An “Plug-and-Play, Customizable” Intelligent Upgrade Solution Designed for Small and Medium-Sized Slaughterhouses

Introduction: Meeting the Needs of Modern Poultry Processing

In the increasingly competitive poultry processing market, scale is no longer the only barrier. Rapid response, flexible production, and controlled investment risk have become core demands for small and medium-sized slaughterhouses and farm-direct brands. However, traditional large-scale slaughter lines require huge investments, strict site conditions, and complex installation, while manual workshops suffer from low efficiency and inconsistent quality, failing to meet modern food safety and market requirements.

To address this industry challenge, NPW leverages years of technical expertise to introduce an innovative, deeply customizable compact modular poultry slaughter line. This is not simply a scaled-down version of a large production line but an intelligent, integrated solution designed from the ground up for flexibility and adaptability—making it the ideal choice for small and medium-capacity users seeking automation upgrades and standardized production.

1. Core Customization Capabilities: Your Site, Your Capacity & Layout

We understand that no two slaughterhouses are exactly alike. Our solution begins with in-depth communication and precise customization.

1.1 Flexible Capacity Matching for Targeted Investment

- 300 BPH Basic Version: Suitable for community farms, boutique brands, or start-ups processing thousands of birds per day. Low investment threshold with quick results.

- 500 BPH Standard Version: Meets the needs of most small and medium-sized slaughterhouses and cooperatives, balancing efficiency and investment with a short payback period.

- 800 BPH Enhanced Version: Designed for enterprises with stable orders and growth potential, offering near-medium-line capacity while allowing room for future expansion.

1.2 Space Optimization and Layout Flexibility

Equipment is no longer a fixed monolith but intelligent modules tailored to your workshop:

- Dimensional Customization: Core equipment (e.g., scalding tanks, pre-cooling tanks) dimensions, overhead line height, and length can be adjusted to fit irregular or narrow spaces.

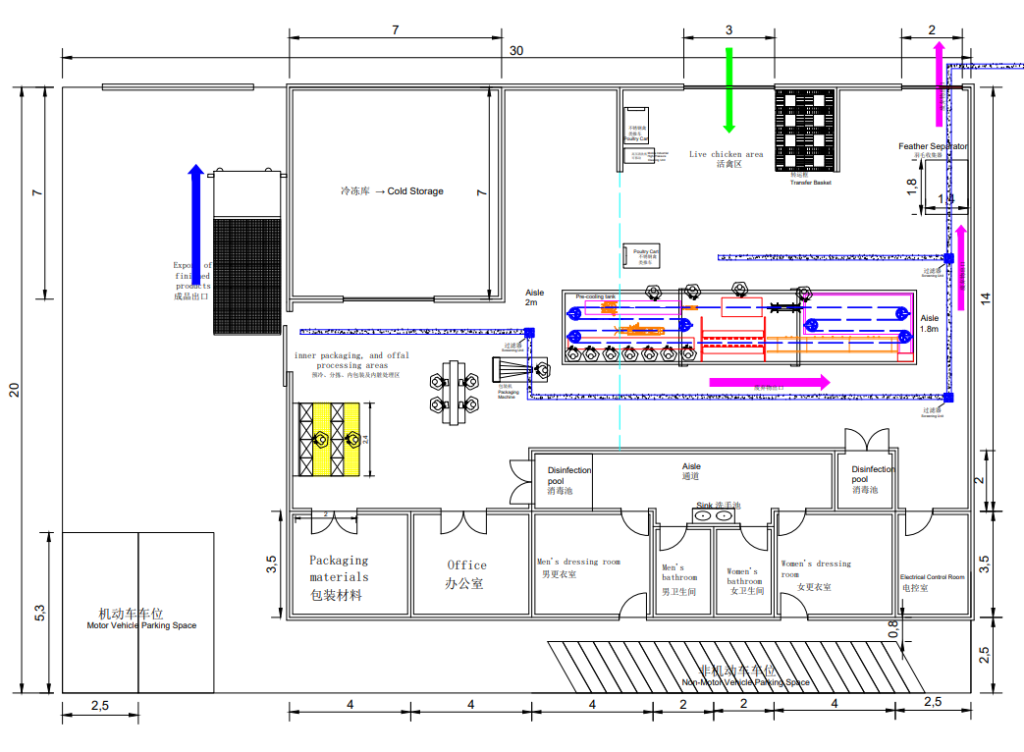

- Layout Reconfiguration: From straight-line to L-shaped or even U-shaped arrangements, we replan equipment placement based on your material flow (from live bird reception to finished product storage) to achieve optimal ergonomic efficiency.

- Containerized Modules: We offer standard 20-foot and 40-foot containerized module designs. The core production line is pre-assembled, tested, and shipped in containers. On-site, it is quickly connected like “building blocks,” significantly reducing installation complexity and time, especially in areas with limited infrastructure.

