Increase overall facility efficiency

Superior Quality Output

- Thorough, consistent hair removal

- Minimal hide damage

- Preserved hide integrity for leather production

- Clean, ready-to-process hides

Cost Efficiency

- Reduced labor costs through automation

- Lower operational expenses

- Minimal maintenance requirements

- Energy-efficient operation

- Long-term durability reduces replacement costs

Improved Working Conditions

- Reduced physical strain on workers

- Cleaner, more hygienic processing environment

- Safer operation compared to manual methods

- Consistent results regardless of operator experience

Processing Capabilities

Pig Skin Processing

- Efficient removal of coarse pig hair

- Suitable for culinary-grade skin preparation

- Clean processing for industrial applications

- Gentle handling to preserve skin integrity

Cattle Hide Processing

- Thorough dehairing of thick cattle hides

- Preparation for premium leather production

- Consistent results across different hide sizes

- Minimal damage to valuable hide surface

Sheep Skin Processing

- Gentle yet effective wool and hair removal

- Suitable for specialty leather production

- Preservation of delicate skin structure

- Preparation for various end-use applications

Quality Assurance & Support

Comprehensive Warranty

- 1-year warranty coverage on all components

- Quality guarantee on mechanical systems

- Replacement parts availability

- Technical support throughout warranty period

Professional Documentation

- Mechanical test reports provided

- Video factory inspection available before shipment

- Pre-shipment performance testing

- Complete quality documentation included

- Operation and maintenance manuals

Secure Packaging & Delivery

- Professional wooden case packaging

- Protection during international shipping

- Secure component arrangement

- Complete installation accessories included

- Safe delivery to your facility

Expert Manufacturing

- Professional production from Shandong, China

- Experienced engineering team

- Quality control at every production stage

- Proven manufacturing processes

- International quality standards

| Product Name | Sheepskin Hair Removal Machine / Hide Dehairing Machine |

| Application | Pig, Cattle, Sheep |

| Suitable For | Pig Skin, Cattle Hide, Sheep Skin |

| Function | Customized Hide Dehairing Machine, Hair Removal |

| Capacity | Customized |

| Efficiency | 20 Pieces/Hour |

| Material | Painted Steel |

| Dimensions (L×W×H) | 1600×900×1800mm |

| Voltage | 380V/220V |

| Color | Metallic Color |

| Operation | Easy |

| Core Component | Bearing, Gear |

| Core Selling Point | High Productivity |

| Warranty Period | 1 Year |

| Place of Origin | Shandong, China |

| Mechanical Test Report | Available |

| Video Factory Inspection | Available |

| Packaging | Wooden Case |

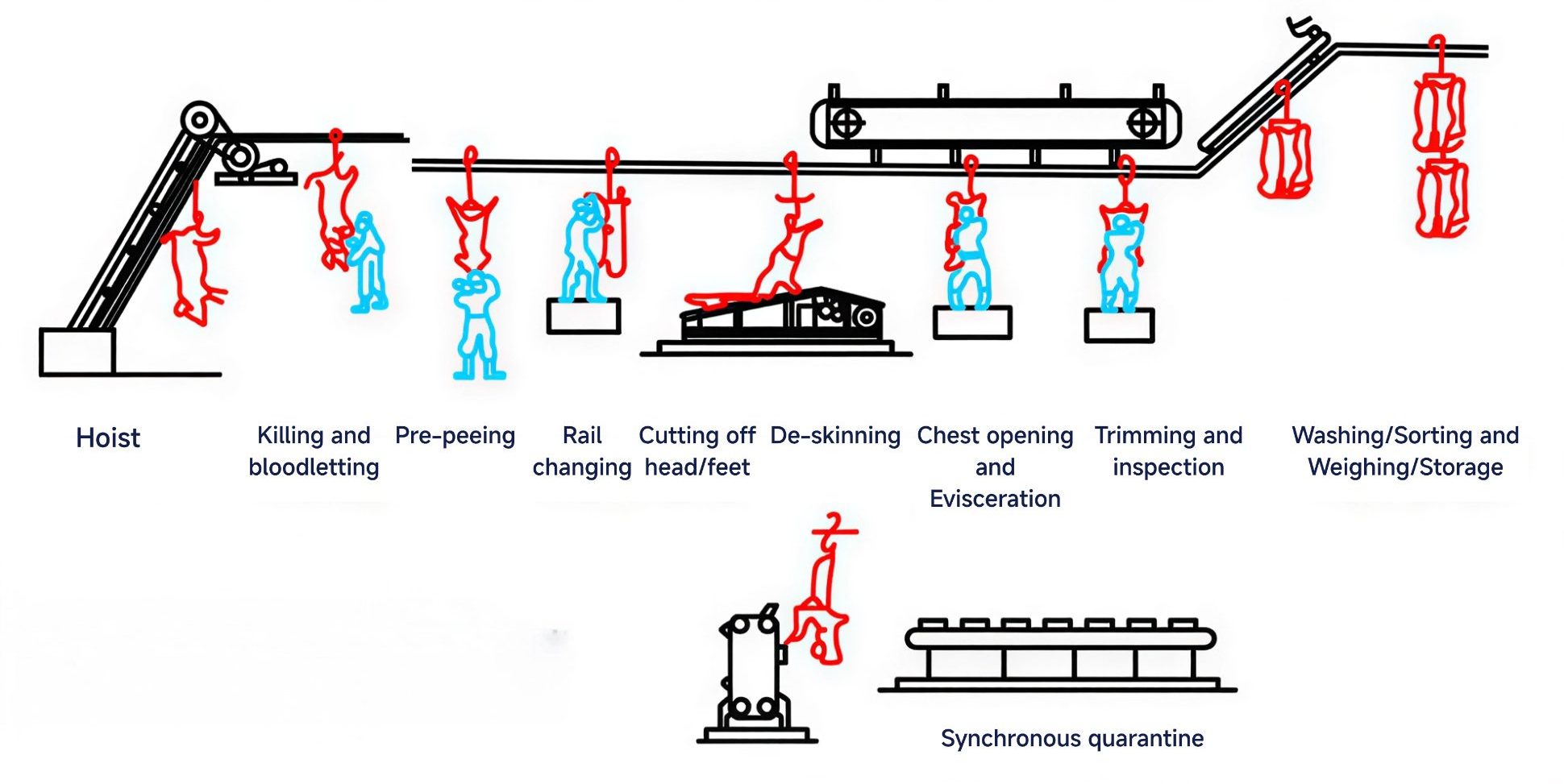

TECHNOLOGY FLOW SHEET FOR SHEEP SLAUGHTERING AND PROCESSING