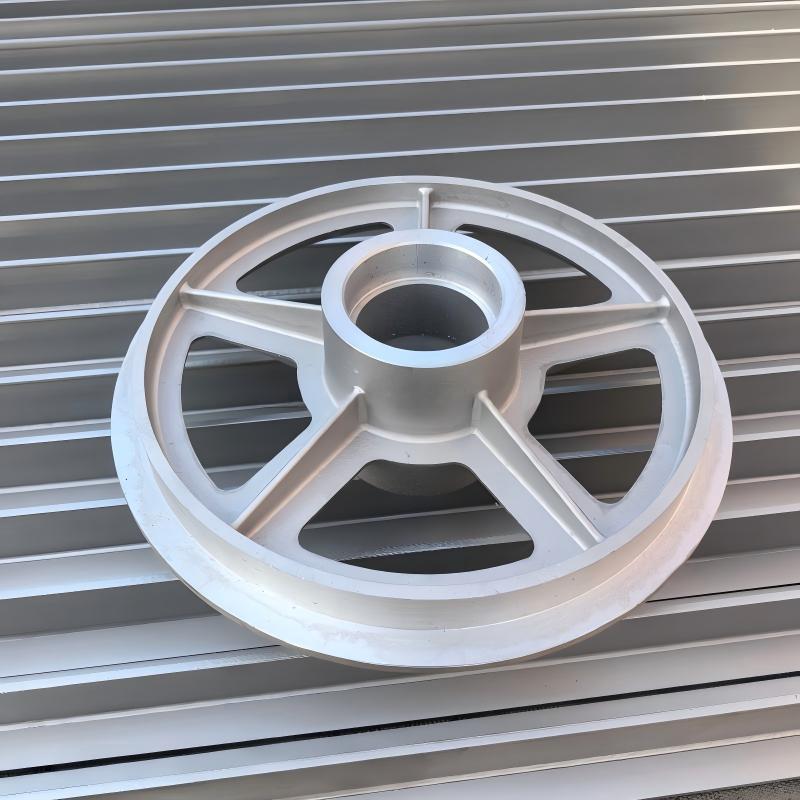

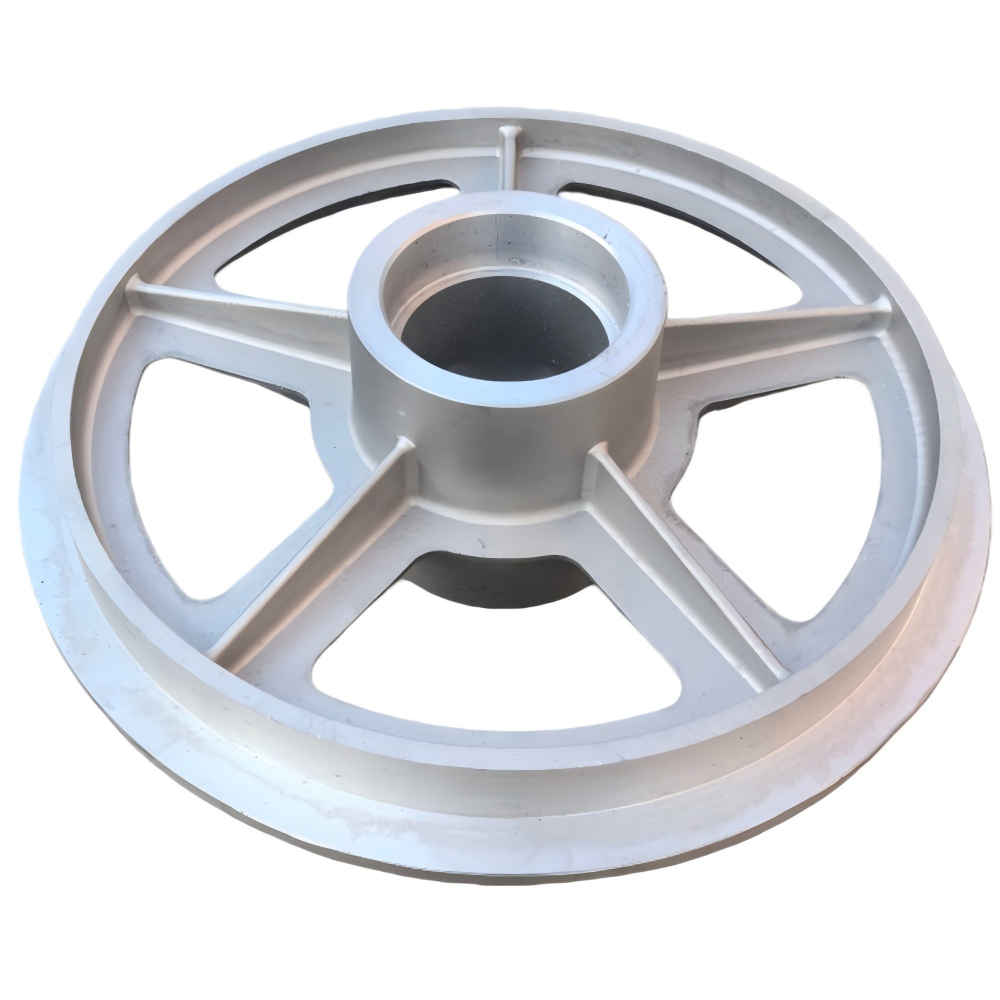

Aluminum Alloy Sprocket Hub for Poultry Slaughtering Line

This is a sprocket center hub specially designed for poultry slaughtering production lines. It is manufactured as a single piece from high-strength cast aluminum and is available in three standard outer diameter specifications: 285mm, 385mm, and 485mm.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Product Overview

This is a sprocket center hub specially designed for poultry slaughtering production lines. It is manufactured as a single piece from high-strength cast aluminum and is available in three standard outer diameter specifications: 285mm, 385mm, and 485mm. This product is a pure metal inner core, with the outer ring designed for tightly fitting a nylon gear ring. It serves as the core foundational component for the drive unit of slaughter line overhead conveyor systems.

485MM CAST ALUMINUM WHEEL

385MM CAST ALUMINUM WHEEL

285MM CAST ALUMINUM WHEEL

Product Features

- Lightweight & High Strength: Made from premium cast aluminum, ensuring structural strength while achieving lightweight properties, reducing the inertial load on the transmission system.

- Precise Fit: Precisely machined outer ring dimensions ensure a tight fit with standard nylon gear rings, preventing loosening.

- Corrosion-Resistant Design: Surface-treated with anodization, resistant to corrosion in humid environments, suitable for slaughterhouse working conditions.

- Easy Installation: Standard keyway design allows for simple and secure connection to the drive shaft.

