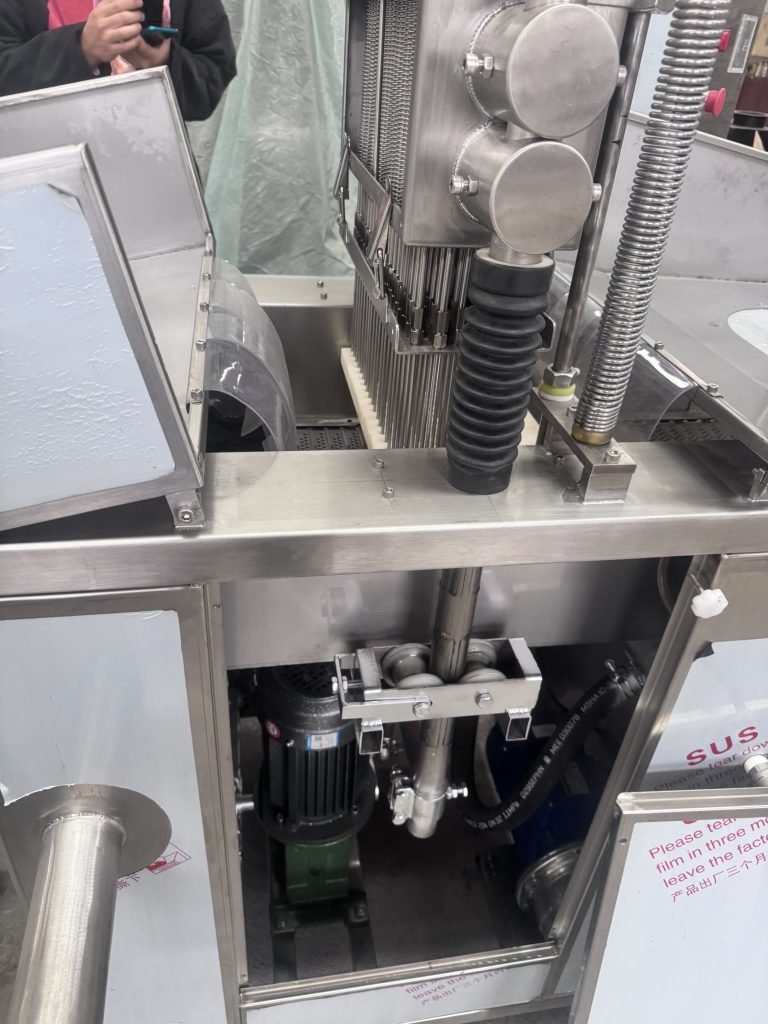

Brine Injector

Production Capacity: 1000 kilograms/hour

Injection Pressure: 2-6.3 kilograms

Power: 4.8 kilowatts

Overall Dimensions: 1470×1150×1750 millimeters

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Product Name: High-Efficiency Brine Injector (1000kg/h Model)

I. Product Overview

This high-efficiency brine injector is specifically designed for processing poultry, pork, beef, and other meat products. It utilizes a high-pressure injection system to uniformly inject curing solutions, seasoning liquids, water-retaining agents, and other additives into meat blocks, significantly enhancing product tenderness, flavor, water retention, and yield. The equipment is constructed with food-grade stainless steel and features an intelligent pressure control system. It is suitable for large-scale production scenarios such as central kitchens, meat processing plants, and prepared food enterprises, making it a core piece of equipment for achieving standardized, high-quality meat product processing.

