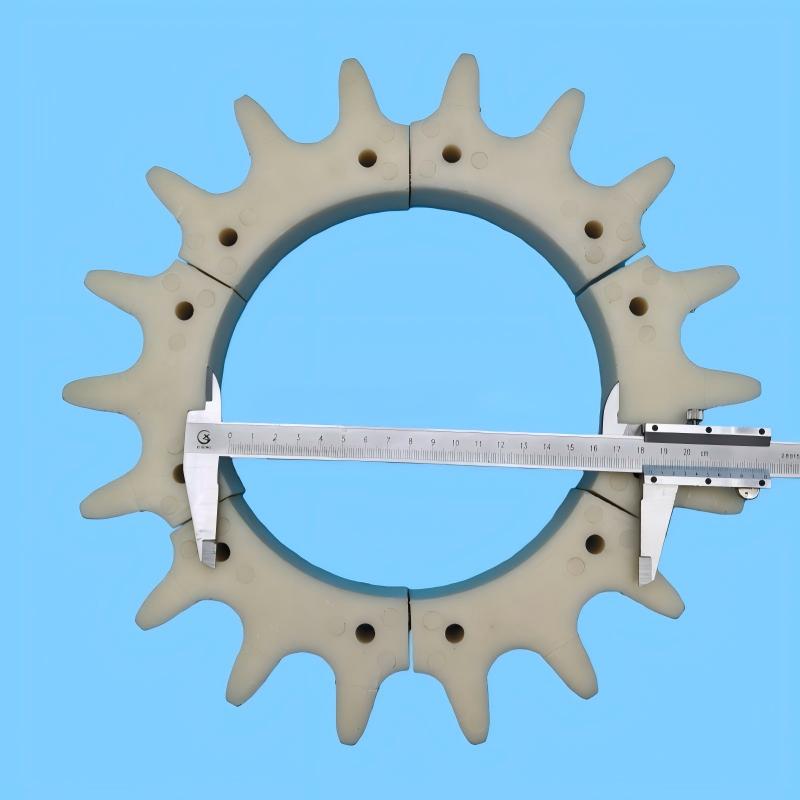

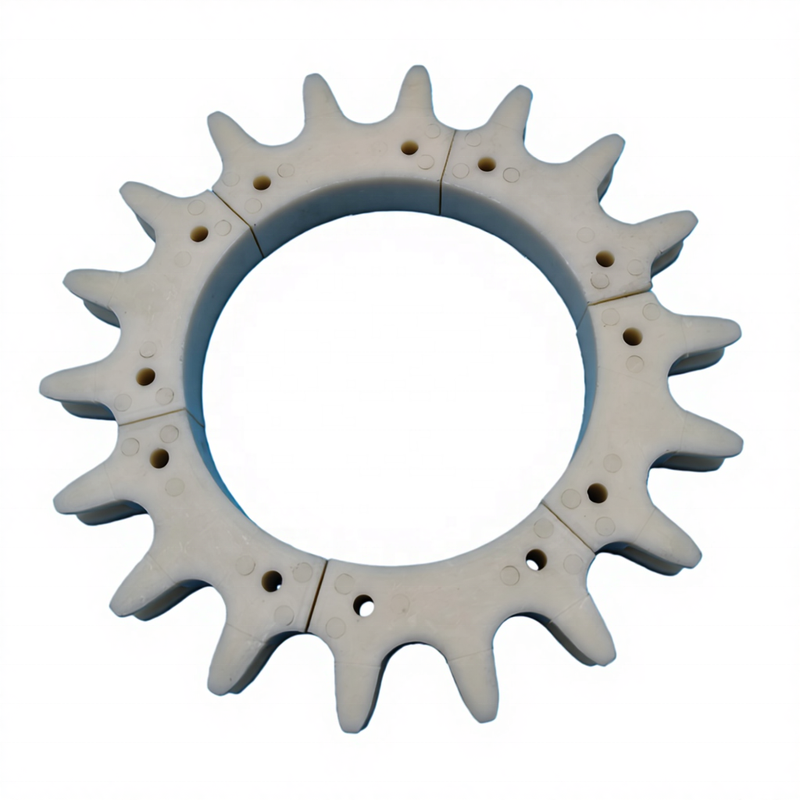

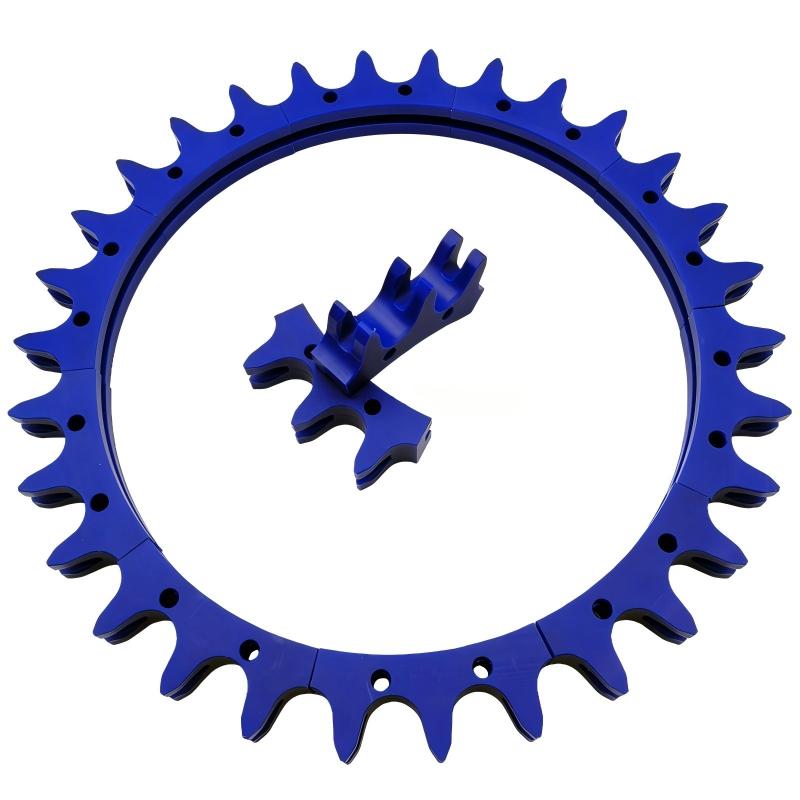

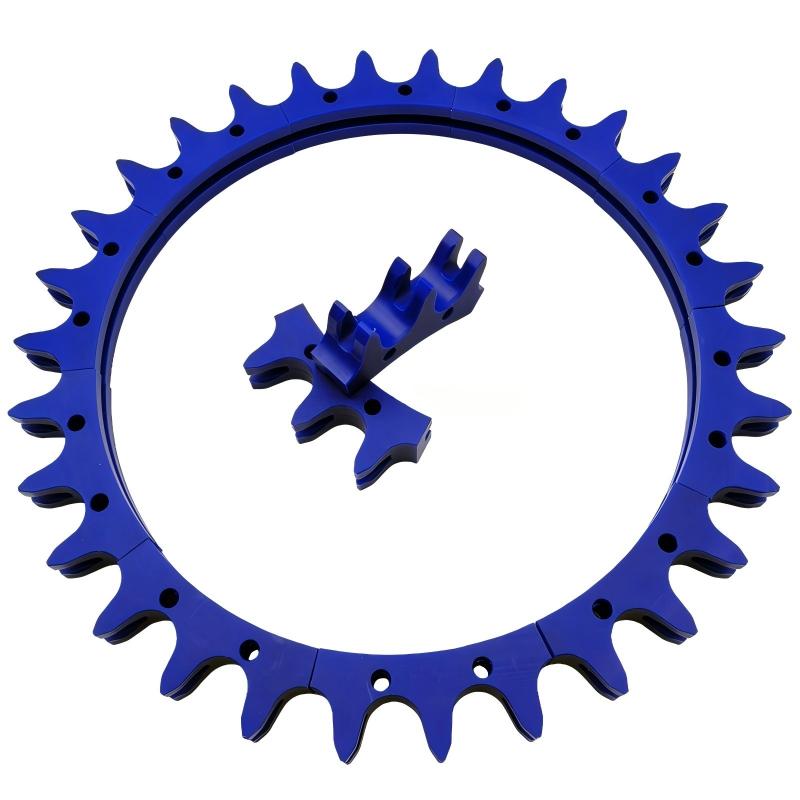

Nylon Combined Gear for Poultry Overhead Conveyor Line

This product is a separable nylon combination drive gear designed for external splicing onto metal guide wheels of poultry overhead lines. The gear assembly is made of high‑strength nylon and can be directly mounted on the outside of existing metal guide wheels, enabling an upgrade to a drive wheel without replacing the original wheel body.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Product Overview

