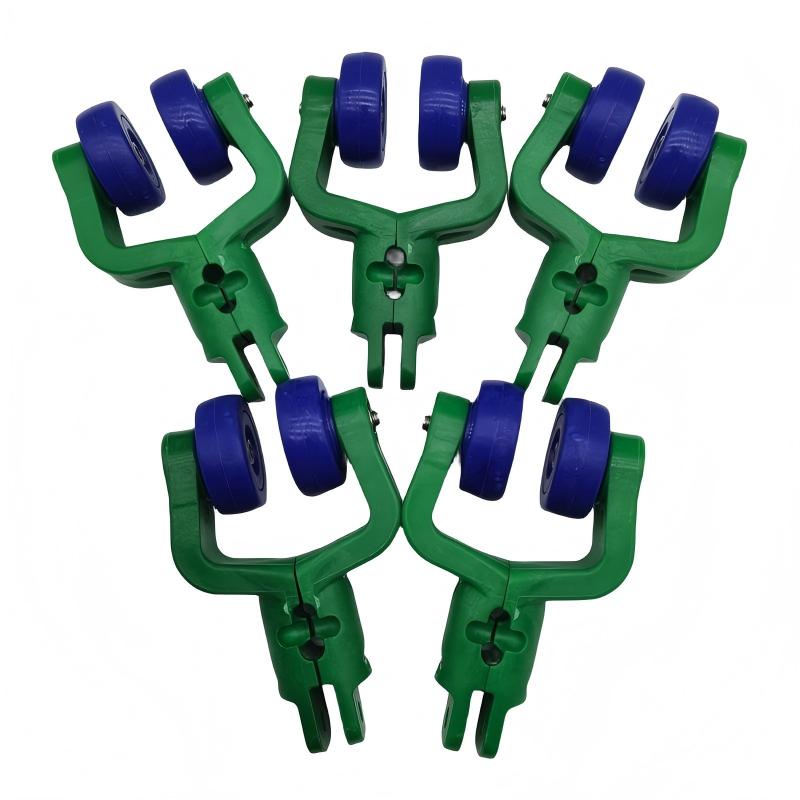

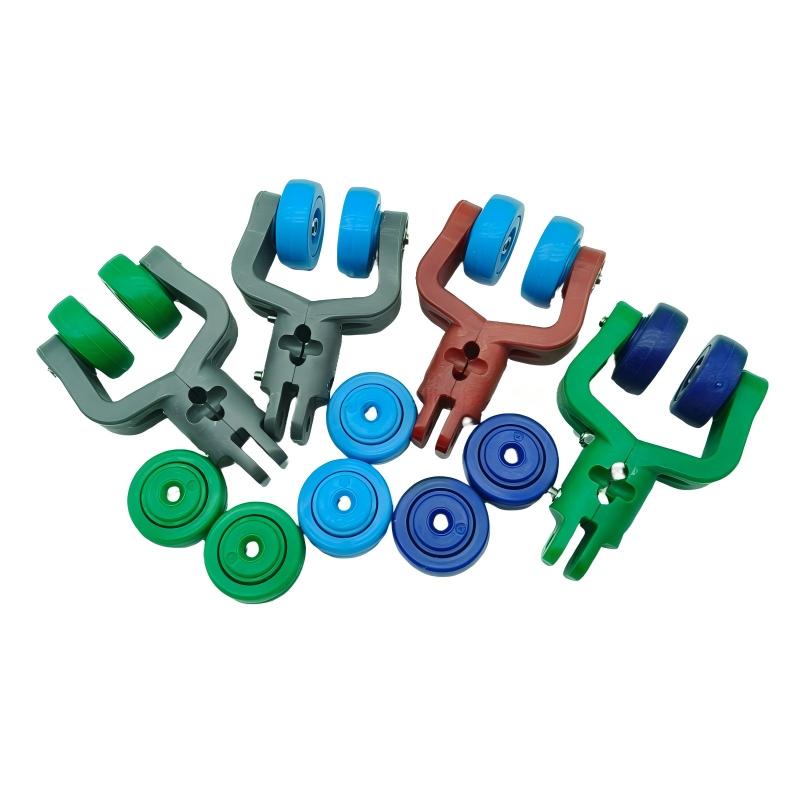

Nylon Carriage for T-Guide Rails

A key support accessory specifically designed for poultry slaughter conveyor lines employing T-shaped steel guide rails. This product is a compact nylon carriage that operates within the grooves of standard T-guide rails via precisely engineered bottom or side pulley assemblies. It is responsible for smoothly and quietly carrying hooks and poultry carcasses, facilitating linear or directional transfer between various processing stations.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Product Positioning

A key support accessory specifically designed for poultry slaughter conveyor lines employing T-shaped steel guide rails. This product is a compact nylon carriage that operates within the grooves of standard T-guide rails via precisely engineered bottom or side pulley assemblies. It is responsible for smoothly and quietly carrying hooks and poultry carcasses, facilitating linear or directional transfer between various processing stations.

