800 BPH Compact Poultry Slaughter Line

This is a high-efficiency, flexible, and ready-to-use modern Poultry Slaughter Line solution specially designed for small and medium-sized slaughterhouses. Its core highlights lie in its compact modular design and full support for Halal certification.

Processes 800 chickens per hour and supports rapid deployment. The equipment is pre-installed and commissioned at the factory, allowing for quick production start-up upon arrival without complicated on-site installation.

Introduction to the Matching Spiral Pre-Chiller 4.5-Meter Spiral Pre-Chiller for 800BPH Compact Poultry Slaughter Line

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

| Specification Item | Details |

|---|---|

| Designed Capacity | 800 BPH (800 birds per hour) |

| Applicable Poultry | Broiler Chicken |

| Live Bird Weight | 1.8–2.5 kg per bird |

| Finished Product | Whole Chicken (Headless & Clawless) |

| Power Supply Requirement | 380V, 3-Phase, 50Hz (Customizable on Demand) |

| Total Installed Power | 68.6 kW (Mainly Consumed by Scalding Machine and Other Equipment) |

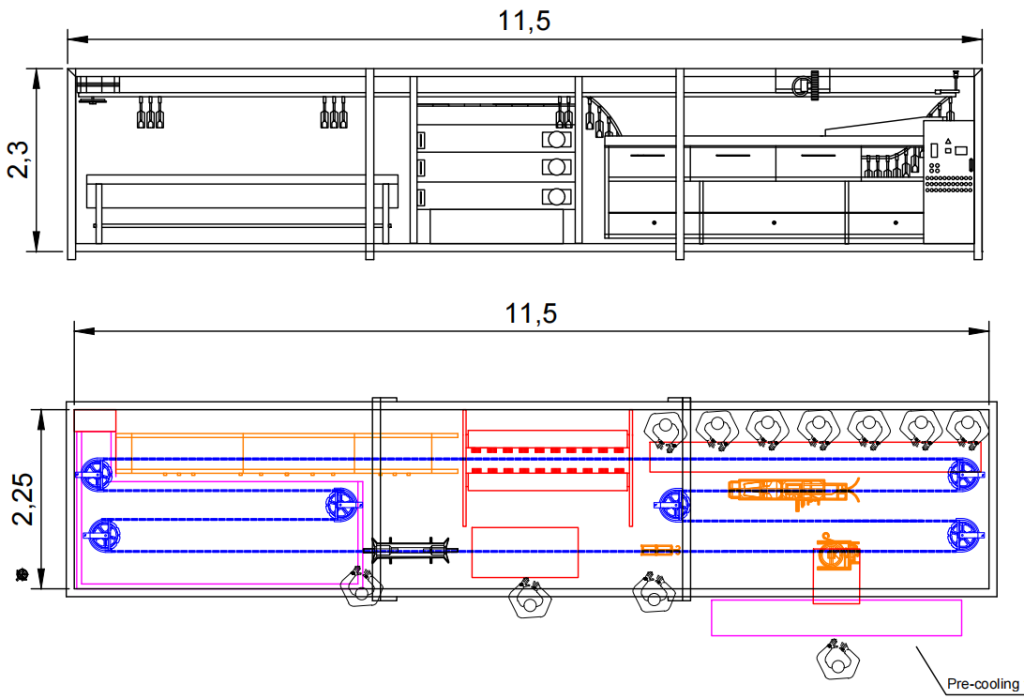

| Production Line Length | Approximately 11.5 Meters (Estimated Based on Layout Drawing) |

| Floor Space Requirement | Compact Design; Exact Area Subject to Workshop Layout Arrangement |

| Main Material | 304 Stainless Steel (Main Frame & Contact Surfaces) |

| Shipping Volume | 1×40HQ Container (40-foot High Cube Container) |

THE SPECIFIC CONFIGURATIONS FOR SEVERAL KEY PROCESS POINTS ARE AS FOLLOWS:

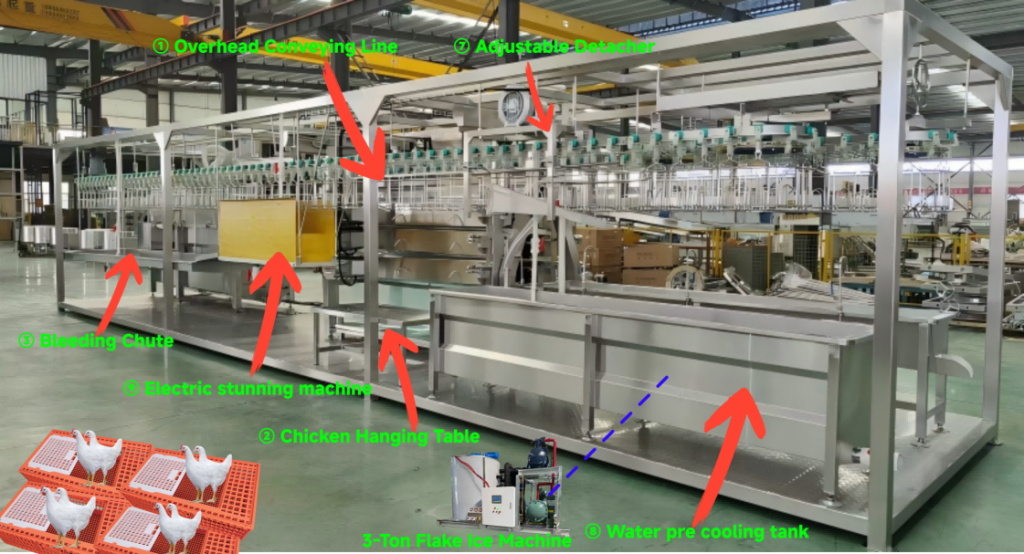

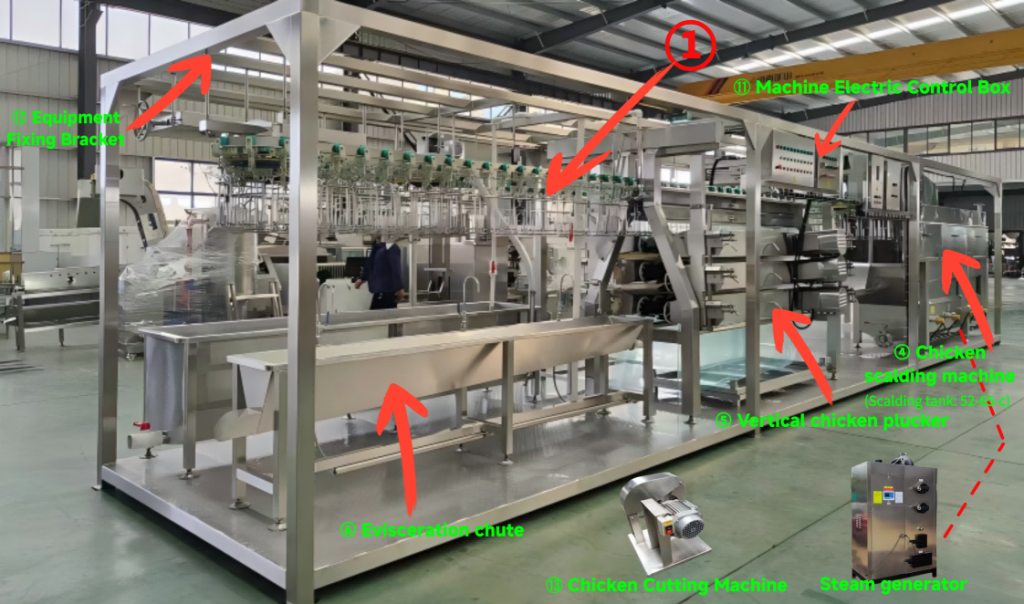

1.Production Line Composition

The production line comprises 12 processes.

2.Stunning Method

Equipped with an electric stunning machine, but it can be removed upon customer request to meet halal certification requirements.

3.Slaughter and Bleeding

Manual slaughtering, with adjustable bleeding time of 4–5 minutes to comply with halal slaughtering standards.

4.Scalding and Defeathering

- Scalding Machine: Electrically heated, 54 kW power, heats to the set temperature (adjustable between 52–61°C) in 30 minutes, with an optional steam boiler.

