CLIENT BACKGROUND AND REQUIREMENTS

Mr. Hw, who runs a local small-scale slaughterhouse in Malaysia, is facing business expansion and automation upgrade needs. He is in urgent need of a high-efficiency and reliable poultry scalding and defeathering machine to boost the capacity and efficiency of his new processing line.

INSPECTION TOUR: DECISIONS BASED ON WHAT YOU SEE

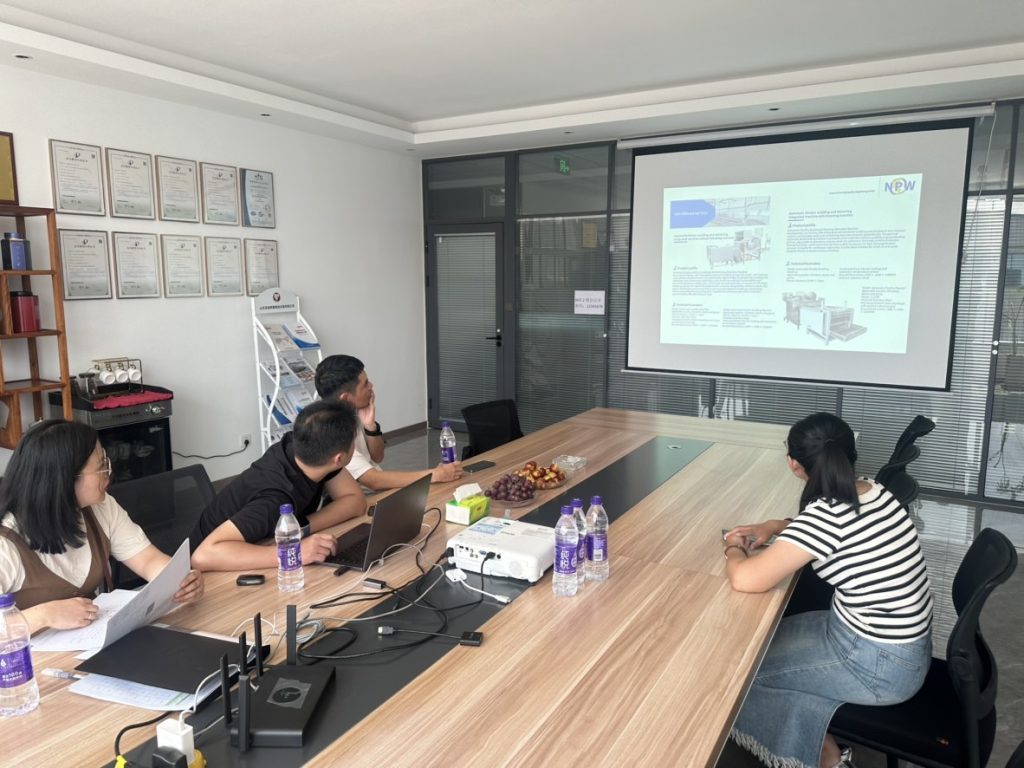

In September 2025, Mr. Hw made a special trip to China to visit our manufacturing plant.