This product is a separable nylon combination drive gear designed for external splicing onto metal guide wheels of poultry overhead lines. The gear assembly is made of high‑strength nylon and can be directly mounted on the outside of existing metal guide wheels, enabling an upgrade to a drive wheel without replacing the original wheel body.

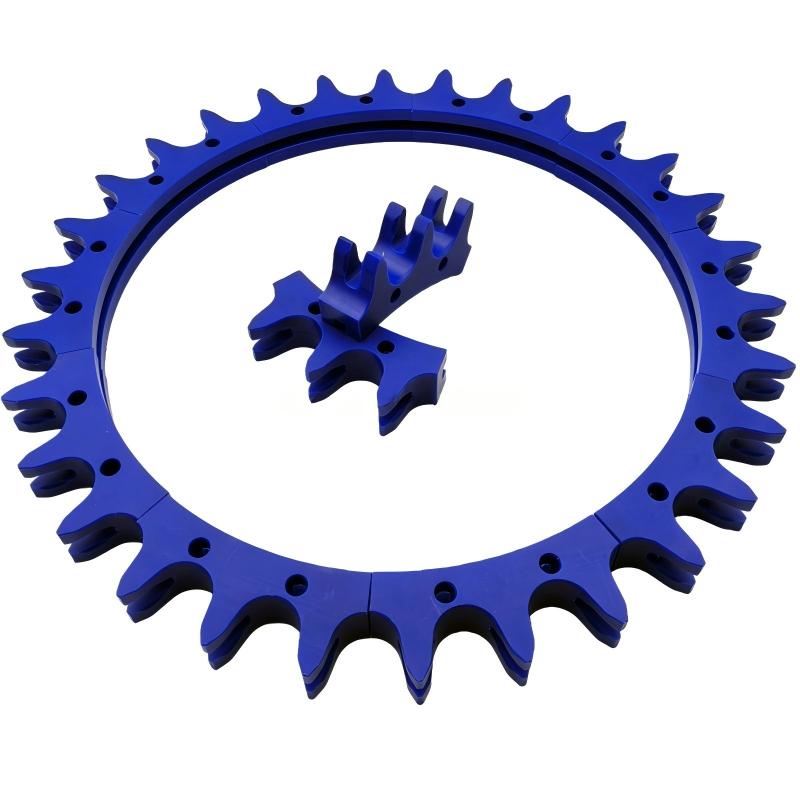

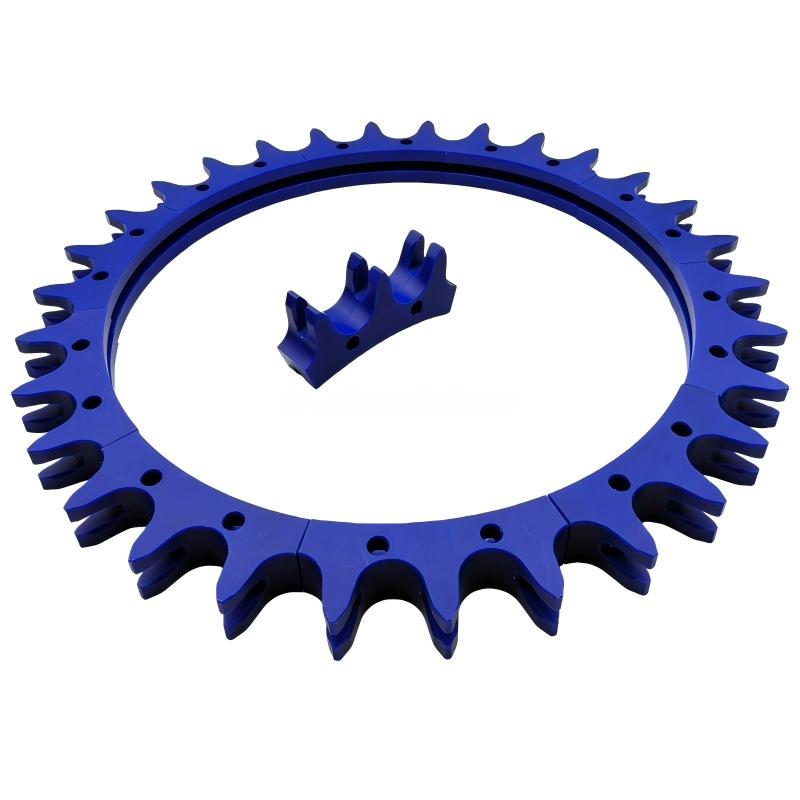