Core Features

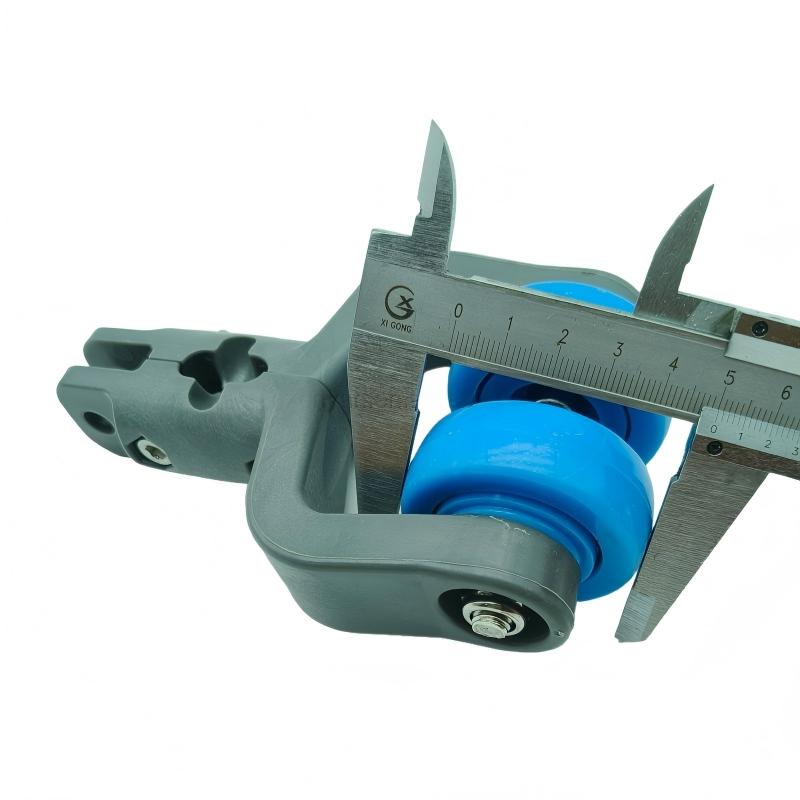

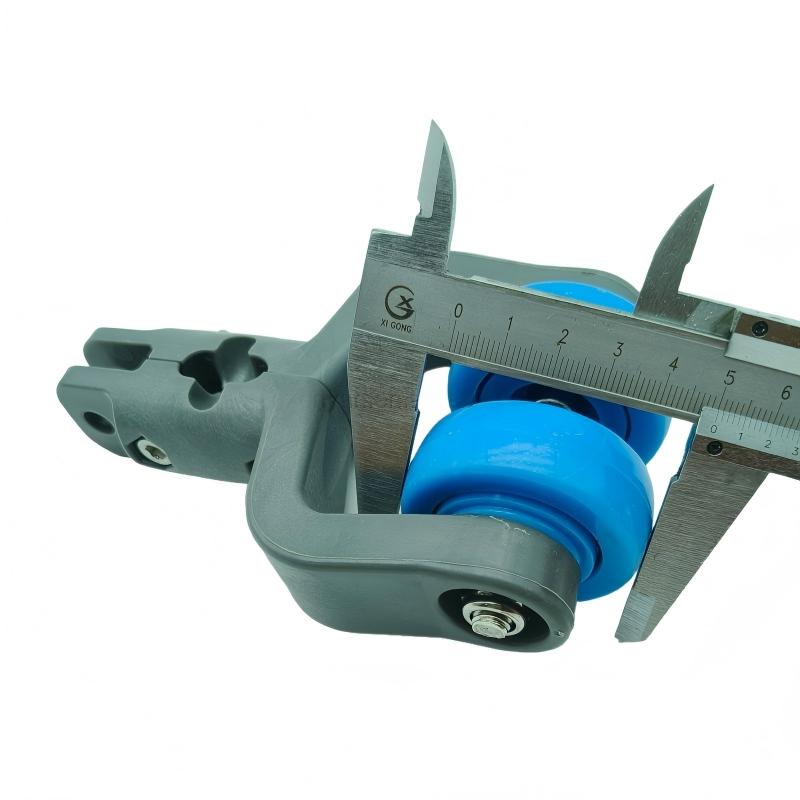

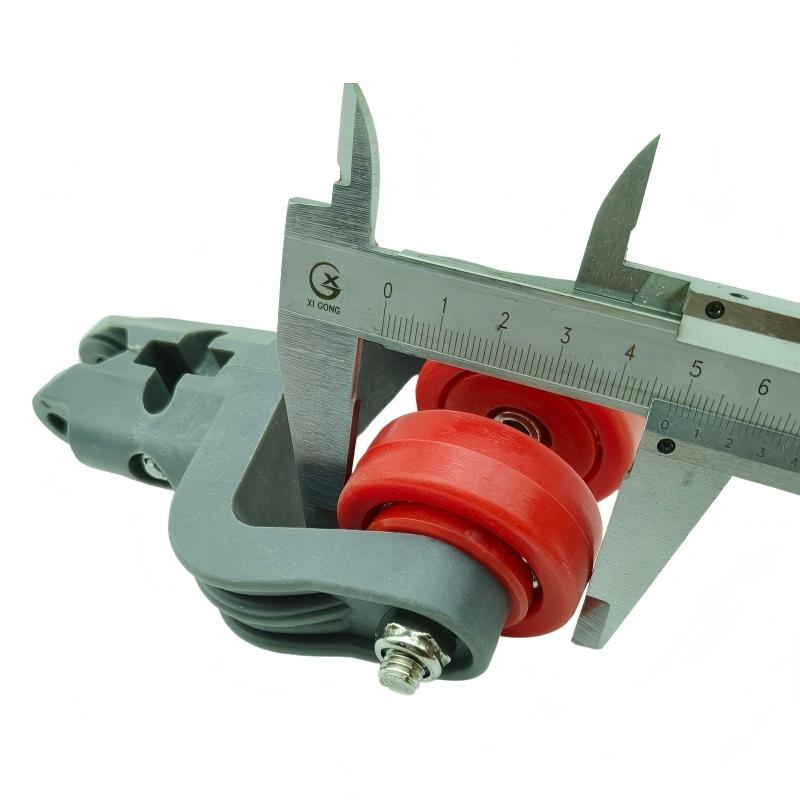

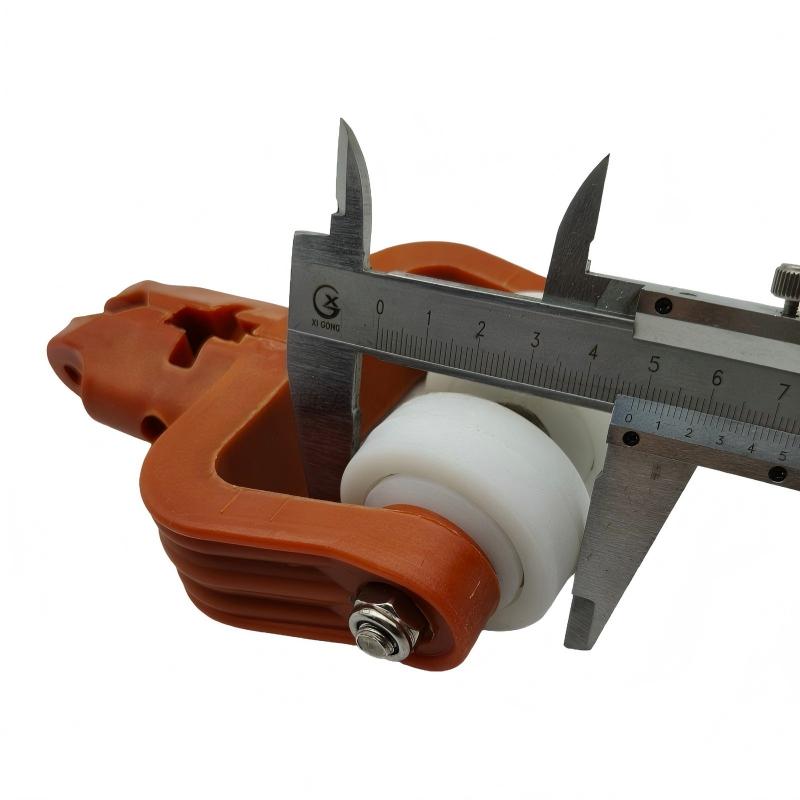

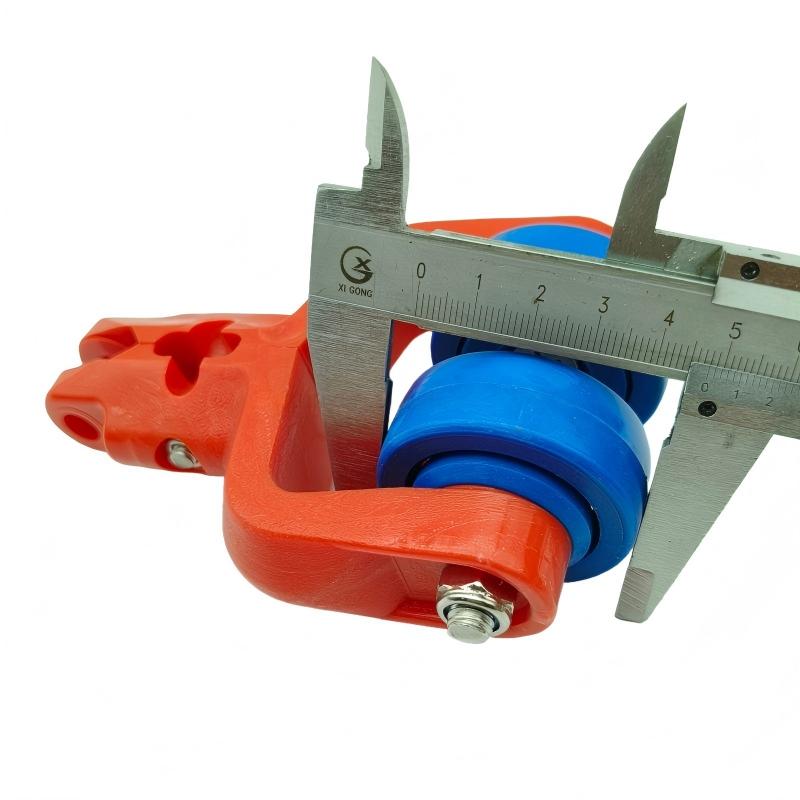

