— Unveiling the Path to Efficient, Stable, and Worry-Free Slaughter Process Enhancement

Dear Client,

Thank you for your interest in the core aeration system integrated into our compact poultry slaughter line. This system is far more than a simple “oxygenation device”; it is a hydrodynamic optimization system that deeply integrates process principles with intelligent control. Specifically designed to enhance the quality, efficiency, and reliability of the scalding and cooling stages, its four core advantages are detailed below:

Advantage One: Significantly Enhanced Product Quality and Processing Efficacy

- Revolutionary Breakthrough in Scalding Uniformity

- Permanently Solves the “Undercooked” Dilemma: Traditional static scalding often leads to uneven heat distribution at the feather follicles, resulting in incomplete defeathering and high damage rates. Our aeration system creates a three-dimensional water circulation through continuous, gentle airflow agitation, ensuring every bird and every follicle receives thorough, uniform scalding at the set temperature.

- Result: Defeathering residue rate can be stably controlled at ≤1%, with bird skin emerging intact and smooth, laying a solid foundation for subsequent production of high-end products.

- Simultaneous Leap in Cooling Efficiency and Cleanliness

- Rapid Lock-in of Freshness, Inhibits Bacteria & Cleans: In the cooling tank, the aeration system maintains the chilled water temperature uniformly within the optimal freshness range of 4-5°C, rapidly cooling the carcasses and effectively inhibiting microbial growth. Concurrently, the water flow acts like countless “tiny brushes,” automatically flushing away residual traces of blood and lymph fluid from the carcass surface.

- Result: This achieves cooling and cleaning in one step, yielding a more hygienic product with an extended shelf life.

Advantage Two: Substantial Reduction in Operational Costs and Energy Consumption

- Direct Energy Savings, Tangible Benefits

- Reduced Heating Energy: In the scalding tank, water circulation prevents the stratification of “hot water layers” and “cold water layers,” improving heat transfer efficiency. Field tests show this can help you save approximately 10-15% in heating energy consumption.

- Water Conservation & Reduced Discharge: Improved efficiency in cooling water utilization allows for extended water change cycles, reducing overall water consumption by over 20%. This subsequently lowers wastewater treatment load and costs.

- Labor Savings, Reduced Work Intensity

- The system operates fully automatically, requiring no manual intervention for stirring or frequent cleaning of tank sediment. This liberates labor for higher-value tasks.

Advantage Three: Extreme Equipment Protection, Extending Service Life

- Eradicates the Heater Element “Killer”

- In static scalding tanks, contaminants like feathers and grease settle and firmly adhere to costly electric heating elements, forming an insulating layer that causes localized overheating and burnout, and is extremely difficult to clean. Our aeration system keeps these pollutants in suspension through continuous water flow, allowing them to be smoothly discharged with the drainage system, completely preventing their deposition on heating elements.

- Value for You: Extends electric heater element life by 2-3 times, dramatically reducing downtime repair costs and part replacement expenses due to heater failure.

- System Self-Cleaning, Easier Maintenance

- The constant water flow inhibits the growth of algae and bacterial biofilm on tank walls and pipelines, giving the system inherent self-cleaning properties and reducing the frequency and intensity of manual cleaning.

Advantage Four: Intelligent Stability, Ensuring Continuous Production

- Unmatched Process Stability

- The aeration system integrates seamlessly with your line control system (e.g., PLC), intelligently adjusting airflow based on production rhythm. This ensures highly consistent process conditions (temperature, water flow) for every batch, guaranteeing the stability and traceability of final product quality.

