Equipment Overview

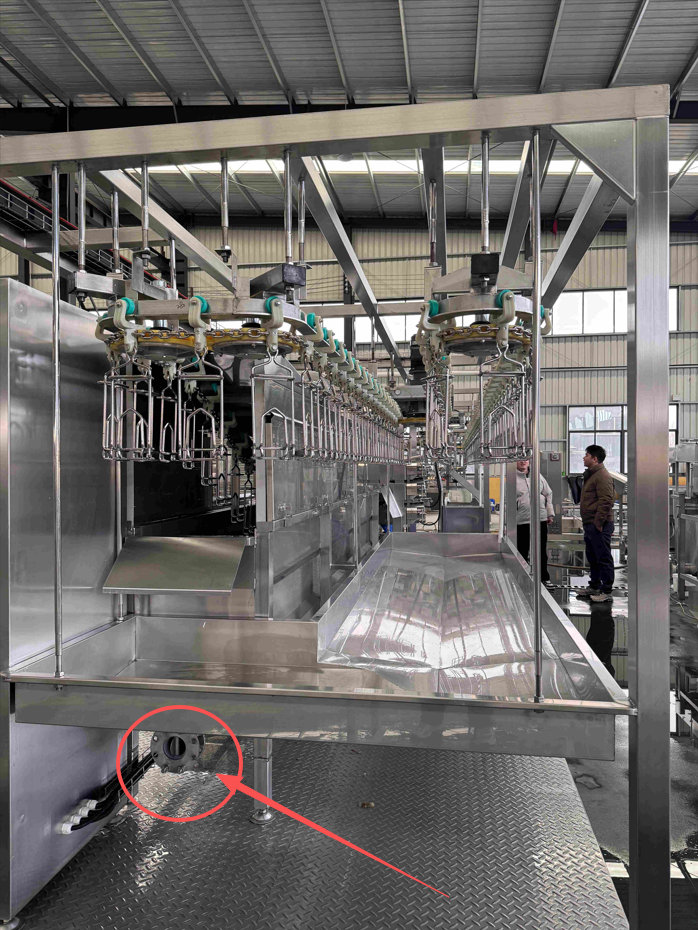

The scalding tank is a critical equipment in poultry slaughtering process, primarily used to expand poultry pores through precisely controlled water temperature, facilitating subsequent defeathering operations. This guide focuses on the electrically heated scalding tank equipped in compact slaughter lines. The equipment is constructed with 304 stainless steel and features an automatic temperature control system, suitable for processing 300-800 birds per hour.

Technical Parameters

- Capacity Specifications: 4300×500×2200mm (L×W×H) The 800BPH scalding tank operates in a circular mode and requires customized dimensions.

- Heating Power: 54KW electric heating system (with three 15KW heaters)

- Water Temperature Range: Adjustable 52-61℃

- Heating Time: Approximately 30 minutes from room temperature to set temperature

- Temperature Control: Automatic constant temperature control with ±0.5℃ accuracy

- Material Structure: 304 stainless steel main body, 2mm thickness tank

Operation Procedures

Pre-production Preparation

- Equipment Inspection:

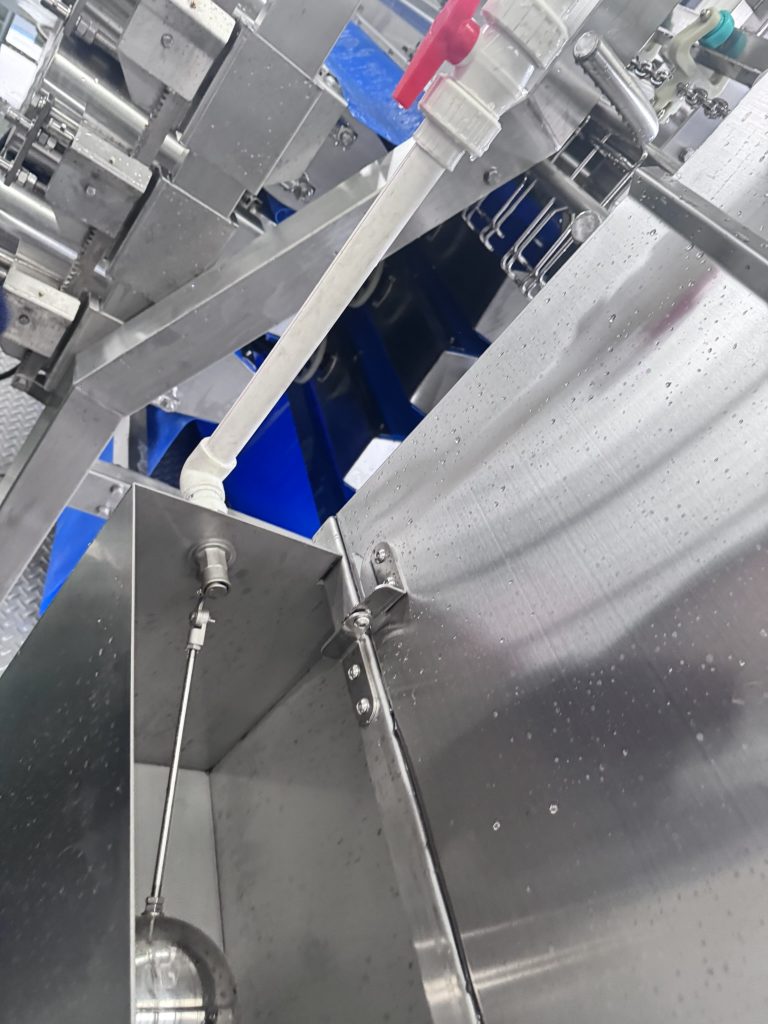

- Check if water level reaches the standard line (approximately 1.6 tons of water)

- Confirm heating tubes are undamaged and terminal connections are tight

- Verify proper operation of temperature sensors

- Preheating Startup:

- Start heating system 30 minutes in advance

- Set target temperature (recommended 58-60℃ for broilers)

- Monitor heating indicator status and confirm three-phase balance

- Operation Monitoring:

- Record temperature fluctuations hourly

- Observe operation status of automatic water level compensation system

- Monitor cycling frequency of heating tubes

Maintenance

Daily Maintenance

- After Production:

- Drain tank water and clean interior walls with high-pressure water

- Clean scale from heating tube surfaces with soft cloth

- Check integrity of sealing gaskets

- Weekly Maintenance:

- Check temperature calibration deviation

- Clean water inlet filter

- Test ground resistance (≤4Ω)

- Monthly Maintenance:

- Disassemble heating tubes to check scaling condition

- Calibrate temperature sensor accuracy

- Test sensitivity of overheat protection device

Troubleshooting

| Symptom | Possible Cause | Solution |

|---|---|---|

| Slow heating | Scaling on heating tubes/Single-phase failure | Clean or replace heating tubes/Check circuit |

| Large temperature fluctuations | Sensor malfunction/Water pump abnormality | Calibrate or replace sensors/Check water pump |

| Water leakage | Aged sealing rings/Weld cracks | Replace sealing rings/Weld repair |

Energy Saving Suggestions

- Switch to Keep Warm Mode (50℃) during production intervals

- Use insulation cover when shutting down overnight

- Regularly remove scale from heating tubes to improve thermal efficiency

- Consider installing heat recovery system (optional)

Safety Regulations

- Operators must wear anti-scalding equipment

- Must disconnect power and hang warning signs before maintenance

- Operation with malfunctions is strictly prohibited

- Test leakage protection function weekly

Important Notes

- Water quality requirements: Recommended to use softened water to reduce scale formation

- Heating tube cleaning: Use food-grade descaling agent, perform deep cleaning annually

- Long-term shutdown: Need to drain accumulated water and maintain dry, ventilated interior

As a core component of the compact slaughter line, proper use and maintenance of this equipment can not only ensure defeathering effectiveness but also significantly extend equipment lifespan. It is recommended to establish specialized maintenance records and conduct regular comprehensive inspections by professionals.

COMPACT POULTRY SLAUGHTER LINE

VIEW DETAILED MODEL INFORMATION FOR THE COMPACT POULTRY SLAUGHTER LINE.

“As a beginner, this guide is practically my ‘scalding tank operation bible.’ I used to be most afraid of adjusting the temperature and maintaining the equipment, but now I follow the steps in the guide exactly. The daily checklist and weekly maintenance items are especially useful. I printed them out and posted them next to the equipment. The first thing I do every day when I get to work is to check the water level, thermometer, and filter. After setting the temperature and time according to the ‘standard operating procedure,’ the pigskin is scalded evenly, the hair removal effect is stable, and there have been no more cases of over-scalding or under-scalding. The preventive maintenance section helped me avoid a major malfunction. When I was cleaning the nozzles regularly, I found signs of limescale blockage and dealt with it in time. This makes me feel very confident when I work.”