In a compact poultry processing line, the Electrical Panels serve as the core control unit of the automation system, responsible for integrating and coordinating the operation of electrical equipment across all processing stages. As a vital component of the NPW compact poultry slaughtering line, the Electrical Panels ensure the stability, safety, and efficiency of the processing workflow through advanced electrical control and software systems. They support the entire production value chain, covering shackling, stunning, bleeding, scalding and heating, defeathering, secondary bleeding, foot cutting, head pulling, as well as cooling and cleaning. These panels are the critical infrastructure enabling modular and scalable production.

Technical Specifications

1.Basic Parameters

- Processing Object: Broiler Chicken

- Live Bird Weight Range: 1.8-2.5 kg

- Processing Capacity: 300-800 birds per hour (BPH), standard configuration based on 500 BPH

- Power Supply Requirement: 380V/3P/50Hz three-phase power (can be customized according to voltage standards of different countries)

- Total Power: Approximately 68.4 kW (including heating, transmission, and other systems)

- Rated Current: 140 A

- Equipment Dimensions: Length 11500 mm × Width 2250 mm × Height 2300 mm

- Recommended Workshop Area: Not less than Length 20 m × Width 8 m (approximately 160 m²)

2.Key Process Parameters

- Bleeding Time: 4-5 minutes (adjustable, compliant with Halal certification requirements)

- Scalding Time: Approximately 90 seconds

- Scalding Temperature: 52-61°C (electric heating with automatic temperature control, supports modification to steam boiler)

- Transmission System: Overhead conveyor pitch 203.2 mm, adjustable line speed (standard speed 2.58 m/min)

- Pre-chilling Method: Water bath chilling, requires customer to provide 0-4°C cold water

