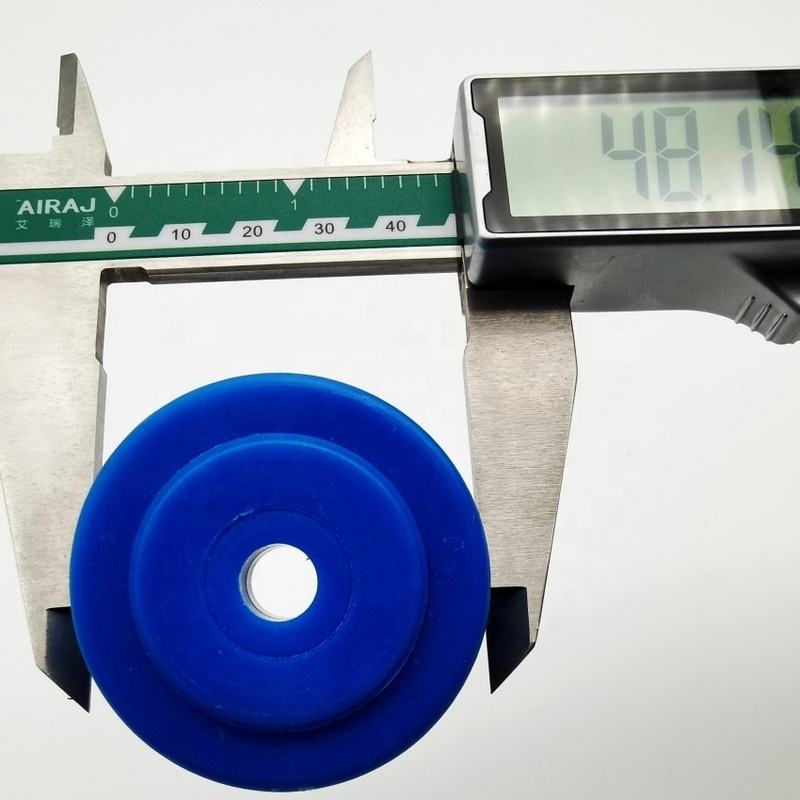

Slaughtering Line Conveyor Roller

A high-performance, long-life conveyor roller assembly specifically designed for slaughter and meat processing lines. This product combines a wear-resistant nylon outer wheel with a precision-embedded stainless steel bearing, providing a quiet, corrosion-resistant, and maintenance-free rolling support solution for conveyor chains, drive belts, and hanging systems. It is a key fundamental component for ensuring the smooth and efficient operation of production lines.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Product Positioning

A high-performance, long-life conveyor roller assembly specifically designed for slaughter and meat processing lines. This product combines a wear-resistant nylon outer wheel with a precision-embedded stainless steel bearing, providing a quiet, corrosion-resistant, and maintenance-free rolling support solution for conveyor chains, drive belts, and hanging systems. It is a key fundamental component for ensuring the smooth and efficient operation of production lines.

Core Features

- Durable Composite Structure:

- Outer Layer: Made of high-strength, wear-resistant nylon (food-grade material available). It offers excellent impact resistance, a low friction coefficient, and self-lubricating properties, ensuring quiet operation and preventing damage to contacting rails or chains.

- Inner Core: Equipped with a high-precision stainless steel bearing (304/316 grade), featuring a fully sealed design for dust and water protection. This prevents jamming caused by corrosion or contamination, ensuring long-term, smooth rotation.

- Adaptability to Harsh Environments:

- Corrosion Resistance: The nylon material itself is resistant to acids and alkalis, while the stainless steel bearing withstands humid conditions, high-temperature washdowns, and disinfectants, perfectly meeting the hygiene requirements of high-moisture, high-pressure cleaning slaughterhouse environments.

- Wide Temperature Stability: Maintains stable performance across a range from low-temperature cooling rooms to high-temperature cleaning environments, with no operational issues due to thermal expansion or contraction.

- Energy-Efficient Design:

- The lightweight nature of nylon reduces start-stop inertia, and the stainless steel bearing offers low friction resistance. This combination significantly lowers the energy consumption of the drive system, enabling energy-efficient operation.

- Maintenance-Free & Long Service Life:

- Features an integrated design with bearings pre-lubricated with high-performance grease, achieving “install-and-forget” maintenance, greatly reducing downtime for upkeep.

- The combination of wear-resistant nylon and stainless steel offers a service life 3-5 times longer than standard carbon steel rollers.

Core Advantages

- Quiet & Smooth Operation: The vibration-damping properties of nylon combined with precision bearings deliver nearly silent and smooth rolling, improving the workshop environment.

- Hygienic & Safe: No rust formation or metal particle generation, compliant with food production equipment hygiene standards, and easy to thoroughly clean.

- Reliable & Durable: Designed for the high-intensity, continuous operation of slaughter lines, with an extremely low failure rate, ensuring uninterrupted production.