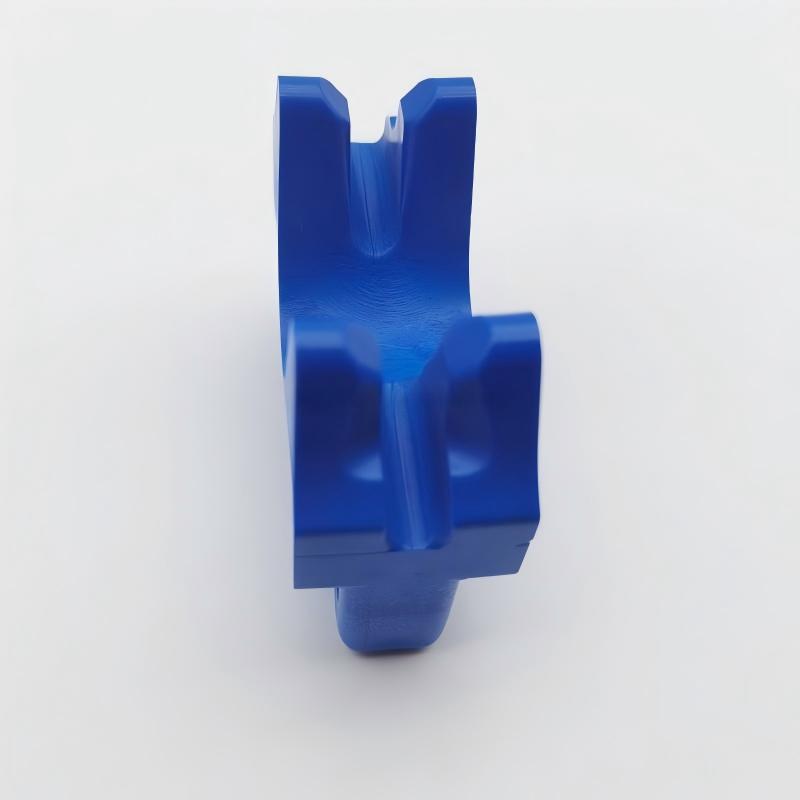

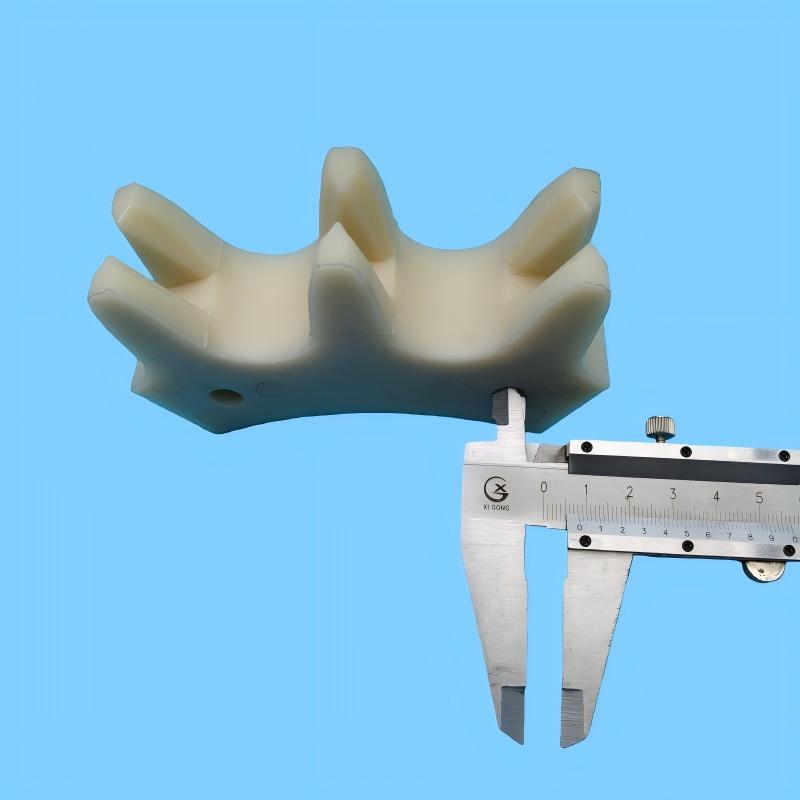

Product Structure

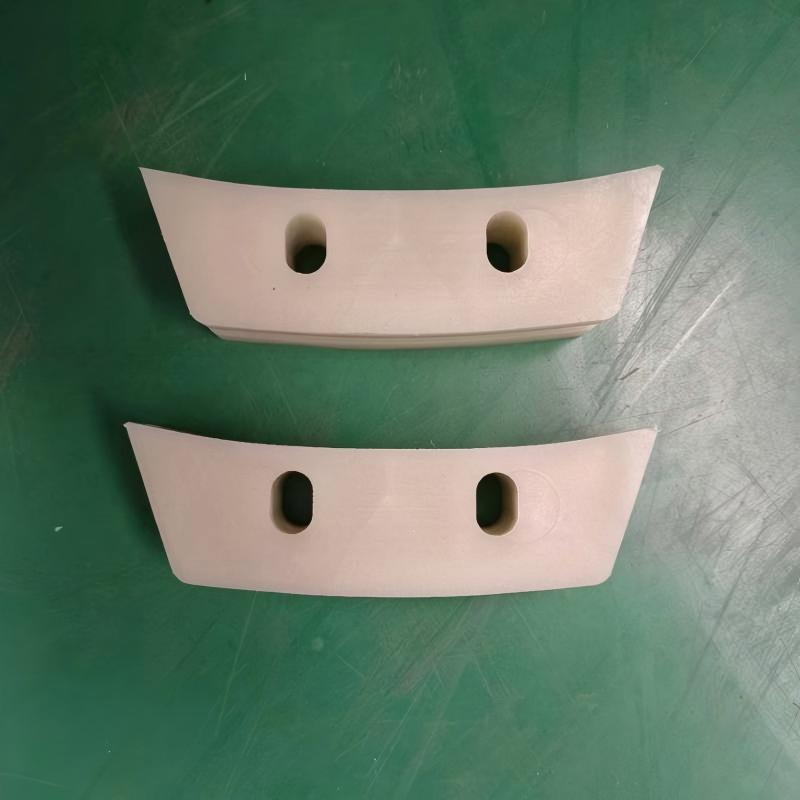

- Split‑type nylon gear ring (two‑piece design)

- Stainless steel locking sleeve

- Anti‑skid positioning pins

Key Features

✅ Modular design: Directly spliced onto the outside of metal guide wheels, easy to install

✅ Wear‑resistant and durable: High‑strength nylon material with wear‑treated tooth surfaces

