Nylon Conveyance Saddle

A key moving accessory designed for modern poultry slaughter conveyor lines. This product is a nylon saddle (also called a conveyance trolley) installed on round or square pipe rails and connected in series via galvanized drive chains. It is responsible for carrying hook or hanger assemblies, enabling smooth, low-noise, and efficient transfer of poultry carcasses between various stations along the production line.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Product Positioning

A key moving accessory designed for modern poultry slaughter conveyor lines. This product is a nylon saddle (also called a conveyance trolley) installed on round or square pipe rails and connected in series via galvanized drive chains. It is responsible for carrying hook or hanger assemblies, enabling smooth, low-noise, and efficient transfer of poultry carcasses between various stations along the production line.

Core Features

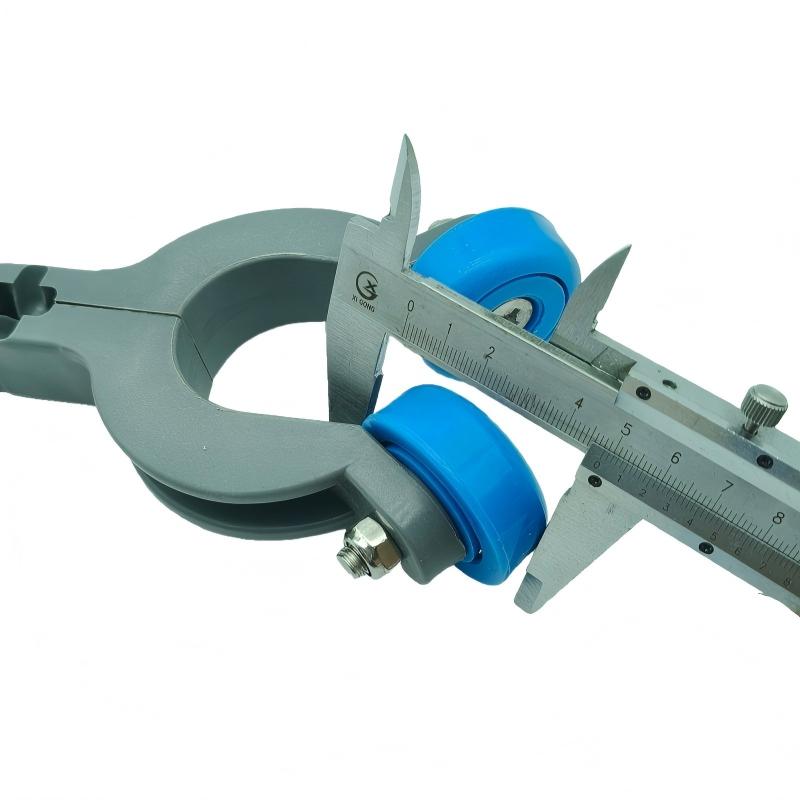

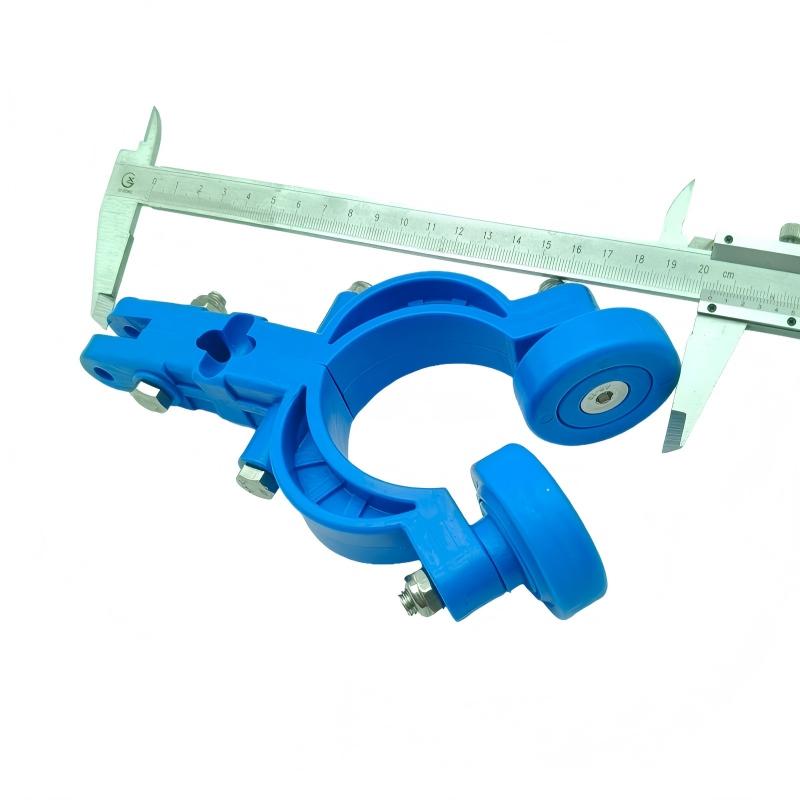

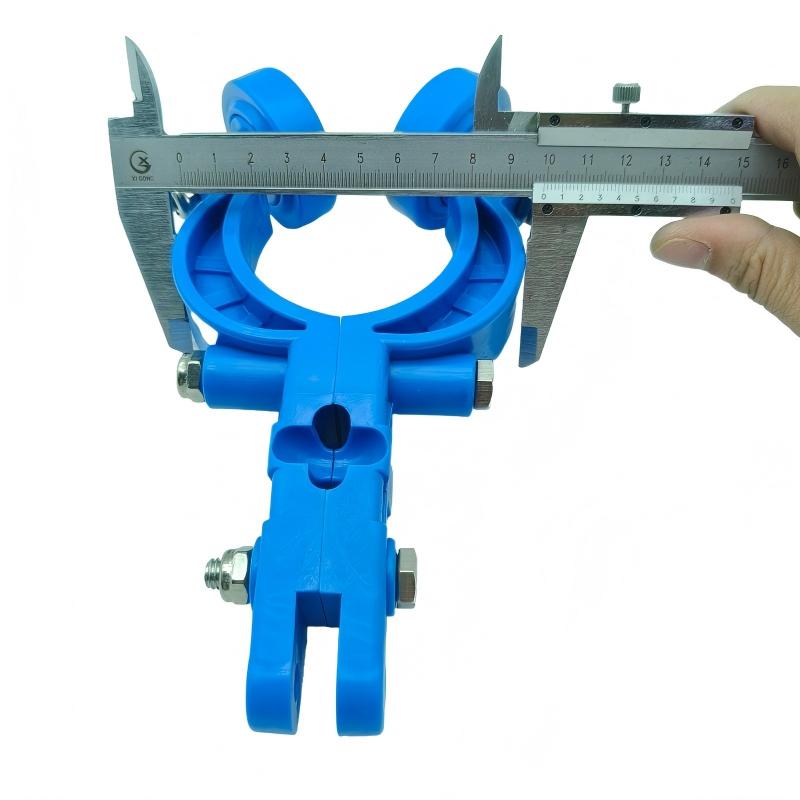

- Specialized Nylon Material: Made from high-strength, wear-resistant nylon through injection molding. It is lightweight, low-noise, corrosion-resistant, easy to clean, fully compliant with food production hygiene standards, and causes minimal wear to the rails, ensuring a long service life.

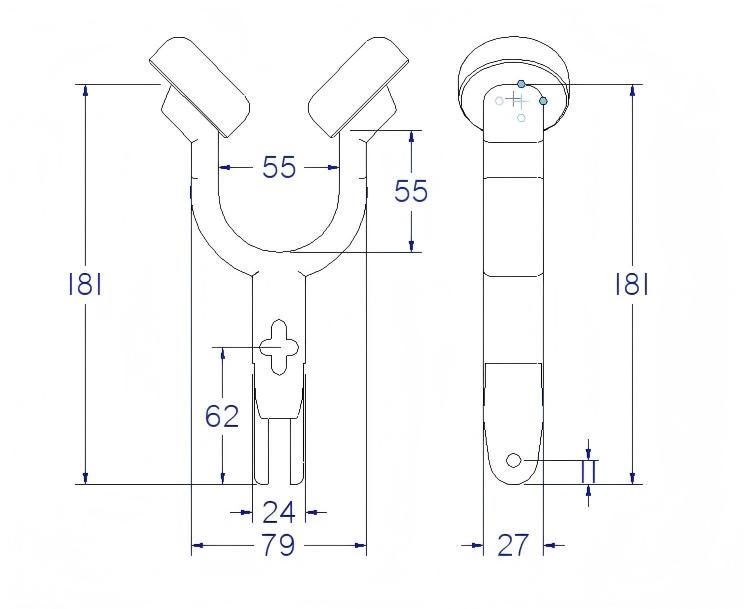

- Pipe-Rail Adapted Design: Specifically engineered to match the curved profile of pipe rails. Through its bottom wrapping or roller structure, it ensures smooth and stable movement along the pipe rail without jamming, offering better stability compared to some open-rail designs.

