Pulley Carrying Hook

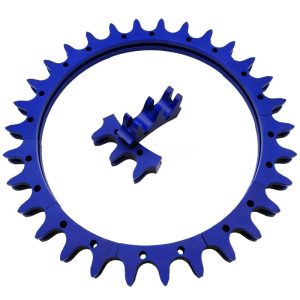

The Pulley Carrying Hook is a core connecting and load-bearing component of the overhead suspension conveyor system in modern automated slaughter lines (for pigs, cattle and sheep).

It integrates the upper dual-track pulley block with the lower slaughter hook (which holds the carcass), enabling the carcass to move smoothly along the track through all processes including bleeding, scalding, skinning, cutting and cooling.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

1. Product Overview

The Pulley Spreader Bar Hook is a core connecting and load-bearing component in modern automated slaughterhouse conveyor lines (for pigs, cattle, sheep). It connects the overhead dual-rail pulley assembly to the slaughter hooks (which carry the carcasses) below, enabling carcasses to move smoothly along the track through all processes including bleeding, scalding, dehairing/skinning, splitting, and chilling.

Its core functions are efficient load-bearing, smooth transition, and automatic self-centering, making it a critical hardware component for ensuring continuous, efficient, and low-failure operation of the production line.

2. Detailed Technical Specifications

The following are general parameters, which can be customized according to specific production line specifications (e.g., track model, animal type, capacity).

| Parameter Category | Detailed Specifications |

|---|---|

| Main Material | Austenitic Stainless Steel. Standard: SUS304; Highly corrosive environments (e.g., frequent chemical sanitation): Recommended SUS316 or 316L. |

| Structure Form | Integrated forging or precision welded construction. Main structure is an “I-beam” or “H-beam” style spreader bar with connection holes at both ends. |

| Key Dimensions | Length (Center Distance between Holes): Customized based on track gauge, common range: 280mm – 600mm. Width/Thickness: Designed based on load, typical section height 60mm – 120mm. Connection Hole Diameter: Top hole for pulley pin (e.g., Φ25mm, Φ30mm), bottom hole for hook (e.g., Φ20mm). |

| Load Capacity | Safe Working Load (SWL): 500kg – 2500kg or higher. • Common for Pig/Sheep Lines: 500kg – 1000kg. • For Cattle Lines: 1500kg – 2500kg+. Safety Factor: ≥ 4:1 (Breaking load ≥ 4 x SWL). |

| Surface Finish | Satin brushed polish or electropolish. Surface roughness Ra ≤ 0.8μm, ensuring no sanitation dead ends, easy cleaning, and corrosion resistance. |

| Compatibility | Top End: Compatible with pin interfaces of mainstream dual-rail pulley assemblies (e.g., sprocket type, bearing type). Bottom End: Standardized interface, adaptable to various models of slaughter hooks and hangers. |

| Weight | Approximately 3kg – 8kg (varies by size and load capacity). |

3. Core Performance & Features

- High-Strength Load Bearing: Optimized structural mechanics design using dense materials withstands dynamic impact loads (e.g., carcass swinging, sudden starts/stops), ensuring no deformation during long-term use.

- Smooth Operation: Precise hole positioning and dimensions ensure rigid connections with the pulley assembly and hooks, effectively reducing operational vibration, noise, and track system wear.

- Hygienic & Safe: Full stainless steel construction with smooth, seamless surfaces complies with food contact material and HACCP hygiene management requirements. Withstands high-pressure, high-temperature washing and food-grade disinfectants.

- Wear-Resistant & Durable: Can be equipped with wear-resistant bushings (e.g., copper-based or engineering plastic) at contact points with the pulley pin to reduce metal-on-metal wear and extend service life.

- Automatic Self-Centering: The carefully designed structure helps hooks maintain centered operation on dual rails, preventing deviation and jamming, especially in curved track and switch areas.

4. Application Scenarios

- Applicable Animals: Pigs, cattle, sheep, etc.

- Applicable Processes: The entire overhead conveying process from post-stunning/bleeding to pre-chilling/splitting.

- Compatible Tracks: Standard dual-rail overhead conveyor lines, suitable for straight sections, curves, and switch areas.

5. Selection, Installation & Maintenance Guide

- Selection Key Points:

- Identify the line’s maximum single-point load (considering max. carcass weight + impact allowance).

- Measure the exact center distance of existing tracks to determine spreader bar length.

- Confirm the hole diameters and connection types at both ends to ensure compatibility with existing pulleys and hooks.

- Installation Requirements:

- Use high-strength stainless steel专用 pins for connections, equipped with anti-drop circlips or lock nuts.

- After installation, check all connection points to ensure no looseness and smooth, interference-free operation.

- Maintenance:

- Daily Check: Visually inspect for obvious deformation, cracks, or abnormal wear each shift.

- Regular Check: Monthly inspection of wear on connection pins and holes; replace if wear exceeds limits.

- Cleaning: Perform thorough cleaning and disinfection with the production line daily after operation.