The Poultry Automatic 9-Piece Cutting System is a high-efficiency automated production line specifically designed for modern poultry slaughter and processing enterprises, integrating advanced mechanical engineering, food science, and intelligent control technologies. This equipment incorporates high-precision mechanical drive systems, multi-stage precision guidance structures, and multi-station synchronous cutting processes, enabling the accurate and efficient segmentation of a whole broiler into nine standard parts: left/right whole wings, head & neck, breast meat, backbone meat, left/right leg meat, and drumsticks. It fully automates the entire process from manual hanging to automatic sorting and collection of all parts, significantly reducing reliance on manual labor. The main structure is constructed from high-quality food-grade 304 stainless steel, offering excellent corrosion resistance and anti-contamination capabilities. Its modular design philosophy facilitates easy installation, disassembly, cleaning, and future maintenance/upgrades, fully complying with international food safety management systems like HACCP and the national standard GB/T 41548-2022 “Livestock and Poultry Slaughtering and Processing Equipment – Livestock and Poultry Meat Cutting Line.” With its scientific design and rational layout, it is widely suitable for large-scale livestock/poultry slaughterhouses, central kitchen distribution centers, prepared food deep-processing enterprises, and export-oriented poultry processing bases, making it the ideal core equipment for achieving standardized, large-scale, and intelligent production.

Workflow

Manual Hanging Area

Operators, at the hanging station, use dedicated U-shaped hooks to securely suspend the whole chicken (which has undergone head removal, foot removal, evisceration, and cleaning) from the leg roots, ensuring the carcass hangs vertically with stable gravity and a uniform posture. This provides a consistent and reliable initial positioning reference for the subsequent automated cutting process, effectively preventing cutting deviations or product damage due to hanging errors, thereby ensuring continuous line operation and a high finished product rate.