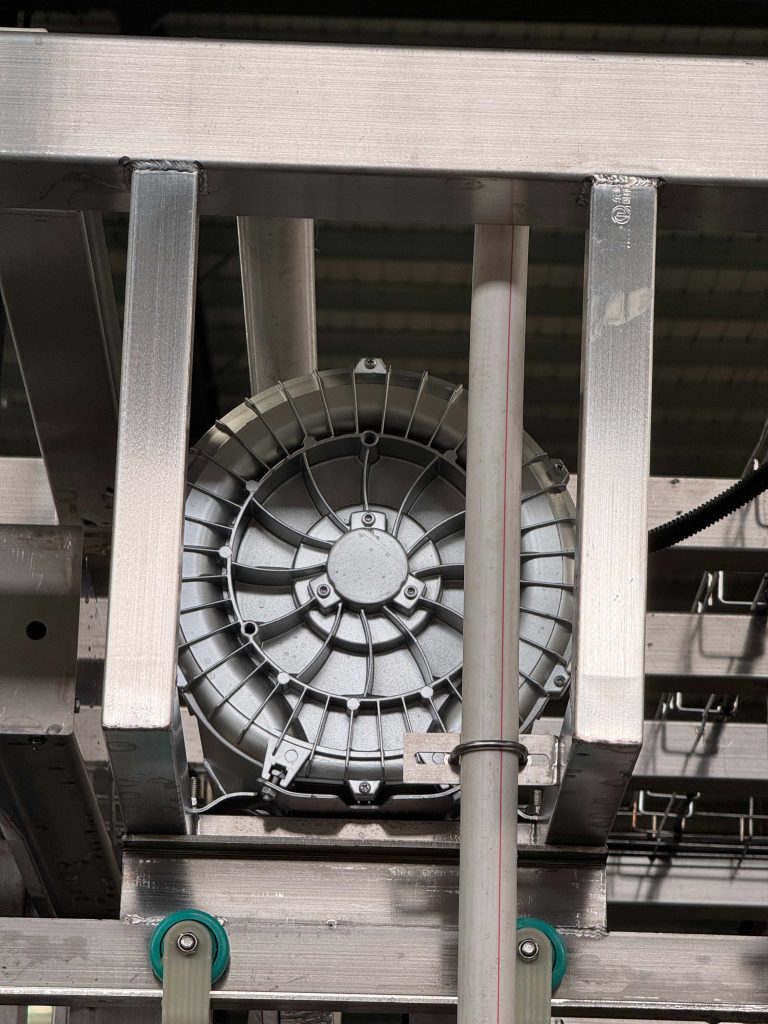

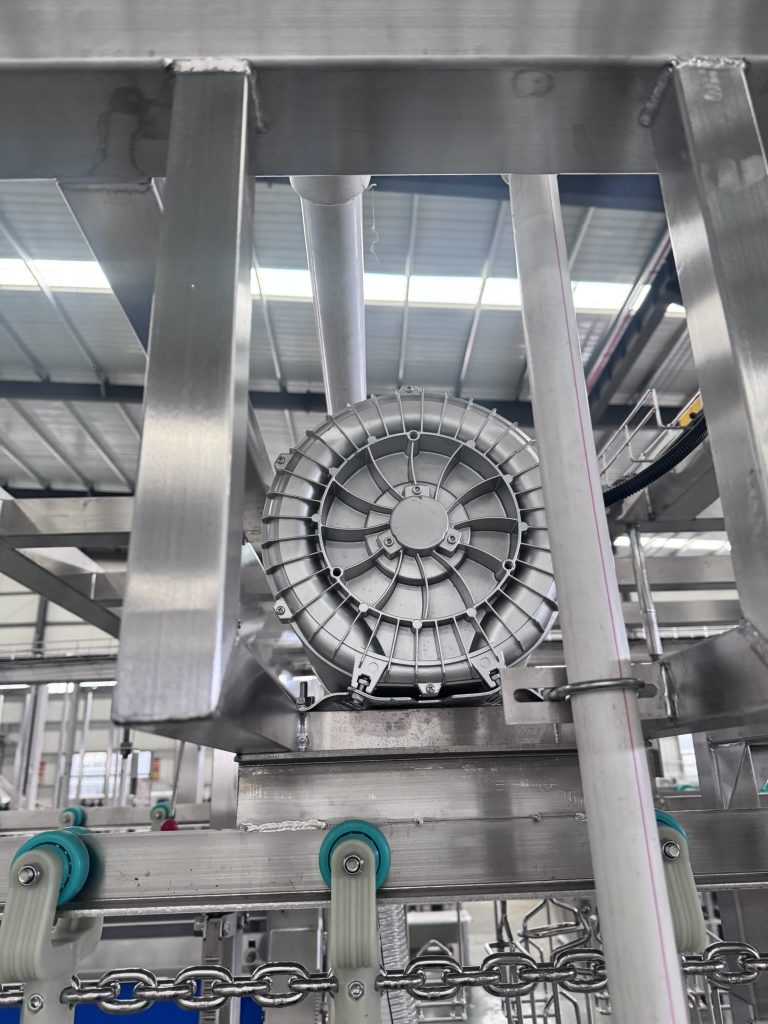

- High Reliability, Low Failure Rate

- The core power source utilizes industrial-grade, low-noise, wear-resistant blowers. Key pneumatic components are made of corrosion-resistant materials. With a simple and robust design, the system boasts an extremely long Mean Time Between Failures (MTBF), providing a solid guarantee for your 24/7 stable production.

Summary: Choosing Our Aeration System Means You Gain…

| Return on Investment | Concrete Manifestation |

|---|---|

| Higher Quality Products | Cleaner defeathering, intact skin, elevated hygiene standards—enhancing market competitiveness. |

| Lower Comprehensive Costs | Direct savings on water and electricity, reduced labor and equipment maintenance expenses. |

| A More Assured Production Experience | Drastically lower equipment failure rates, smoother production flow, easier management. |

| More Sustainable Development | Aligns with modern food processing requirements for energy efficiency, environmental protection, and high productivity. |

This aeration system is the result of our meticulous design, born from a profound understanding of slaughterhouse processes. While seemingly simple, it plays a pivotal “leveraging” role at the most critical junctures. We sincerely invite you to visit our facility to witness firsthand how it can deliver tangible quality improvements and profit growth for your production line.

Summary: Choosing Our Compact Slaughter Line Brings You Comprehensive Value Beyond Expectations

As exemplified by the meticulously designed aeration system—which is just one reflection of the pursuit of excellence throughout the entire compact slaughter line—we understand that investing in a production line is a major decision impacting development for years, even decades to come. Therefore, in every component, from core systems like the aeration system down to every detail, we apply the same rigorous approach to design and optimization. We ensure the delivery of not merely a collection of individual machines, but a complete solution that is efficient, reliable, and worry-free.

