Feather plucking is a critical process in poultry slaughtering and processing, and its effectiveness directly impacts the appearance and hygienic quality of products. As a core piece of equipment in compact slaughter lines, it is constructed entirely from 304 stainless steel, which offers advantages such as rust resistance, corrosion resistance, and ease of cleaning and disinfection, meeting the requirements for safe food production. The 6-line, 60-disc design enables continuous and efficient feather plucking operations, ensuring a high processing capacity of 300 to 800 chickens per hour.

The flexibility of the adjustable design: the overall frame of the vertical plucker configured for the NPW compact slaughter line can be freely adjusted. For chickens weighing from 1.8 kg to 3.5 kg, a clean feather plucking effect can be achieved by adjusting the spacing.

Note the correct operating procedures for the machine:

- Link with the preceding process: Emphasize that the scalding process (scalding temperature: 52-61°C, duration: 90 seconds) has a decisive impact on the feather plucking effect. Insufficient or excessive scalding will both affect feather removal.

- Pre-startup inspection: Check whether the motor and transmission components are functioning properly.

- Operation monitoring: Observe the feather plucking effect during operation and fine-tune the plucking spacing in a timely manner.

Detailed Display and Functional Introduction of the Vertical Poultry Plucker

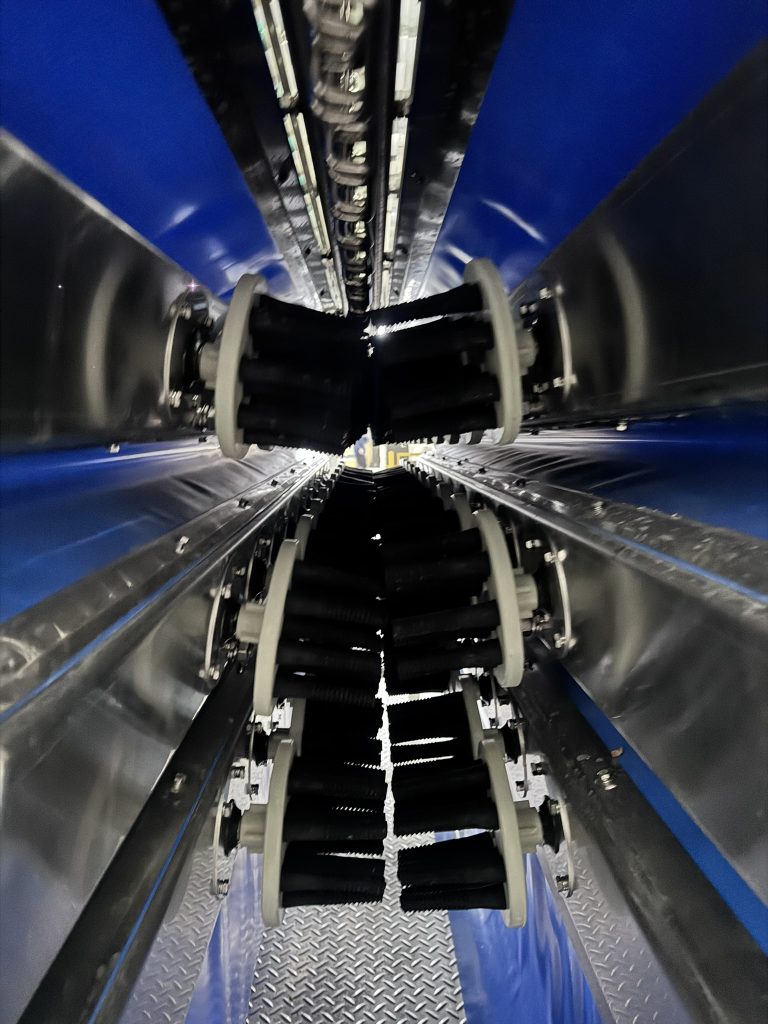

1.Six drive motors enclosed in a stainless steel housing

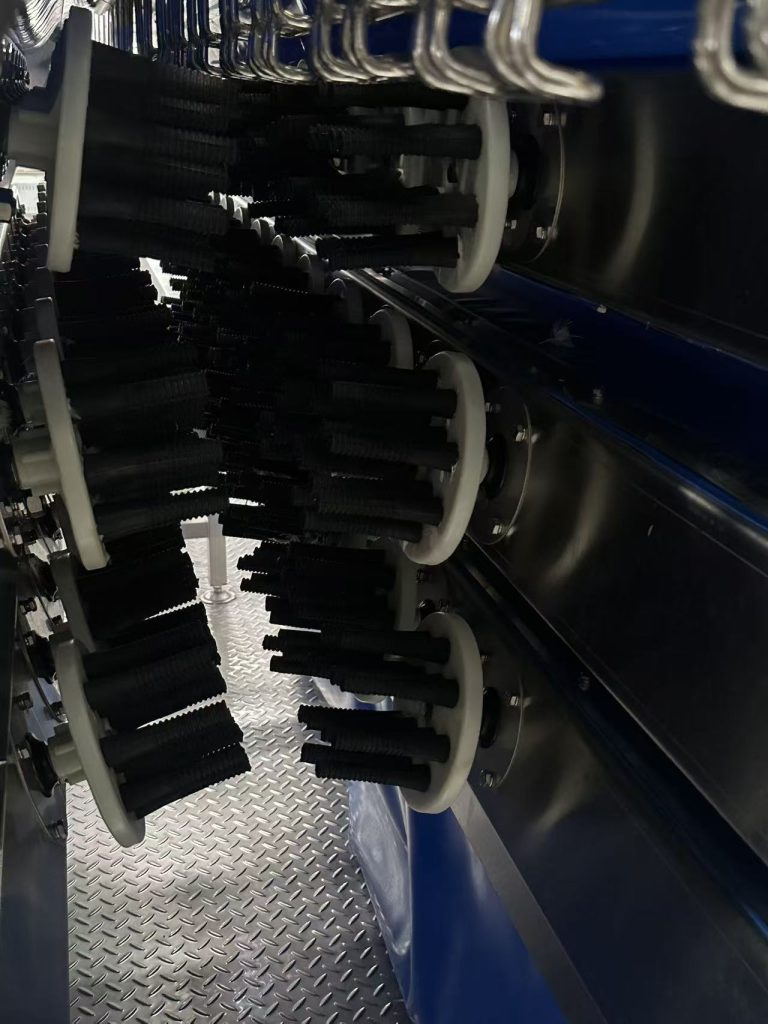

2.A feather plucking system composed of 6 internal groups of 60 feather plucking discs

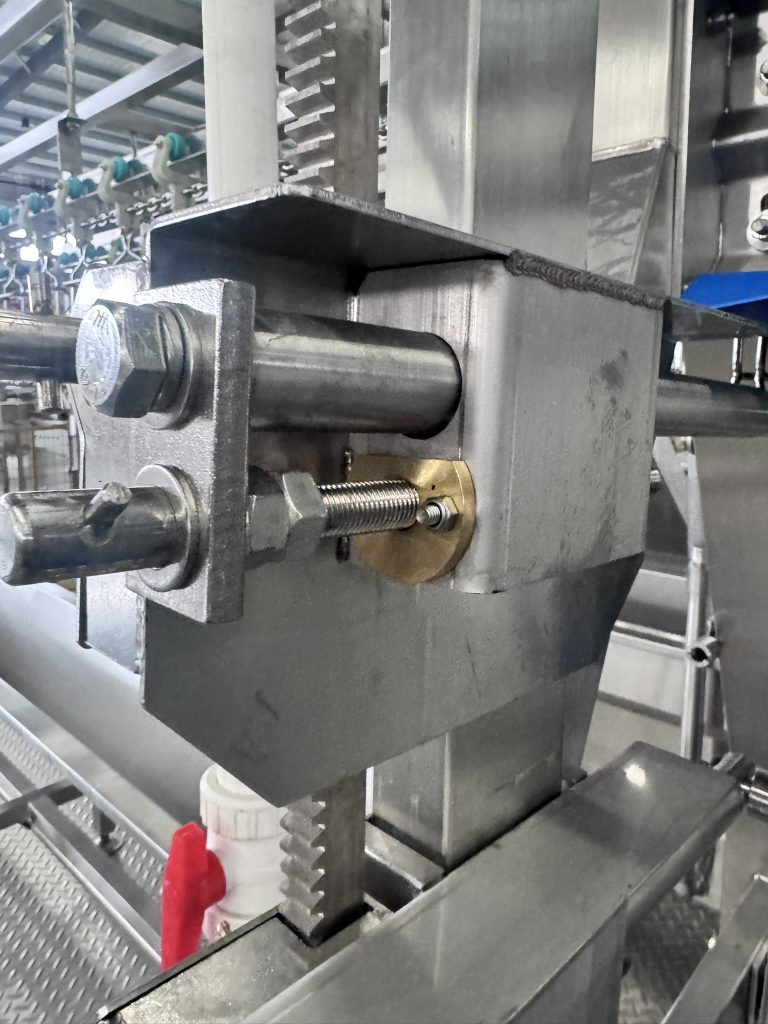

3.Adjustment Wrench for the Feather Plucker

This is a tool used to adjust the spacing of the feather plucker. By adjusting the machine’s position, the optimal processing effect for chickens of different sizes can be achieved.