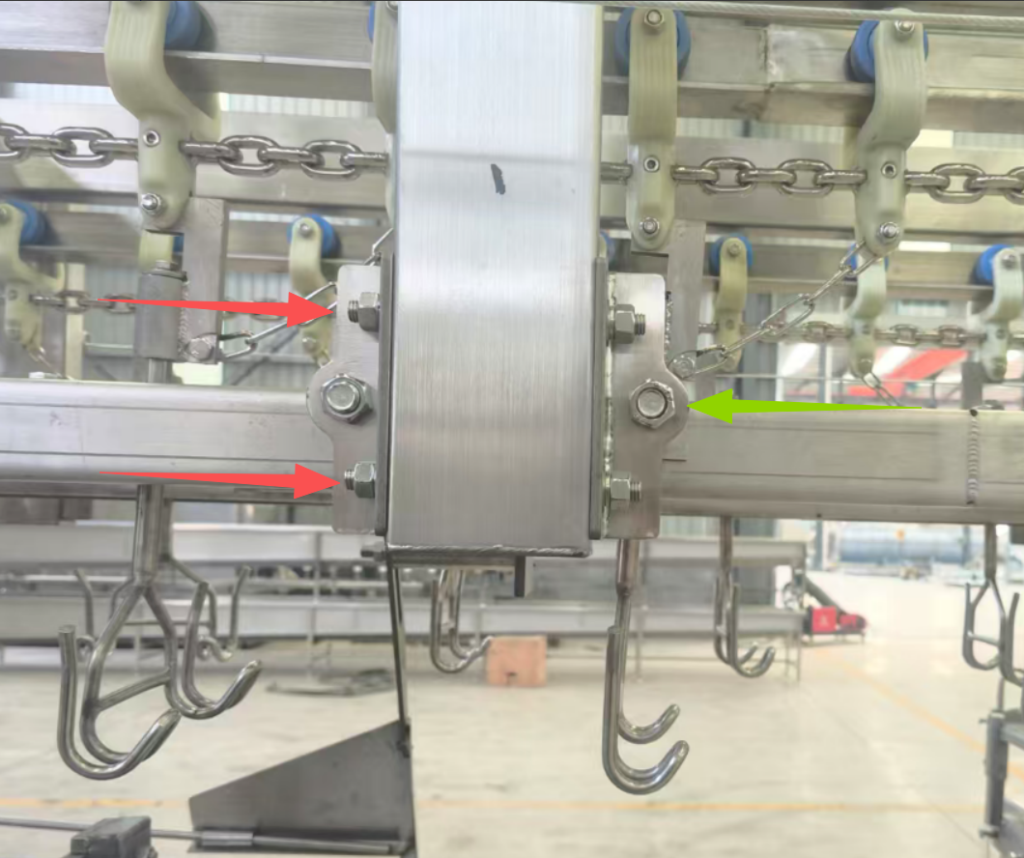

Conveyor System

The equipment employs a closed-loop, high-strength stainless steel chain as the core conveying mechanism. Hooks are evenly installed on the chain at standard intervals and travel smoothly along a preset track at a constant speed. The system is equipped with a high-performance variable frequency drive (VFD) for speed adjustment, allowing flexible adaptation to different production rhythms and seamless integration with upstream and downstream processes. During operation, the chain runs stably without vibration, ensuring precise transfer of the carcass between stations, avoiding misalignment or jamming, and guaranteeing cutting accuracy and production efficiency.

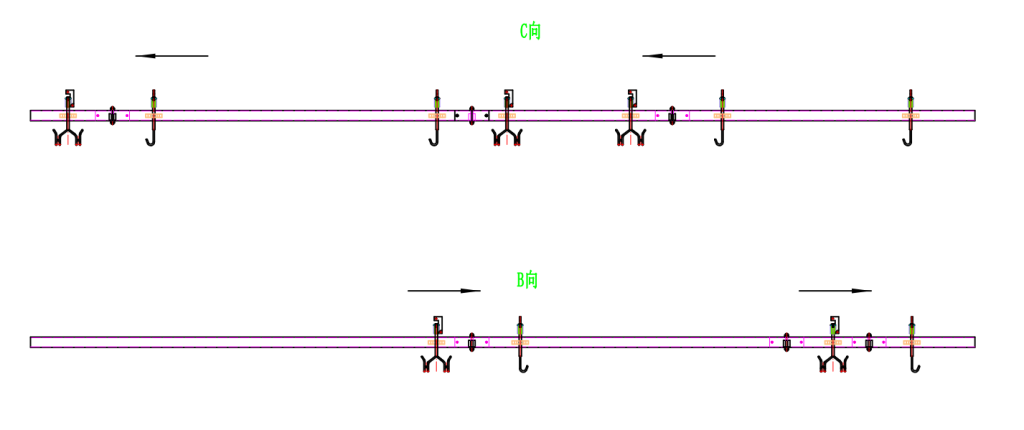

Hook Rotation Mechanism

Before key cutting stations, a precision mechanical guide rail system is installed. When a hook carrying a carcass arrives at the designated position, a special interface between the guide rail and the hook automatically triggers a 90-degree rotation. This mechanism precisely reorients the carcass in space, ensuring the cutting surfaces of each part face the corresponding tool head-on, significantly improving cutting accuracy, product consistency, and overall yield, while effectively reducing waste.

- Loosen the bolt to adjust the vertical distance of the guide rail; tighten the nut to fix after adjustment.

- Loosen the bolt to adjust the lateral distance of the guide rail; tighten the nut to fix after adjustment.