II. Technical Parameters

| Item | Parameter |

|---|---|

| Model | SYZ-1000 Brine Injector |

| Production Capacity | 1000 kg/hour (adjustable) |

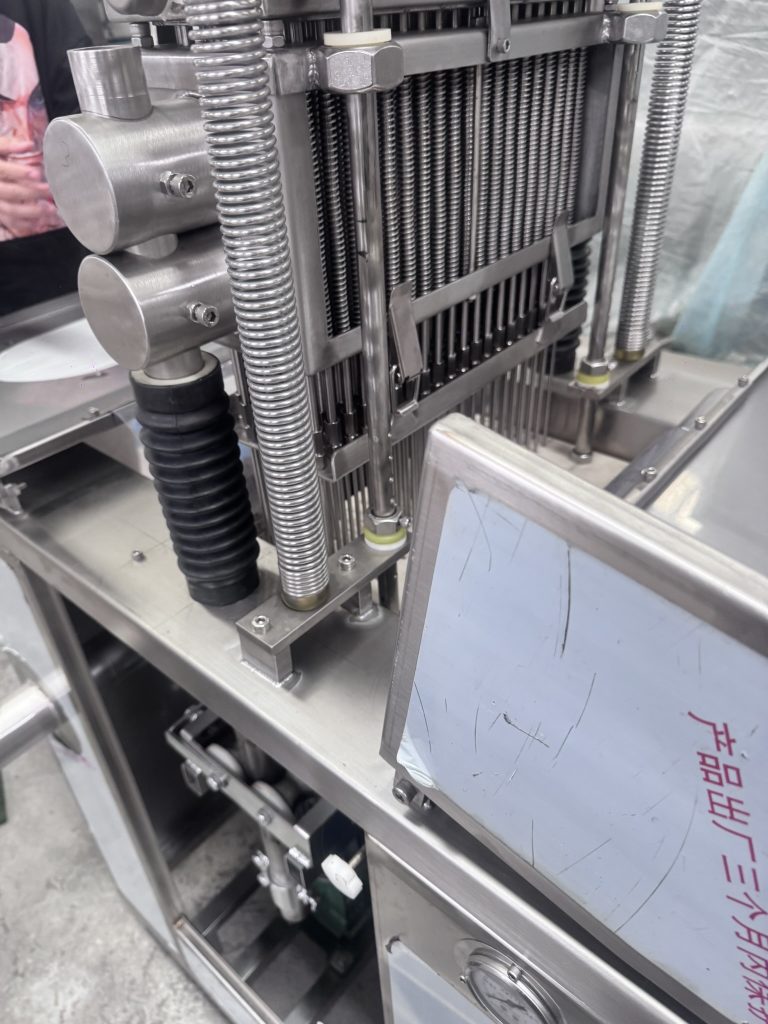

| Injection Pressure | 2–6.3 kg (programmable segmented control) |

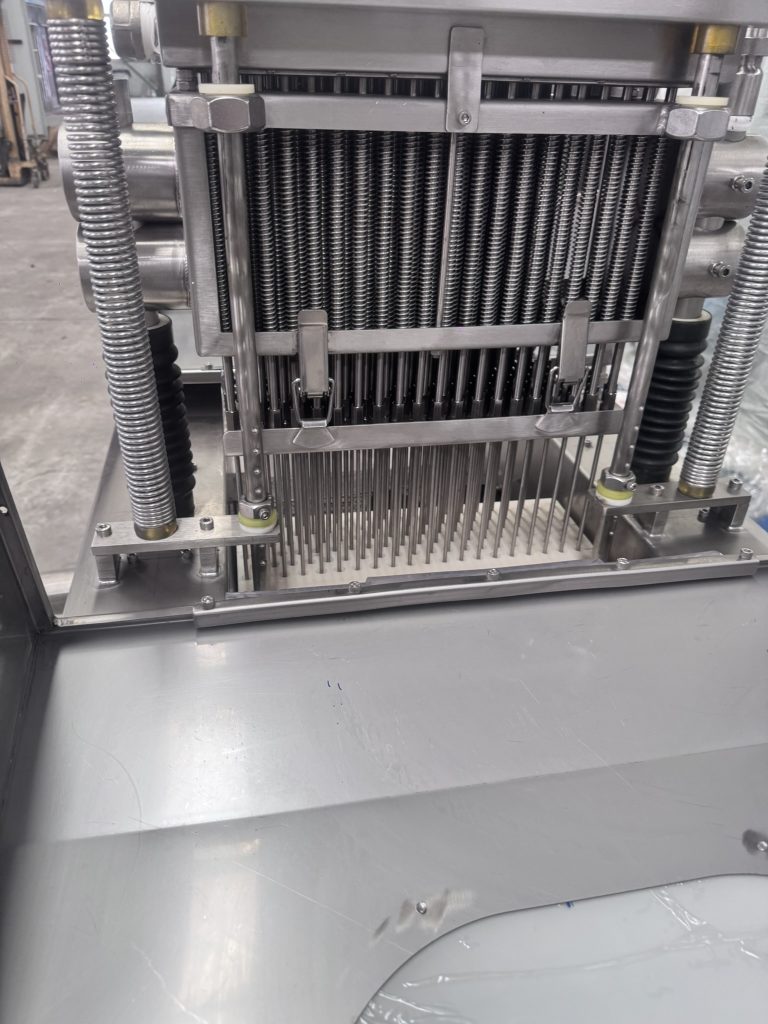