1.3 Detailed Space Utilization Advantages

1.3.1 Revolutionary Space Efficiency

Compared to traditional slaughter lines, NPW’s compact line maximizes space efficiency through three innovative designs:

- 20-foot Container Module: Minimum configuration 6×3m, occupying only 18㎡, supporting 300 BPH.

- 40-foot Container Module: Standard configuration 12×3m, occupying 36㎡, supporting 500-800 BPH.

- Height Integration: Uniform height of 2.2m suits various workshop ceiling heights.

1.3.2 Flexible Layout Options

- Straight-Line Layout: Ideal for long, narrow workshops; sequential equipment arrangement ensures smooth logistics.

- L-Shaped Layout: Fits right-angled spaces, maximizing corner utilization.

- U-Shaped Layout: Minimizes operator movement, boosting efficiency.

1.3.3 Retrofitting Advantages for Existing Facilities

- No need for new construction; utilizes existing infrastructure.

- Simplified foundation requirements reduce civil engineering costs.

- Flexible utility connections adapt to various site conditions.

1.3.4 Chain Benefits of Space Savings

- Logistics Cost Reduction: Material handling distance shortened by 30%.

- Energy Savings: Reduced workshop space cuts HVAC/lighting energy use.

- Management Efficiency: Centralized layout reduces supervisory movement.

2. Integrated Design: Simplified Installation, Rapid Deployment

“Rapid deployment” is another core principle of our design.

2.1 Pre-Integrated Factory Assembly

The entire line’s electrical control systems, pneumatic circuits, and water pipelines are integrated and tested at the factory. You receive a fully functional, pre-assembled unit, not a collection of loose parts.

2.2 Streamlined On-Site Setup

On-site work is greatly simplified to: equipment positioning, module interconnection, and utility hookup. Typically, installation and commissioning can be completed within days, cutting the time from investment decision to production by over 60%.

2.3 Compact Footprint

Optimized design reduces the line’s footprint by 30-50% compared to traditional lines of equivalent capacity, significantly lowering building rental or construction costs.

3. Complete Process Coverage Ensuring Product Quality

Compact yet comprehensive, this line covers all core modern slaughter processes:

- Hanging & Stunning: Gentle handling and humane stunning ensure animal welfare and meat quality.

- Scalding & Defeathering: Custom scalding tanks paired with efficient pluckers achieve >99% feather removal with intact skin.

- Evisceration & Washing: Adjustable evisceration lines meet varying processing depths, coupled with high-efficiency cleaning for hygiene.

- Pre-Chilling & Preservation: Integrated pre-chilling rapidly reduces carcass core temperature to safe levels, extending shelf life.

4. The Essential Upgrade: Bridging Manual Workshops and Smart Production

For small slaughterhouses aiming to transition from manual labor to enhanced competitiveness, this line is the most cost-effective upgrade path:

- Reduced Labor Dependency: Automation cuts direct labor by 50-70% and reduces physical strain.

- Improved Product Consistency: Standardized processing ensures uniform quality and specifications, supporting brand development.

- Regulatory Compliance: Equipment materials and designs meet food safety standards, aiding certifications and access to premium markets (e.g., supermarkets, restaurants).

5. Clear Return on Investment

For a custom 500 BPH line, operating at full capacity, the initial investment is typically recouped within 1-2 years. Comprehensive benefits from efficiency gains, reduced waste, and product premiumization deliver sustained growth.

5.1 In-Depth ROI Analysis

5.1.1 Initial Investment Breakdown (500 BPH Example)

- Main Equipment: $48,000

- Installation & Commissioning: Only 5% of traditional line cost

- Civil Works: Significantly reduced or eliminated

- Total Investment: 35-40% lower than traditional lines

5.1.2 Operational Cost Savings

- Labor Costs: Automation replaces 60% of labor, saving $10,000/year

- Utilities: Energy-efficient design reduces water use by 40%, electricity by 30%

- Maintenance: Modular design cuts maintenance costs by 25%

5.1.3 Efficiency & Value Gains

- Capacity Utilization: Increases from ~70% to over 90%

- Yield Improvement: Standardization boosts product yield by 2-3%

- Quality Premium: Standardized production increases selling price by 5-8%

5.2 Hidden Benefits & Long-Term Value

5.2.1 Risk Mitigation

- Phased investment possible with modular design, lowering initial risk

- Rapid deployment shortens capital commitment

- Scalable capacity adapts to business growth

5.2.2 Strategic Value

- Quick production launch captures market opportunities

- Standardized products enhance brand image

- Export certifications open international markets

5.3 Success Case: Ghana Client

- Before: Manual slaughter, 1,000 birds/day, 20 workers

- After: NPW 500 BPH compact line, 4,000 birds/day, 8 workers

- Payback Period: 22 months

- Current Status: Expanded to 2 lines, exporting to the EU

6. Act Now: Start Your Customization Journey

Whether you have a constrained existing facility or are planning a new processing center, NPW’s compact modular slaughter line offers the optimal solution. Provide your target capacity, site layout, and dimensions, and our engineering team will deliver a tailored layout plan and investment benefit analysis—free of charge.

