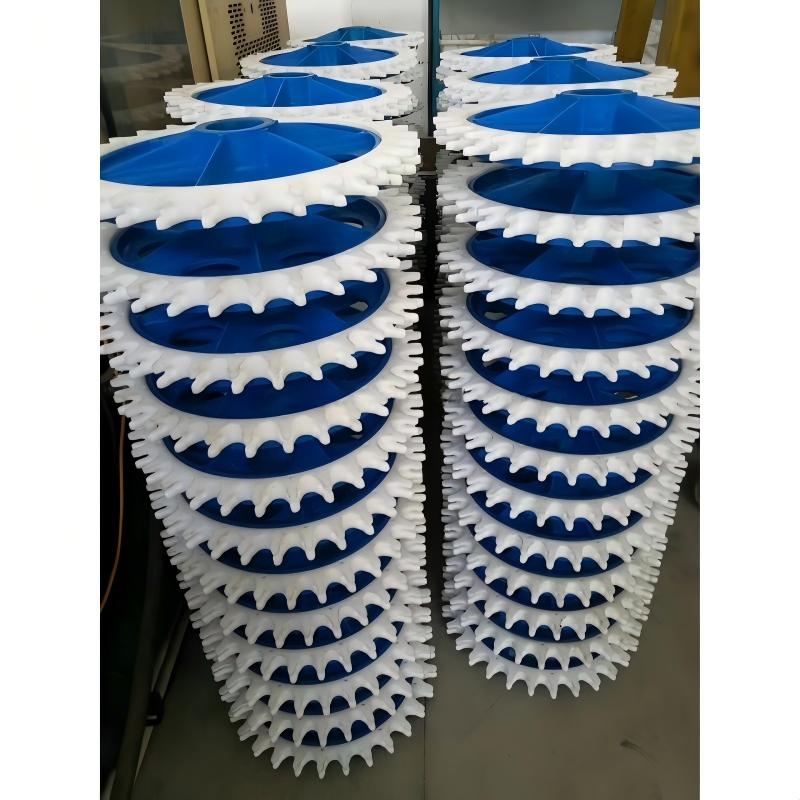

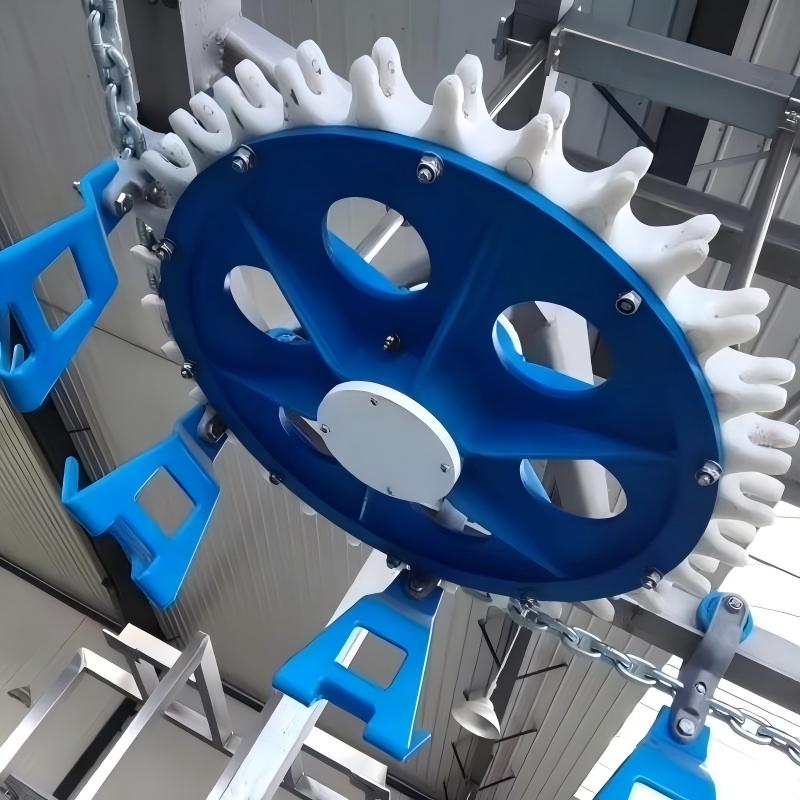

485 Corner Plastic Tug Wheel for Poultry Overhead Conveyor Line

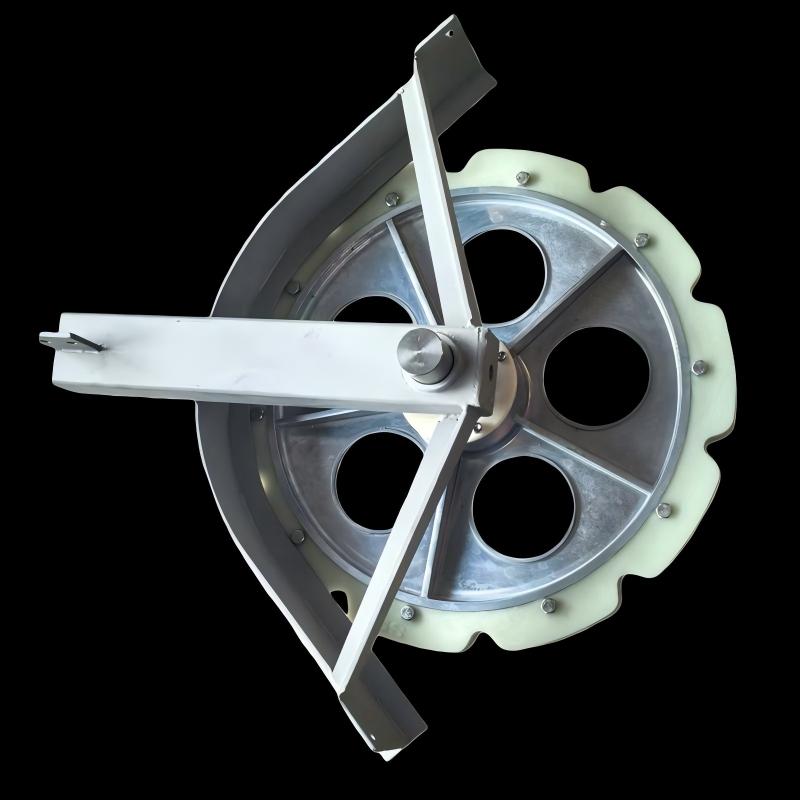

485mm large diameter all-plastic corner wheel, specially designed for corner applications in high-load conveying systems. It is integrally molded from high-strength engineering plastic and equipped with a stainless steel shaft core, providing reliable guiding and load-bearing performance.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Product Overview

The 485mm large-diameter all-plastic corner wheel is specifically designed for high-load conveying systems in corner working conditions. Made from high-strength engineering plastic in a single molding process and equipped with a stainless steel shaft core, it delivers reliable guidance and load-bearing performance.

Core Specifications

| Parameter | Specification |

|---|---|

| Outer Diameter | 485mm (approx. 19 inches) |

| Wheel Width | 70mm |

| Shaft Diameter | 35mm stainless steel shaft |

| Rated Load | 150kg/wheel |

| Wheel Material | Reinforced nylon (PA66 + 30% glass fiber) |

| Operating Temperature | -30℃ to 90℃ |

| Compatible Chains | Heavy-duty conveying chains / overhead chains |

Key Advantages

- High-Load Design

- Glass fiber reinforced structure increases load capacity by 50% compared to standard nylon wheels

- Stainless steel shaft core enhances support, improving bending strength by 60%

- Durable and Wear-Resistant

- Wheel rim uses wear-resistant composite material, with a lifespan of up to 12,000 hours

- Low-friction surface treatment reduces chain wear

- Environmental Adaptability

- All-plastic structure resistant to humid, acidic, and alkaline environments

- Wide temperature tolerance, suitable for cold storage and high-temperature washdown areas

Application Scenarios

- ✅ Heavy-duty corner stations in large-scale slaughter lines

- ✅ 90°/180° turning sections in material conveying systems

- ✅ Heavy-duty conveying equipment in food processing plants

- ✅ Guide wheels in automated warehousing systems

Optional Services

- Teflon-coated wheel surface available (anti-adhesion)

- Custom shaft lengths and mounting hole patterns supported

- Wear indication marking services provided

This product has passed ISO 9001 quality system certification and is suitable for industrial applications with high requirements for hygiene, durability, and load capacity.