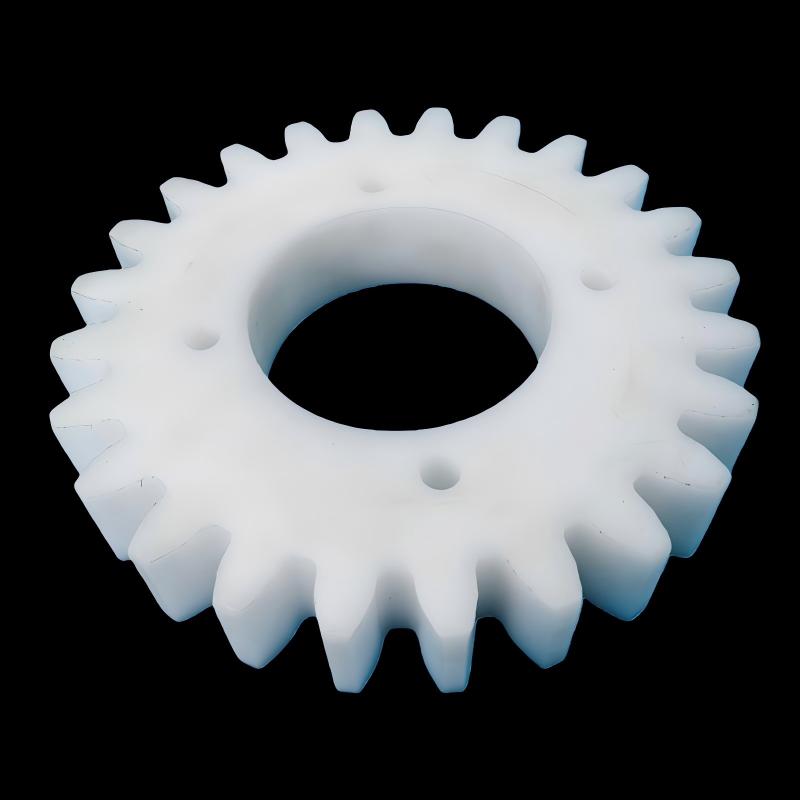

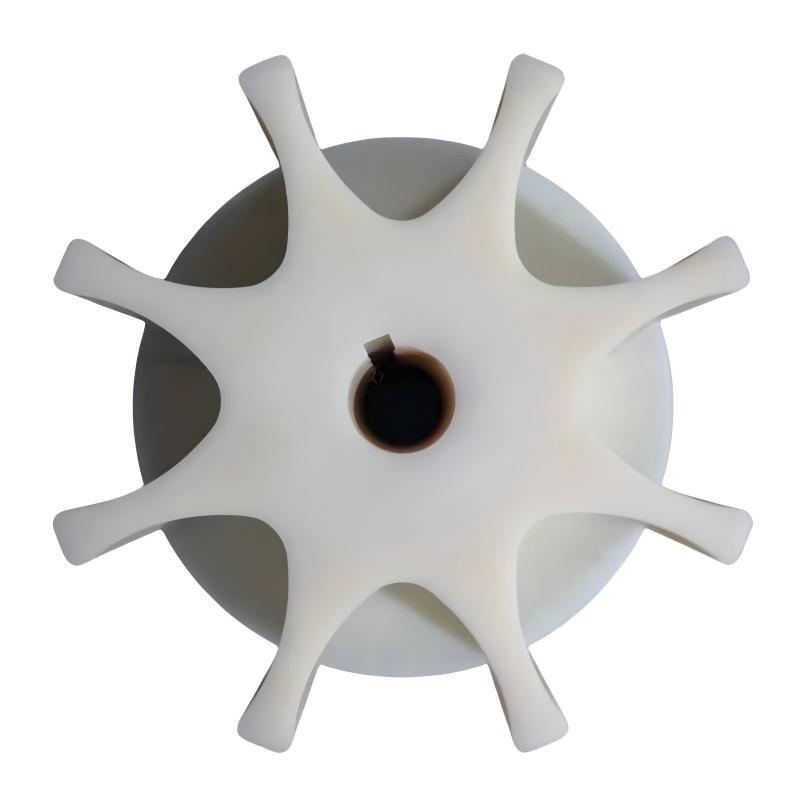

Poultry Slaughter Line Nylon Plastic Sprocket

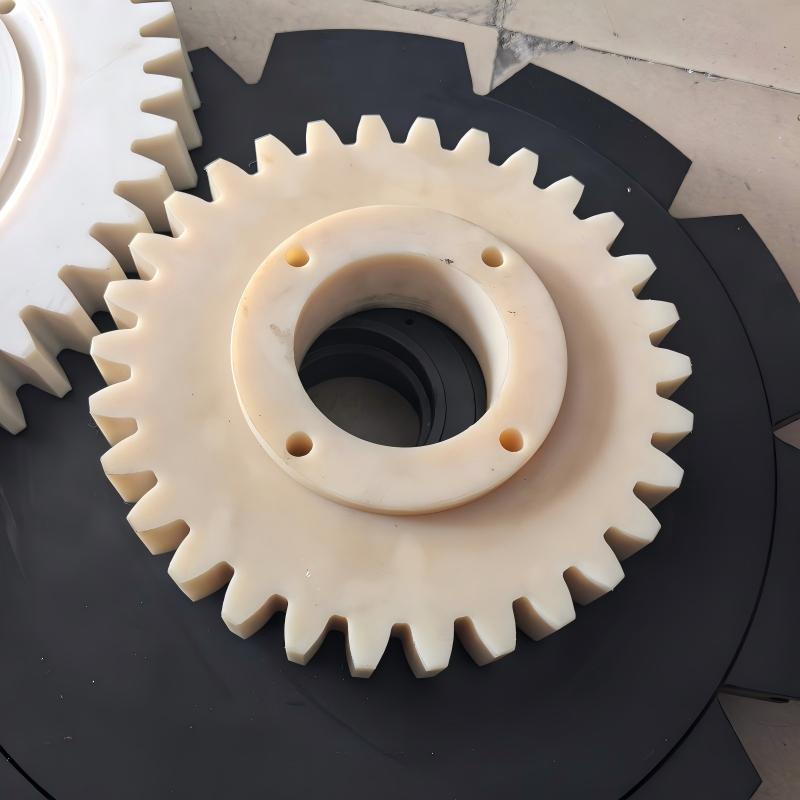

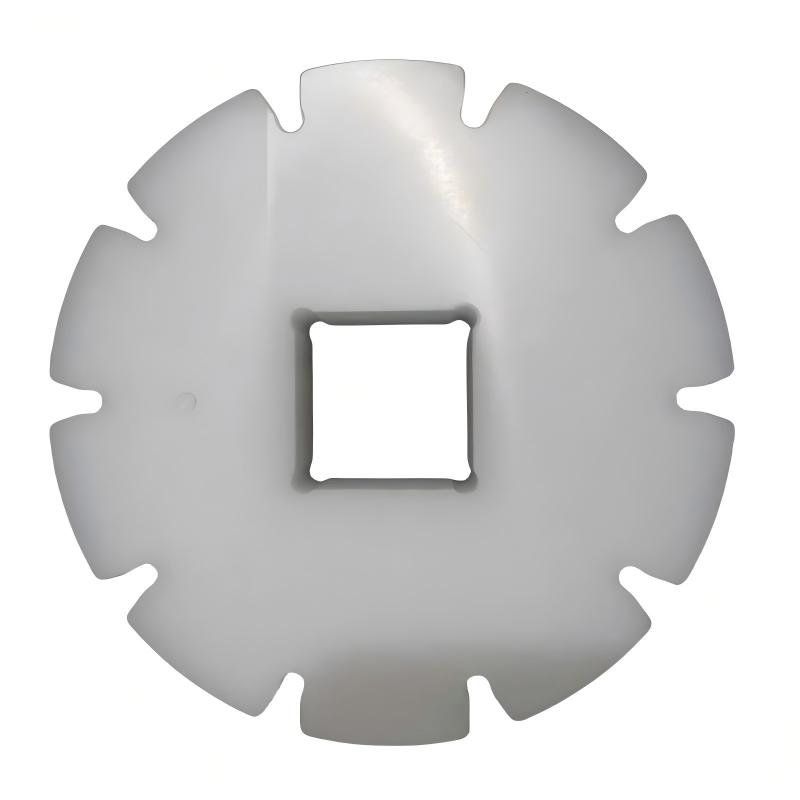

Nylon plastic sprocket components specially designed for poultry slaughter overhead conveyor lines, including drive sprockets, idler sprockets, and transmission sprockets. All are made from high-strength PA6/PA66 nylon, serving as replacements for traditional metal sprockets.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Product Overview

Nylon plastic sprocket components specially designed for poultry slaughter overhead conveyor lines, including drive sprockets, idler sprockets, and transmission sprockets. All are made from high-strength PA6/PA66 nylon, serving as replacements for traditional metal sprockets.

