Sheep Hoof Hair Removal Machine

The Sheep Hoof Hair Removal Machine, also known as the Animal Hoof Dehairing Machine, is a high-performance industrial equipment specifically engineered for efficient and thorough removal of hair from animal hooves during slaughterhouse processing operations. This versatile machine is designed to handle multiple species including sheep, goats, pigs, and cattle, making it an indispensable tool for modern meat processing facilities that require clean, presentation-ready hooves for further processing, by-product utilization, or specialty product preparation.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Core Advantages

High Productivity

With an impressive processing capacity of 1-2 tons per hour, this machine dramatically increases throughput compared to manual or semi-automated dehairing methods. This exceptional productivity enables slaughterhouses to:

- Process large volumes of hooves efficiently and consistently

- Reduce processing time per hoof by up to 85%

- Eliminate labor bottlenecks in by-product processing operations

- Maintain steady production flow throughout operational hours

- Meet high-volume market demands for clean hooves

- Maximize daily output and profitability from by-product streams

- Support large-scale commercial operations

The automated operation ensures continuous, reliable performance that significantly outpaces manual methods while delivering superior and consistent dehairing quality across all processed hooves.

Multi-Species Versatility

Designed to handle multiple animal types with one machine:

- Sheep Hooves: Efficient hair removal from lamb and sheep hooves for various applications

- Goat Hooves: Thorough cleaning of goat hooves for specialty products

- Pig Hooves: Effective dehairing of pig trotters for culinary and industrial uses

- Cattle Hooves: Robust processing of cattle hooves for gelatin and by-product applications

This versatility makes it an ideal investment for:

- Multi-species slaughterhouses

- Facilities processing seasonal variations in animal types

- Operations looking to expand product range

- By-product processing centers handling diverse inputs

- Integrated meat processing facilities

The ability to process multiple species eliminates the need for separate equipment purchases, maximizing capital efficiency and floor space utilization.

Premium SS304 Stainless Steel Construction

Built entirely from SS304 (Stainless Steel 304), the machine offers superior quality:

- Food-Grade Material: Full compliance with international food safety standards

- Exceptional Corrosion Resistance: Superior resistance to moisture, chemicals, and harsh processing environments

- Enhanced Durability: SS304 provides better strength and longevity than standard stainless steel

- Easy Cleaning: Smooth, non-porous surfaces facilitate thorough sanitization

- Hygienic Operation: Prevents bacterial growth and contamination

- Professional Appearance: Maintains aesthetic quality throughout service life

- Long-Term Reliability: Minimal maintenance requirements and extended service life

- Chemical Resistance: Withstands cleaning agents and sanitizing solutions

SS304 is the premium choice for food processing equipment, offering superior performance compared to lower-grade materials.

Robust Heavy-Duty Construction

The machine’s substantial 500kg weight and solid construction provide:

- Exceptional Stability: Heavy construction eliminates vibration and movement during high-speed operation

- Consistent Performance: Stable platform ensures uniform dehairing results

- Durability: Robust build withstands continuous commercial use processing 1-2 tons per hour

- Safety: Secure, stable operation protects workers and equipment

- Longevity: Heavy-duty construction ensures years of reliable service

- Reduced Maintenance: Solid construction minimizes wear and component failure

- Professional Quality: Industrial-grade build suitable for demanding environments

Large Processing Capacity

The generous dimensions (2400×1170×1400mm) provide:

- Ample Processing Space: Large working area accommodates high-volume throughput

- Efficient Material Flow: Optimized dimensions facilitate smooth hoof movement through the machine

- Batch Processing: Process multiple hooves simultaneously for maximum efficiency

- Reduced Bottlenecks: Large capacity prevents processing delays

- Scalable Operation: Suitable for both medium and large-scale facilities

Flexible Power Configuration

Multiple voltage options ensure global compatibility:

- 220V: Suitable for regions with standard single-phase power

- 380V: Ideal for three-phase industrial applications

- Custom Voltage: Adaptable to customer local electrical requirements

- Power and Phase: Configurable to match facility specifications

- Global Compatibility: Ensures seamless integration worldwide

This flexibility ensures the machine can be installed in any facility regardless of local electrical standards, eliminating compatibility concerns and facilitating international sales.

