THE WORLD OF POULTRY PROCESSING

The global poultry market continues to grow. The market demands more, safer, and an increasingly diverse range of end poultry meat products.

POULTRY CONSUMPTION

Poultry meat (predominantly chicken) has been the world's most consumed meat since 2020, accounting for approximately 33-35% of total meat consumption and surpassing pork and beef.

MANUFACTURER OF MODERN POULTRY SLAUGHTERING PRODUCTION LINES

We are the developer and manufacturer of complete processing and slaughtering systems for broilers, layers, breeders, turkeys, ducks, and geese.

RESPONSIBLE EFFICIENCY

We redefine "efficiency" as "creating safer, more ethical, and more resilient value with fewer resources and lower social and environmental costs."

TECHNOLOGICAL LEADER

We are an equipment supplier, as well as a solver of common technical challenges in the poultry slaughtering industry, an initiator of standards, and an integrator of value.

PASSION FOR THE INDUSTRY

We have visible, verifiable, and ongoing initiatives to drive technology in the poultry slaughtering industry, along with the strategic resolve to boldly invest in the future.

BUILDING A POULTRY SLAUGHTERHOUSE FOR YOU

In close co-operation with our customers, we create innovative solutions for the poultry processing industry, driving excellence in performance, food safety and sustainability.

TURKEY SLAUGHTERING

Turkeys feature a massive size, long growth cycle, unique meat structure, and high economic value, requiring a heavy-duty and high-precision slaughtering line.

OVERVIEW OF STANDARD PROCESSING PROCEDURES FOR POULTRY SLAUGHTERING LINES

PHASE 1: PREPARATION AND STUNNING

Core Processes: 1. Receiving and Resting; 2. Hanging; 3. Stunning;

Main Purposes: Reducing stress, ensuring animal welfare, and preparing for humane slaughter.

Key Equipment/Control Points: Resting pens, automatic hanging system, electrical or gas stunning system.

PHASE 2: SLAUGHTERING AND DEFEATHERING

Core Processes:4.Slaughtering and Bleeding;5. Scalding;6. Defeathering;

Main Purposes: To end life, fully drain blood, and remove feathers.

Key Equipment/Control Points: Automatic throat cutter, blood draining line, scalding tank, multi-stage feather.

PHASE 3: EVISCERATION AND CLEANING

Core Processes:7. Rerailing and Evisceration;8. Internal and External Cleaning;9. Chilling;

Main Purposes: To remove internal organs, conduct official inspections, and rapidly lower carcass temperature to inhibit microbial growth.

Key Equipment/Control Points: Rerailing table, automatic eviscerator, synchronous visceral inspection line, high-pressure cleaner, pre-chilling tank/air-cooled tunnel.

PHASE 4: FINAL PROCESSING

Core Processes:

10. Draining, Grading and Subsequent Processing;

Main Purposes: To prepare carcasses for weighing, grading, and subsequent entry into cutting, packaging or cold chain logistics.

Key Equipment/Control Points: Water drainer, automatic weighing and grading system, cutting line, packaging line.

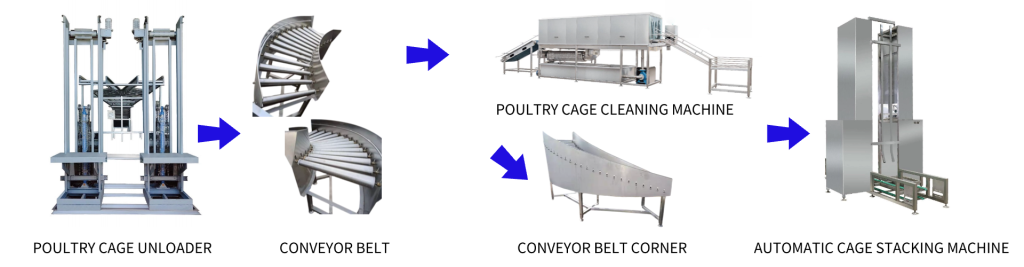

LIVE POULTRY RECEPTION PROCESS EQUIPMENT

COMPLETE COLLECTION OF POULTRY EQUIPMENT

In close co-operation with our customers, we create innovative solutions for the poultry processing industry, driving excellence in performance, food safety and sustainability.

OUR SERVICE ITEMS

We provide professional one-stop services for slaughtering equipment from design to installation to meet your business needs.