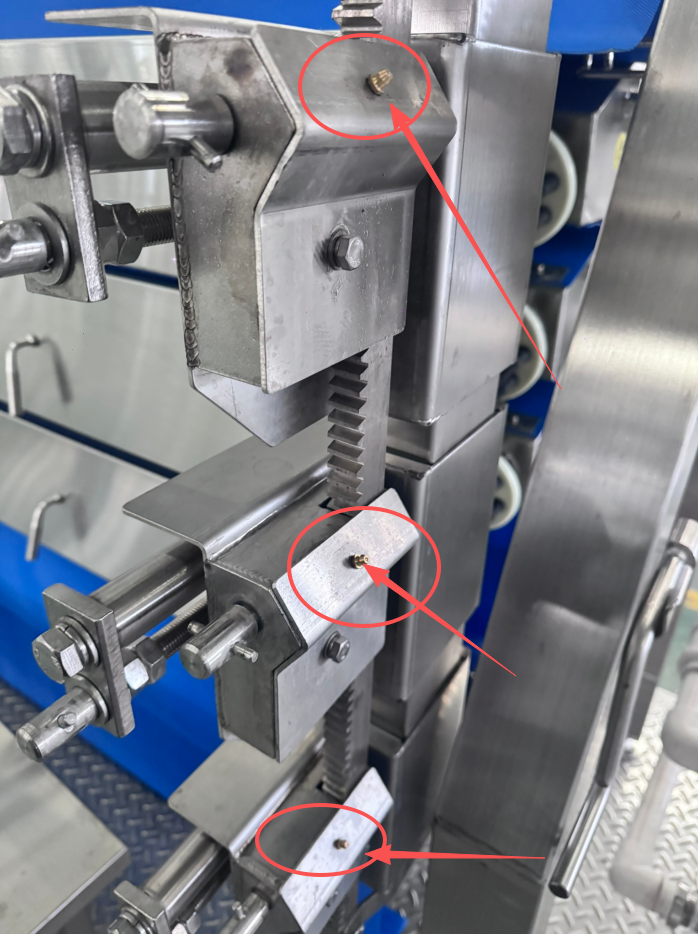

4.Butter Filling Port of the Vertical Feather Plucker

The brass cone head in the picture is the grease filling port. Use a grease gun to add lubricant, and perform the addition every six months to one year.

