Sheep Head Splitting Machine

The Sheep Head Splitting Machine is a high-performance automated equipment specifically engineered for precise and efficient splitting of animal heads in modern slaughterhouse operations. This professional-grade machine is designed to handle sheep, pig, and sow heads with exceptional speed and accuracy, making it an indispensable tool for meat processing facilities that require consistent head splitting for further processing, inspection, or specialized product preparation. Manufactured with premium stainless steel construction and powered by a robust 3kW motor system, this machine delivers outstanding productivity of up to 500 pieces per hour. The compact yet sturdy design (960×890×2100mm, 250kg) ensures stable operation while maintaining a space-efficient footprint suitable for various slaughterhouse layouts. With flexible voltage options (220V/380V/460V or customized) and customizable power configurations, this machine adapts seamlessly to different regional electrical standards and operational requirements worldwide. The head splitting process is critical in slaughterhouse operations for veterinary inspection, brain removal, tongue extraction, and specialized meat product preparation. This automated machine eliminates the safety risks and inconsistencies associated with manual splitting methods, providing clean, precise cuts that facilitate downstream processing while improving workplace safety and operational efficiency.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Core Advantages

High Productivity

With an impressive capacity of 500 pieces per hour, this machine dramatically increases processing throughput compared to manual or semi-automated methods. This exceptional productivity enables slaughterhouses to:

- Meet high-volume production demands efficiently

- Reduce processing bottlenecks in the slaughter line

- Maximize daily output and profitability

- Maintain consistent processing speed throughout operational hours

- Accommodate peak production periods without compromising quality

The automated operation ensures continuous, reliable performance that significantly outpaces manual splitting methods while maintaining superior precision and safety standards.

Precision Splitting Technology

The machine employs advanced splitting mechanisms that deliver:

- Clean, accurate longitudinal cuts through the skull

- Consistent splitting results across different head sizes

- Minimal bone fragmentation and tissue damage

- Optimal presentation for veterinary inspection

- Facilitated access to brain, tongue, and other valuable parts

This precision is crucial for maintaining product quality, meeting inspection requirements, and maximizing the value of head meat and by-products.

Enhanced Safety

Automated head splitting eliminates one of the most hazardous manual operations in slaughterhouses:

- Removes workers from direct contact with sharp cutting tools

- Eliminates repetitive strain injuries associated with manual splitting

- Reduces risk of blade-related accidents

- Provides protective barriers during operation

- Improves overall workplace safety standards

Premium Stainless Steel Construction

Built entirely from high-grade stainless steel, the machine offers:

- Exceptional durability and corrosion resistance

- Full compliance with food safety and hygiene standards

- Easy cleaning and sanitization

- Resistance to harsh processing environments

- Long-term reliability with minimal maintenance

- Professional appearance and build quality

Versatile Multi-Species Application

Designed to handle multiple animal types:

- Sheep Heads: Efficient splitting for lamb and mutton processing

- Pig Heads: Precise cutting for pork head meat preparation

- Sow Heads: Robust performance for larger animal heads

This versatility makes it an ideal investment for facilities processing multiple species or those looking to expand their product range without additional equipment purchases.

Flexible Power Configuration

Multiple voltage options ensure global compatibility:

- 220V for regions with standard single-phase power

- 380V for three-phase industrial applications

- 460V for North American and specific international markets

- Customized voltage configurations available upon request

- Power and phase adaptable to customer local requirements

This flexibility ensures seamless integration into any facility’s existing electrical infrastructure.