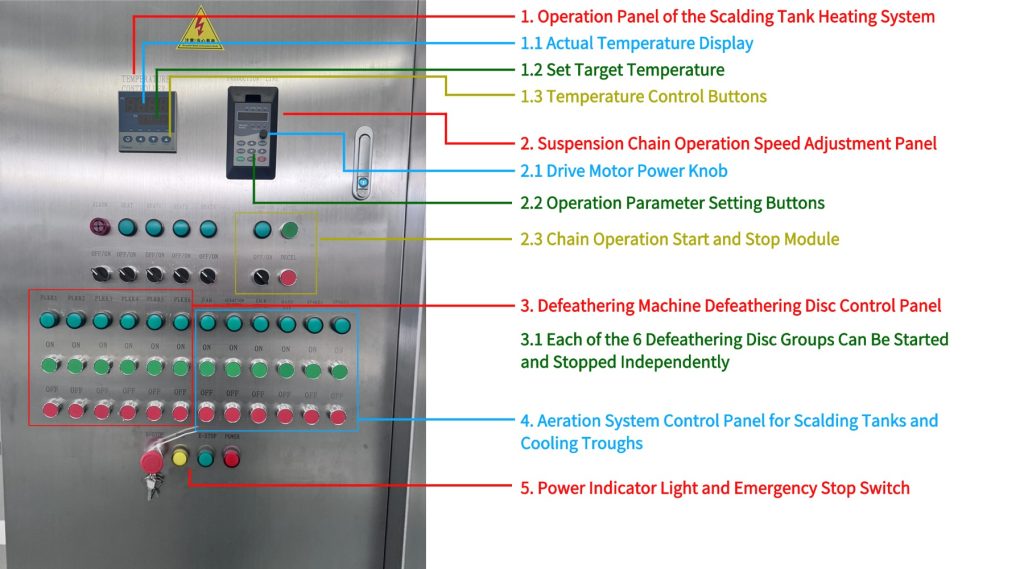

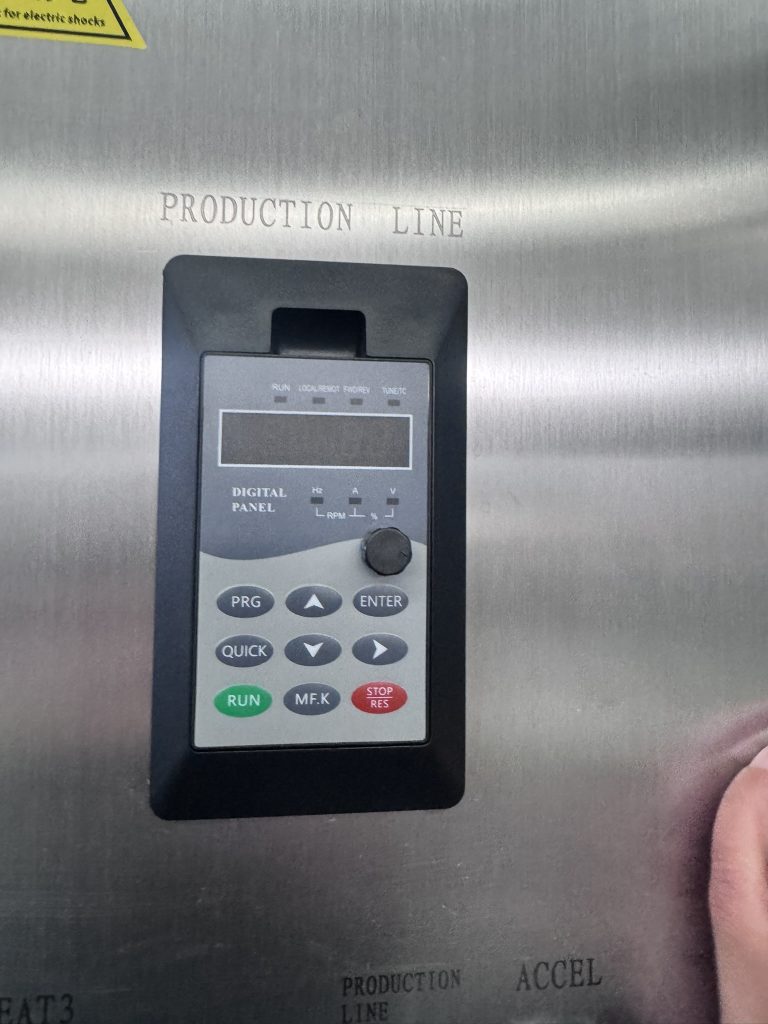

Introduction to the Electrical Panel Interface

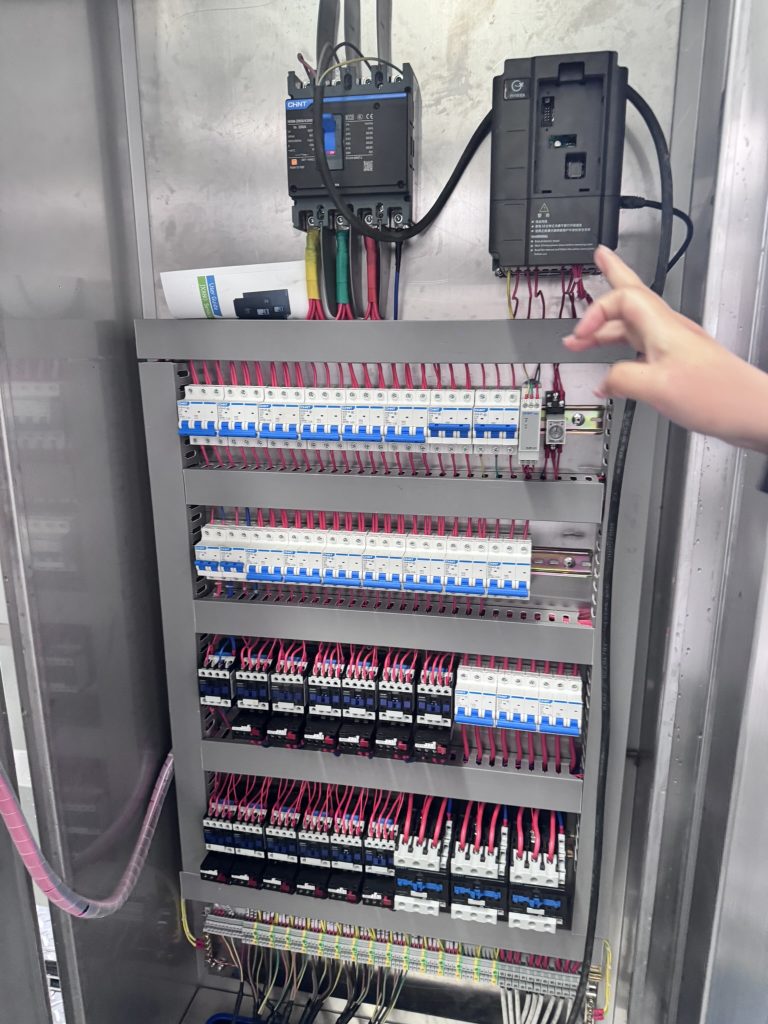

Wiring Management System Inside the Control Box

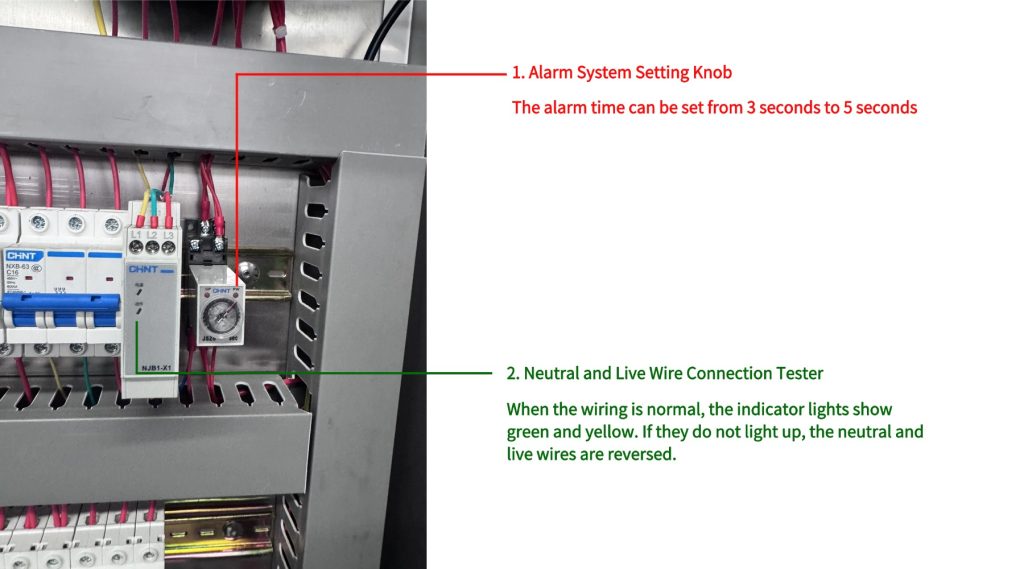

1.System Alarm Controller Setting

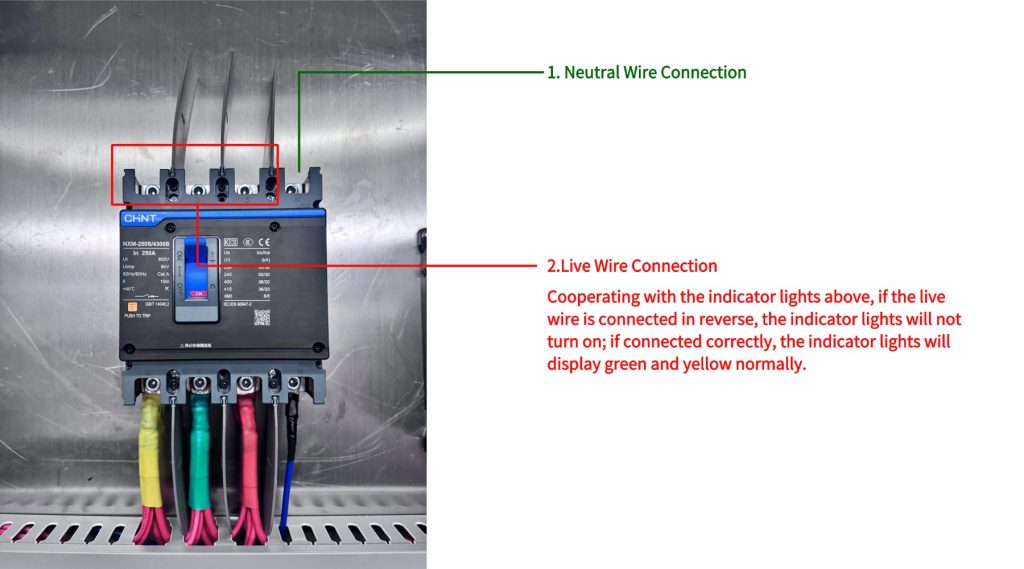