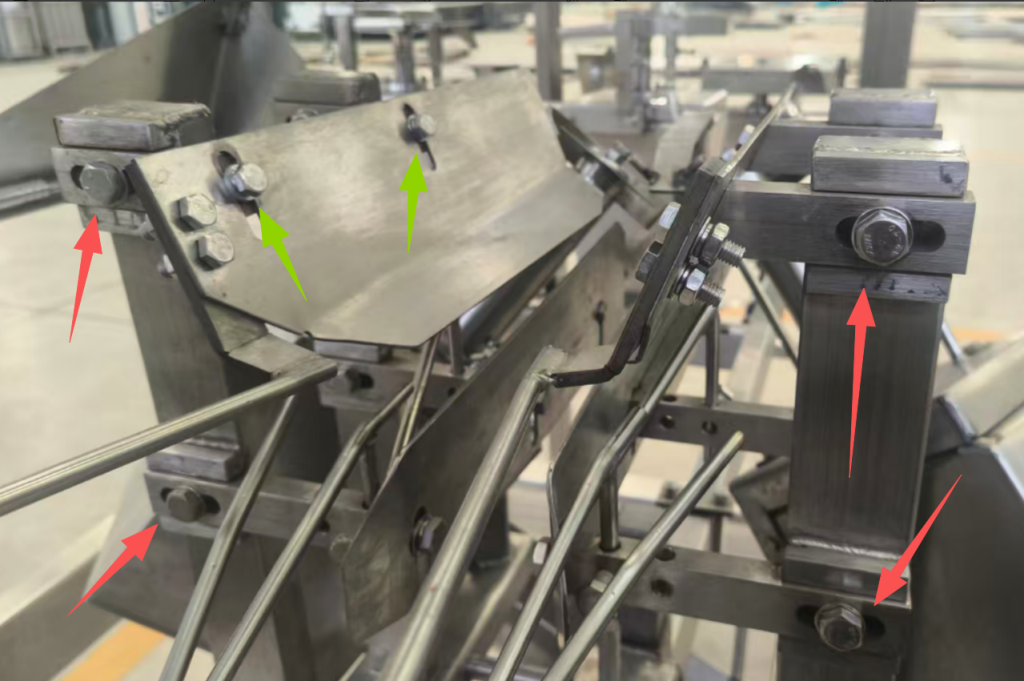

Whole Wing Cutting Station (2 pieces)

This station is equipped with symmetric, adjustable dual-side rotating disc blade assemblies. Blade height, spacing, and cutting angle can be finely tuned according to carcass size to adapt to different product specifications. As the carcass passes through, high-precision guide rods automatically guide the left and right wings into preset cutting zones. The disc blades on both sides, driven by independent motors, synchronously and rapidly cut into the shoulder joint connections, achieving complete and precise separation of the left and right whole wings. Cutting depth is program-controlled to ensure only joint tissues are severed without damaging adjacent breast meat. The separated whole wings fall by gravity via dedicated guide chutes into collection bins below for sorted collection.

- Loosen the bolts to adjust the lateral spacing of the blades; tighten the nuts after adjustment.

- Loosen the bolts to adjust the support plate vertically according to carcass size; tighten the bolts after adjustment.

- Loosen the bolts to adjust the support plate laterally according to carcass size; tighten the bolts after adjustment.

Head & Neck Cutting Station (1 piece)

As the carcass reaches this station, the head and neck portion is precisely guided into a dedicated cutting slot by a support plate structure, ensuring a constant cutting position. A high-speed motor-driven rotating disc blade synchronously completes the separation cut between the head/neck and the torso. It adapts to different poultry breeds and processing requirements, ensuring neat cuts without residual meat. The severed head and neck slide down an independent chute into a dedicated collection bin for subsequent batch processing or further utilization.

- Loosen the bolts; adjust the vertical position of the support plate slot to locate the neck cutting position; tighten the bolts after adjustment.

- Adjust the vertical distance of the blade.

