Stainless Steel Hooking and Slaughtering Hooks

This series of hooks is specially designed for modern poultry slaughtering lines, serving as a key basic component that connects the conveying chain with poultry carcasses and ensures the continuous and stable operation of the production line.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Product Introduction: Stainless Steel Hooks for Poultry Slaughter Line

I. Product Overview

This series of hooks is specifically designed for modern poultry slaughtering Production Line, serving as a critical component that connects the conveyor chain to the bird carcass, ensuring the continuous and stable operation of the production line. The product strictly adheres to food industry hygiene standards, featuring high load-bearing capacity, strong corrosion resistance, and excellent durability. It is widely applicable for the automated slaughtering and processing of various poultry, including chickens, ducks, geese, rabbits, pigeons, and quails.

II. Core Specifications

To meet different production requirements, this series offers two mainstream stainless steel material options, with their core parameters compared as follows:

| Parameter | 201 Stainless Steel Hook | 304 Stainless Steel Hook | Notes |

|---|---|---|---|

| Compatible Chain Size | 8# (Standard) | 8# (Standard) | Perfectly matches the industry-standard 8号 conveyor chain, ensuring smooth connection and uninterrupted operation. |

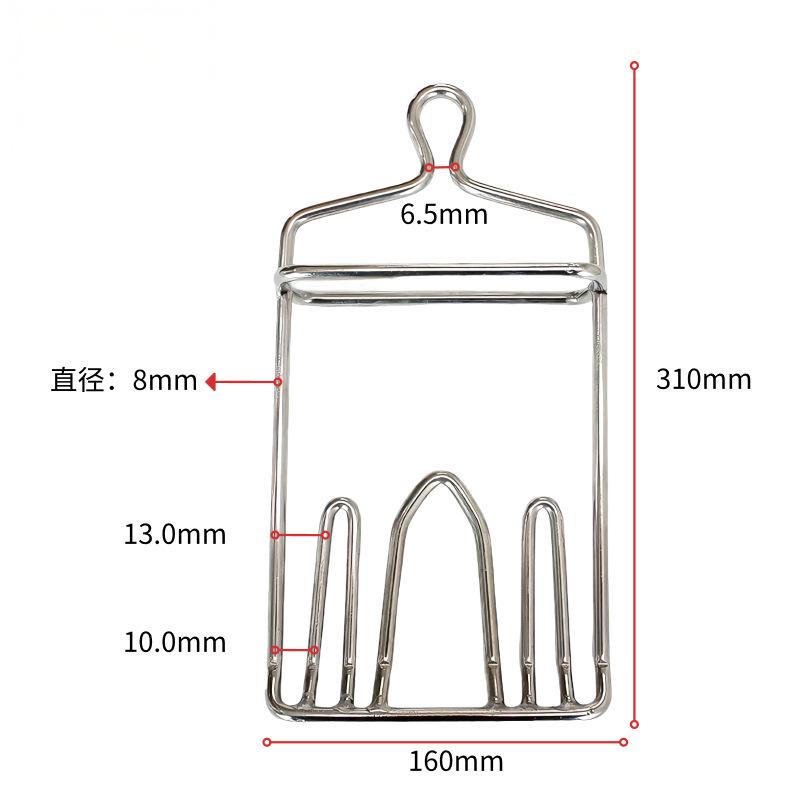

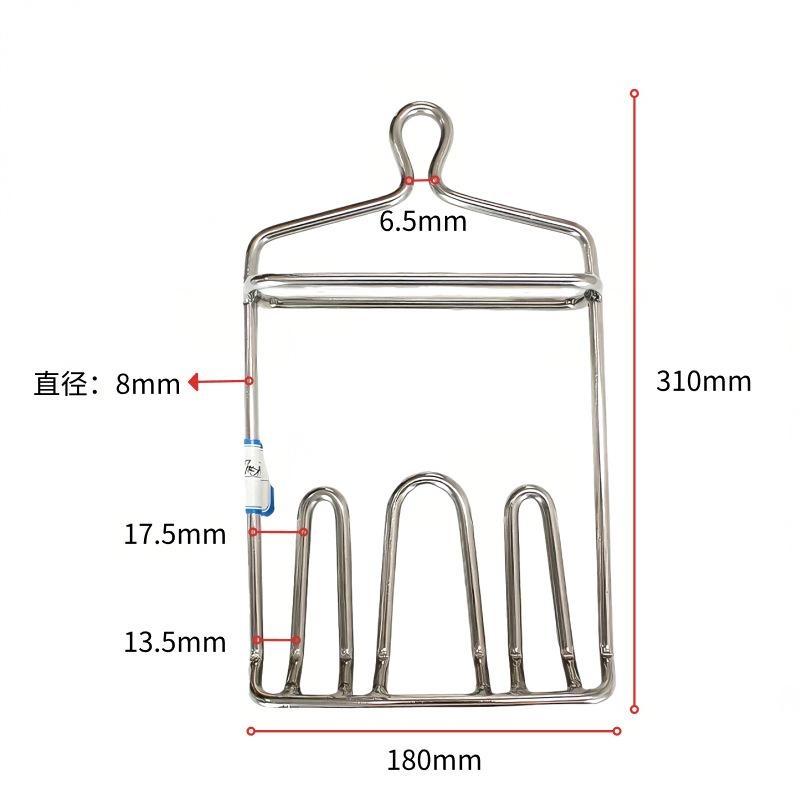

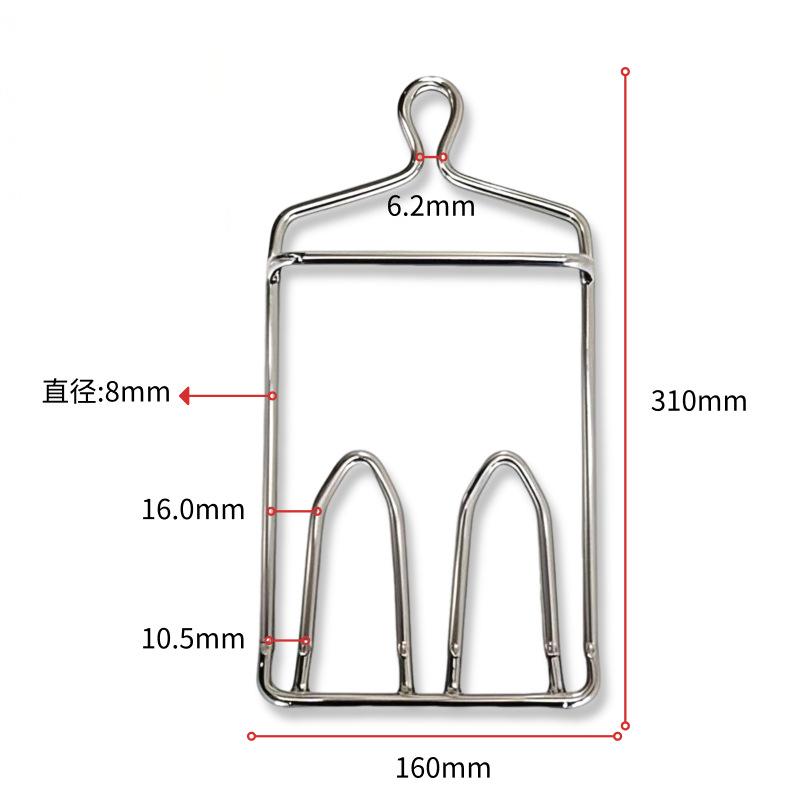

| Hook Shank Diameter | 8mm | 8mm | Provides balanced structural strength and durability, considering both load capacity and lightweight needs. |

| Rated Breaking Force | ≥ 8kN | ≥ 8kN | Possesses outstanding mechanical strength; single-hook load capacity far exceeds the weight of common poultry, effectively preventing breakage during operation. |