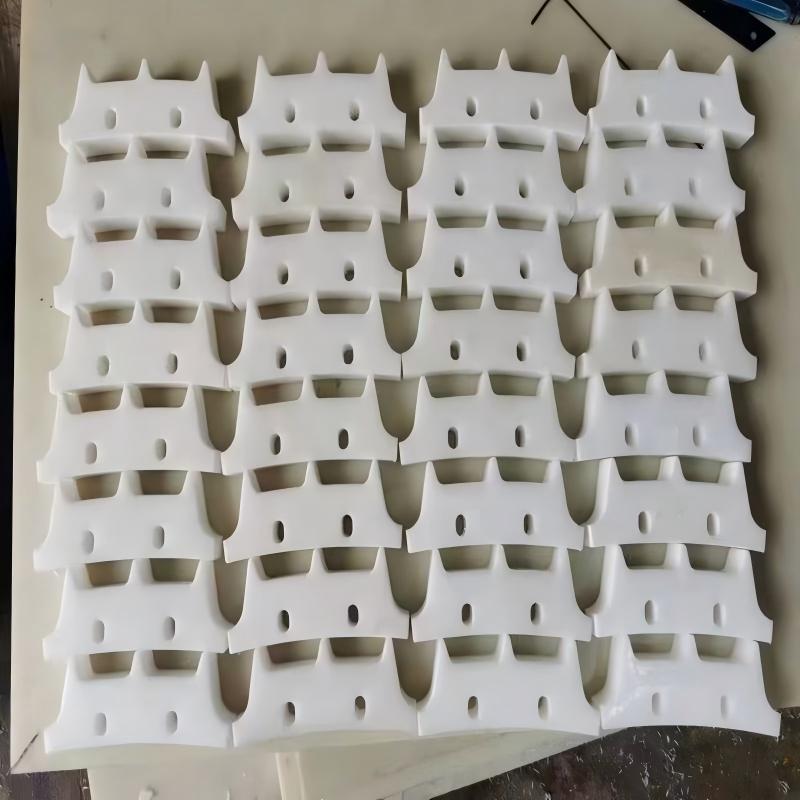

✅ Easy maintenance: Only the gear ring needs replacement; the metal wheel body can be used long‑term

✅ High compatibility: Fits metal guide wheels of Φ150‑300mm in various specifications

