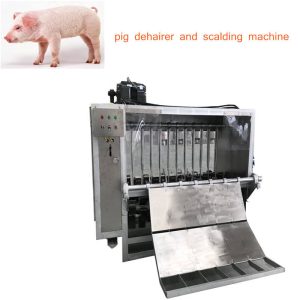

Pig Trotter Singeing Machine

This multi-purpose hoof and head singeing machine is a highly efficient and environmentally friendly automatic singeing device, specially designed for the deep singeing treatment of hooves and heads of various livestock and poultry.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Product Name: Multi-purpose Hoof & Head Singeing Machine

(Applicable to Cattle Hooves, Cattle Heads, Pig Heads, Sheep Hooves, Sheep Heads, etc.)

I. Product Overview

This multi-purpose hoof and head singeing machine is an efficient and environmentally friendly automated singeing equipment designed for the deep singeing treatment of various livestock hooves and heads. It combines liquefied petroleum gas (LPG) heating with mechanical conveying to quickly remove residual hair and surface impurities from cattle hooves, cattle heads, pig heads, sheep hooves, sheep heads, and other parts, thereby enhancing product appearance and food safety standards. The equipment features easy operation, low energy consumption, and strong adaptability, making it an ideal choice for modern slaughtering and processing enterprises, central kitchens, and meat deep-processing plants.

II. Technical Parameters

| Item | Parameter |

|---|---|

| Model | 2-Meter Multi-purpose Singeing Machine |

| Dimensions | 2000 mm × 1500 mm × 2000 mm (L × W × H) |

| Conveyor Power | 0.37 kW (variable frequency speed regulation, stable conveying) |

| Heating Method | LPG Heating (natural gas option available) |

| Gas Consumption | Approximately 15 kg/hour (LPG) |

| Applicable Objects | Cattle hooves, cattle heads, pig heads, sheep hooves, sheep heads, etc. |

| Processing Efficiency | Continuous operation, adaptable to assembly line production pace |

| Control Method | Manual/Automatic optional, PLC control interface |

| Material Structure | Main body made of 304 stainless steel, heat-resistant and easy to clean |

III. Product Features

1. Multi-purpose Adaptability

- Flexible handling of hooves and heads from various animals such as cattle, pigs, and sheep. One machine serves multiple purposes, saving equipment investment.

2. High Efficiency and Energy Saving

- LPG heating system with high thermal efficiency and uniform flames ensures thorough singeing.

- Conveyor system consumes only 0.37 kW, resulting in low operating costs.

3. Safe Operation

- Equipped with multiple safety devices, including flame monitoring, gas leakage alarms, and overheat protection.

- Adjustable conveyor speed to prevent over-singeing or insufficient singeing.

4. Hygienic and Environmentally Friendly

- Fully stainless steel structure, compliant with food hygiene standards, easy to clean and disinfect.

- Complete combustion ensures smoke emissions meet environmental requirements.

5. Compact Structure

- Small footprint (approximately 3 m²), suitable for optimized workshop layout.

IV. Workflow

- Feeding → Place the hooves or heads to be processed at the conveyor entrance.

- Conveying → Move steadily through the high-temperature flame zone (adjustable speed).

- Singeing → Uniform LPG flames remove surface hair.

- Cooling/Discharge → Naturally cool after singeing and collect from the outlet.

V. Application Scenarios

- Initial processing of hooves and heads in slaughterhouses.

- Pre-processing workshops in meat processing plants.

- Central kitchens and cooked food production lines.

- Deep processing of traditional meat products (e.g., pig trotters, sheep heads).

VI. Optional Configurations

- Natural gas conversion interface.

- Automatic spray cooling system.

- Dust and smoke exhaust device.

- Customized conveyor belt width (adaptable to different product sizes).

VII. Service Support

- Free installation guidance and operational training provided.

- 12-month warranty for the entire machine, with lifelong technical support.

- Gas system safety manual provided.

If you have specific production capacity requirements or special processing needs, feel free to inquire about customized solutions!