- Cost-Effective: While the unit cost may be slightly higher, its extended lifespan and maintenance-free characteristics significantly reduce the total lifecycle cost.

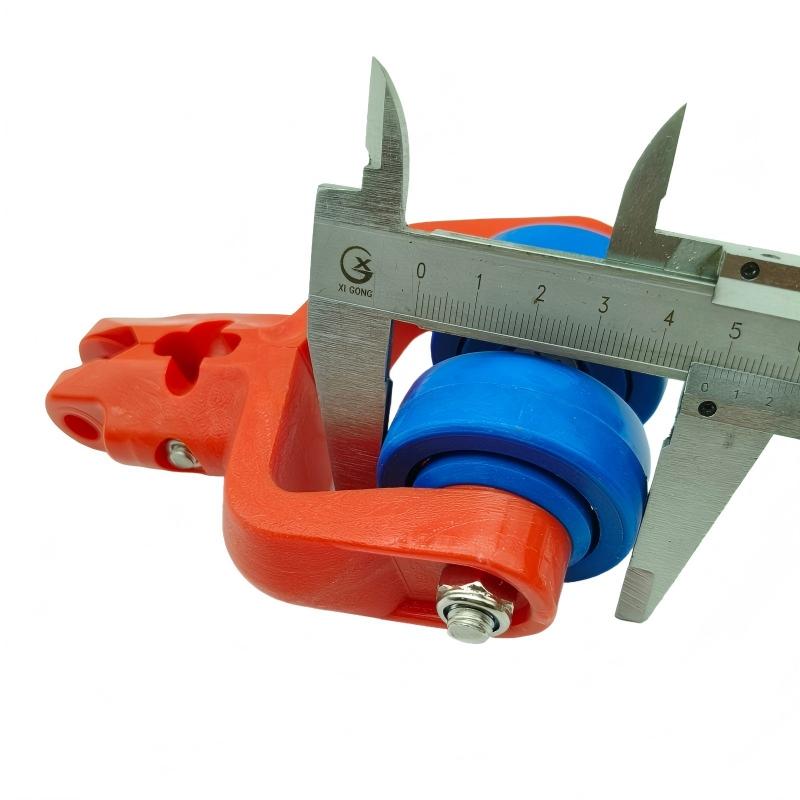

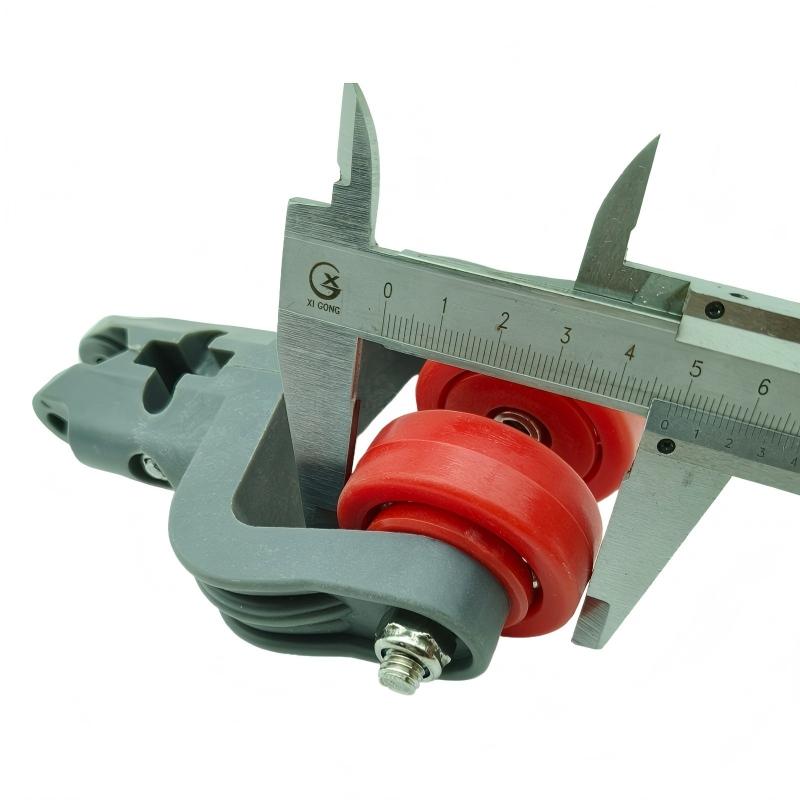

Typical Applications

- Support rollers for straight and curved sections of slaughter conveyor lines

- Guide wheels and load-bearing wheels for overhead chain systems

- Drive roller sets for meat cutting and packaging lines

- Drive components within washers, dryers, and other equipment

We offer various specifications for wheel diameter, shaft diameter, and load capacity, with customization available based on your rail dimensions and load requirements. The product strictly adheres to food machinery safety standards and is a reliable choice for modern slaughter and processing plants upgrading their equipment.