Compact Yet Powerful Design

Despite its high capacity, the machine maintains a space-efficient footprint:

- Dimensions: 960×890×2100mm (L×W×H)

- Weight: 250kg for stable operation

- Suitable for various facility layouts

- Easy integration into existing slaughter lines

- Optimal height for ergonomic operation and maintenance

Technical Features

High-Performance Power System

- 3kW motor provides consistent, reliable power

- Efficient energy consumption

- Smooth operation under continuous use

- Minimal vibration and noise

- Long motor service life

Robust Mechanical Construction

- 250kg weight ensures operational stability

- Precision-engineered components

- Durable cutting mechanisms

- Minimal wear and tear

- Designed for heavy-duty continuous operation

Impressive Processing Capacity

- 500 pieces per hour standard capacity

- Consistent output throughout operational hours

- Suitable for high-volume production facilities

- Scalable integration into complete slaughter lines

- Accommodates varying production demands

Space-Efficient Design

- Compact footprint: 960×890×2100mm

- Vertical design maximizes floor space utilization

- Easy access for operation and maintenance

- Suitable for facilities with space constraints

- Professional industrial appearance

Global Electrical Compatibility

- Multiple voltage options: 220V/380V/460V

- Customizable electrical configurations

- Adaptable power and phase settings

- Compliant with international electrical standards

- Flexible installation requirements

Application Scenarios

This head splitting machine is ideal for:

Commercial Slaughterhouses

- Large-scale sheep and lamb processing facilities

- Pig and pork processing plants

- Multi-species slaughter operations

- Export-oriented meat processing facilities

- High-volume production environments

Complete Slaughter Line Integration

- Seamless integration with stunning equipment

- Compatible with bleeding and washing systems

- Coordinates with head processing stations

- Works efficiently with inspection areas

- Facilitates downstream by-product processing

Specialized Processing Operations

- Head meat extraction facilities

- Brain and tongue processing operations

- Specialty meat product manufacturers

- By-product processing departments

- Halal and Kosher certified facilities

Veterinary Inspection Stations

- Facilitates mandatory head inspection procedures

- Enables thorough brain examination

- Supports disease surveillance programs

- Complies with regulatory inspection requirements

- Improves inspection efficiency and accuracy

Operational Benefits

Enhanced Productivity

- Process up to 500 heads per hour

- Reduce manual labor requirements by up to 80%

- Eliminate processing bottlenecks

- Increase overall line efficiency

- Maximize daily throughput

Superior Quality Output

- Clean, precise longitudinal cuts

- Consistent splitting results

- Minimal bone fragmentation

- Preserved tissue integrity

- Optimal presentation for inspection and processing

Cost Efficiency

- Reduced labor costs through automation

- Lower operational expenses

- Minimal maintenance requirements

- Energy-efficient 3kW power consumption

- Long-term durability reduces replacement costs

Improved Safety

- Eliminates hazardous manual splitting operations

- Reduces workplace injuries

- Protects workers from sharp tools

- Improves overall safety compliance

- Creates safer working environment

Regulatory Compliance

- Facilitates mandatory veterinary inspections

- Supports food safety protocols

- Enables thorough disease surveillance

- Meets international processing standards

- Ensures traceability and quality control

Processing Capabilities

Sheep Head Processing

- Efficient splitting of lamb and sheep heads

- Suitable for various sheep breeds and sizes

- Clean cuts for meat extraction

- Facilitates brain and tongue removal

- Optimal for specialty sheep head products

Pig Head Processing

- Precise splitting of pig heads

- Handles standard market weight pigs

- Facilitates cheek meat extraction

- Enables brain and tongue processing

- Supports pork head meat product preparation

Sow Head Processing

- Robust performance for larger sow heads

- Consistent results despite size variations

- Durable construction handles heavy-duty use

- Efficient processing of breeding stock

- Suitable for industrial-scale operations

| Product Name | Sheep Head Splitting Machine |

| Application | Sheep / Pig / Sow |

| Capacity | 500 Pieces/Hour |

| Material | Stainless Steel |

| Power | 3kW |

| Dimensions (L×W×H) | 960×890×2100mm |

| Weight | 250kg |

| Voltage | 220V/380V/460V/Customized |

| Power and Phase | Customer Local Request |

| Core Component | Other |

| Core Selling Point | High Productivity |

| Warranty Period | 1 Year |

| Place of Origin | Shandong, China |

| Mechanical Test Report | Available |

| Video Factory Inspection | Available |

| Packaging | Standard Wooden Case |

| Shipping Cost | Contact Customer Service for Confirmation |

| Minimum Order Quantity | 1 Set |

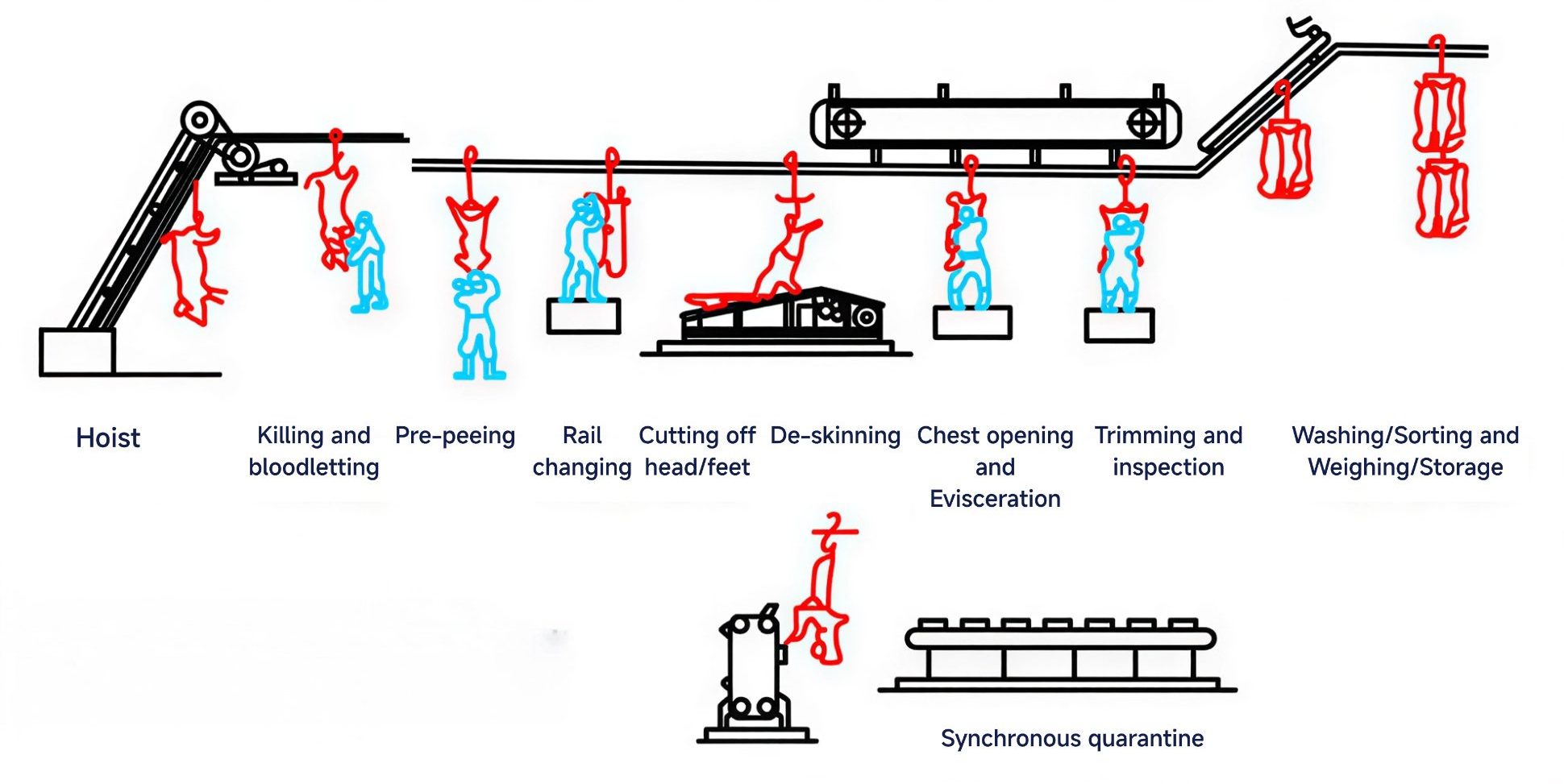

TECHNOLOGY FLOW SHEET FOR SHEEP SLAUGHTERING AND PROCESSING