HIGHLIGHTS OF ON-SITE INSPECTION

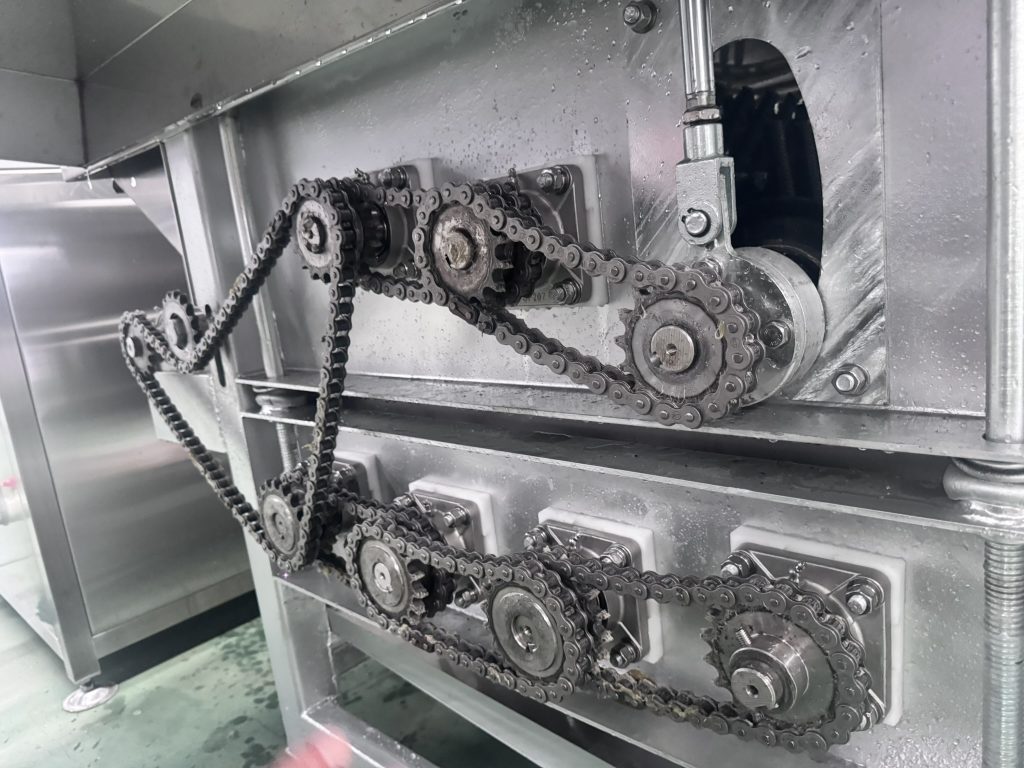

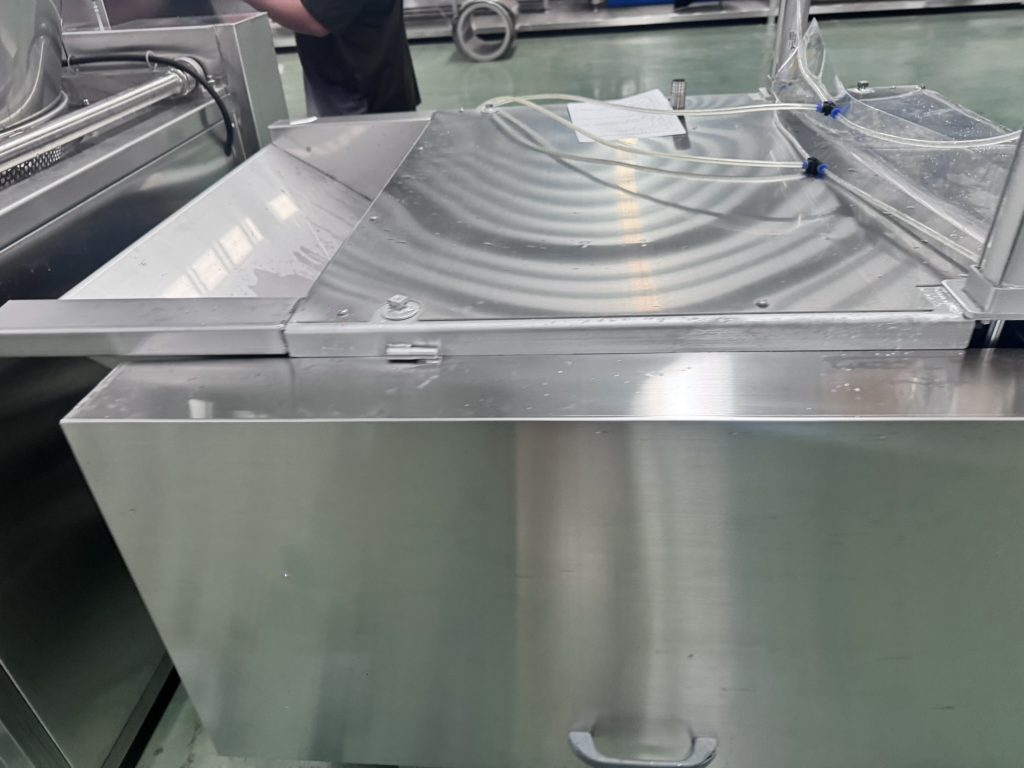

- Full-process ObservationThe client witnessed the entire process from raw material inbound to finished product assembly in person, and expressed high recognition of our quality control system.

