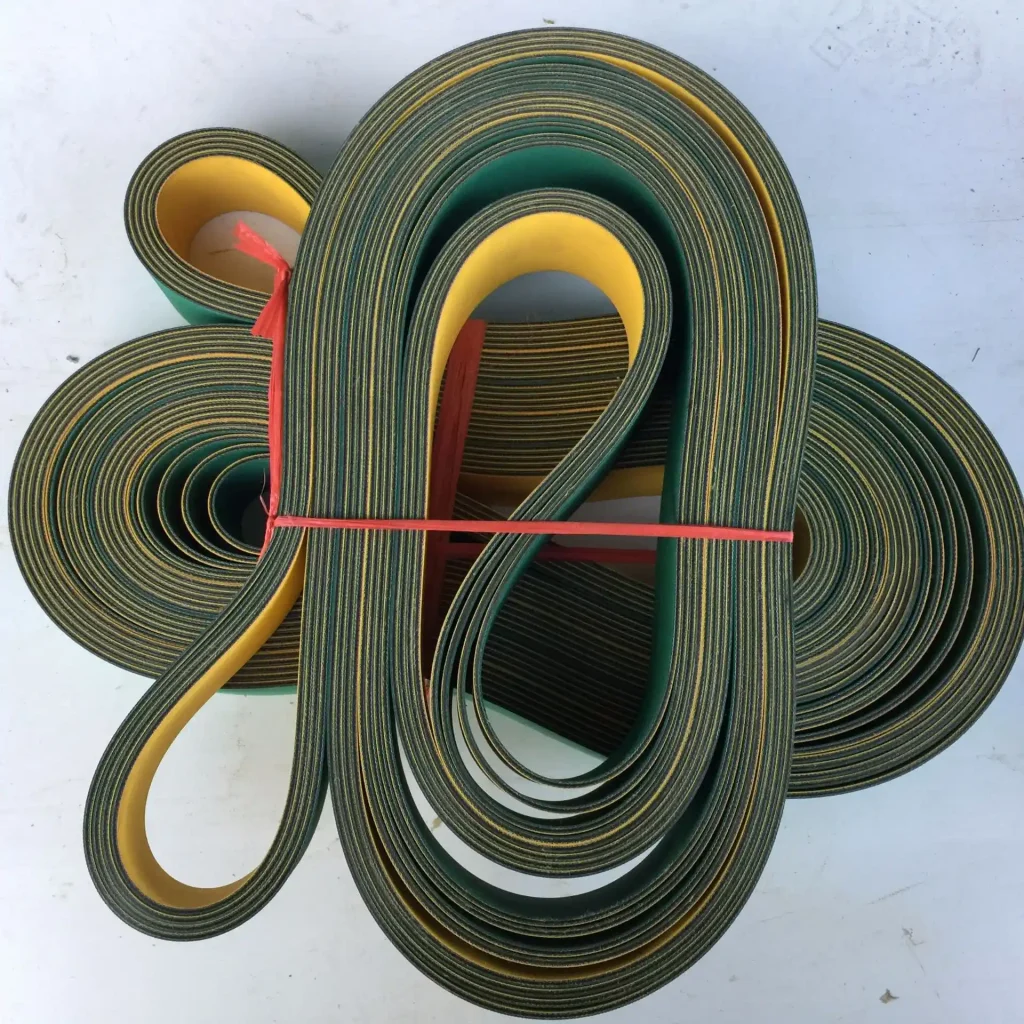

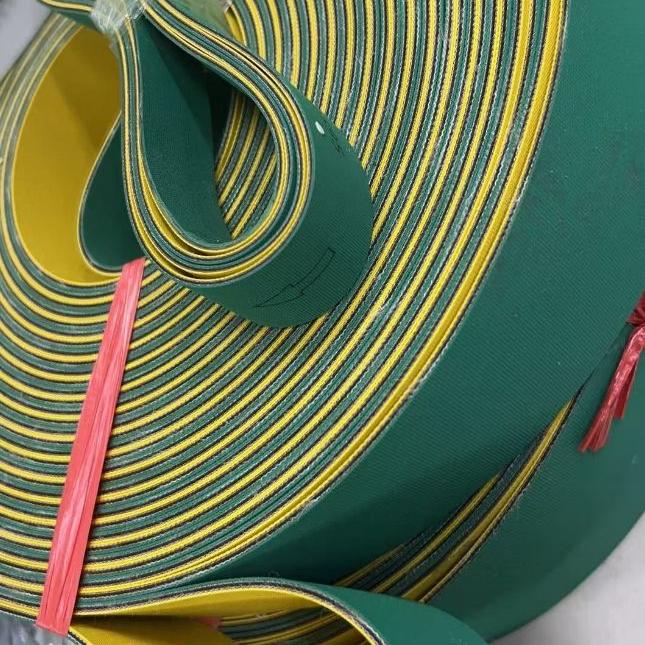

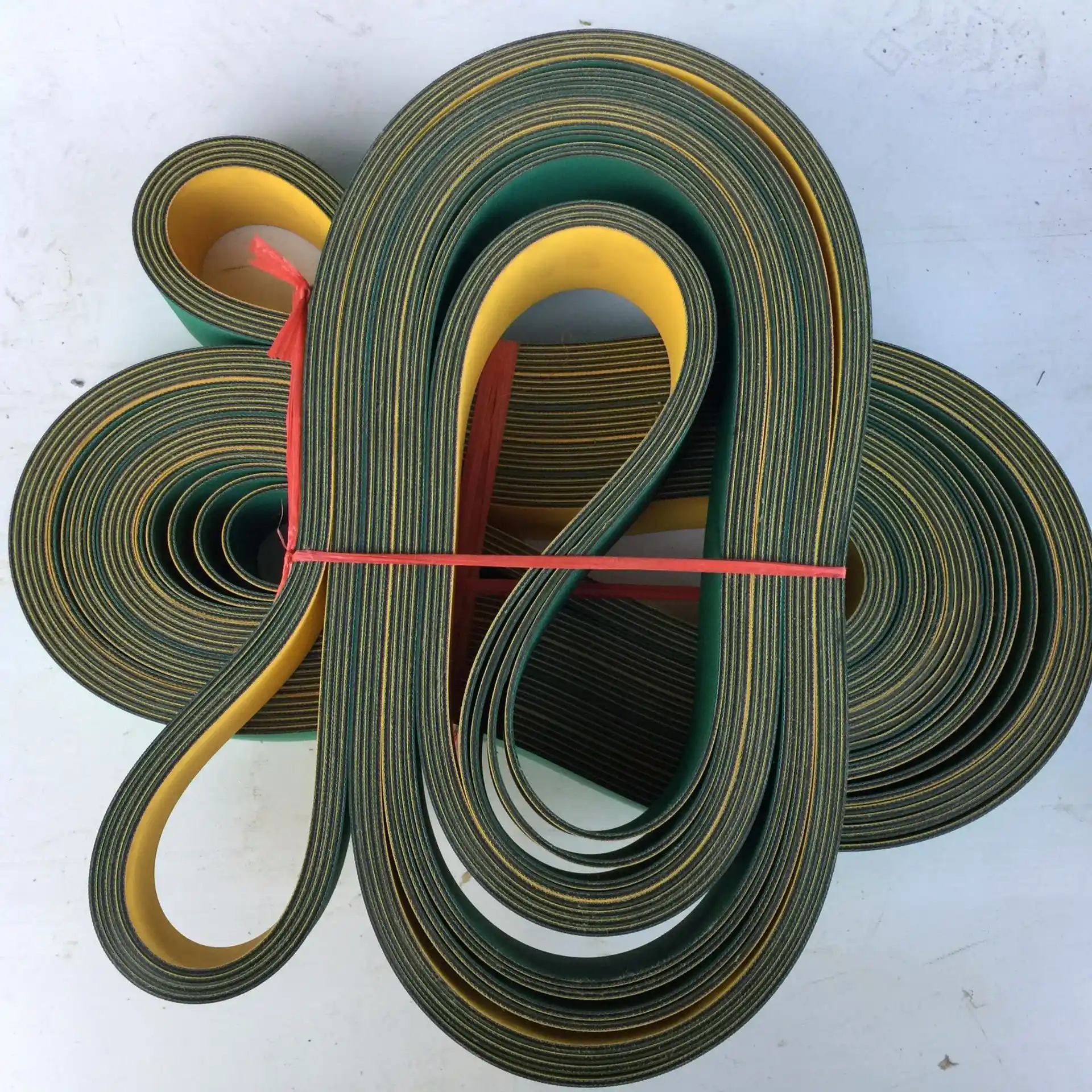

Nylon Drive Belt for Poultry Defeathering Machine

This product is a specialized nylon drive belt designed for the core transmission system of poultry slaughter defeathering machines. It is precision-engineered from high-strength nylon base material and wear-resistant composite materials, optimized for the harsh operating conditions of defeathering machines, including high speed, heavy loads, and environments with high moisture and debris.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

This product is a specialized nylon drive belt designed for the core transmission system of poultry slaughter defeathering machines. It is precision-engineered from high-strength nylon base material and