High-Quality Motor System

Equipped with premium motor components:

- Reliable Performance: Consistent power delivery for continuous operation

- Efficient Operation: Optimized motor efficiency reduces energy consumption

- Long Service Life: Quality motors ensure extended operational lifespan

- Smooth Operation: Minimal vibration and noise during use

- Easy Maintenance: Accessible motor design facilitates servicing

- Proven Reliability: Industrial-grade motors suitable for heavy-duty use

Technical Features

Large-Scale Processing Capacity

- 1-2 tons per hour throughput

- Suitable for high-volume commercial operations

- Consistent output throughout operational hours

- Scalable integration into complete processing lines

- Accommodates varying production demands

Substantial Dimensions

- Length: 2400mm – provides extended processing area

- Width: 1170mm – optimal working width for efficiency

- Height: 1400mm – ergonomic height for operation and maintenance

- Space-efficient design despite large capacity

- Professional industrial footprint

Heavy-Duty Construction

- 500kg weight ensures operational stability

- SS304 stainless steel throughout

- Precision-engineered components

- Minimal wear and tear

- Designed for continuous heavy-duty operation

Premium Material Quality

- SS304 (Stainless Steel 304) construction

- Superior corrosion resistance

- Food-grade material compliance

- Enhanced durability and longevity

- Professional finish and appearance

Flexible Electrical Configuration

- 220V option for standard power systems

- 380V option for industrial three-phase power

- Custom voltage configurations available

- Power and phase adaptable to local requirements

- Global electrical compatibility

Quality Motor System

- High-performance motor as core component

- Reliable power delivery

- Energy-efficient operation

- Long service life

- Easy maintenance access

Application Scenarios

This hoof hair removal machine is ideal for:

Multi-Species Slaughterhouses

- Integrated facilities processing sheep, goats, pigs, and cattle

- Large-scale commercial slaughter operations

- Export-oriented meat processing facilities

- High-volume production environments

- Halal and Kosher certified facilities

By-Product Processing Centers

- Dedicated hoof processing operations

- Gelatin production facilities

- Bone meal manufacturing plants

- Pet food ingredient suppliers

- Collagen extraction operations

Specialty Product Manufacturing

- Traditional culinary product preparation (pig trotters, etc.)

- Ethnic food processing facilities

- Specialty meat product manufacturers

- Value-added by-product processing

- Gourmet and premium product lines

Industrial Applications

- Rendering plants

- Animal protein processing

- Industrial gelatin production

- Pharmaceutical ingredient preparation

- Technical gelatin manufacturing

Agricultural Processing

- Farm-based by-product processing

- Cooperative processing facilities

- Regional collection and processing centers

- Small to large-scale operations

- Custom processing services

Operational Benefits

Enhanced Productivity

- Process 1-2 tons of hooves per hour

- Reduce manual labor requirements by up to 85%

- Eliminate time-consuming manual dehairing

- Increase overall processing efficiency

- Maximize daily throughput and profitability

- Support high-volume commercial operations

Superior Quality Output

- Thorough, consistent hair removal

- Clean, presentation-ready hooves

- Minimal residual hair

- Preserved hoof integrity

- Enhanced product appearance and value

- Meets quality standards for various applications

Cost Efficiency

- Reduced labor costs through automation

- Lower operational expenses

- Minimal maintenance requirements (SS304 durability)

- Energy-efficient motor operation

- Long-term durability reduces replacement costs

- Increased by-product value through quality improvement

- Multi-species capability maximizes equipment utilization

Improved Hygiene

- SS304 stainless steel prevents contamination

- Easy cleaning and sanitization

- Reduced manual contact with products

- Compliance with food safety regulations

- Enhanced traceability and quality control

- Suitable for food-grade applications

Versatile Application

- Process multiple animal species with one machine

- Adapt to seasonal variations in animal types

- Expand product range without additional equipment

- Maximize capital efficiency

- Optimize floor space utilization

Processing Capabilities

Sheep Hoof Processing

- Efficient hair removal from lamb and sheep hooves

- Suitable for various sheep breeds and sizes

- Clean hooves for gelatin production

- Prepared hooves for pet food ingredients

- Ready for bone meal processing

Goat Hoof Processing

- Thorough cleaning of goat hooves

- Suitable for specialty product applications

- Clean processing for various end uses

- Consistent results across different sizes

- Quality output for premium applications

Pig Hoof Processing (Trotters)

- Effective dehairing of pig trotters

- Preparation for culinary applications

- Clean hooves for traditional dishes

- Suitable for Asian and European cuisines

- Ready for cooking or further processing

- Industrial applications (gelatin, collagen)

Cattle Hoof Processing

- Robust processing of cattle hooves

- Thorough hair removal from large hooves

- Preparation for gelatin production

- Suitable for industrial applications

- Clean hooves for bone meal manufacturing

- Quality output for pharmaceutical ingredients

Market Applications

Gelatin Production

- Clean hooves essential for high-quality gelatin

- Food-grade gelatin manufacturing

- Pharmaceutical gelatin production

- Technical gelatin applications

- Premium quality requirements

Pet Food Industry

- Natural pet treats and chews

- Pet food ingredient preparation

- High-protein animal products

- Premium pet food applications

- Growing market demand

Culinary Applications

- Pig trotters for Asian cuisines

- Traditional European dishes

- Middle Eastern preparations

- Specialty restaurant supplies

- Gourmet food products

Industrial By-Products

- Bone meal production

- Animal protein processing

- Collagen extraction

- Rendering operations

- Industrial ingredient preparation

Agricultural Feed

- Animal feed supplements

- Protein meal production

- Agricultural by-products

- Feed ingredient preparation

| Product Name | Sheep Hoof Hair Removal Machine / Animal Hoof Dehairing Machine |

