1. Introduction

The compact poultry slaughter line is an efficient solution specifically designed for small-scale slaughterhouses, suitable for processing 300-800 broiler chickens per hour. This production line features a modular design, offering benefits such as installation-free operation, compact structure, and user-friendly operation. Constructed entirely from food-grade 304 stainless steel, it ensures hygiene and durability. This report, based on relevant technical documentation, provides a detailed analysis of its technical specifications, equipment configuration, advantages, and operational maintenance guidelines, serving as a comprehensive reference for potential users.

2. Product Overview

The compact poultry slaughter line is a complete processing line covering the entire process from live bird hanging to finished product packaging. Key stages include stunning, slaughter, bleeding, scalding, plucking, evisceration, head and foot cutting, pre-chilling, and packaging. The line utilizes an integrated frame design, assembled and debugged at the factory. Upon arrival at the user’s site, it only requires connection to water and electricity to begin operation, significantly reducing the time to production. This equipment is particularly suitable for locations with limited space or little installation experience, such as small slaughter units or start-up enterprises.

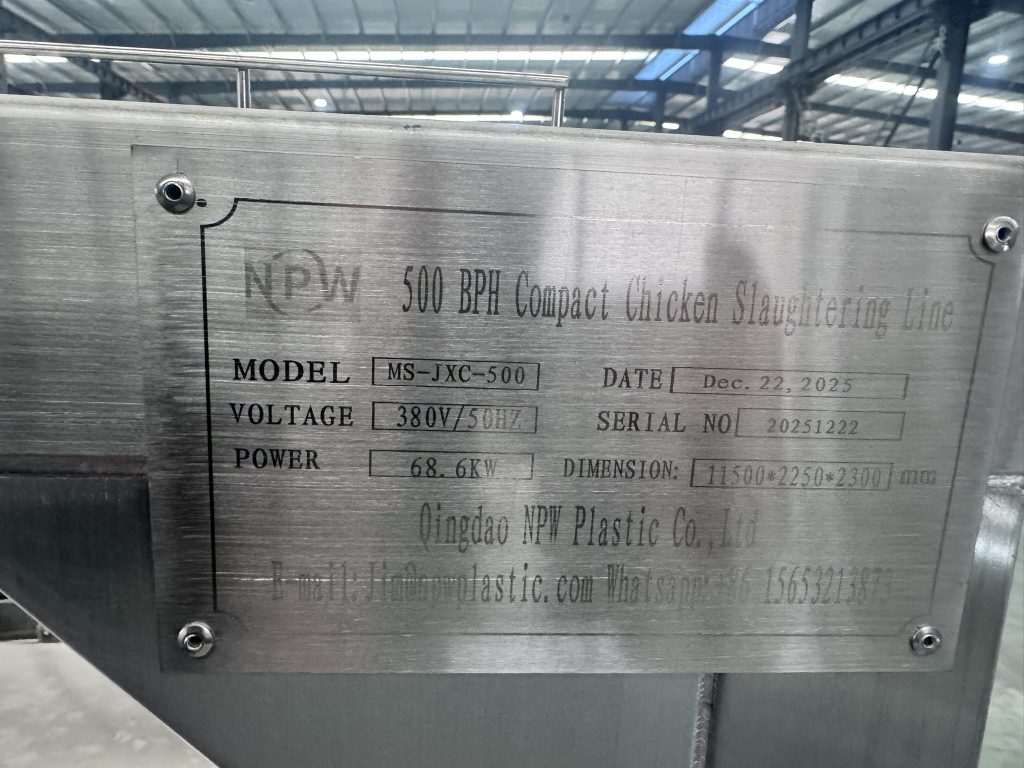

3. Technical Specifications

3.1 Basic Parameters

- Processing Object: Broiler Chicken

- Live Bird Weight Range: 1.8-2.5 kg

- Processing Capacity: 300-800 birds per hour (BPH), standard configuration based on 500 BPH

- Power Supply Requirement: 380V/3P/50Hz three-phase power (can be customized according to voltage standards of different countries)