- Chain-Driven Connection: Equipped with dedicated connecting mechanisms at the bottom or side for secure linkage to galvanized drive chains. Driven by the chains, it achieves synchronized and continuous group conveyance with reliable transmission.

- Key Difference from T-Type Saddles: Unlike T-type saddles, which are primarily used for T-shaped steel rails or flat steel rails, this product is optimized for pipe rail systems. T-type saddles typically rely on rollers or sliders to move along specific grooves or planes of T-shaped rails, whereas this saddle is designed to closely fit the curved surface of pipe rails, with specialized contact methods and force distribution. The two are generally not directly interchangeable in terms of rail interfaces, installation methods, and compatible chain systems.

Product Advantages

- Smooth Operation: The pipe-rail-fitting design reduces shaking and impact, ensuring stable conveyance.

- Easy Maintenance: The corrosion-resistant nylon material requires no lubrication, lowering routine maintenance frequency and costs.

- Strong Compatibility: Suitable for mainstream domestic and international slaughter line designs using pipe-rail chain conveyance.

- Cost-Effective and Durable: Quieter and less wear-prone than metal saddles, resulting in lower overall operating costs.

Typical Applications

Used in poultry slaughter processing lines for transferring poultry carcasses between stages such as scalding, defeathering, cooling, and segmentation. It is a core load-bearing component of pipe-rail chain conveyance systems.

We offer various specifications to accommodate different pipe diameters and chain pitches, ensuring perfect compatibility with your existing production line. Samples are available upon request. Welcome to inquire.