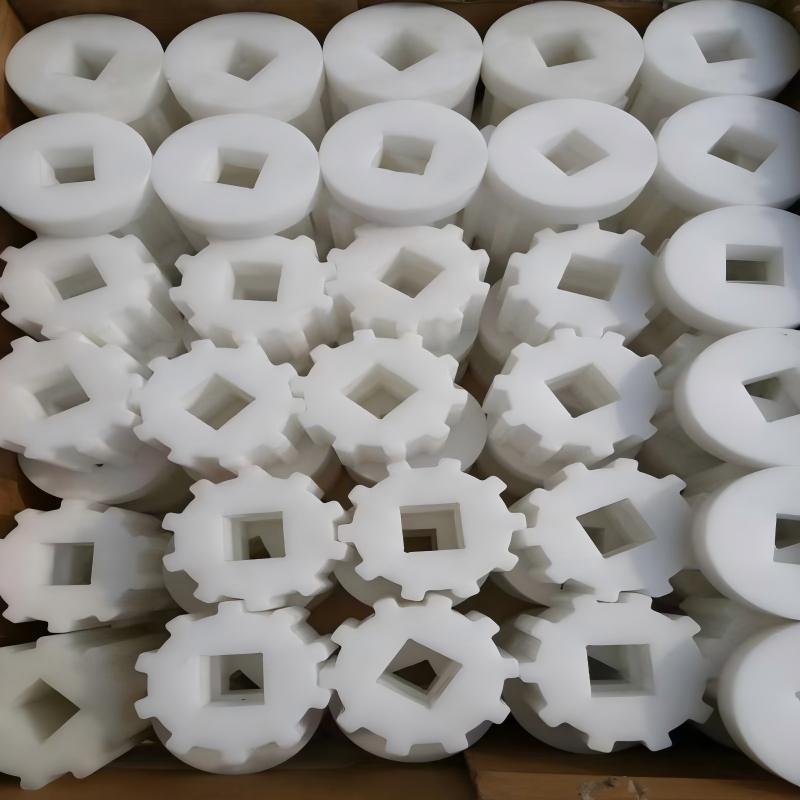

Product Types

Drive Sprockets – Transmit power and drive the chain operation

Idler Sprockets – Support and guide the chain

Transmission Sprockets – Assist in power transmission and directional changes

Key Advantages

- Lightweight and Durable: 60% lighter than metal sprockets with a longer service life