- Cost-Effective: As the load-bearing inner core for nylon gears, it extends the overall service life and reduces maintenance costs.

Technical Specifications

| Model | Outer Diameter | Suitable Chain No. | Bore Range | Approx. Weight |

|---|---|---|---|---|

| TL-285 | 285mm | #80 / #100 | 40-80mm | 3.8kg |

| TL-385 | 385mm | #100 / #120 | 50-100mm | 6.5kg |

| TL-485 | 485mm | #120 / #140 | 60-120mm | 10.2kg |

Material: High-strength cast aluminum alloy

Surface Treatment: Anodized

Package Dimensions: 20×15×5 cm/unit (individual packaging)

Minimum Order Quantity: 100 units

Usage Instructions

- Assembly: Heat the nylon gear ring to expand it, then slide it onto the outer ring of this aluminum hub.

- Installation: Align the hub with the drive shaft via the keyway and secure it with locking bolts.

- Inspection: After installation, ensure there is no relative displacement between the hub and the nylon gear ring.

Applications

- Drive stations for poultry slaughter overhead conveyor lines

- Corner tensioning devices

- Elevator transmission systems

- Replacement and repair of existing nylon gears

Ordering Information

- Packaging: Each hub is individually packaged in a carton with shock-absorbent lining.

- Delivery Lead Time: 15-20 working days after receipt of deposit.

- Payment Terms: 30% deposit, 70% balance before shipment.

- Quality Assurance: 12-month product warranty.

Important Note

Please select the appropriate hub size based on your conveyor line chain specification (#80/#100/#120, etc.). Custom machining is available for special bore requirements upon providing drawings.

Simple & Reliable · Designed for Slaughter Lines

Welcome to inquire about detailed technical parameters and sample requests!