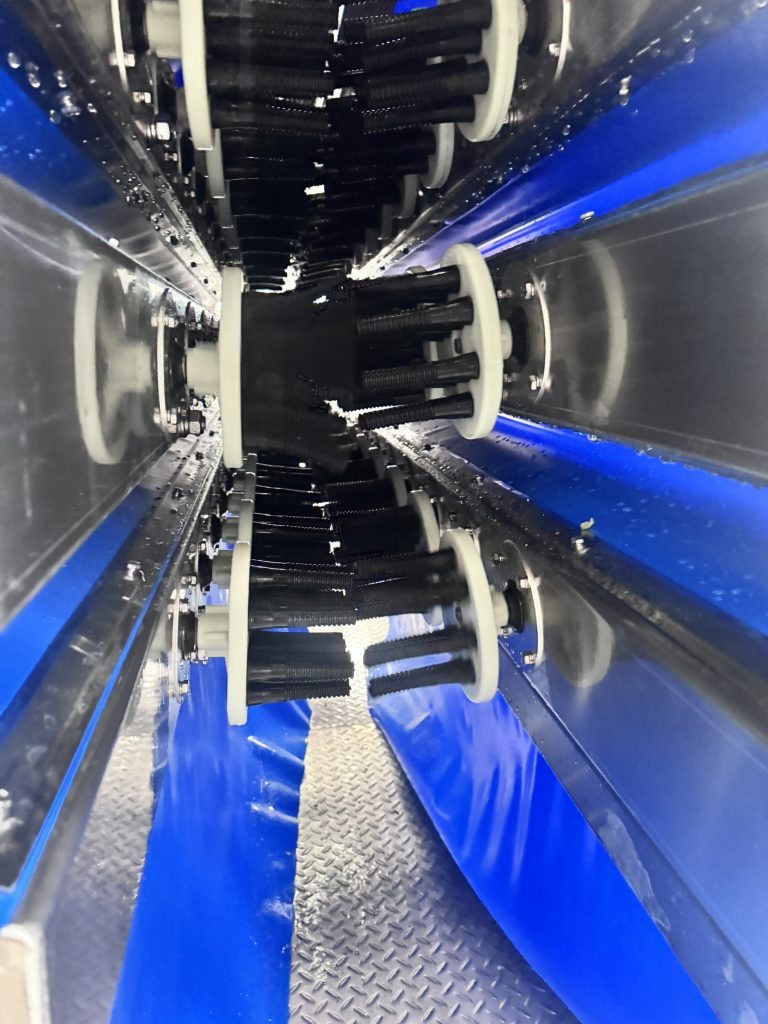

- Vertical Defeathering Machine: A total of 60 defeathering discs across 6 lines, suitable for different chicken sizes.

5.Pre-cooling Process

Utilizes a water bath pre-cooling tank, requiring customers to provide their own 0–4°C cold water.

6.Automation Level

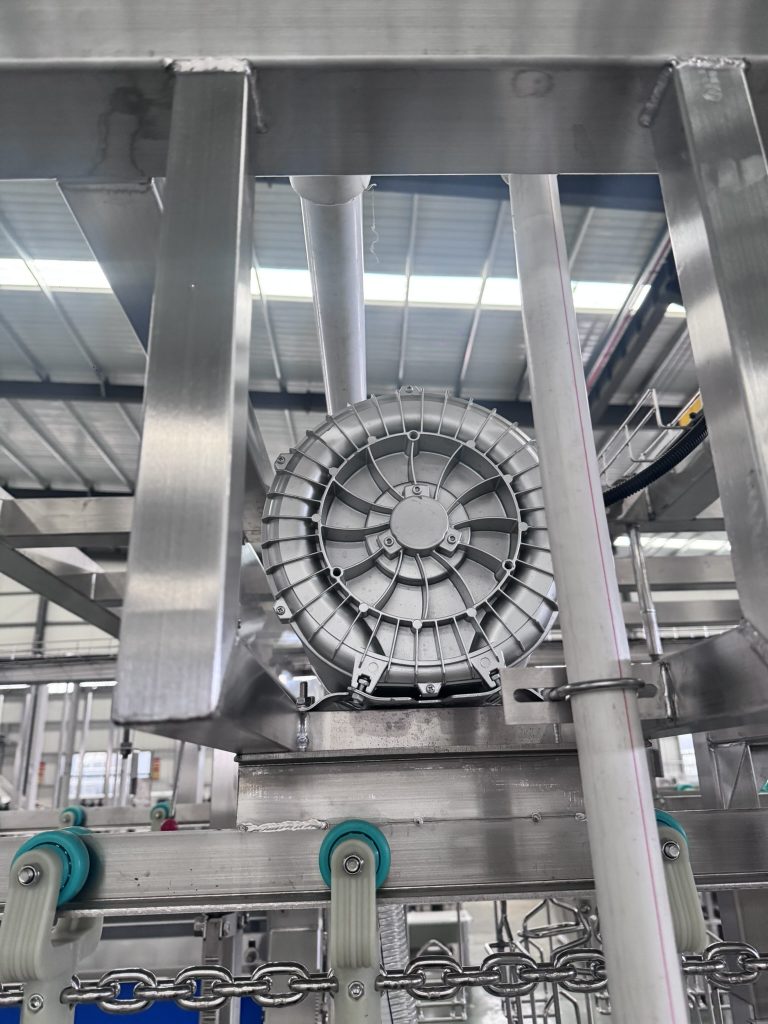

Core conveying (overhead conveyor line), scalding, defeathering, claw cutting, and head removal are automated; evisceration, trimming, and other processes are performed manually online.