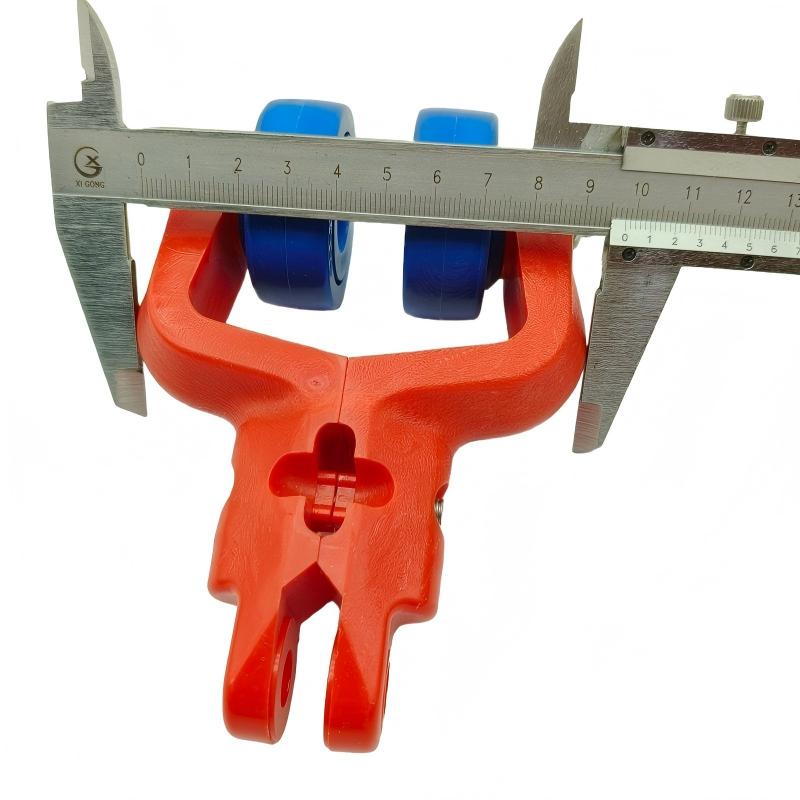

- Designed for T-Rail Systems: Its structure and dimensions are strictly matched to the cross-sectional profile of standard T-shaped steel guide rails. Utilizing multiple sets of nylon guide wheels or sliders, it precisely engages and runs within the T-shaped grooves of the rails, ensuring accurate radial positioning and guidance, effectively preventing derailment.

