10 Tons/Day Poultry Wastewater Treatment Equipment

This equipment is an integrated, high-efficiency wastewater treatment solution specifically developed for the characteristics of wastewater from small poultry slaughterhouses. Slaughter wastewater is notably characterized by high levels of organic matter (COD/BOD), high grease content, high suspended solids, and fluctuating ammonia nitrogen. Traditional treatment methods often face challenges such as large footprint, complex processes, and difficult operation and maintenance.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Integrated Wastewater Treatment Equipment for Small-Soultry Slaughterhouses (10 tons/day)

1. Product Overview

This equipment is an integrated, high-efficiency wastewater treatment solution specifically developed for the characteristics of wastewater from small poultry slaughterhouses. Slaughter wastewater is notably characterized by high levels of organic matter (COD/BOD), high grease content, high suspended solids, and fluctuating ammonia nitrogen. Traditional treatment methods often face challenges such as large footprint, complex processes, and difficult operation and maintenance.

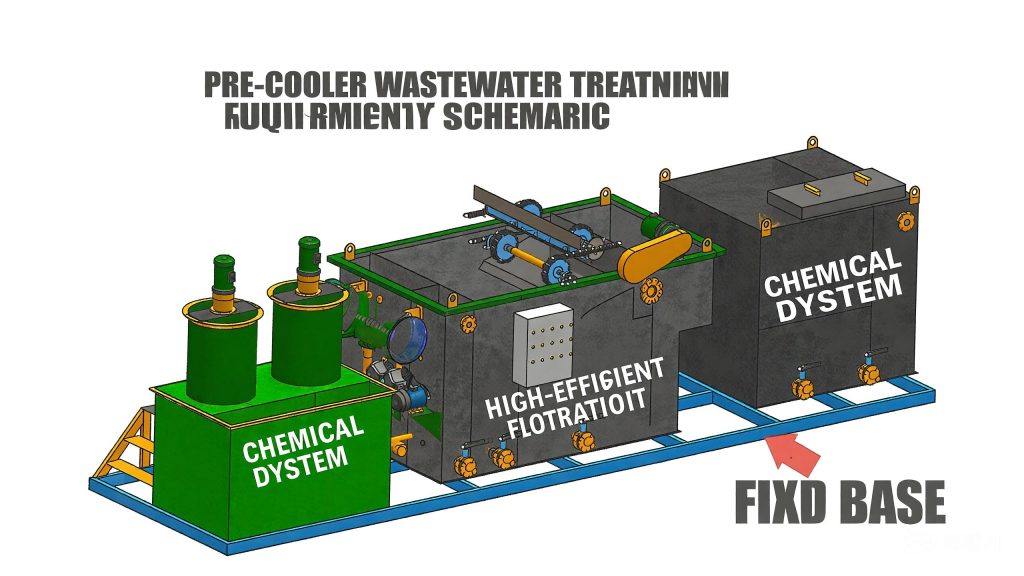

This integrated unit innovatively combines the core treatment stages—the Dosing System, the High-Efficiency Flotation Machine, and the Filtration System—onto a single robust steel structure base, forming a compact, efficient, and reliable standardized treatment module. The standard treatment capacity is 10 tons per day. When paired with our standardized civil works design (including collection tanks, clean water tanks, etc.) and auxiliary equipment (such as dedicated aerators), the system’s capacity can be easily expanded up to 50 tons per day to accommodate future business growth. The entire core equipment is compactly designed and can be fully loaded into a 40-foot standard shipping container, facilitating easy transportation, installation, and potential relocation.

2. Core Components & Process Flow

- Dosing System:

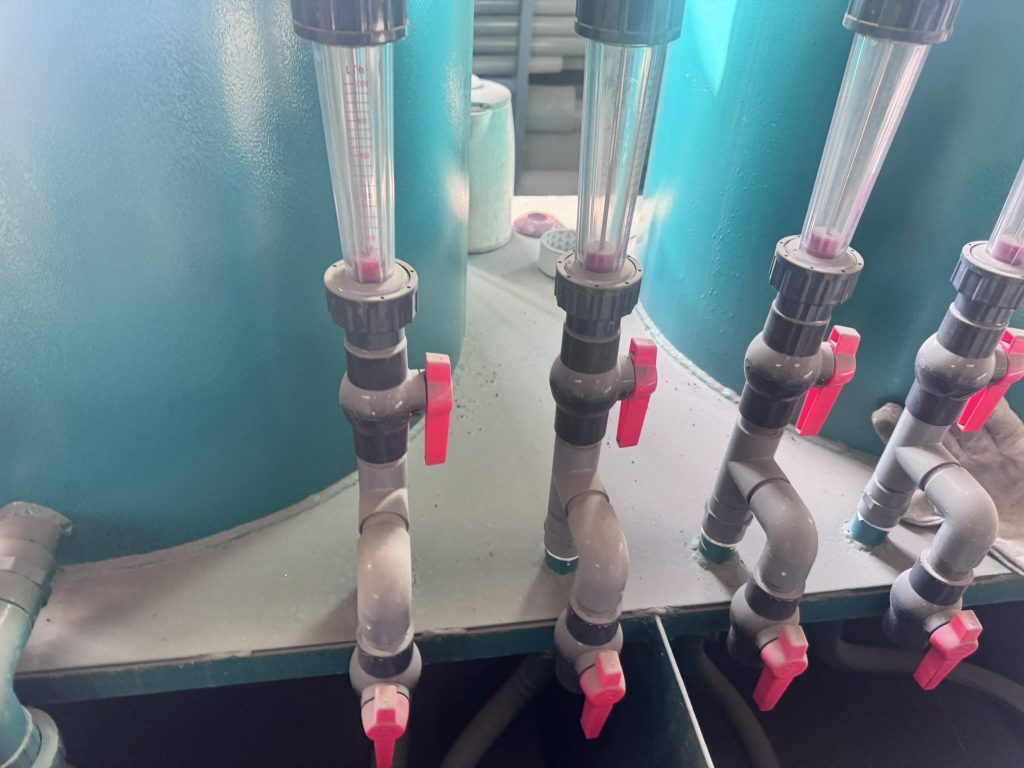

- Equipped with an intelligent dosing unit for precise addition of PAC (Polyaluminium Chloride) and PAM (Polyacrylamide).

- Automatically adjusts the dosage based on real-time wastewater quality changes to achieve efficient coagulation. This process agglomerates fine suspended solids, colloids, and part of the dissolved organic matter into flocs that are easy to separate, laying the foundation for subsequent treatment stages.

- High-Efficiency Flotation Machine (Core Treatment Unit):

- Utilizes Dissolved Air Flotation (DAF) or Cavitation Air Flotation (CAF) technology (customizable based on client needs) to generate a multitude of micro-fine bubbles.

- These micro-bubbles thoroughly mix with the coagulated wastewater, adhering to pollutants like grease, fine flocs, blood proteins, etc., causing them to float rapidly and form a surface sludge layer.

- An automatic surface scraper removes the floated sludge, enabling high-efficiency removal of grease and suspended solids (SS), significantly reducing the organic load.

- Filtration System (Polishing Stage):

- The effluent from the flotation unit enters a multi-media filtration system to further remove residual fine suspended solids, some organic matter, and color.

- Ensures the final effluent is clear and stable, meeting requirements for subsequent discharge or further advanced treatment.

3. Core Product Advantages

- Highly Effective for Slaughterhouse Wastewater: Specifically designed to enhance removal of grease, blood contaminants, and suspended solids. The process is proven and reliable, ensuring stable effluent quality that can meet the “Discharge Standard of Water Pollutants for the Meat Processing Industry (GB 13457-92)” or local discharge requirements.

- Highly Integrated, Minimal Footprint: The three core systems are designed as one integrated unit with a compact structure, significantly saving space—ideal for small slaughterhouses with limited area.

- Modular Design, Easy Expansion: The equipment itself is a standard module that integrates seamlessly with standardized civil tanks (collection, clean water) and auxiliary equipment. For future capacity increases, the system can be quickly expanded from 10 to 50 tons/day by adding modules or adjusting operational parameters, avoiding repetitive investment.

- Quick Installation, Easy Mobility: The unit is pre-assembled on the base. On-site work mainly involves placement and connection of pipelines and electrical circuits, drastically shortening the installation timeline. The container-friendly design concept provides mobility, suitable for temporary sites or potential future relocation.

- Intelligent Operation, Simple Management: Features a high degree of automation, enabling automatic control of dosing, flotation, backwashing, etc., reducing dependency on specialized operators and simplifying daily operation and management.

- Robust & Durable, Low Maintenance Cost: Key components are made of corrosion-resistant materials. The structure is sturdy, ensuring a long service life with straightforward routine maintenance.

4. Typical Application Value

- Solves Environmental Compliance Challenges: Provides a cost-effective solution for small poultry slaughterhouses to achieve compliant discharge, mitigating environmental risks.

- Reduces Operational Costs: Offers lower investment, energy consumption, and simpler O&M compared to traditional built-in-place wastewater treatment plants.

- Enhances Corporate Image: Demonstrates standardized wastewater treatment, reflecting the company’s social responsibility and modern management standards.

- Supports Sustainable Development: Treated water can be reused for purposes like flushing or irrigation, conserving water resources.

5. Service Commitment

We provide not just equipment, but a full range of services including site survey, solution design, equipment supply, installation guidance, commissioning, and personnel training. The equipment comes with a one-year warranty, backed by lifelong technical support and maintenance services.

Choosing our integrated system means acquiring not just a piece of wastewater treatment equipment, but a long-term, stable, and worry-free environmental compliance solution. Please feel free to contact us anytime for a detailed proposal and quotation tailored to your specific situation.