7.Halal Compliance

The entire line is designed to support halal slaughter certification, with key features including the optional removal of stunning and ensuring sufficient bleeding time (supports 3 minutes and 5 seconds).

8.Supporting Equipment

When the processing capacity of the slaughter line increases to 800–1000 BPH, it is recommended to additionally configure a spiral pre-cooler with dimensions of 4.5 m (length) × 2.1 m (width) × 2.6 m (height). It will work in conjunction with the built-in pre-cooling tank of the compact slaughter line to complete the pre-cooling process of broilers.

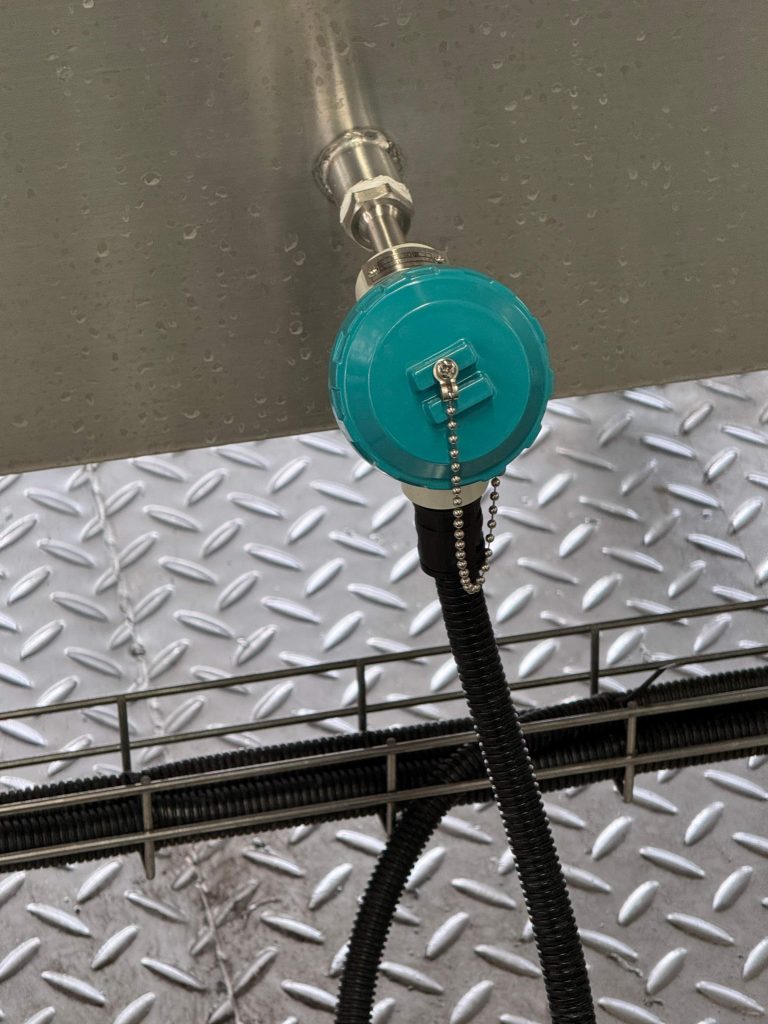

EQUIPMENT CLEANING PROCESS BEFORE FACTORY SHIPMENT

EQUIPMENT PACKAGING AND TRANSPORTATION PROCESS

QUALITY AND SERVICE COMMITMENT

1.Comprehensive Support:

Standard warranty is provided, with optional technical training, installation guidance (water and electrical connections), and after-sales support.

2.Quality Verification:

Factory acceptance testing and video documentation can be provided for confirmation.

3.Manufacturer Philosophy:

NPW is dedicated to delivering innovative and practical machinery for the global meat industry. This product embodies our commitment to lowering operational barriers and offering scalable technology that grows with your business.