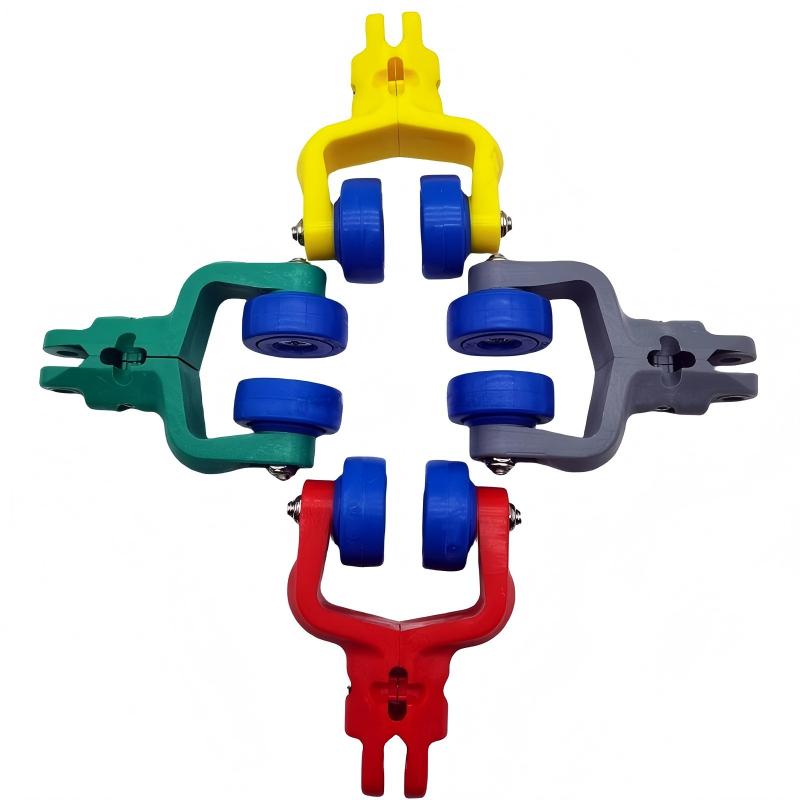

- High-Strength, Wear-Resistant Nylon Material: The main body and pulleys are made from reinforced, wear-resistant nylon via injection molding. It provides sufficient load-bearing strength while offering advantages such as light weight, extremely low operational noise, and requiring no additional lubrication. The material complies with food hygiene standards, is corrosion-resistant, and easy to clean.

- Optimized Pulley/Slider Assembly: Designed specifically for contact with T-rails, it utilizes wear-resistant nylon wheels or pads with low friction coefficients. This minimizes rolling friction for smooth operation and significantly reduces long-term wear on the rails themselves, extending the overall system’s lifespan.

- Excellent Lateral Force Resistance: The T-rail structure inherently provides good lateral constraint. This carriage, through multi-point contact within the rail grooves, can stably withstand lateral swinging and impact forces generated by the hanging system during starts, stops, or turns, ensuring stable travel.

- Key Difference from Pipe-Rail Carriages: This carriage is designed for embedded, guided operation within solid T-shaped steel rail systems. It is fundamentally different from “pipe-rail carriages” that run on the outer surface of round or square pipes in terms of mounting interface, force distribution, and drive linkage structure. They belong to different conveyance technology systems and are not interchangeable.

Product Advantages

- Precise and Stable Operation: The T-groove guidance mechanism effectively eliminates derailment risks, making it particularly suitable for complex line sections like curves and lifts.

- Ultra-Quiet and Maintenance-Free: The nylon-on-metal pairing generates minimal noise and offers self-lubricating properties, significantly reducing daily maintenance needs and costs.

- Strong System Protection: The nylon material protects the expensive T-rail itself from direct metal-to-metal wear and the associated risk of ferrous contamination.

- Cost-Effective and Efficient: Provides a lightweight, cost-competitive alternative to all-metal solutions while ensuring load capacity and service life.

Typical Applications

Widely used in poultry slaughter processing lines equipped with T-guide rail systems, especially suitable for pre-cooling rooms, hanging rooms, segmentation conveyor lines, and complex conveying sections requiring frequent turns, merging, or diverging.

We offer models compatible with various international and domestic standard T-rail profiles and support customization based on your chain pitch and load requirements. Please provide rail drawings for an accurately matched solution.