9-Piece Automatic Chicken Cutting System

Automatically and precisely cuts whole broiler chickens into 2 legs, 2 wings, 2 breasts (with ribs), 2 thigh quarters, and 1 chicken frame. It enables efficient and standardized cutting, enhancing product added value and the automation level of production lines in poultry slaughterhouses.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Complete Set of Equipment for Precise 9-Piece Chicken Cutting

I. Core Overview

This equipment is a high-efficiency automated production line specifically designed for modern poultry slaughtering and processing enterprises. It integrates advanced mechanical transmission, multi-stage precision guidance, and multi-station synchronous cutting technology. It can precisely and efficiently segment a whole broiler into nine standard parts (left and right whole wings, head & neck, breast meat, back meat, left and right leg meat, and drumsticks), achieving fully automated operation from manual hanging to automatic sorting and collection of each part.

Whole Chicken Wings

Chicken Necks

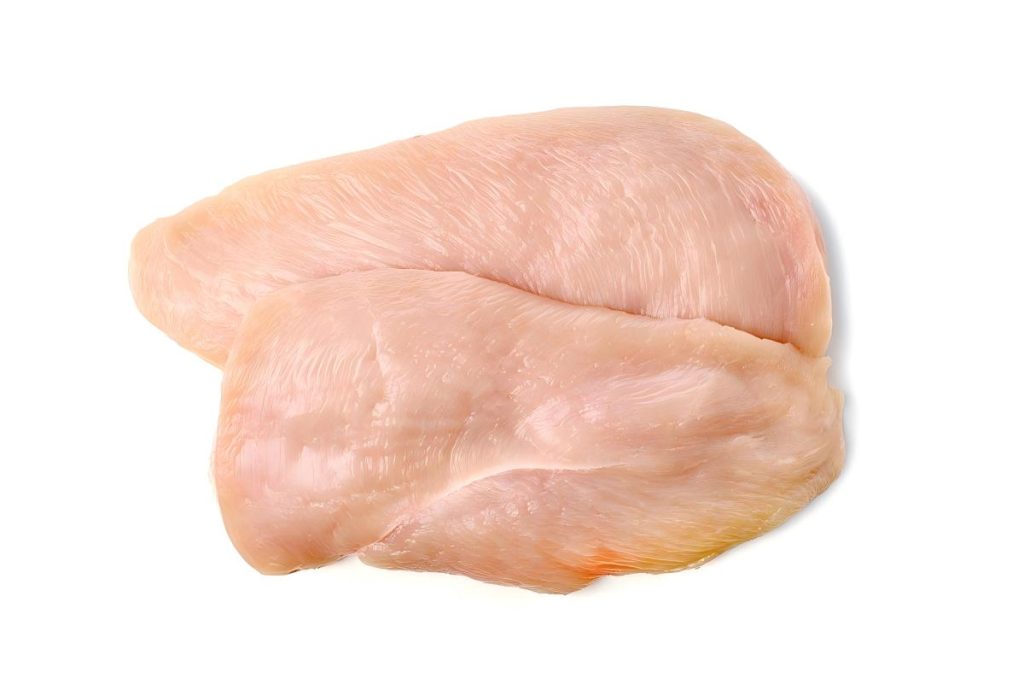

Chicken Breast

Chicken Thighs

Chicken Drumsticks

The main body of the equipment is made of food-grade 304 stainless steel, offering excellent corrosion resistance and anti-contamination capabilities. It complies with the technical requirements of HACCP and the Chinese national standard GB/T 41548-2022 “Livestock and Poultry Slaughtering Equipment – Livestock and Poultry Meat Segmentation Line.” It is suitable for large-scale slaughterhouses, central kitchens, prepared food deep-processing facilities, and export-oriented poultry processing bases.

II. Main Technical Specifications

| Item | Specifications |

|---|---|

| Overall Dimensions | 6850 × 1400 × 2430 mm |

| Power Consumption | 20 KW |

| Production Capacity | 1500-2500 chickens/hour |

| Equipment Weight | 1500 KG |

| Suitable Chicken Weight | 1.5-3.5 kg |

Specifications for Each Cutter Group (in line sequence)