wear-resistant composite materials, optimized for the harsh operating conditions of defeathering machines, including high speed, heavy loads, and environments with high moisture and debris. Featuring properties such as high tensile strength, wear resistance, anti-slip performance, and ease of cleaning, it serves as an upgraded alternative to traditional rubber belts or ordinary flat belts.

I. Core Features

| Feature | Description |

|---|---|

| High Tensile Strength | Nylon core layer provides extremely high tensile strength with low elongation, ensuring stable transmission. |

| Excellent Wear Resistance | Special surface coating withstands continuous friction from defeathering rollers and poultry carcasses. |

| Anti-Slip Design | Backside can be customized with anti-slip patterns or toothed structures to adapt to high-speed starts/stops and load variations. |

| Water and Corrosion Resistance | Non-absorbent, resistant to blood, grease, and mild cleaning agents; performance unaffected by humid environments. |

| Hygienic and Easy to Clean | Smooth, dense surface prevents adhesion of feathers and bloodstains; supports high-pressure washing and quick drying. |

| Low-Noise Operation | Excellent material flexibility ensures smooth transmission and significantly reduces operational noise. |

II. Technical Specifications (Standard Models)

| Parameter | Specification |

|---|---|

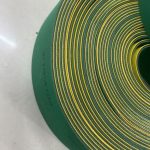

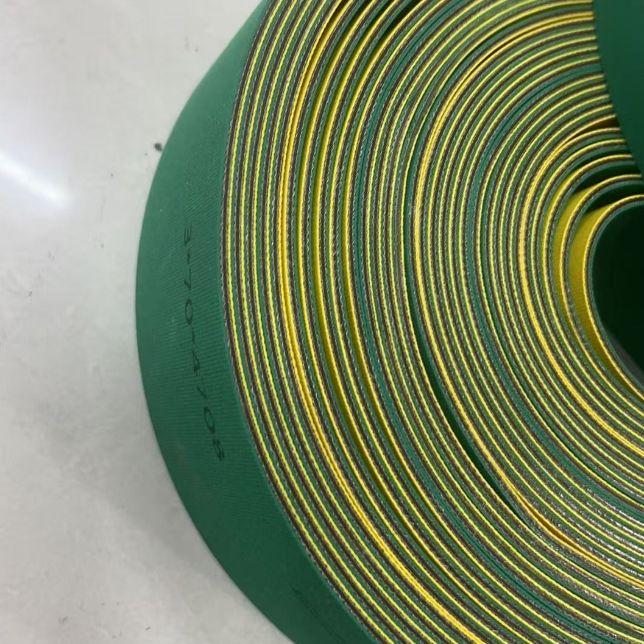

| Base Material | High-strength nylon canvas / Polyester-nylon composite fabric |

| Surface Treatment | Polyurethane (PU) coating or Chloroprene rubber (CR) overlay |