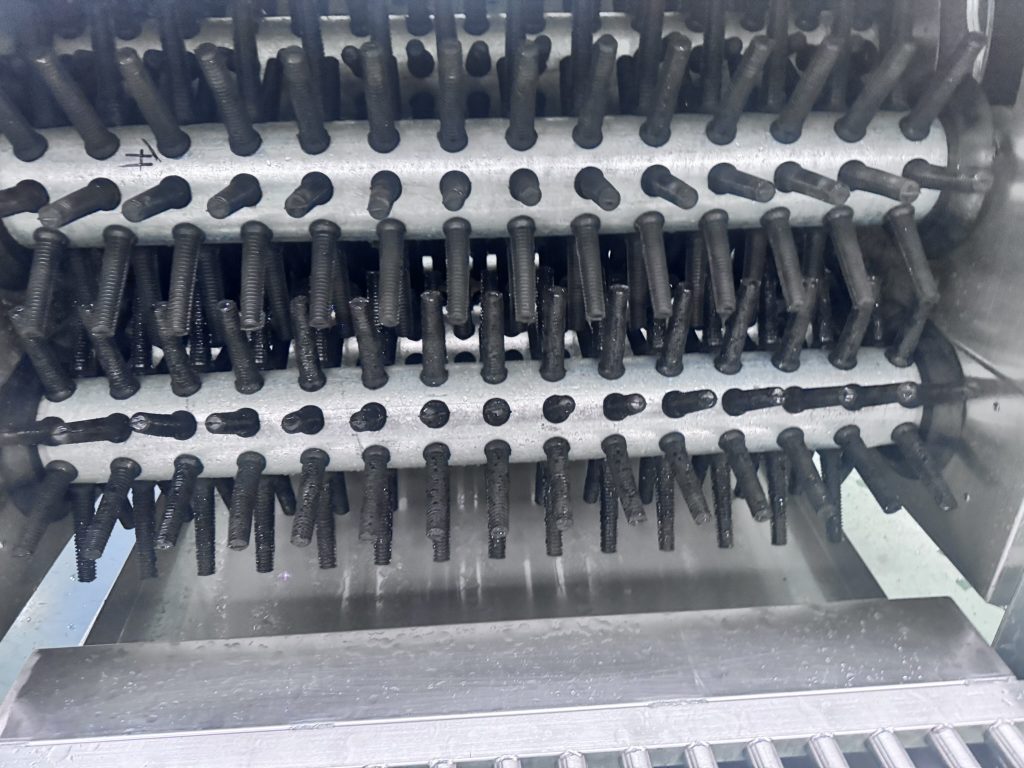

- On-site DemonstrationWe conducted a live demonstration of the complete workflow of the poultry scalding and defeathering all-in-one machine for the client, showcasing the equipment’s high-efficiency defeathering performance and stability.

- Sharing of Similar Client CasesWe presented the client with our successful cases exported to multiple Southeast Asian countries, especially our customized experience in adapting to tropical climates and special power supply requirements.

After the visit, the client commented: “I have seen your factory’s advanced production equipment and rigorous quality control procedures, which have filled me with confidence in the reliability of your products. In particular, your professional knowledge of international power standards has addressed our core concerns.”

CUSTOMIZED SOLUTION

In accordance with the special requirements of the Malaysian client, we have provided the following customized solution:

CORE TECHNICAL PARAMETERS

- Processing Capacity: 200–500 chickens per hour (adjustable according to actual needs)