| Application | Pig, Sheep, Goat, Cattle |

| Capacity | 1-2 Tons/Hour |

| Material | SS304 (Stainless Steel 304) |

| Dimensions (L×W×H) | 2400×1170×1400mm |

| Weight | 500kg |

| Voltage | 220V/380V/Customer Local Request |

| Power and Phase | Customer Local Request |

| Core Component | Motor |

| Core Selling Point | High Productivity |

| Warranty Period | 1 Year |

| Place of Origin | Shandong, China |

| Mechanical Test Report | Available |

| Video Factory Inspection | Available |

| Minimum Order Quantity | 1 Set |

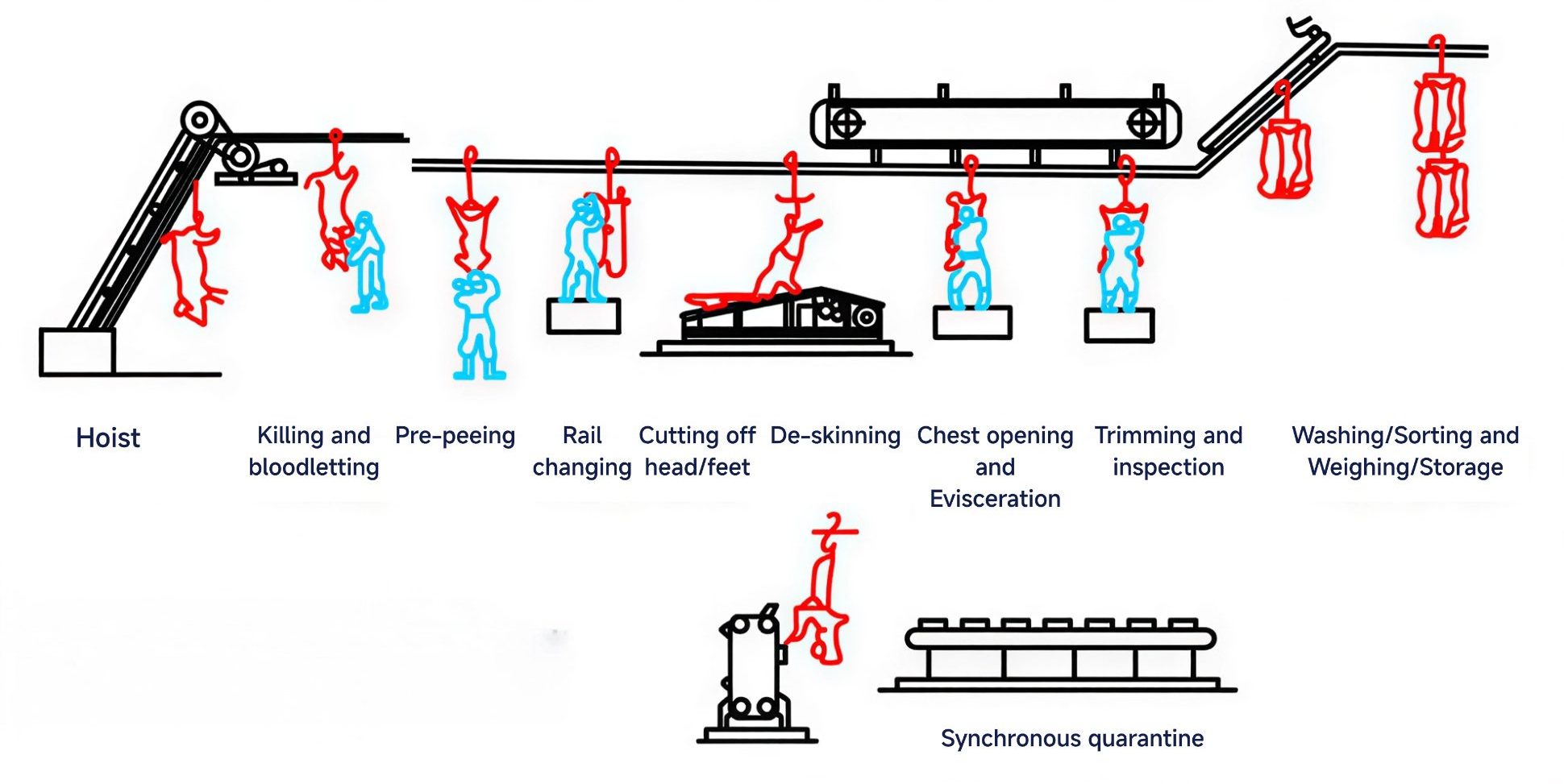

TECHNOLOGY FLOW SHEET FOR SHEEP SLAUGHTERING AND PROCESSING