- Quiet Operation: Low noise, no lubrication required

- Rust and Corrosion Resistant: Withstands washing and disinfection, never rusts

- Hygienic and Safe: Complies with food-grade standards, easy to clean

- Energy Efficient: Reduces motor load, saving over 15% in electricity

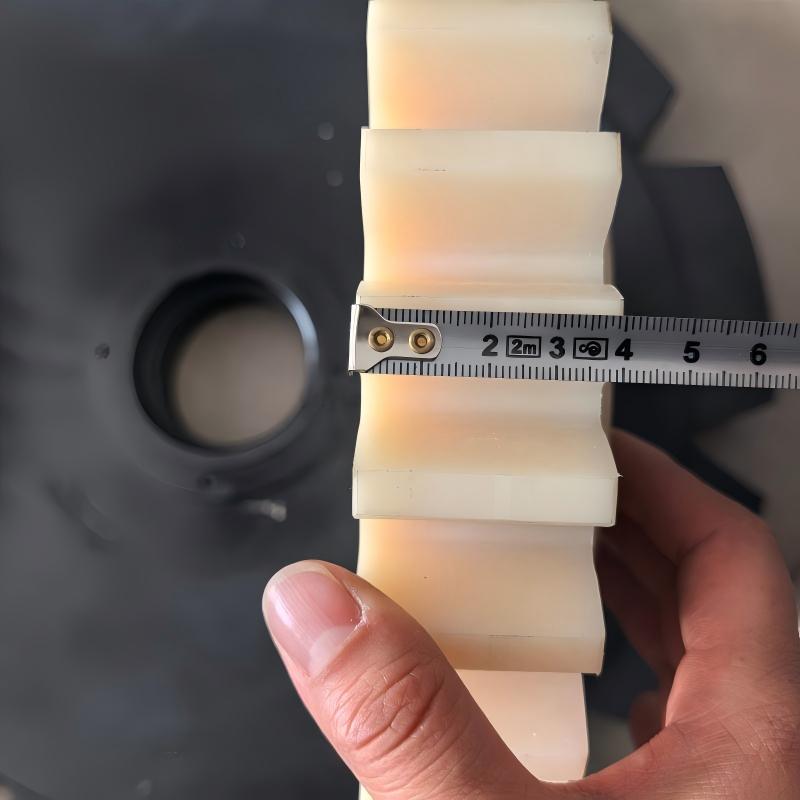

Specifications

- Material: PA6 (economical) / PA66 (enhanced)