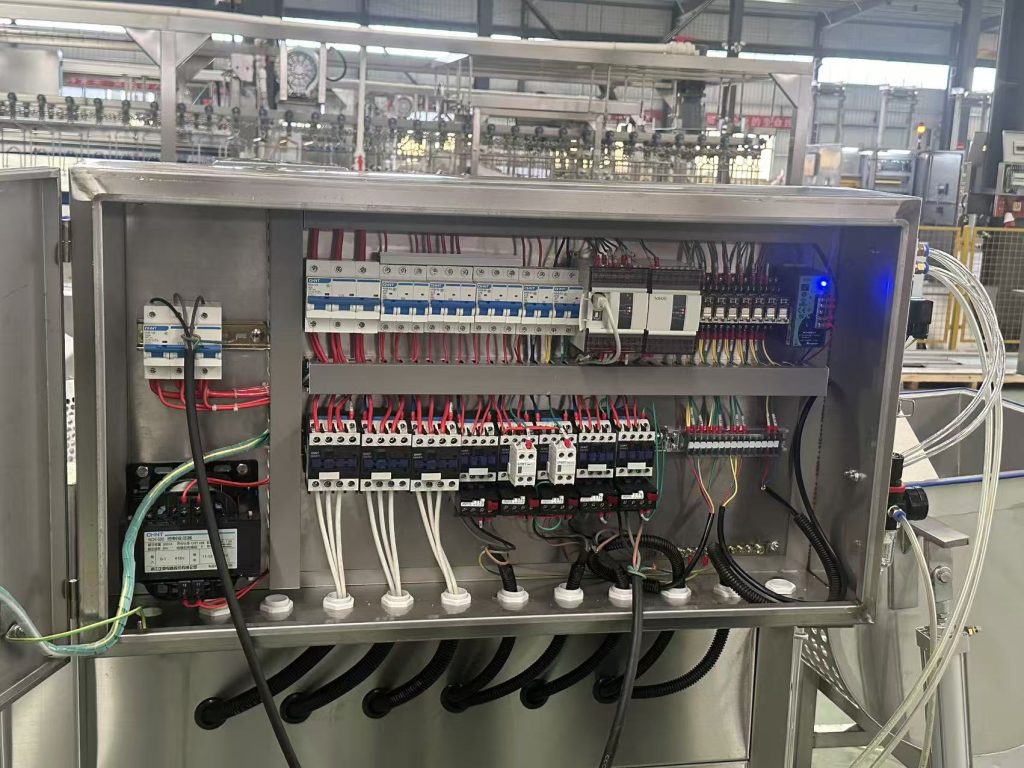

- Total Machine Power: 54kW

- Power Supply Requirements: Three-phase alternating current, customized 415V/50Hz motor compliant with Malaysian standards

- Rated Current: 100A

- Equipment Dimensions: Customized design to fit the client’s workshop layout

SPECIAL CUSTOMIZATIONS FOR THE MALAYSIAN MARKET

- Voltage Customization: A dedicated 415V motor is designed to perfectly comply with Malaysia’s industrial voltage standards.

- High-temperature Resistant Design: Enhanced heat dissipation system and high-temperature resistant materials are adopted to adapt to Malaysia’s tropical climate.

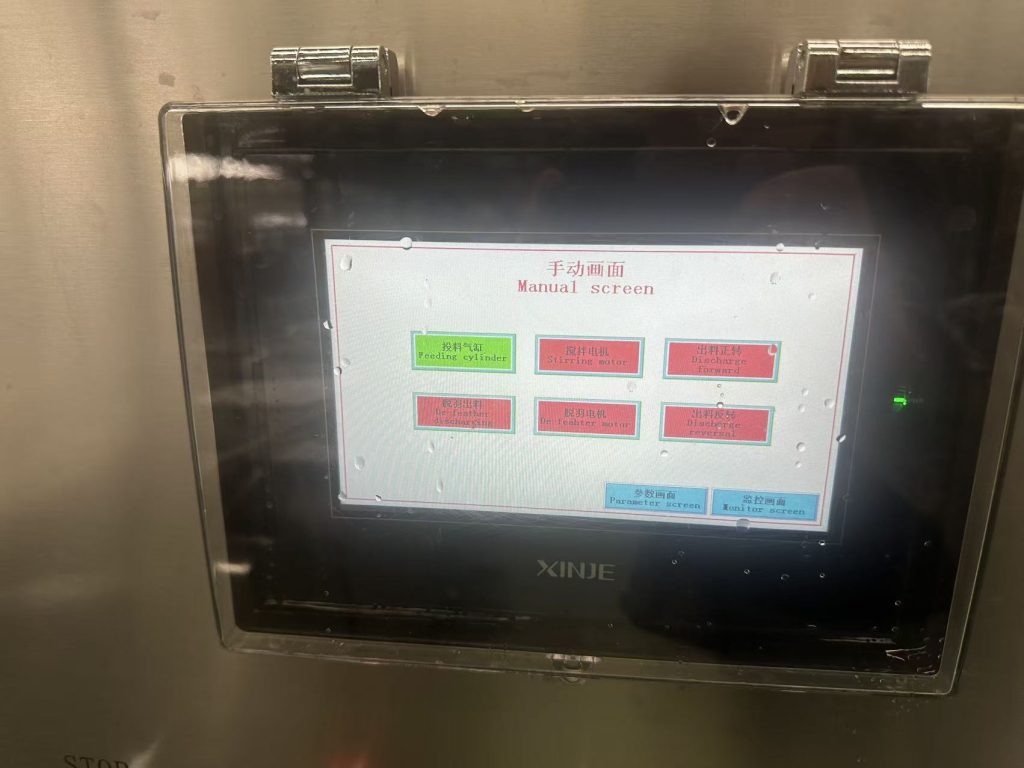

- Multilingual Operation Interface: English and Chinese bilingual operation panel is provided.

ON-SITE TRANSACTION AND FOLLOW-UP

After two days of in-depth inspection and technical exchange, the client decided on the spot to purchase a custom-built poultry scalding and defeathering all-in-one machine, and signed a long-term maintenance cooperation agreement.