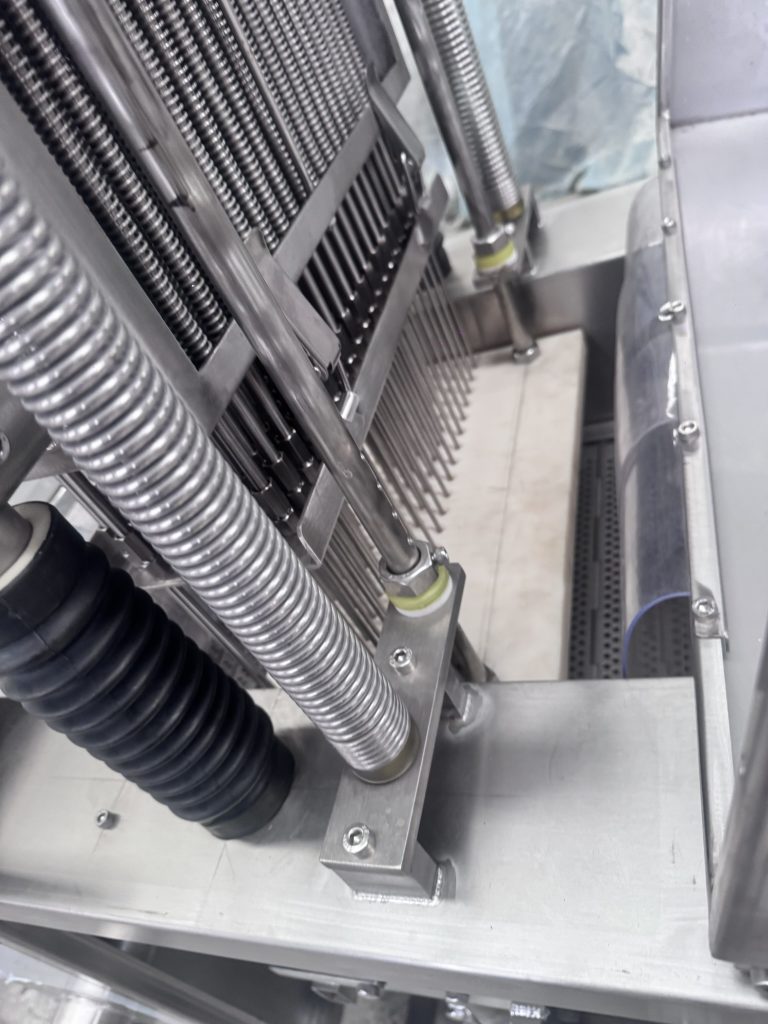

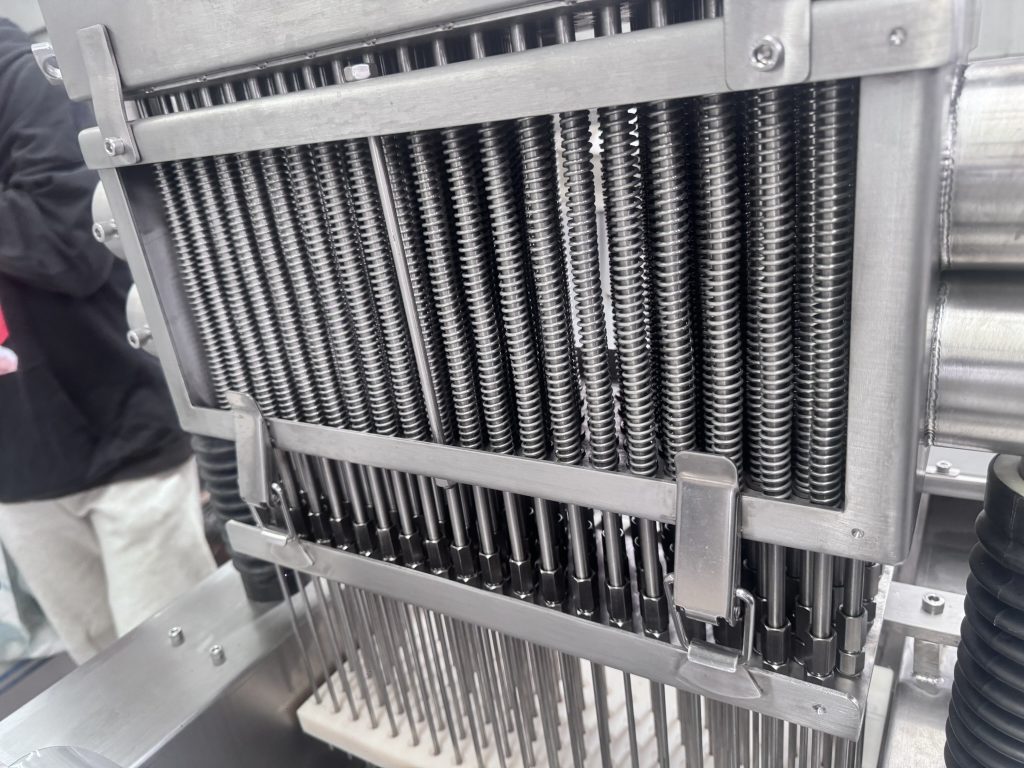

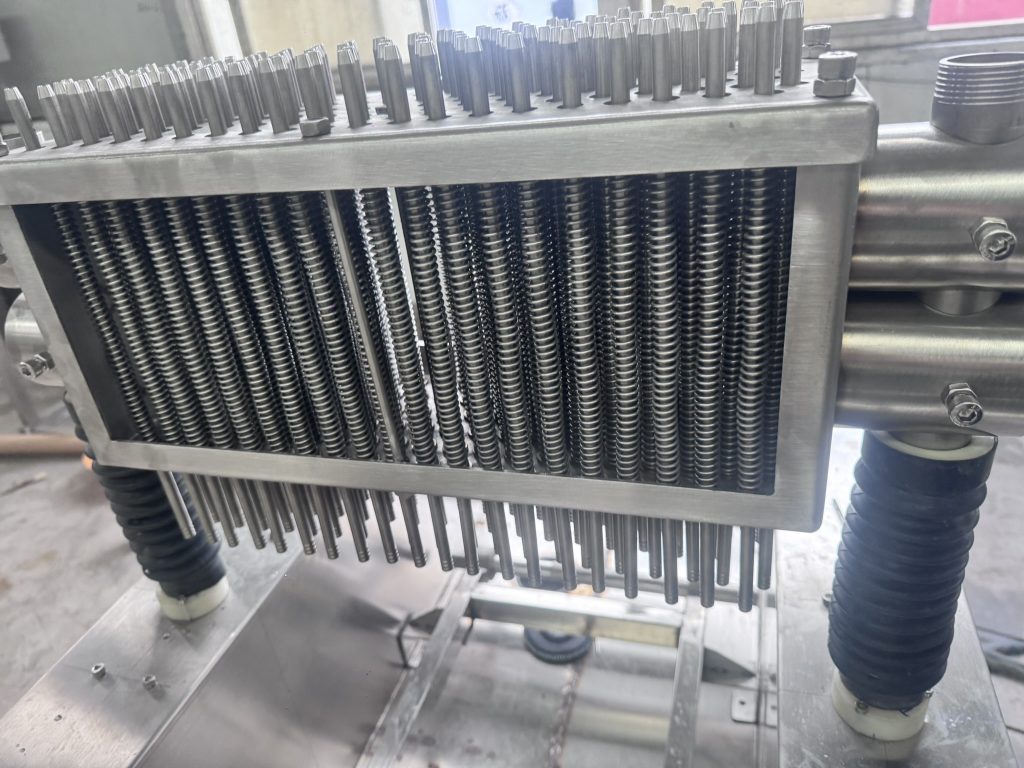

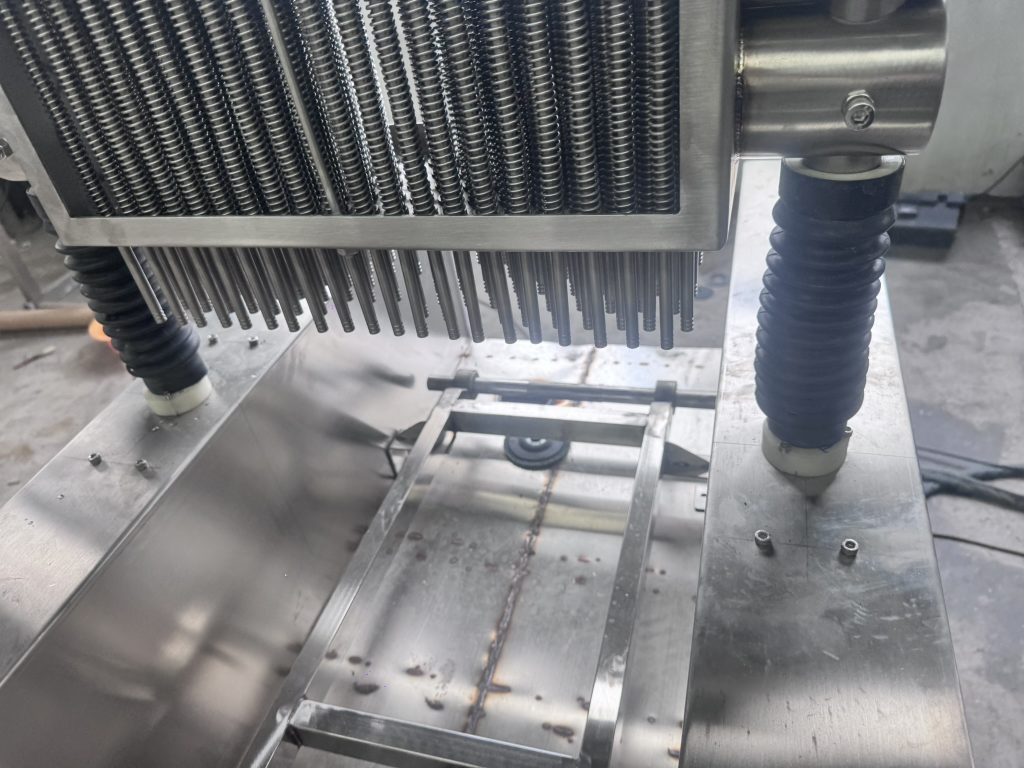

| Number of Needles | Customizable (standard 32–48 needles) |

| Needle Diameter | Φ2.5–Φ3.5 mm (food-grade stainless steel needles) |

| Power | 4.8 kW (380V/50Hz, three-phase) |

| Dimensions | 1470 × 1150 × 1750 mm (L × W × H) |

| Machine Weight | Approximately 580 kg |

| Material Structure | 304 stainless steel contact surfaces, carbon steel frame with powder coating |

| Control System | PLC + touchscreen, supports parameter storage and production statistics |

III. Core Features

1. Efficient and Uniform Injection

- Multi-needle synchronous high-pressure injection with adjustable penetration depth ensures even distribution of curing liquid without dead zones.

