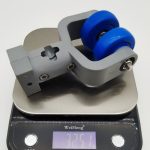

Integrated Weighing Nylon Carriage

A core functional component for poultry slaughter lines, designed for the integrated automation of weighing and cutting systems. This product is a high-precision nylon carriage based on a T-rail system. Its unique standardized square base interface allows for direct and rapid connection with compatible automated weighing hooks or automated cutting hooks. It enables seamless and precise transfer of poultry between conveyance, dynamic weighing, and automated cutting processes, serving as the key hardware carrier for enhancing processing automation and data accuracy.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Product Positioning

A core functional component for poultry slaughter lines, designed for the integrated automation of weighing and cutting systems. This product is a high-precision nylon carriage based on a T-rail system. Its unique standardized square base interface allows for direct and rapid connection with compatible automated weighing hooks or automated cutting hooks. It enables seamless and precise transfer of poultry between conveyance, dynamic weighing, and automated cutting processes, serving as the key hardware carrier for enhancing processing automation and data accuracy.

Core Features

- Modular Square Interface Base: The carriage bottom features a high-precision, standardized square connection platform equipped with quick-lock or positioning mechanisms. This enables a rigid, play-free connection with dedicated weighing or cutting hooks, ensuring that the hook and carriage function as a stable unit during high-speed operation and precise operations.

- High-Precision T-Rail Guidance: Utilizes nylon guide wheel sets that fit precisely with the T-rails, ensuring the carriage runs with accurate trajectory and no drift within the rail groove. This characteristic is crucial for dynamic weighing (avoiding data inaccuracies from Shaking) and automated cutting (requiring precise hook positioning at the cutting station).

- Structure Optimized for Weighing and Cutting: The main carriage structure is reinforced to effectively dampen and disperse interference with delicate signals from load cells and to withstand instantaneous impact forces from cutting actions. The material uses reinforced nylon with low creep and high dimensional stability, ensuring the connection plane remains undeformed during long-term use and safeguarding the system’s repeatable positioning accuracy.

- Seamless Integration with Automation Systems:

- With Weighing Systems: The stable connection ensures reliable transmission of weight signals from the hook to the load cell, providing the physical foundation for automatic grading and data traceability.

- With Cutting Systems: The carriage precisely delivers the poultry carcass to the cutting station. Through its Stable Interface, it secures the cutting hook and absorbs the reaction forces from the cutting action, ensuring stable and safe cutting operations.

- Lightweight and Hygienic Design: While providing sufficient strength, the nylon material achieves light weight, reducing the load on the drive system. The overall design has no hygiene dead angles, complies with food-contact standards, and is easy to clean with high-pressure water and disinfect.

Core Value

- Enables Process Automation: Links the three stages of conveyance, weighing, and cutting into a continuous, automated workflow through standardized hardware, reducing manual intervention and improving efficiency.

- Ensures Data and Action Accuracy: The high rigidity and high guidance precision are fundamental to ensuring accurate dynamic weighing data and precise execution of cutting actions.

- Enhances System Reliability: The structure, optimized for automated scenarios, reduces the risk of system failure, downtime, or process errors caused by unstable accessory connections or operational vibration.

Typical Applications

- Automatic Weighing and Grading Lines: The carriage, equipped with a weighing hook, passes uniformly over an in-line scale on the T-rails, enabling real-time automatic weighing and data recording for each bird.

- Automatic Cutting Conveyor Lines: The carriage, equipped with a cutting hook, precisely delivers poultry carcasses to rotary or positioned cutting stations, coordinating with automated equipment to perform standard cutting operations.

- Integrated Weighing and Cutting Lines: The carriage can sequentially perform dynamic weighing followed by automated cutting on the same line, realizing a highly integrated automated processing flow.

This carriage is the core connecting component within our integrated solution. We can provide fully compatible dedicated weighing hooks and cutting hook assemblies, along with overall interface design and compatibility support for your automation system.