CLIENT EVALUATION

“We chose this Chinese manufacturer not only because their equipment parameters meet our requirements, but more importantly because they truly understand the needs of international clients. From the customized 415V voltage to the design adapted for tropical climates, they have taken care of every single detail. The on-site inspection allowed us to witness their professional capabilities and production standards, which were the key factors behind our on-the-spot decision to purchase.”— Boss Hw

EQUIPMENT OPERATION PERFORMANCE

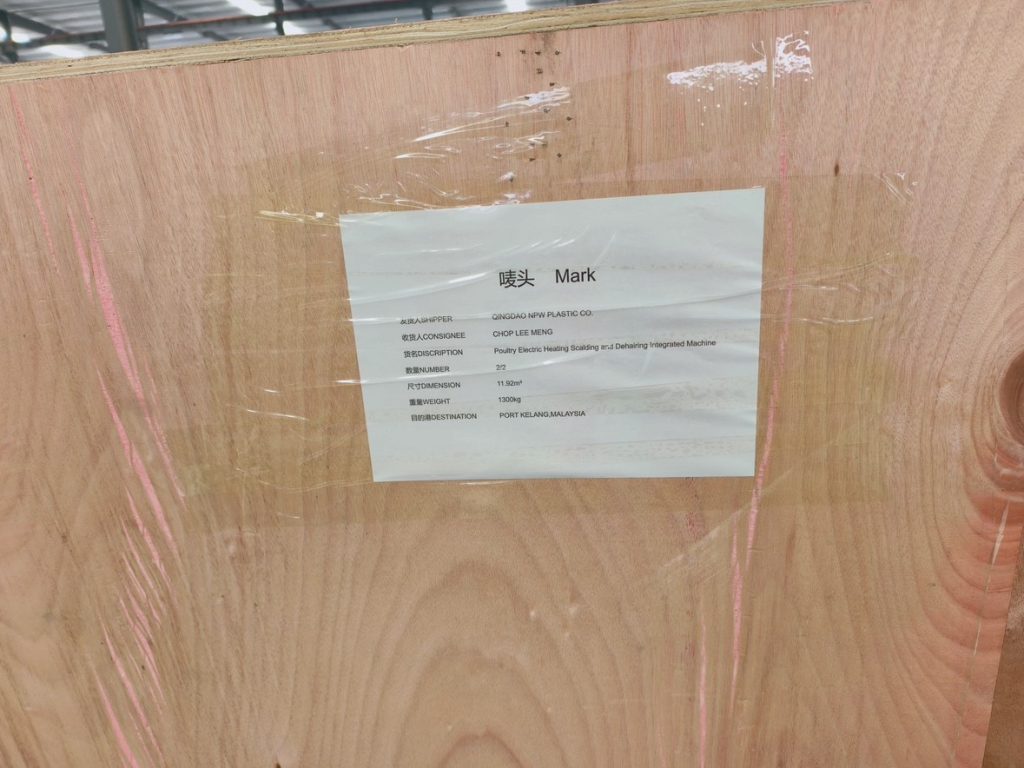

The equipment was successfully delivered, installed and commissioned in October 2025, and has been operating stably for 2 months at the Pasir Gudang processing plant in Malaysia:

- Improved Production Efficiency: Defeathering efficiency has been increased by 100% compared with the original equipment.

- Positive Employee Feedback: The operation is simple and the safety performance is high, which has greatly improved the original workflow.

- After-sales Response: Problems encountered during equipment operation have been handled in a timely manner.

EXPERIENCE SHARING AND INSIGHTS

This successful case has provided us with valuable experience:

- On-site Inspection Is the Key to Building Trust: Opening the factory for clients to personally witness the production process and quality control is far more convincing than any promotional materials.

- In-depth Customization Wins the Market: Customized design tailored to the specific requirements of the target market (such as voltage, climate, and language) is the core competitiveness to win over international clients.

- Professional Technical Support Is Indispensable: Full-process professional support, from preliminary consultation and installation & commissioning to after-sales maintenance, is the guarantee for the long-term stable operation of the equipment.

CONCLUSION

This cooperation with the Malaysian client is not only a single equipment sale, but also a successful validation of our capabilities in deeply cultivating the Southeast Asian market and providing customized solutions. We firmly believe that only by truly understanding and meeting the special needs of clients can we win trust and cooperation in the fierce international market competition.

We look forward to providing high-quality, customized poultry processing equipment for more clients in Malaysia and Southeast Asia, and jointly promoting the automation upgrade of the regional food processing industry!