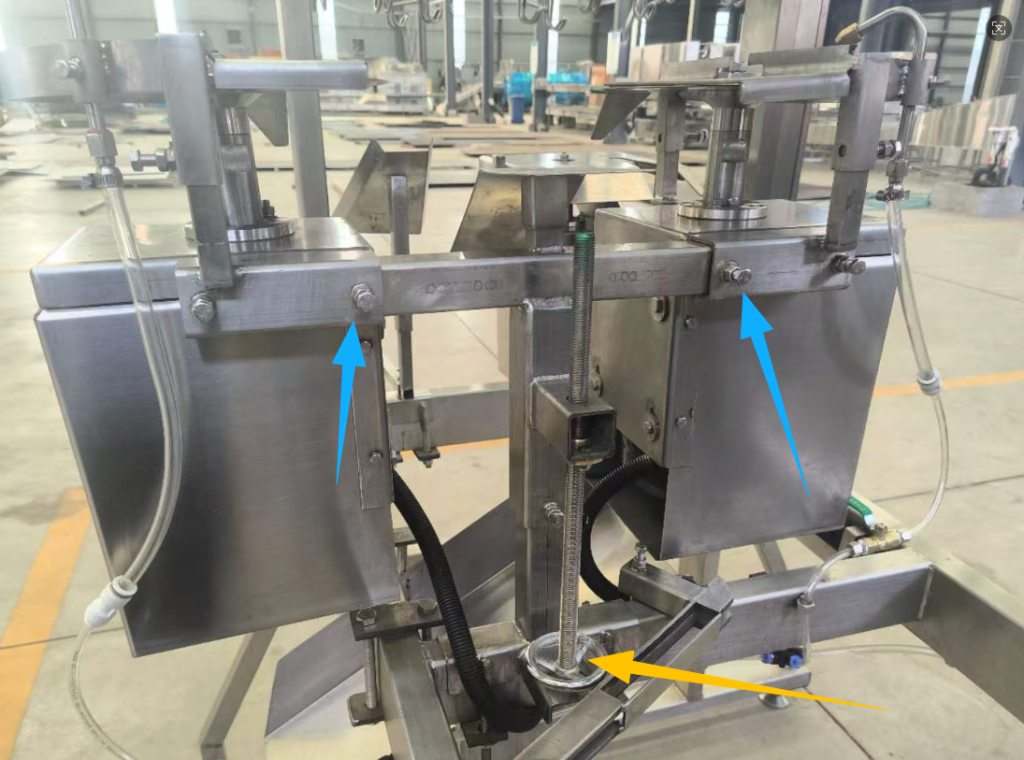

Breast Meat Cutting Station (1 piece)

This station is equipped with a front-mounted material guiding and positioning device that accurately directs the tail end of the carcass into the guiding structure, positioning the breast downward to pass smoothly under the high-speed rotating disc blade. The blade system undergoes precision dynamic balancing and vibration damping, ensuring stable operation and smooth, clean cutting surfaces that maximize the preservation of breast meat integrity and appearance. The separated whole breast meat slides via a dedicated chute into an independent collection bin, achieving physical isolation from other parts to prevent cross-contamination and ensure product hygiene and safety.

- Adjust the front/back distance of the support plate.

- Adjust the vertical distance of the support plate to alter the carcass angle.

- Adjust the lateral spacing of the blades.

- Adjust the vertical distance of the blades.

Backbone Meat Cutting Station (1 piece)

After breast meat separation, the carcass proceeds via guide rods to the backbone separation station. This station employs an inclined disc blade that performs precise cutting along the natural contour of the spine, effectively separating the vertebral bones from attached residual meat. The cutting angle and depth are adjustable. The separated backbone meat is collected via an independent chute.

- Adjust the lateral distance of the blades.

- Adjust the vertical distance of the blades.