- Total Power: Approximately 68.4 kW (including heating, transmission, and other systems)

- Rated Current: 140 A

- Equipment Dimensions: Length 11500 mm × Width 2250 mm × Height 2300 mm

- Recommended Workshop Area: Not less than Length 20 m × Width 8 m (approximately 160 m²)

3.2 Key Process Parameters

- Bleeding Time: 4-5 minutes (adjustable, compliant with Halal certification requirements)

- Scalding Time: Approximately 90 seconds

- Scalding Temperature: 52-61°C (electric heating with automatic temperature control, supports modification to steam boiler)

- Transmission System: Overhead conveyor pitch 203.2 mm, adjustable line speed (standard speed 2.58 m/min)

- Pre-chilling Method: Water bath chilling, requires customer to provide 0-4°C cold water

4. Equipment Detailed Description

The production line consists of several core modules, each optimized for specific process stages:

- Overhead Conveying Line: Serves as the core transmission component, using stainless steel chains and guide rails. Hook spacing is 8 inches, with a total of 200 hooks. Equipped with drive motor (diameter 485 mm, power 1.5 kW), frequency converter, tensioning device, and guide wheels to ensure smooth operation.

- Chicken Hanging Table: Made of stainless steel, dimensions 1300×630×500 mm, height customizable based on operator height, used for placing crates and facilitating bird hanging.

- Bleeding Chute: Stainless steel structure for blood collection. Bleeding time is adjustable to meet Halal slaughter certification standards.

- Scalding Machine: Stainless steel tank, dimensions 4300×500×2200 mm, equipped with automatic temperature and water level control systems. Electric heating power 54 kW (includes three 15 kW heaters and a 9 kW blower), supports rapid heating (reaches set temperature within 30 minutes).

- Vertical Plucking Machine: Adjustable frame accommodates different bird sizes, equipped with 6 sets of motors and 60 plucking plates, ensuring thorough feather removal without damaging the carcass.

- Evisceration Chute: Includes water inlet faucet for temporary storage and transport of viscera.

- Automatic Head/Foot Cutting Machines: Include foot cutter and head puller, using precision chucks for improved processing efficiency.

- Water Pre-cooling Tank: Dimensions 3800×630×800 mm, used for carcass washing and cooling.

- Electric Control System: Centralized control box integrates frequency converter, temperature controller, and safety protection devices for one-touch operation.

Auxiliary accessories include a cutting machine, packing cones, visceral tools, transfer cages (15 units), plucking rubbers (300 rods), and spare chains (5 meters), ensuring sustainable daily operation.

5. Design Features and Advantage Analysis

5.1 Technical Advantages

- Installation-Free Design: Equipment is fully assembled, debugged, and tested at the factory. Upon delivery, only water and electricity connections are needed for operation, saving 90% installation time and enabling commissioning within 3 days.

- Modularity and Customizability: Layout can be customized according to customer site conditions, and functions can be added or removed (e.g., removing stunner for Halal compliance). Bleeding time adjustable to 3 minutes 5 seconds to comply with certification standards.

- High Efficiency and Energy Saving: Frequency conversion control system optimizes energy consumption. Automatic temperature and water level management reduce resource waste. Electric heating system can be replaced by a steam boiler to lower energy consumption.

- Hygiene and Safety: 304 stainless steel material is rust and corrosion-resistant. The overall design complies with 6S management standards. Equipment includes emergency stop buttons and electric shock protection systems for operational safety.

- User-Friendly Operation: High degree of automation reduces manual labor intensity. Transmission system uses waterproof and noise-reducing bearings for extended service life.

5.2 Economic Efficiency and Applicability

- High Space Utilization: Compact layout suitable for small spaces, reducing infrastructure investment.

- Low Maintenance Requirements: Standardized components and spare accessories simplify maintenance. Daily cleaning requires only high-pressure water rinsing.

- Rapid Deployment: Production lead time is 25 working days, ensuring efficient order-to-delivery.