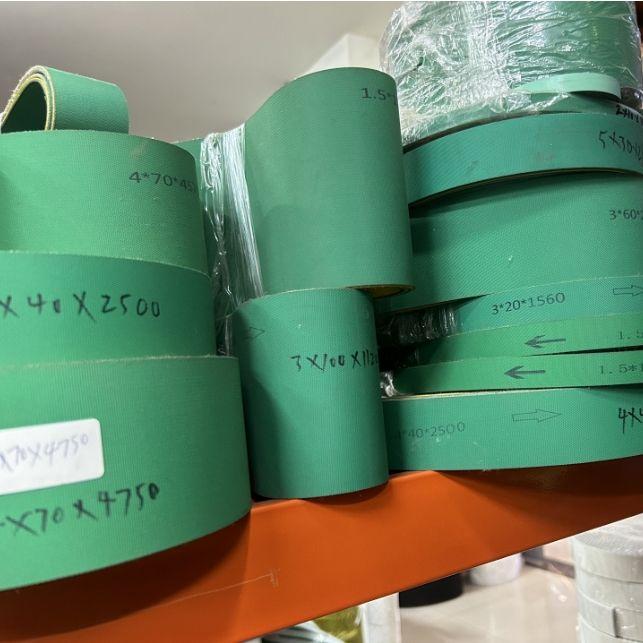

| Thickness Range | 1.5mm ~ 3.0mm (customizable) |

| Width Range | 20mm ~ 200mm (customizable) |

| Tensile Strength | ≥ 300 N/mm (longitudinal) |

| Operating Temperature | -30℃ ~ 80℃ (up to 100℃ for short periods) |

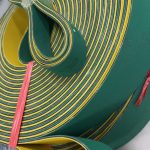

| Joining Method | Endless loop / Steel fastener joints / Thermal fusion splicing (optional) |

III. Compatible Machines and Applications

- Suitable Equipment:

- Horizontal, vertical, and drum-type defeathering machines

- Imported brands (e.g., Meyn, Stork, Baader) and mainstream domestic defeathering equipment

- Application Areas:

- Main drive belts, plucker roller drive belts, conveyor belts, etc.

- Ideal Scenarios:

- Production lines with high humidity and frequent cleaning requirements

- Export-oriented factories with strict demands for transmission stability and hygiene

- Conditions where traditional rubber belts are prone to aging, slipping, or breaking

IV. Selection and Customization Services

| Service Type | Description |

|---|---|

| Standard Models | Available in common widths and lengths, suitable for most domestic defeathering machines. |

| Customization by Drawing | Customized dimensions and characteristics based on provided equipment drawings or old belt samples. |

| Performance Upgrades | Optional upgrades include increased thickness, reinforced tensile layers, special tooth profiles, and conductive types. |

| Quick Matching | Provide your equipment model or original belt parameters, and we will recommend compatible specifications. |

V. Usage Recommendations

- Installation Tension: Install with recommended tension and regularly check tightness.

- Cleaning and Maintenance: After daily rinsing, wipe dry or allow to air dry to extend service life.

- Regular Inspection: Monitor for signs of cracking, wear, or edge fraying.

- Storage Conditions: Avoid prolonged exposure to direct sunlight, high temperatures, or contact with oils and chemicals.

VI. Ordering Information

- Minimum Order Quantity: 50 meters or 50 belts (negotiable based on actual needs)

- Delivery Time: 5–7 days for standard specifications; 10–15 days for customized specifications

- Packaging: Coiled or reeled, moisture-proof and pressure-resistant

- Warranty: 12-month quality guarantee under normal operating conditions

This product is specifically developed to address common industry challenges such as easy wear, slippage, and difficult cleaning of defeathering machine drive belts. It significantly reduces downtime and replacement frequency. Please provide your equipment details or samples, and we will offer the most suitable drive belt solution for your needs.