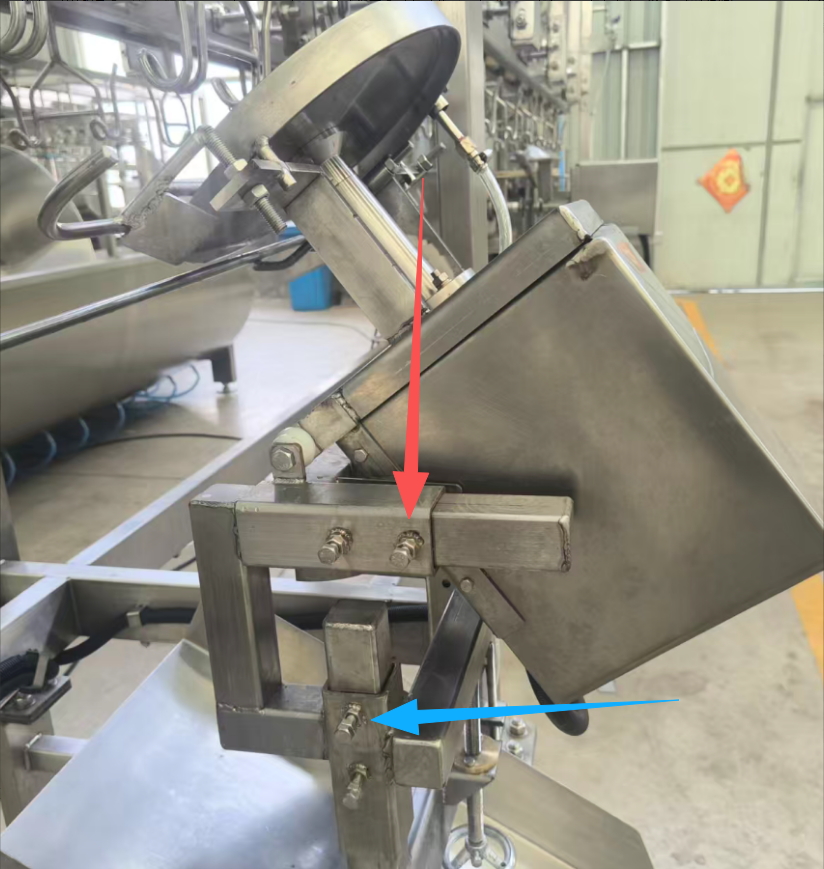

Leg Meat Adhesion Cutting Station

To ensure complete independence of the left and right leg meat, a dedicated adhesion tissue cutting station is incorporated. It uses high-precision mechanical clamping devices to securely hold the carcass torso, preventing movement during cutting. Paired with a vertically mounted high-speed disc blade, it precisely severs the pelvic tissues and fascia connecting the two legs, completely eliminating adhesion. This step lays the foundation for subsequent independent leg meat separation, ensuring thorough segmentation.

- Adjust the blade height.

- Adjust the lateral distance of the blades.

Leg Meat Cutting Station (2 pieces)

Located at the conveyor system’s turning transition area, the carcass processed by previous stations positions the left and right legs hanging separately on the two sides of the U-shaped hook. As the hook passes through this station, a horizontally mounted high-speed disc blade precisely cuts into the joint between the leg meat and the drumstick, completing the independent separation of the left and right leg meat. The cutting action is synchronous and stable, ensuring each piece of leg meat is intact and uniformly weighted. The finished products automatically slide down left and right chutes into corresponding collection bins.

- Adjust the blade position.

Drumstick Detaching Device

A mechanical push-rod detaching mechanism is installed at the process end. When only the drumsticks remain hanging on the hook and reach the designated position, they engage with the push-rod mechanism, causing the drumsticks to detach smoothly. This process achieves lossless detachment, avoiding product impact or deformation and ensuring the drumsticks remain intact. The detached drumsticks are centrally collected via a chute, completing the final step of automation, greatly reducing manual intervention and enhancing overall line automation.

Equipment Features

High Efficiency & Precision

The machine adopts a multi-station cooperative operation mode combined with high-precision transmission, enabling continuous and efficient cutting of 1000-2500 chickens per hour. Each cutting point is mechanically positioned, ensuring precise, consistent cutting locations and uniform product specifications, with a significantly higher finished product rate than traditional manual methods.

Flexibility & Adjustability

Key blade systems, guide structures, and clamping devices feature adjustable designs. Height, spacing, and angle support rapid adjustment to adapt to broilers of different weights (e.g., 1.5kg to 3.5kg) and breeds (e.g., white-feathered, yellow-feathered), meeting diverse and customized production scenarios.

Safety & Hygiene

All food-contact parts are made of food-grade 304 stainless steel, with smooth, crevice-free surfaces compliant with GMP and food safety regulations. The overall structure is easy to disassemble for cleaning, with proper drainage design to prevent water accumulation and bacterial growth. All critical moving parts are equipped with safety guards and integrated emergency stop buttons, ensuring comprehensive operator safety.

Stability & Reliability

Core transmission components utilize imported high-precision bearings, wear-resistant chains, and timing pulleys for long-lasting durability. The control system employs industrial-grade PLCs for stable operation and low failure rates. Designed for 7×24 continuous industrial operation, the machine is easy to maintain with low overall operating costs, suitable for long-term operation in large-scale production lines.

Maintenance & Servicing

Daily Cleaning

After each production shift, the main power must be switched off. Once the equipment has completely stopped, disassemble modules like blade assemblies, guide chutes, and support plates for thorough cleaning using high-pressure water or food-grade detergents. Focus on removing blood stains, grease, and tissue residues. Dry with a cloth or air-dry after cleaning to prevent microbial growth.

Blade Maintenance

Regularly (recommended every 200 operating hours or after each daily shift) inspect the sharpness of all disc blade edges. Replace immediately if dulling, chipping, or wear is detected. During installation, ensure blades are securely fastened and rotate in the correct direction to prevent equipment damage or safety hazards from reverse rotation.

Lubrication

Weekly, apply food-grade grease to moving parts such as conveyor chains, guide rail sliders, and bearing housings to ensure smooth transmission and reduce mechanical wear. The use of non-food-grade lubricants is strictly prohibited to prevent product contamination. Also, check chain tension regularly and adjust promptly to avoid skipping or detachment.