| Cutter Group Name | Model/Power | Remarks |

|---|---|---|

| Head & Neck Cutter Group | YS-632-4P / 0.37KW | Customer optional |

| Whole Wing Cutter Group | YS-801-2P / 0.75KW (2 units) | |

| Breast Meat Segmentation Cutter Group (1) | YE2-90L-6P / 1.1KW | |

| Back Meat Segmentation Cutter Group | YE2-90L-6P / 1.1KW (2 units) | |

| Breast Meat Segmentation Cutter Group (2) | YE2-90L-4P / 1.1KW | |

| Leg Meat Separation Cutter Group | YE2-90L-4P / 1.1KW (2 units) | |

| Leg Meat Cutter Group | YE2-90L-4P / 1.1KW |

III. Workflow

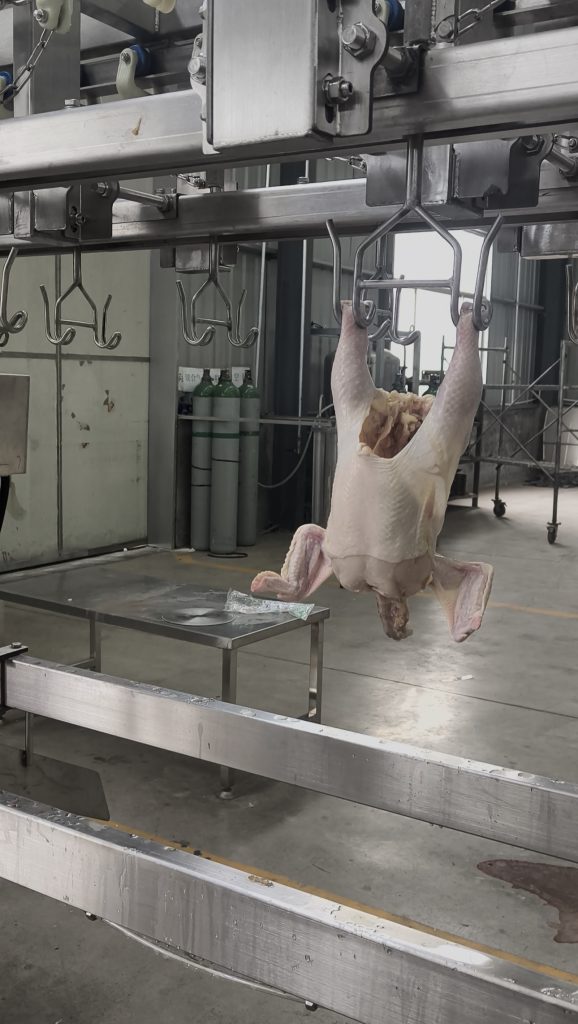

1.Manual Hanging: Processed whole chickens are stably hung on the conveyor chain using U-shaped hooks.

2.Conveying and Orientation: The chain conveys at a constant speed, and an orientation mechanism adjusts the chicken’s posture before key stations.

3.Multi-Station Synchronous Segmentation:

- Whole Wing Cutting: Bilateral rotating disc cutters synchronously separate the left and right whole wings.

- Head & Neck Cutting: A high-speed disc cutter separates the head & neck from the carcass.

- Breast Meat Cutting: A guiding structure directs the breast through a disc cutter to separate the entire breast piece.

- Back Meat Cutting: An inclined disc cutter separates residual meat along the backbone.

- Leg Meat Processing: First, connective tissue is cut, then the left and right leg meat is segmented.

4.Automatic Unhooking and Collection: Drumsticks are automatically unhooked via a push-rod device. Each part slides down dedicated chutes into corresponding collection bins.

IV. Equipment Features

- High Efficiency & Precision: Multi-station cooperation allows processing 1500-2500 chickens per hour. Precise cutting positioning ensures uniform product specifications.

- Flexible & Adjustable: The height, spacing, and angle of key cutters, guides, and holding devices are adjustable, accommodating different breeds and weights of broilers.

- Safe & Hygienic: All food-contact parts are made of 304 stainless steel, easy to disassemble and clean, complying with food safety standards. Equipped with safety guards and emergency stop devices.

- Stable & Reliable: Utilizes imported core transmission components and an industrial PLC control system, supporting long-term continuous operation with easy maintenance.

Key Links in Automatic Broiler Cutting

Hanging

Cutting Chicken Wings

Cutting Chicken Necks

Cutting Chicken Breast

Rib Meat Cutting

Chicken Leg Cutting

Chicken Thigh Cutting

Drumstick Collection

Automatic Cutting System Online Video Demonstration

V. Maintenance & Care

- Daily Cleaning: Thoroughly clean detachable parts like cutters and chutes after each shift.

- Cutter Maintenance: Regularly inspect and replace dull or worn blades.

- Lubrication: Apply food-grade grease to moving parts weekly and check chain tension.

- Electrical Inspection: Inspect the electrical system monthly to ensure secure connections and accurate signals.

Extra Parts List

Rotary Parts

Prototype Blade

Blade Motor

Plastic Fixture

Hanging Chain

Conveyor Hook

Linkage Device

Round Blade

VI. Safety Warnings

- Operators must receive professional training.

- Never insert any body part into cutting zones or between moving parts during operation.

- Always disconnect the main power supply and display a “Maintenance in Progress – Do Not Switch On” warning sign before cleaning, maintaining, or replacing cutters.

- In case of any abnormality (unusual noise, vibration, smoke, cutting deviation), press the emergency stop button immediately. Only resume operation after troubleshooting and confirmation by responsible personnel.

VII. Conclusion

This Automatic Broiler Segmentation Machine integrates high efficiency, precision, safety, and hygiene. It significantly improves production efficiency and product consistency while reducing labor costs and food safety risks. It is an ideal core equipment for modern poultry processing enterprises aiming for intelligent upgrading and enhanced market competitiveness.