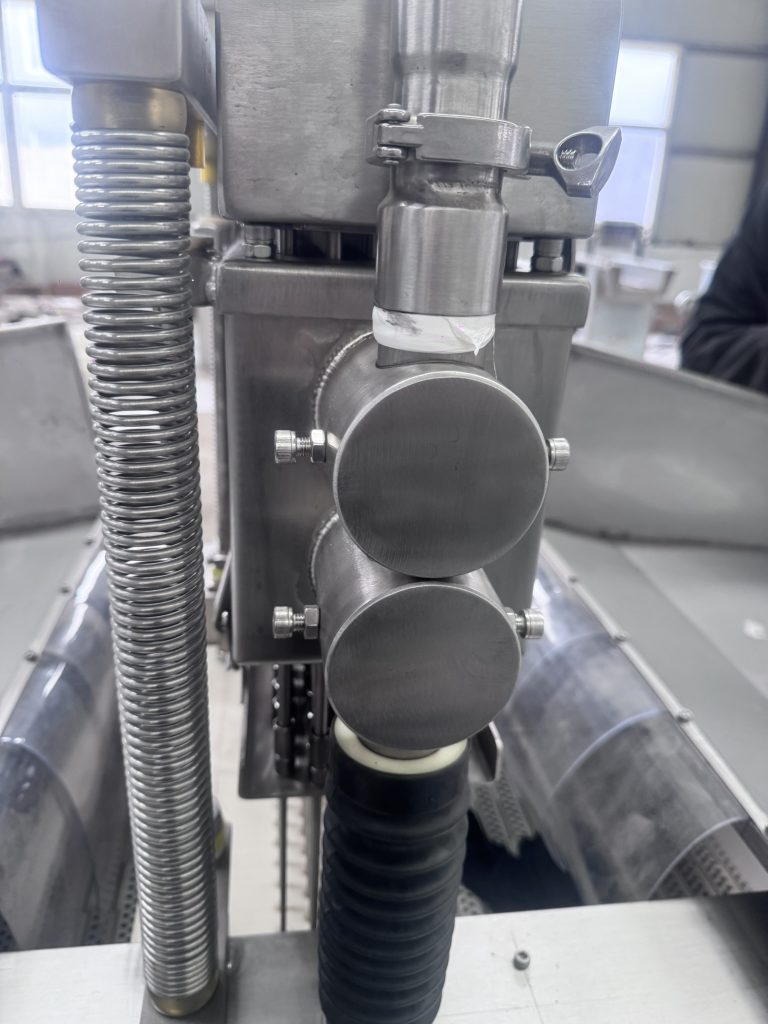

2. Intelligent Pressure Control

- Injection pressure can be set in segments within the 2–6.3 kg range, adapting to different meat textures and process requirements.

3. Energy Efficient and Low Consumption

- Total power consumption is only 4.8 kW, ensuring low operating costs. The circulation pump design minimizes curing liquid waste.

4. Easy to Clean and Maintain

- Detachable needle plates, filter screens, and liquid delivery pipelines comply with food hygiene standards.

5. Safe and Reliable

- Equipped with protective covers, emergency stop buttons, and anomaly alarm systems to ensure operational safety.

IV. Applicable Range

- Meat Types: Chicken breast, chicken legs, pork chops, steak, ham, bacon, etc.

- Processing Scenarios:

- Pre-treatment of meat product curing

- Central kitchens for prepared foods

- Deep processing of snack foods

- Export-oriented meat processing plants

V. Optional Configurations

- Customizable number of needles (16–96 needles)

- Injection liquid filtration and recovery system

- Frequency-conversion adjustable-speed conveyor belt

- Mobile liquid collection tray

- Remote monitoring interface (IoT module optional)

VI. Service Support

- Free installation, debugging, and operational training

- 12-month warranty for the entire machine, lifelong technical support

- Provision of process formulas and production guidance

If you require customization of needle plate layouts or injection pressure curves based on specific meat types, please feel free to discuss further!