2.Main Switch for External Power Supply Connection

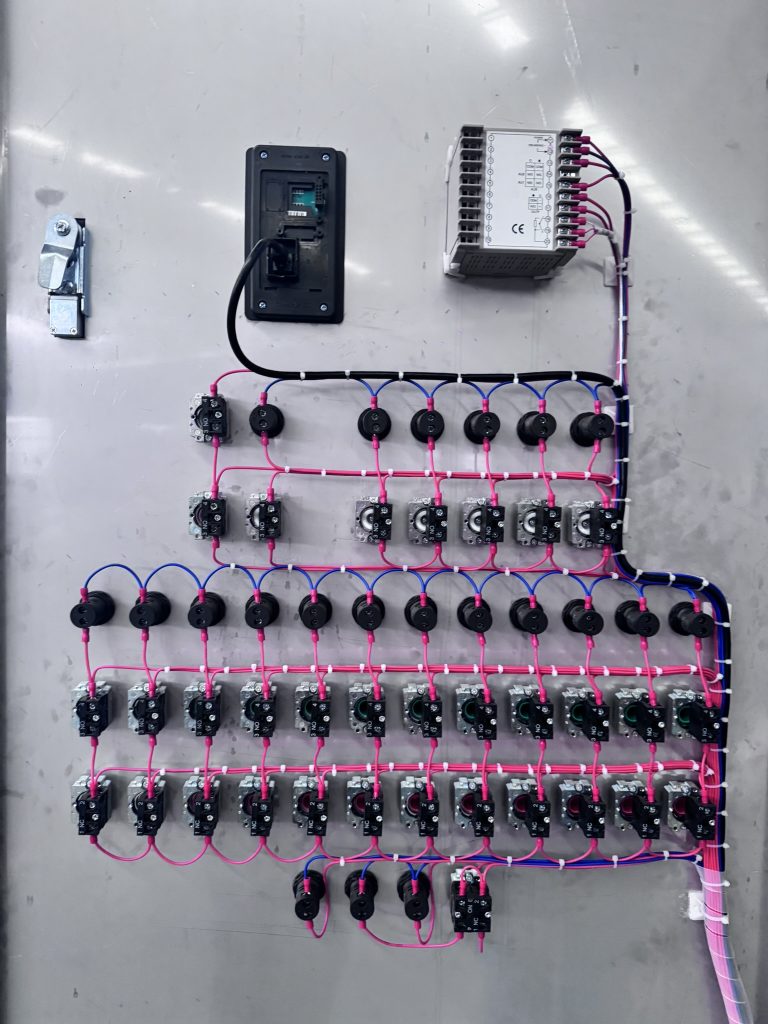

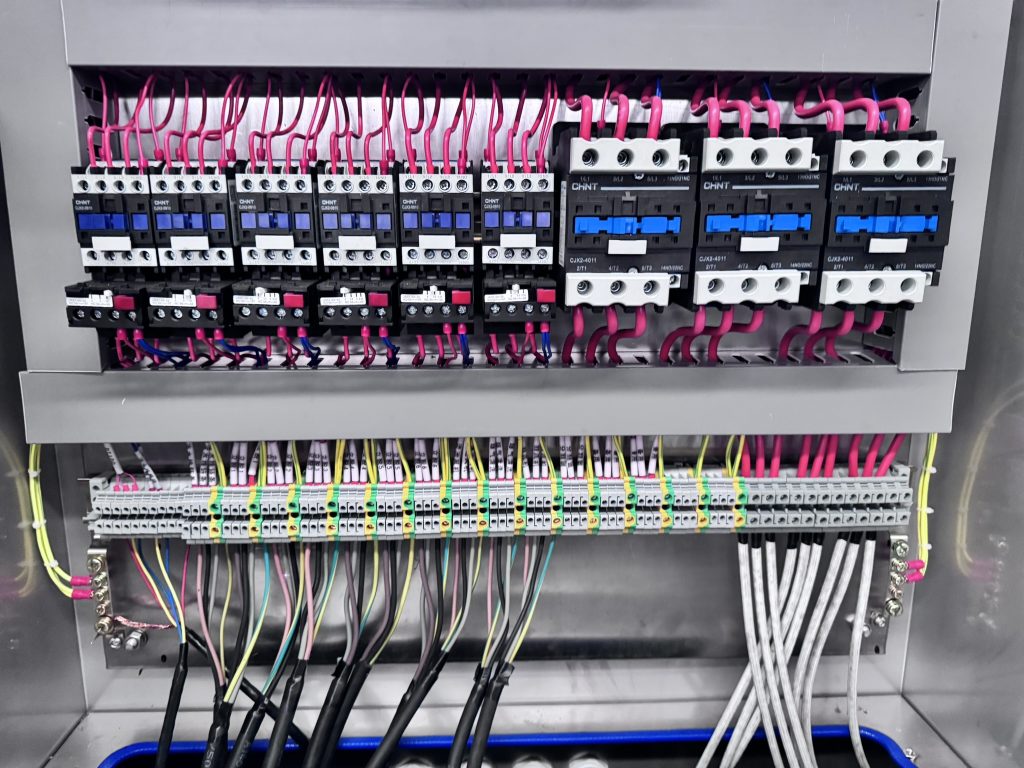

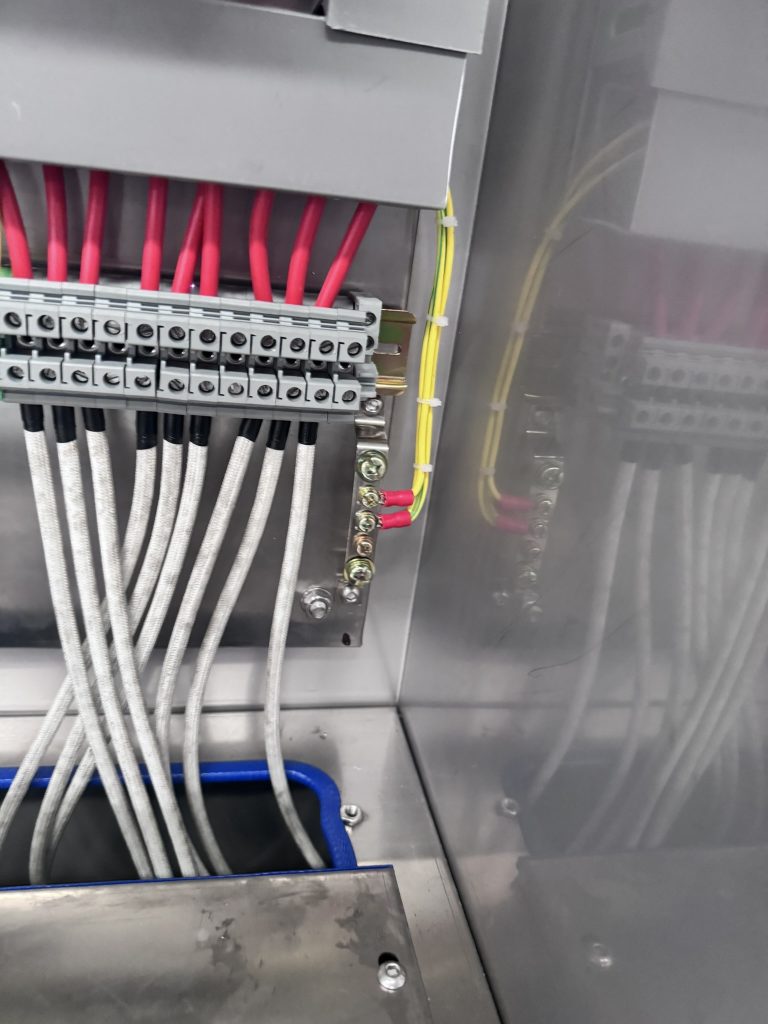

3.Wiring Layout Display Inside the Electric Control Box

The design of the electric control box complies with international safety standards, with built-in overload protection, short-circuit protection and emergency stop mechanisms. It ensures stable operation in the high-voltage and high-humidity processing environment, and prevents production interruptions caused by electrical failures. All parameters of the compact slaughter line are configured before delivery.

After the equipment is delivered to the factory site, it can be directly used by connecting to the main power supply. Meanwhile, NPW will provide detailed technical guidance services, so please feel free to use the machine.

COMPACT POULTRY SLAUGHTER LINE

VIEW DETAILED MODEL INFORMATION FOR THE COMPACT POULTRY SLAUGHTER LINE.