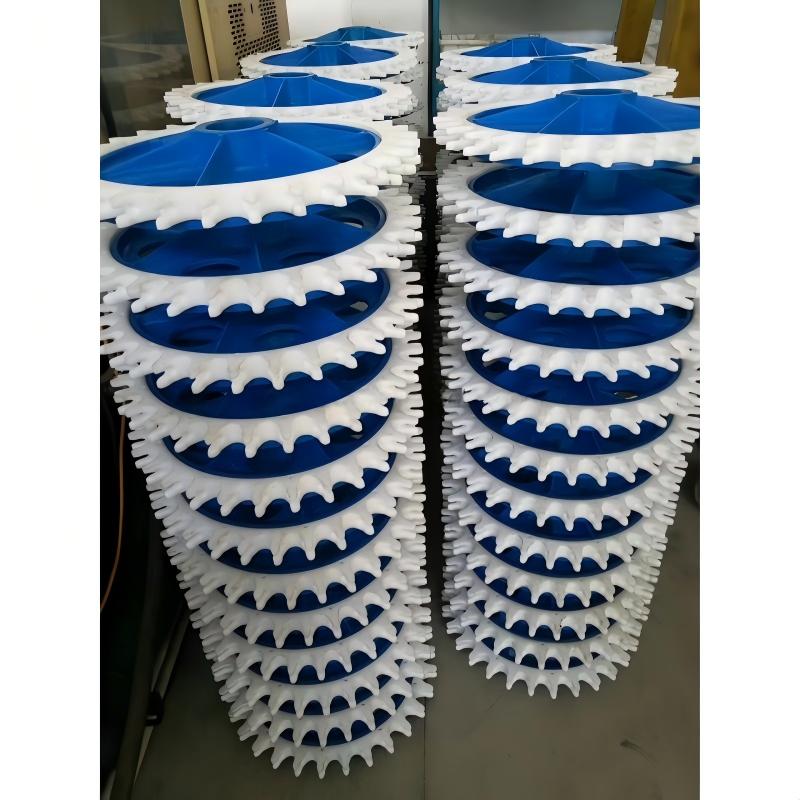

30-tooth gear idler for poultry slaughter line

A 30-tooth gear idler assembly specifically designed for poultry slaughter overhead conveyor systems, featuring an all-stainless steel drive shaft. Available in 385mm and 485mm diameter options to meet high hygiene standards in conveying applications.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Product Overview

A 30-tooth gear idler assembly specifically designed for poultry slaughter overhead conveyor systems, featuring an all-stainless steel drive shaft. Available in 385mm and 485mm diameter options to meet high hygiene standards in conveying applications.

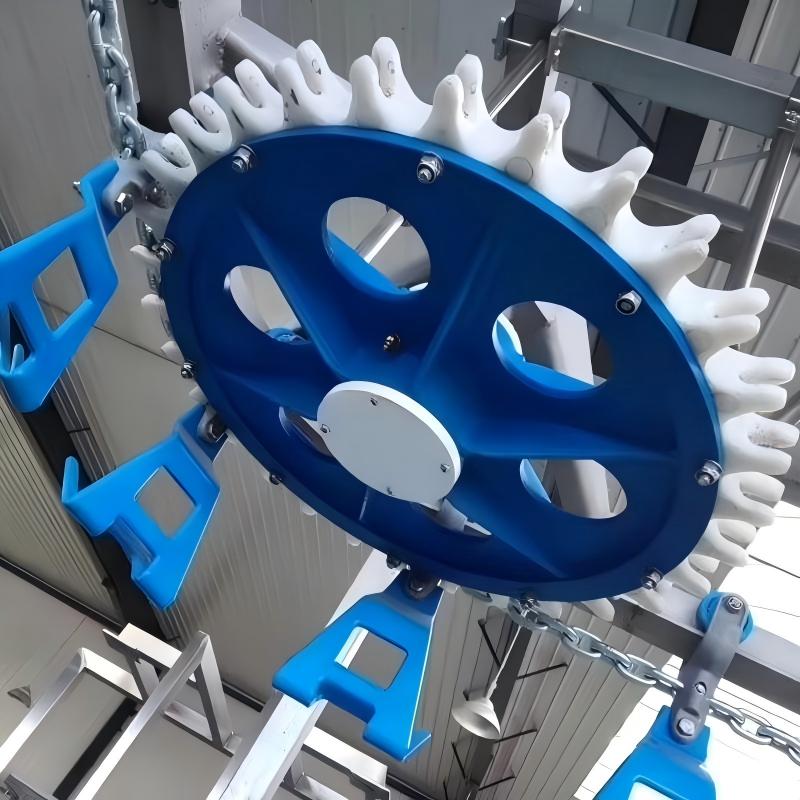

Core Specifications

- Number of Teeth: 30 teeth

- Diameter Options: 385mm / 485mm (selectable)

- Drive Shaft: 40mm solid stainless steel shaft (304 grade)

- Gear Ring Material: 45# steel with high-frequency hardened tooth surface

- Wheel Structure: Q235 steel body integrated with stainless steel shaft

Key Advantages

- Hygienic & Safe – Full stainless steel shaft, corrosion-resistant and easy to clean

- Precision Transmission – Optimized 30-tooth design ensures smooth engagement and low noise

- High Load Capacity – 40mm solid shaft design improves bending strength by 50%

- Maintenance-Free Operation – Dual-sealed bearings with dust and water protection

Technical Parameters

- Shaft Diameter: 40mm (tolerance ±0.02mm)

- Tooth Surface Hardness: HRC 48–52

- Operating Temperature: -20℃ to 120℃

- Dynamic Balance Grade: G6.3

Application Scenarios

- High-standard poultry slaughter overhead lines

- Conveyor systems in humid environments

- Processing sections requiring frequent cleaning

- Export-oriented food processing lines

Service Support

- Standard Packaging: Individual anti-rust packaging

- Minimum Order: 100 sets per specification

- Optional Services: Laser marking, Teflon coating

This assembly is particularly suitable for production environments with strict hygiene requirements. The stainless steel shaft design completely eliminates rust contamination issues, ensuring long-term stable operation of the conveying system.