Contact us to bring flexible, efficient automation to your workshop—starting tomorrow.

NPW’s compact poultry slaughter line enables feasible automation upgrades for small and medium slaughterhouses through spatial optimization and maximized economic benefits. It addresses space constraints while delivering quick ROI and sustained value creation.

Immediate Actions We Offer:

- Custom layout plans based on your actual site

- Detailed ROI calculation sheets

- Reference cases from similar clients

- Financing and installment payment support

Choose NPW—Maximize the value of every square meter!

Contact us immediately

We are here to help you address any problems or concerns you may encounter.

As the manager of a small-scale slaughterhouse operating in Gabon for many years, I have been searching for a solution that could boost our capacity and product quality while adapting to our limited space and less-than-stable power conditions. Everything truly changed when we decided to implement NPW’s Compact Modular Poultry Slaughter Line Customized Solution. I’d like to share our genuine experience from the past six months.

The Most Striking Experience: It Was “Built for Us” Like Lego

The terms “compact” and “modular” were just concepts during the proposal phase, but we fully grasped their brilliance after installation. Our factory building has an irregular layout. Instead of trying to sell us a standard large, the NPW engineers conducted a site survey and then used several core modules to “assemble” an efficient line tailored to our actual space, target capacity of 3,000 birds per hour, and plans for potentially adding a cutting section in the future.

Modules like the Stunning & Scalding Unit, Defeathering & Washing Unit, and Pre-cooling & Dripping Unit function as independent blocks, cleverly connected by conveyors.

When we needed to adjust the process sequence, we found moving and reconnecting these modules was much simpler than expected, providing immense flexibility for future upgrades.

Operational Stability: More Reliable Than We Anticipated in Humid Gabon

Our biggest concern was the impact of the humid climate on the equipment. The full-line use of 304 stainless steel and high protection-rated electrical cabinets from NPW have stood the test. The line has been running smoothly for six months without any electrical failures or serious corrosion due to humidity. While consumables like rubber defeathering fingers require scheduled replacement, the core mechanical and electrical components have been extremely stable, significantly reducing unexpected downtime and allowing us to fulfill daily orders with confidence.

Efficiency and Quality: The Leap from “Workshop” to “Modern Plant”

Efficiency: Previously reliant on extensive manual labor, we struggled even with 1,000 birds. Now, the line consistently and easily meets its designed capacity of 3,000 birds per hour. Daily throughput has multiplied several times over, while the number of core operators required has decreased.

Quality: The most visible change is in product appearance. Precise control in the scalding and defeathering stages results in intact, smooth chicken skin with almost no residual fluff. The core temperature of carcasses after pre-cooling is consistently, significantly extending meat shelf life and drastically reducing customer complaints. Our products can now command higher prices and enter the local premium market with a stronger reputation.

Service Support: Miles Away, Yet Support Feels Close

As an overseas client, we initially had significant concerns about after-sales service. However, NPW’s support has been impressive. Their installation engineers spent two weeks at our plant, not only completing the but also providing hands-on systematic training for our staff. Now, for minor issues, we can troubleshoot ourselves using clear fault codes and manuals. For more complex situations, video calls via WhatsApp with their engineers always yield timely remote guidance. This level of support gives us great peace of mind.

An Honest Word to Fellow Operators

If you are also operating a poultry processing business in a region with imperfect infrastructure but great market potential (like Africa or Southeast Asia), and are grappling with issues of efficiency, quality, and room for expansion, then NPW’s solution is certainly worth your deep consideration. It is not a rigid, unchangeable behemoth, but an intelligent tool that can “grow” alongside your business’s “growth.” It has enabled us to achieve standardized production and seize the market opportunity presented by the local import ban. This was more than just an equipment purchase; it was a crucial upgrade to our factory’s future competitiveness.

After implementing NPW’s compact modular poultry slaughtering line solution, we achieved a leap from a “small workshop” to a “modern factory” within six months. This solution perfectly adapted to our irregular factory layout and our capacity target of 3,000 birds per hour. Its modular design, as flexible as Lego bricks, facilitates future upgrades. In humid climates, the entire line, constructed from 304 stainless steel and featuring high-protection electrical cabinets, demonstrated exceptional stability, significantly reducing unexpected downtime. Production efficiency doubled, and product appearance and shelf life were significantly improved, enabling us to enter the high-end market. Despite being located overseas, NPW provided reassuring after-sales service through on-site training and remote video support. For peers facing infrastructure challenges but possessing market potential, this is a key competitive investment that can grow alongside their businesses.