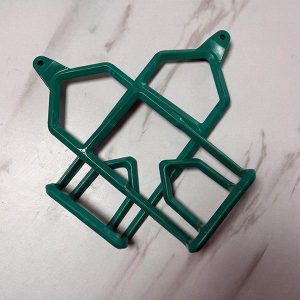

PA6 Nylon Toothed Angle Wheel

High-precision nylon drive guide wheels specially designed for poultry slaughter overhead conveyor systems. Manufactured from reinforced PA6 nylon via integrated injection molding, available in two specifications: 18-tooth and 24-tooth.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Product Overview:

High-precision nylon drive guide wheels specially designed for poultry slaughter overhead conveyor systems. Manufactured from reinforced PA6 nylon via integrated injection molding, available in two specifications: 18-tooth and 24-tooth. The toothed design ensures precise engagement with the conveyor drive chain, delivering stable, low-noise transmission performance as a complete replacement for traditional metal drive wheels.

Key Features:

✅ High-strength PA6 nylon + glass fiber reinforcement, wear-resistant and deformation-resistant

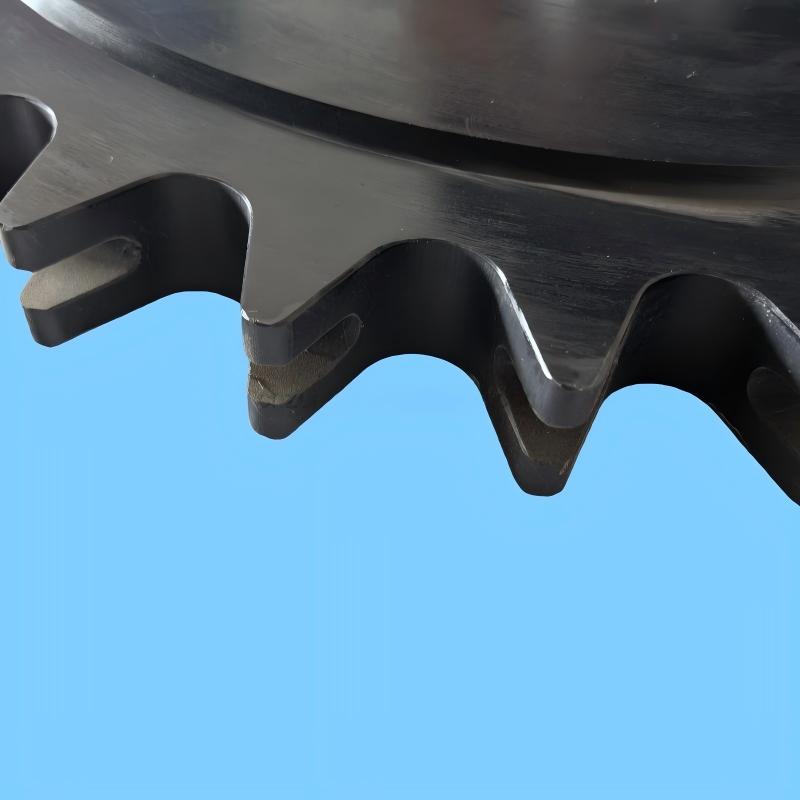

✅ Precision toothed design (18-tooth / 24-tooth), ensuring smooth transmission without slippage

✅ Self-lubricating properties, maintenance-free, no risk of oil contamination

✅ Corrosion and washdown-resistant, suitable for high-temperature, high-pressure cleaning environments

✅ 50% lighter than metal gears, reducing system load and energy consumption

Specification Selection Guide:

- 18-Tooth Guide Wheel: Suitable for standard-speed, medium-load overhead conveyor lines

- 24-Tooth Guide Wheel: Suitable for high-speed conveyor lines requiring smoother transmission

Applications:

- Active drive systems for poultry slaughter overhead conveyor lines

- Conveyor lines in high-humidity environments such as pre-cooling and cutting rooms

- Export-oriented workshops with strict hygiene and noise control requirements

- Upgrades and replacements for existing metal drive wheels

Technical Parameters:

- Material: PA6 + 30% glass fiber reinforcement

- Tooth Count: 18-tooth / 24-tooth (optional)

- Module: M4 / M5 (adapted to chain specifications)

- Load Capacity: Dynamic load 150–300 kg/wheel

- Operating Temperature: -30℃ to 120℃

- Compatible Chains: Standard conveyor chains such as 08B, 10A, 12A, etc.

Installation Advantages:

- Ready-to-install, compatible with mainstream overhead conveyor drive systems

- Tooth precision meets ISO Grade 8, ensuring long-term transmission stability

- Optional stainless steel insert bushings to enhance wear resistance at mounting points

Through precision toothed design and material reinforcement, this product ensures transmission accuracy while completely addressing industry pain points such as rusting, high noise, and lubrication requirements associated with metal drive wheels. It is the preferred upgrade solution for modern poultry slaughter line drive systems.