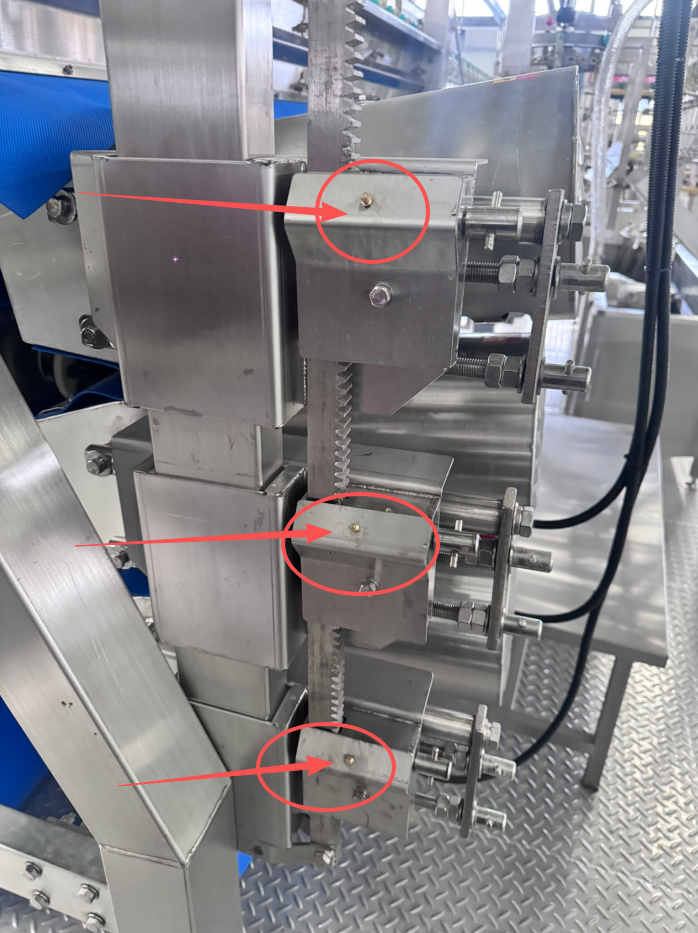

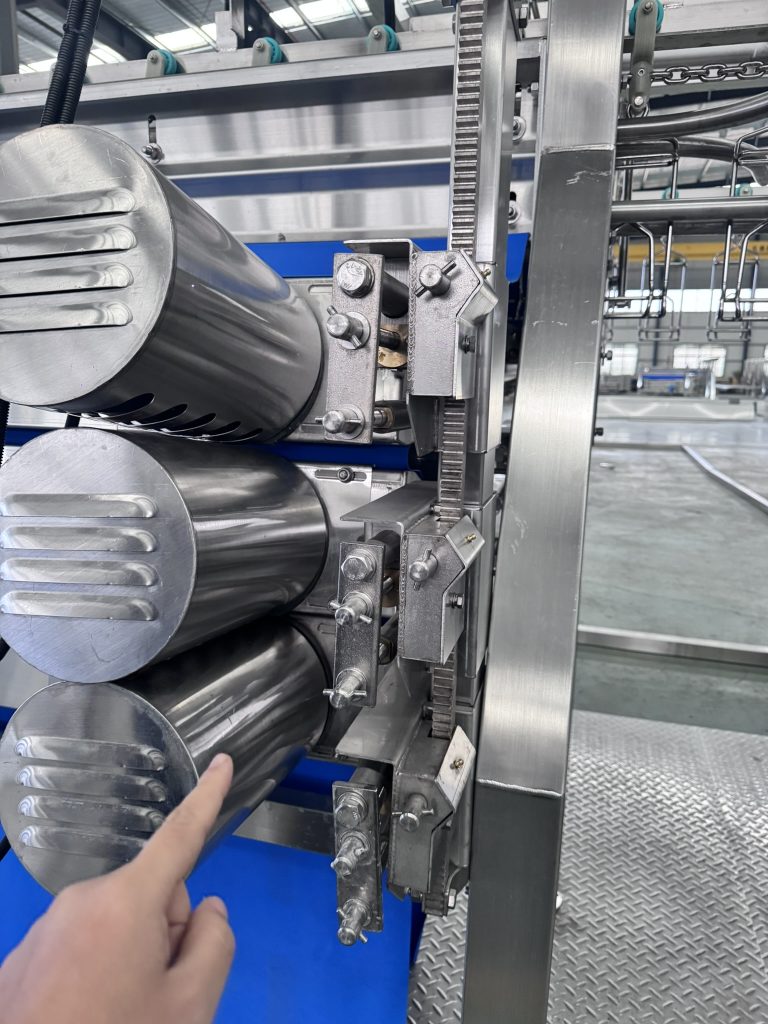

5.Gear Disc for Feather Plucker Size Adjustment

Please note that this is the most important configuration. For transportation purposes, this position will be set to the default closed state before shipment. After the machine is installed in the slaughterhouse building, please adjust the position of the gear disc according to the diagram and the size of the chickens to be processed. The adjustment principles are one-to-one correspondence and parallel configuration.

6.Adjustment Positions for the Height and Width of the Feather Plucking Discs

Adjust using the wrench tool in Function 3 to modify the spacing and width of the feather plucking discs. Ensure that the feather plucking discs on both sides are adjusted to a parallel position; a height difference between the two sides is strictly prohibited.

When the equipment starts commissioning, I will provide you with detailed guidance on the feather plucking discs via remote video. Therefore, please feel free to purchase the equipment. NPW provides comprehensive technical support and services for the adjustment and maintenance of the equipment.

Key Points for the Maintenance and Servicing of the Vertical Feather Plucker

- Daily Maintenance (After Each Shift):

- Thorough Cleaning: Leverage the easy-to-clean property of the equipment’s 304 stainless steel material. Rinse the interior and exterior of the equipment thoroughly with a high-pressure water gun to remove residues such as feathers and bloodstains.

- Inspect Feather Plucking Rubber Rods: Check for severe wear, breakage, or falling-off of the rubber rods. This is the top priority of daily inspections.

- Regular Servicing (Weekly or Monthly):

- Replace Wearing Parts – Feather Plucking Rubber Rods: This is the core of servicing. The 300 complimentary rubber rods are prepared for this purpose.

- Inspect the Transmission System: Check the tension of the motor and whether the gearbox needs lubricating oil replenishment.

- Tightening and Inspection: Check all fastening bolts for loosening.

- Troubleshooting Common Malfunctions:

- Incomplete Feather Plucking: Possible causes include improper chicken scalding temperature/duration, severe wear of feather plucking rubber rods, and excessively large feather plucking spacing.

- Chicken Carcass Damage: Possible causes include excessively small feather plucking spacing, overly hard or unevenly worn rubber rods, and prolonged feather plucking time.

- Abnormal Equipment Noise: Check for damaged bearings or foreign objects jamming inside.

Proper operation and regular maintenance of the vertical feather plucker are crucial for ensuring the stable operation of the production line, improving product quality, and reducing long-term operational costs.

COMPACT POULTRY SLAUGHTER LINE

VIEW DETAILED MODEL INFORMATION FOR THE COMPACT POULTRY SLAUGHTER LINE.