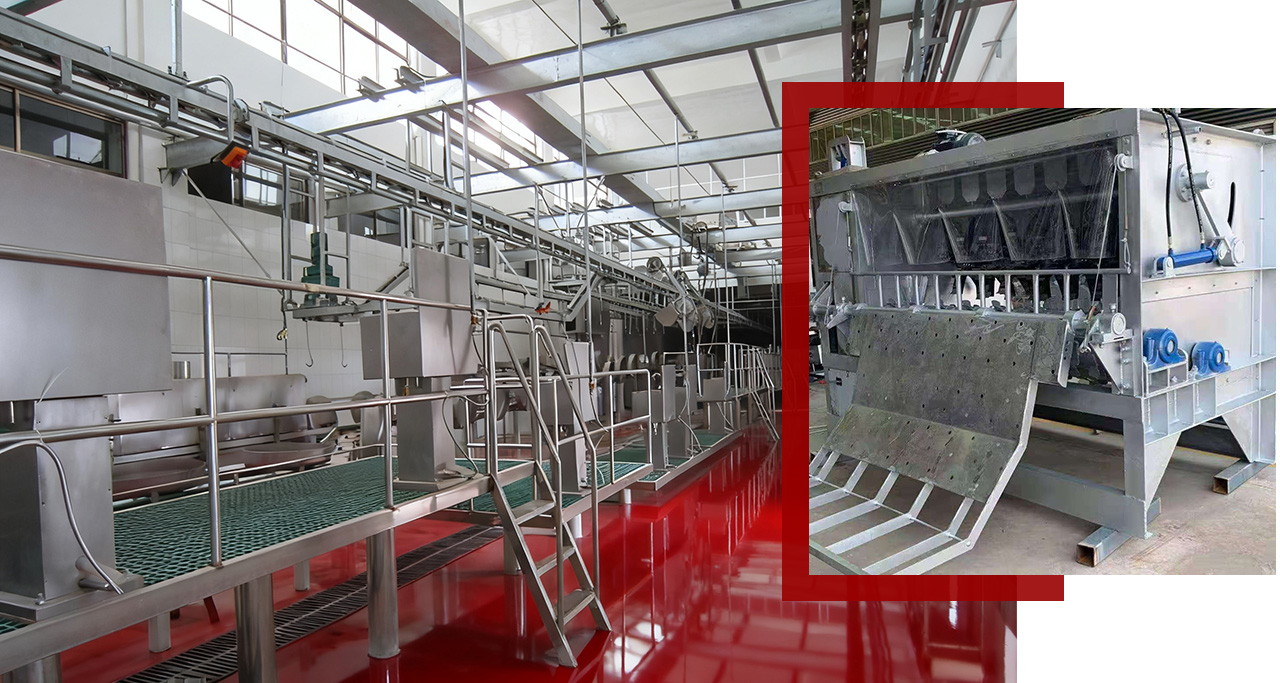

Professional Equipment Installation, System Commissioning, and Operator Training | Aimed at Ensuring High-Efficiency Production Operation of Equipment

Correct installation and commissioning are crucial prerequisites for equipment to achieve optimal performance. NPW will dispatch an experienced team of engineers to provide on-site service and train qualified operators for your team, thereby ensuring the production line operates stably and efficiently from the very first day of operation.

Integrated Equipment Installation, Commissioning, and Production Operation Startup Support Services

On-site Equipment Installation and Mechanical System Commissioning

- Senior Engineer Deployment: Depending on the project’s technical complexity and scale, 1 to 3 highly experienced senior engineers will be dispatched to the client’s production site.

- Precise Equipment Positioning and Integrated Assembly: Provide comprehensive professional guidance on accurate equipment siting, precise horizontal calibration, secure mechanical component connections, and systematic integrated assembly.

- Unitary and Integrated System Commissioning: Conduct no-load and full-load operational tests for each individual equipment unit, followed by integrated commissioning of the entire production line to achieve optimal collaborative efficiency and production cycle timing optimization.

Electrical & Control Commissioning

- Wiring: Guide electricians for standard wiring & inspection.

- System Setup: Debug PLC, temp control, speed & other core parameters.

- Safety Verify: Test E-stop, guards, leakage protection for foolproof safety.

Standardized Operation and Preventive Maintenance Training System

- Theoretical Knowledge System Building: In-depth explanation of core equipment working principles, optimized process flows, and key process control points.

- Practical Operation Skills Enhancement: Through on-site one-on-one guidance, ensure operators master standardized operating procedures such as equipment startup, running, shutdown, product changeover, and daily cleaning and disinfection.

- Preventive Maintenance Skills Impartation: Impart professional knowledge and skills in daily inspection, lubrication maintenance, predictive replacement of wearing parts, and primary fault diagnosis and troubleshooting.

- Complete Set of Technical Documentation Delivery: Provide bilingual (Chinese/English) operation manuals, maintenance manuals, and electrical schematic diagrams as long-term reference materials.

Trial Production Run and Final Project Acceptance

- Production Performance Compliance Verification: Conduct continuous operational tests using actual production raw materials to rigorously verify whether the equipment fully meets the designed capacity and product yield rate indicators explicitly stipulated in the contract.

- Official Project Completion Acceptance: Representatives from both parties will jointly sign the final project acceptance report, which formally declares that the equipment installation and system commissioning work has been completed with high quality and full satisfaction.

Core Competencies of NPW’s Installation Team

- Exceptional Professional Qualifications: Our engineering team undergoes systematic, intensive professional skills training and has accumulated extensive experience in both international and domestic project implementation.

- Strict Standardized Operating Procedures: The team rigorously executes Standard Operating Procedures (SOPs), ensuring that the quality of all installation phases meets consistent and highly reliable standards.

- Superior Cross-Cultural Communication Capabilities: Engineers possess multilingual communication abilities and profound cross-cultural collaboration backgrounds, effectively facilitating seamless communication and efficient cooperation with global clients.