Core Working Principle and Technical Highlights

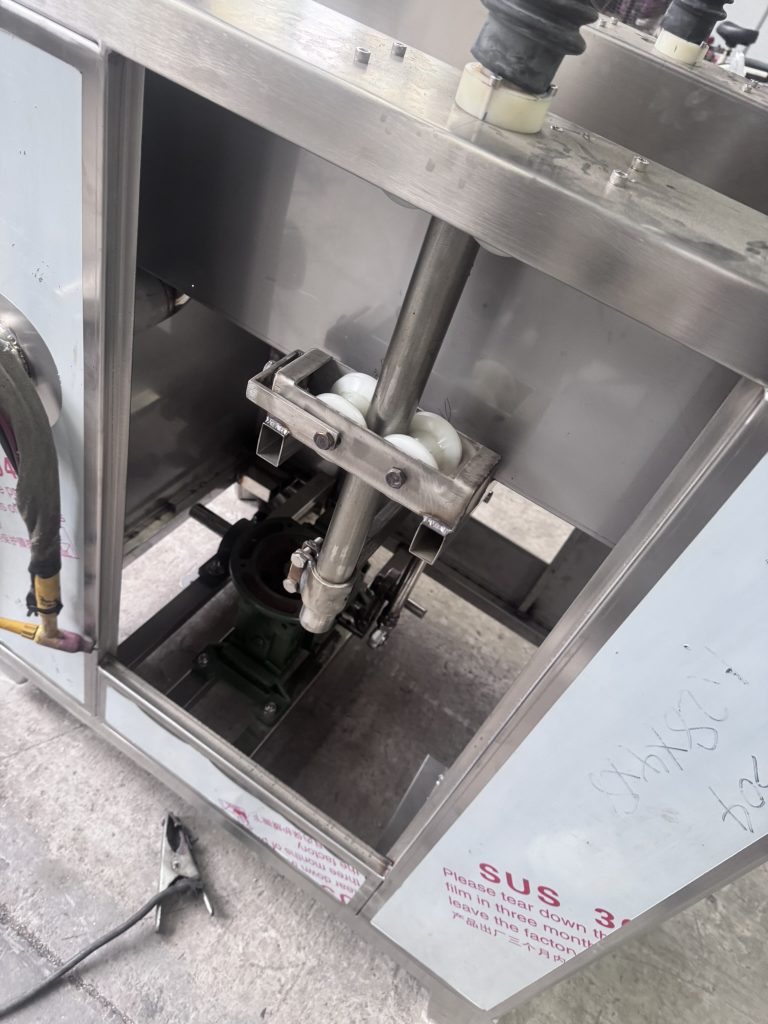

Working Principle: As shown in the diagram above, meat pieces are placed on a conveyor belt and pass under one or multiple rows of stainless steel injection needles. The needles penetrate the meat under high pressure while a pump precisely and evenly injects the curing solution into the meat's interior. The up‑and‑down movement frequency of the needles, injection pressure, and injection volume can all be accurately adjusted.

Key Performance Parameters:

Injection Rate: Refers to the percentage weight increase of the meat after injection (typically 10%–50%), which can be precisely controlled according to product requirements.

Injection Pressure: Affects the penetration depth and uniformity of the curing solution.

Number and Arrangement of Needles: Determines production capacity and injection coverage area, ranging from several dozen to hundreds of needles.

Synchronization: Advanced equipment ensures that injection occurs only when the needles penetrate and stops when they retract, reducing curing‑solution waste and surface pooling.

Main Types:

Step‑by‑Step Injector: The meat pauses during injection, allowing for more precise injection. Suitable for high‑quality products and irregularly shaped meat pieces.

Continuous Injector: The meat moves continuously on the conveyor belt without stopping, offering very high production capacity. Suitable for standardized, high‑volume production.

Brine injectors are key equipment in meat processing (especially in the production of ham, bacon, roast meat, and braised products). They are used to evenly inject marinade (brine, spice water, etc.) into the meat to achieve rapid marinating, improve tenderness, enhance flavor, and increase yield.