Investing in our compact slaughter line means you will gain:

| Investment Dimension | Specific Value Delivered | Long-Term Benefits for Your Operation |

|---|---|---|

| Exceptional Product Quality | Integrated line coordination ensures optimal processing conditions at every stage—from scalding and defeathering to cooling—resulting in carcasses with high integrity and superior hygiene standards. | Enhances market competitiveness, builds trust with high-end clients, and increases brand value. |

| Significant Comprehensive Cost Advantages | The entire line is designed for high efficiency and energy savings (e.g., 10-15% energy saving from the aeration system), integrated controls reduce labor, and modular design lowers maintenance costs. | Significantly reduces unit production costs, increases profit margins, and shortens the return on investment (ROI) period. |

| Worry-Free Production Assurance | Seamless connectivity between equipment ensures high stability (e.g., aeration system guarantees continuous operation), significantly reduces failure rates, and intelligent systems provide early warnings for potential issues. | Enforces strict adherence to production schedules, reduces management complexity, and eliminates worries about frequent downtime for repairs. |

| Future-Oriented Sustainable Development | The entire line complies with modern food industry standards for energy efficiency, environmental protection, and high productivity, supporting future technical upgrades and capacity adjustments, protecting your long-term investment. | Easily meets increasingly stringent environmental regulations and provides flexibility for future business expansion and technological upgrades. |

This compact slaughter line is the result of our deep understanding of processing technology, infused into every detail. We sincerely invite you for an on-site inspection—not only to see the standalone aeration system but to experience how the systematic, precision engineering of the entire production line delivers tangible quality leaps and substantial profit growth for your operation.

COMPACT POULTRY SLAUGHTER LINE

VIEW DETAILED MODEL INFORMATION FOR THE COMPACT POULTRY SLAUGHTER LINE.