Electrical Inspection

Monthly, conduct a comprehensive inspection of the electrical system, including motors, sensors, limit switches, and control cabinet wiring. Ensure connections are secure, signals are accurate, and there is no aging or short-circuiting. Regularly update PLC program backups to ensure control system stability and reliability, preventing unexpected downtime.

Safety Warnings

- All operators must undergo systematic professional training and pass assessment before being allowed to operate the equipment. Unauthorized operation is strictly prohibited.

- During equipment operation, never place hands, arms, or any other body parts into cutting zones, conveyor tracks, or between any moving parts.

- Before performing cleaning, maintenance, repair, or blade replacement, the main power supply MUST be disconnected, and a “UNDER MAINTENANCE – DO NOT SWITCH ON” warning sign MUST be hung on the electrical control cabinet to prevent accidental startup.

- If abnormal noises, vibrations, smoke, cutting deviations, or any other irregularities are detected, immediately press the emergency stop button, shut down the machine, and investigate. Operation may only resume after the fault is completely resolved and confirmed by a responsible person.

Conclusion

This Poultry Automatic 9-Piece Cutting System integrates high efficiency, precision, safety, and hygiene, representing the advanced level of current poultry cutting automation technology. It not only significantly enhances production efficiency and product consistency but also effectively reduces labor costs and food safety risks. It is the ideal core equipment for modern poultry processing enterprises aiming for intelligent transformation, increased product added value, and enhanced market competitiveness. Our company is always committed to customer needs, providing full-process services from equipment installation and commissioning, operator training, to lifelong technical support. We continuously optimize equipment performance to help our clients gain a competitive edge in the fierce market and jointly propel China’s poultry processing industry towards a new stage of standardization, automation, and sustainable development.

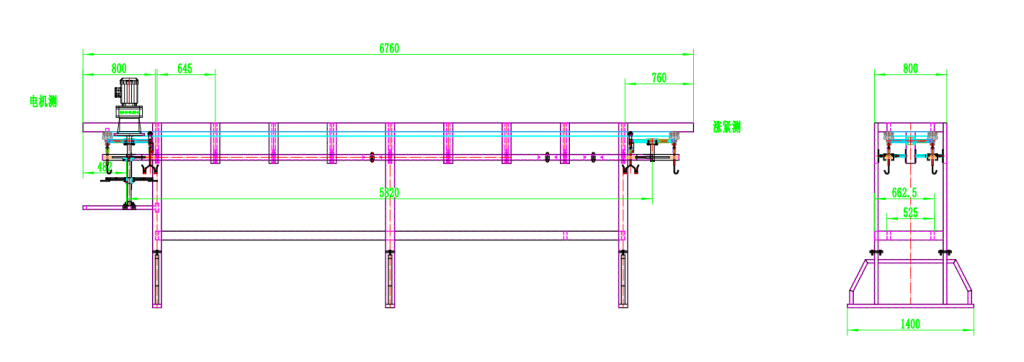

Main Technical Parameters

- Overall Dimensions (LWH): 6850 * 1400 * 2430 mm

- Total Power Consumption: 20 KW

- Production Capacity: 1500-2500 chickens/hour

- Equipment Weight: 1500 kg Blade Group Parameters (in order along the production line)

Name Model/Power Remarks

| Name | Model/Power | Remarks |

|---|---|---|

| Head & Neck Blade Set | YS-632-4P / 0.37KW | Customer Option |

| Whole Wing Blade Set | YS-801-2P / 0.75KW (2 units) | |

| Breast Meat Cutting Set (1) | YE2-90L-6P / 1.1KW | |

| Back Meat Cutting Set | YE2-90L-6P / 1.1KW (2 units) | |

| Breast Meat Cutting Set (2) | YE2-90L-4P / 1.1KW | |

| Leg Meat Separation Set | YE2-90L-4P / 1.1KW (2 units) | |

| Leg Meat Blade Set | YE2-90L-4P / 1.1KW |

Product Illustrations

Frame Schematic Diagram

Hook Rotation Schematic

AUTOMATIC BROILER CUTTING MACHINE

The Automatic Broiler Cutting Machine (Complete Equipment for Precise 9-Piece Chicken Cutting) is a highly efficient automatic production line tailor-made for modern poultry slaughtering and processing enterprises, integrating advanced mechanical engineering, food science and intelligent control technologies.