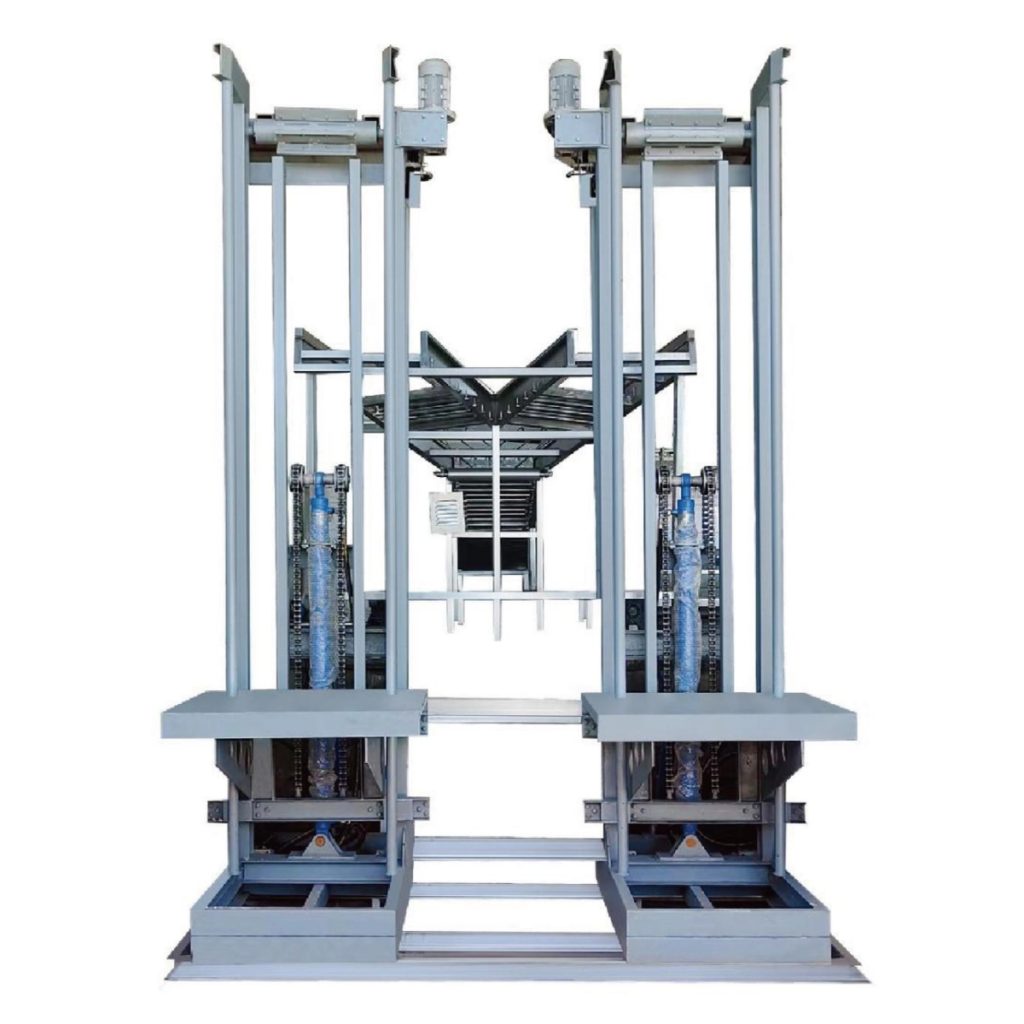

INCLINED LIFTING PLATFORM

Structural features: special equipment for unloading chicken and duck cages. This machine adopts the overall direct inclined conveying mechanism, which is stable, fast and accurate in operation, saves labor, and has strong durability, which greatly improves work efficiency. Ideal for poultry slaughtering businesses.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Key Features

High Production Capacity

- Capable of processing 10,000–13,500 units per hour, based on 6 poultry cages per calculation.

- Ideal for high-volume poultry processing facilities.

- Ensures smooth and continuous operation to meet demanding production schedules.

Advanced Inclined Lifting Mechanism

- Direct inclined conveying system for stable and accurate cage handling.

- Reduces manual labor requirements and improves operational safety.

- Ensures precise positioning and unloading of poultry cages.

Robust Construction

- Overall Dimensions: 2850×1000×3900 mm (Single Unit).

- Combination Size: 4350×4800×3900 mm.

- Heavy-duty design ensures durability and long-term reliability.

- Suitable for continuous operation in demanding environments.

Energy-Efficient Design

- Single Unit Power: 4.75 KW (Pump Motor 4 KW, Distribution Motor 0.75 KW).

- Two Units Power: 9.5 KW (Pump Motor 8 KW, Distribution Motor 1.5 KW).

- Optimized power consumption for reduced operational costs.

- High-efficiency motors ensure consistent performance.

Versatile Application

- Designed for poultry slaughterhouses and processing facilities.

- Compatible with various cage sizes and configurations.

- Ideal for integration into automated processing lines.

Benefits

Enhanced Efficiency

- Streamlines cage unloading operations, reducing manual intervention.

- Accelerates production flow, minimizing downtime and bottlenecks.

- Improves overall facility productivity and throughput.

Labor Savings

- Reduces the need for manual cage handling, lowering labor costs.

- Improves worker safety by automating heavy lifting tasks.

- Simplifies operational workflows, allowing staff to focus on other tasks.

Durability and Reliability

- Heavy-duty construction ensures long-term performance under continuous use.

- High-quality components minimize maintenance requirements.

- Robust design withstands harsh processing environments.

Energy Optimization

- Efficient power usage reduces energy costs.

- High-performance motors ensure smooth operation with minimal energy waste.

- Environmentally friendly design supports sustainable operations.

Applications

The Inclined Lifting Platform is ideal for:

- Poultry Slaughterhouses: High-volume cage unloading for streamlined processing.

- Processing Facilities: Integration into automated production lines for efficient cage handling.

- Large-Scale Operations: Suitable for facilities requiring consistent and reliable performance.

- Export-Oriented Businesses: Ensures high productivity to meet international market demands.

| Overall Dimensions | 2850×1000×3900 mm (Single Unit) |

| Combination Size | 4350×4800×3900 mm |

| Production Capacity | 10,000–13,500 units/hour (Based on 6 poultry cages per calculation) |

| Equipment Power | 4.75 KW (Single Unit: Pump Motor 4 KW, Distribution Motor 0.75 KW) |

| Power (Two Units) | 9.5 KW (Pump Motor 8 KW, Distribution Motor 1.5 KW) |