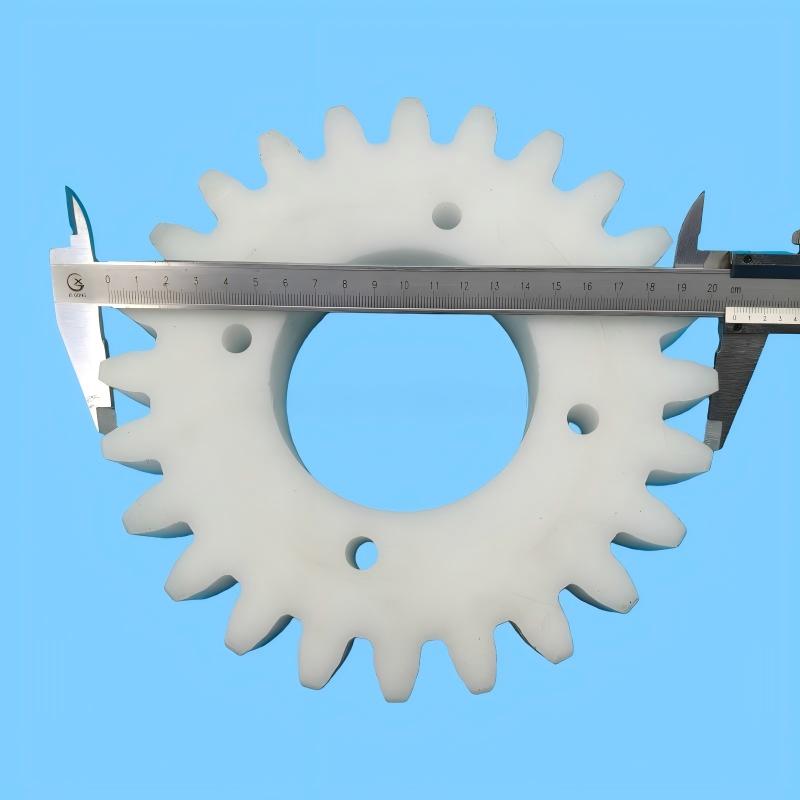

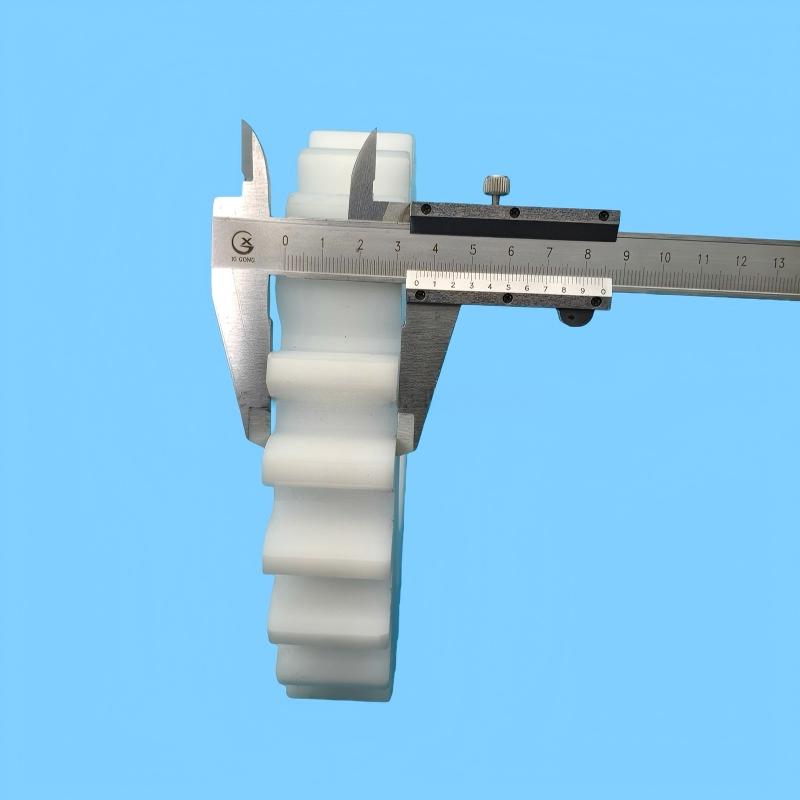

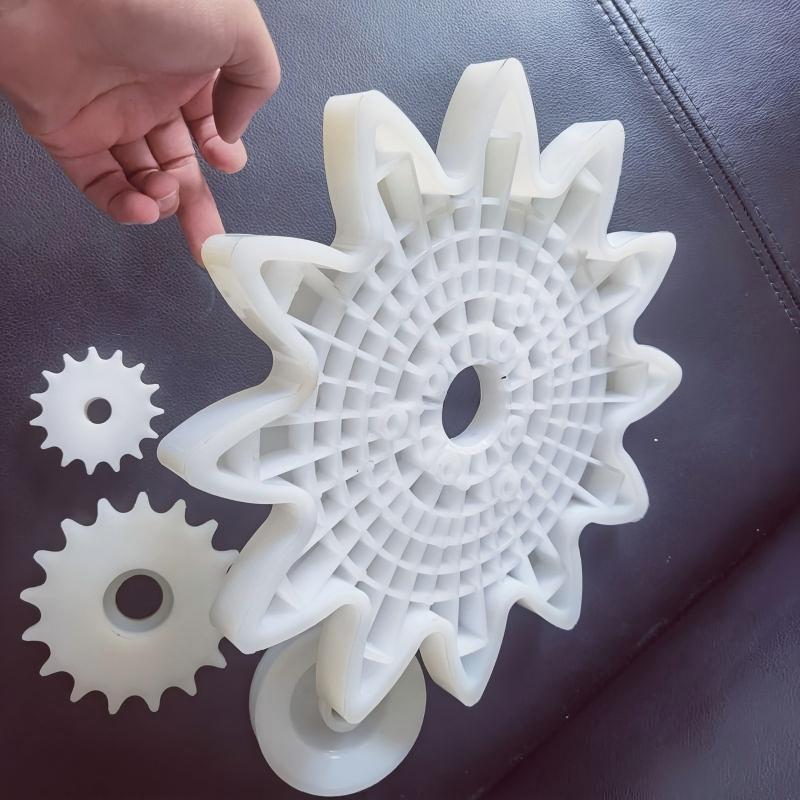

- Tooth Count: 15T, 17T, 30T (standard specifications)

- Customization Support: Special tooth counts and sizes available on demand

- Diameter: 100mm–200mm

- Bore Size: 16mm–50mm

Applications

- Slaughter and conveying lines for chickens, ducks, and geese

- High-humidity environments such as pre-cooling and cutting rooms

- Processing areas requiring frequent cleaning

- Workshops with strict hygiene and noise control requirements

Service Features

✅ Standard specifications: 15T, 17T, 30T

✅ Customization of special tooth counts and sizes supported

✅ Old sprocket measurement for precise replacement

✅ Full technical guidance and installation support

Maintenance Instructions

- Direct installation to replace existing metal sprockets

- Regular high-pressure washing is sufficient; no oil lubrication required

- Replacement recommended when tooth surface wear exceeds 15%

Nylon sprockets are lighter, quieter, and more corrosion-resistant, with customization services available to meet various overhead conveyor transmission needs.