✅ Quiet operation: Nylon material reduces transmission noise

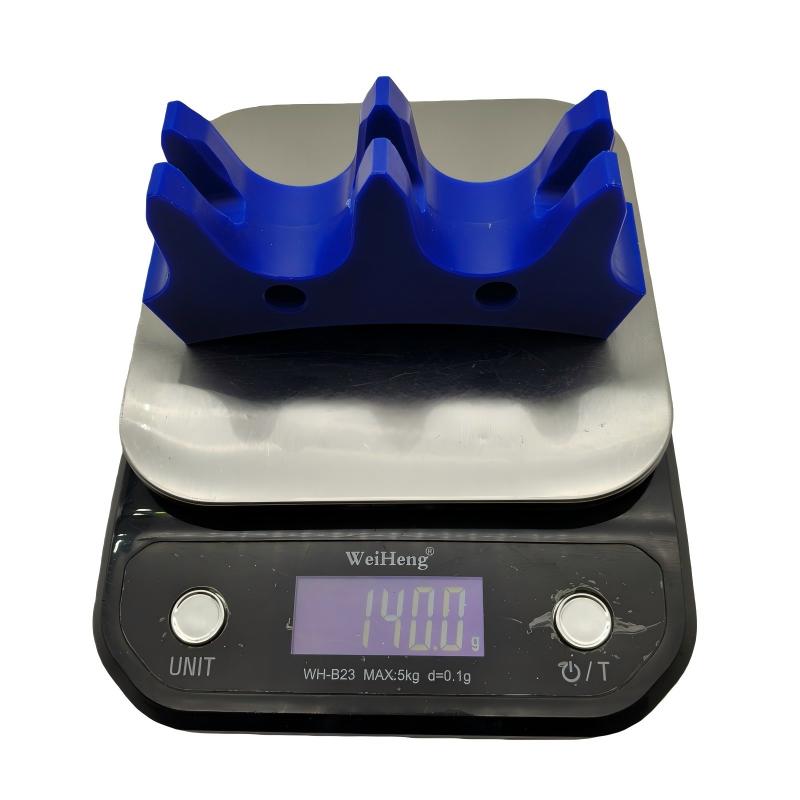

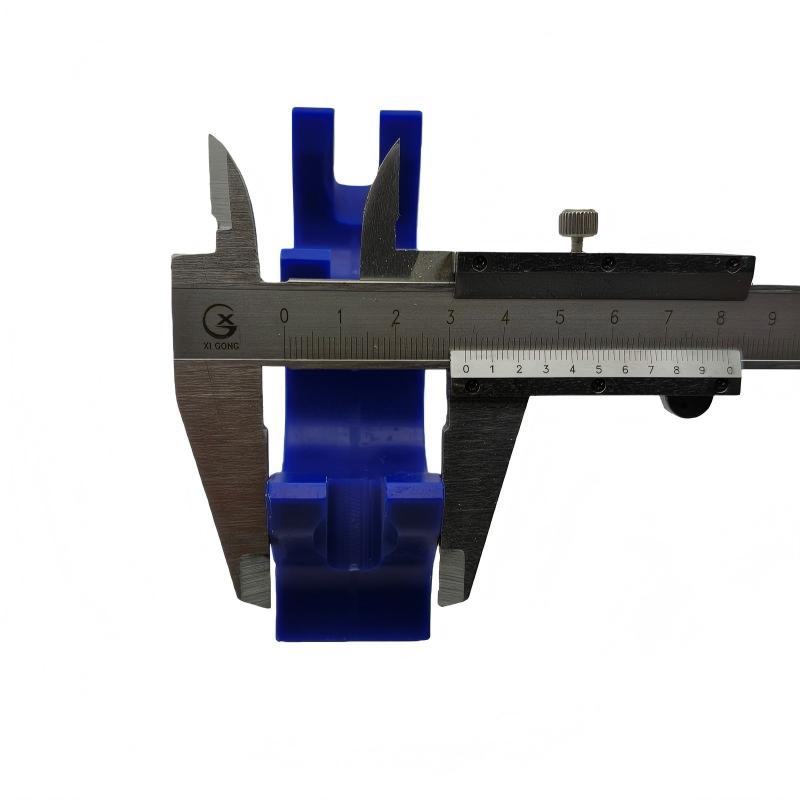

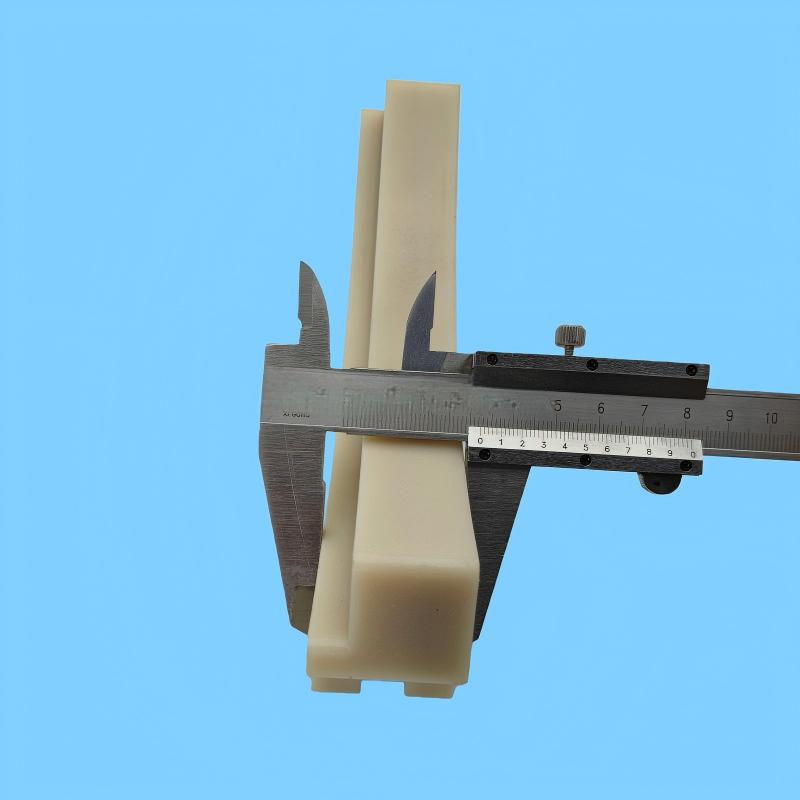

Technical Parameters

- Material: Reinforced nylon PA66

- Compatible wheel diameters: Φ150/200/250/300mm

- Gear module: M3/M4/M5

- Tooth count options: 18, 24, 30 teeth

- Operating temperature: ‑30℃ to 100℃

Application Scenarios

- Upgrading drive systems of existing overhead lines

- Adding drive function to metal guide wheels

- Low‑cost replacement for worn gears

- Overhead conveying lines with multiple speed zones

Installation Advantages

- On‑site installation, completed within 15 minutes per wheel

- No special tools required; ordinary wrenches suffice

- Does not alter the original overhead line structure

- Supports mixed tooth‑count configurations for segmented speed control

With its economical and practical design, this product provides a flexible solution for overhead line drive upgrades, significantly reducing retrofit and maintenance costs.