- Comprehensive Certifications: Certified with ISO9001 Quality Management System, ISO14001 Environmental Management System, CE, and SGS, ensuring quality and reliability.

6. Installation and Commissioning Guide

The equipment adopts a ‘plug-and-play’ model:

- Factory Pre-commissioning: All modules are integrated and tested before leaving the factory, including chain tension adjustment, heating system calibration, and safety function verification.

- Site Preparation: Customer needs to provide a stable water source (water pressure 0.2-0.5 MPa) and power supply (380V three-phase). No additional foundation is required.

- Startup Procedure: Sequentially activate the conveyor line, scalding machine blower, plucking machine, pre-chilling system, and stunning device. Monitor operating status via the electric control box.

7. Operation and Personnel Configuration

7.1 Standard Operating Procedure

- Start the scalding machine heating at least 1 hour in advance to reach the set temperature (e.g., 61°C).

- Slowly start the conveyor line to the required speed, observing chain tension.

- Activate each module equipment in sequence, ensuring seamless operation through bleeding, scalding, plucking, etc.

- After production, rinse all equipment with high-pressure water, focusing on cleaning the heating tubes to prevent scaling.

7.2 Recommended Personnel Configuration

Based on 500 BPH capacity, an 11-person team is recommended:

- Hanging: 1 person, responsible for hanging live birds onto the conveyor.

- Stunning & Slaughter: 1 person, operates stunning and bleeding equipment.

- Evisceration (Viscera Handling): 4 persons, division of labor for opening/venting, viscera removal, heart/liver/gizzard separation, and inspection.

- Washing & Chilling Tank Monitor: 1 person, manages pre-chiller water temperature, flow, and hygiene.

- Packaging: 2 persons, responsible for grading/sorting and vacuum packaging/weighing/labeling.

- Material Handling & Transport: 2 persons, coordinate raw material supply and finished product warehousing. It is recommended to assign 1 additional floater/utility worker for equipment inspection and backup support to ensure continuous line operation.

8. Maintenance and Troubleshooting

8.1 Regular Maintenance Schedule

- Daily: Rinse equipment with high-pressure water after operation, focusing on cleaning the scalding machine heating tubes.

- Weekly: Check chain tension, lubricate adjusting screws with engine oil.

- Monthly: Grease bearing chambers (2 ml per chamber), lubricate the rack and lifter of the vertical plucker with lithium-based grease (5 ml).

- Quarterly/Annually: Check rubber finger wear, assess operational status of motors and reducers.

8.2 Common Troubleshooting

| Fault Phenomenon | Cause Analysis | Solution |

| Pulley jump/freeze | Loose or elongated chain | Adjust tension or replace chain |

| Frequency converter overload | Bearing damage or reducer failure | Replace bearings or reducer |

| Red head, bruises | High stunner voltage or poor bleeding | Adjust stunner voltage |

| Feather removal not clean | Improper scalding temperature or worn rubber fingers | Adjust temperature or replace rubber fingers |

9. Certifications and After-Sales Service

- Quality Warranty: 12-month quality warranty (main framework), lifelong technical support.

- Documentation Support: Free provision of operation manuals, layout diagrams, installation videos, and detailed guides.

- Global Service: Coverage in over 30 countries, 7×24 hours online technical team support.

- Continuous Improvement: Based on 16 years of industry experience, equipment is continuously optimized to adapt to diverse needs.

10. Conclusion

The compact poultry slaughter line, with its innovative design, high efficiency, and ease of use, is an ideal choice for small-scale slaughterhouses. Its installation-free, customizable modules, and comprehensive certifications ensure investment security and return. Through standardized operation and low maintenance requirements, users can quickly achieve scaled production and enhance market competitiveness. For further customization or technical details, it is recommended to contact the supplier for a tailored solution.

Display of Optional Spiral Pre-Cooling and Cleaning Machine for By-Products such as Chicken Viscera and Chicken Feet

COMPACT POULTRY SLAUGHTER LINE

VIEW DETAILED MODEL INFORMATION FOR THE COMPACT POULTRY SLAUGHTER LINE.