| Primary Application Scope | Chickens, Ducks, Rabbits, Pigeons, Quails, etc. | Chickens, Ducks, Geese, Rabbits, Pigeons, Quails, etc. | The universal design meets the needs of most poultry slaughtering. The 304 material is particularly suitable for larger birds (like geese) or high-humidity environments. |

| Surface Characteristics | High strength, moderate corrosion resistance | High strength, exceptional corrosion and oxidation resistance | 304 stainless steel demonstrates a longer service life when consistently exposed to corrosive media such as water, blood, and cleaning agents. |

| Recommended Environment | Standard slaughter environments with moderate humidity and corrosiveness | High-humidity, high-corrosiveness environments, or lines with higher requirements for equipment lifespan and food safety | Selection should be based on budget, cleaning frequency, and production standards. |

| Economic Positioning | Cost-effective choice | Choice for long-term durability and high standards | 201 material meets basic performance needs; 304 material offers lower maintenance costs over extended use. |

DETAILED LIST OF HOOK ACCESSORIES FOR POULTRY SLAUGHTERING LINES

.jpg)

45° FEATHERED CHICKEN HOOK 8MM (MATERIAL S201)

.jpg)

45° FEATHERED CHICKEN HOOK 8MM (MATERIAL S304)

.jpg)

45° FEATHERED DUCK HOOK 8MM (MATERIAL S201)

.jpg)

45° FEATHERED DUCK HOOK 8MM (MATERIAL S304)

.jpg)

45° FEATHERED GOOSE HOOK 8MM (MATERIAL S201)

.jpg)

45° FEATHERED GOOSE HOOK 8MM (MATERIAL S304)

.jpg)

90° FEATHERED CHICKEN HOOK 8MM (MATERIAL S201)

.jpg)

90° FEATHERED CHICKEN HOOK 8MM (MATERIAL S304)

.jpg)

90° FEATHERED DUCK HOOK 8MM (MATERIAL S201)

.jpg)

90° FEATHERED DUCK HOOK 8MM (MATERIAL S304)

.jpg)

DUAL-PURPOSE CHICKEN AND DUCK HOOK 8MM (MATERIAL S201)

.jpg)

DUAL-PURPOSE CHICKEN AND DUCK HOOK 8MM (MATERIAL S304)

.jpg)

ANTI-CLAW BREAKAGE FEATHERED CHICKEN HOOK 8MM (MATERIAL S201)

.jpg)

ANTI-CLAW BREAKAGE FEATHERED CHICKEN HOOK 8MM (MATERIAL S304)

.jpg)

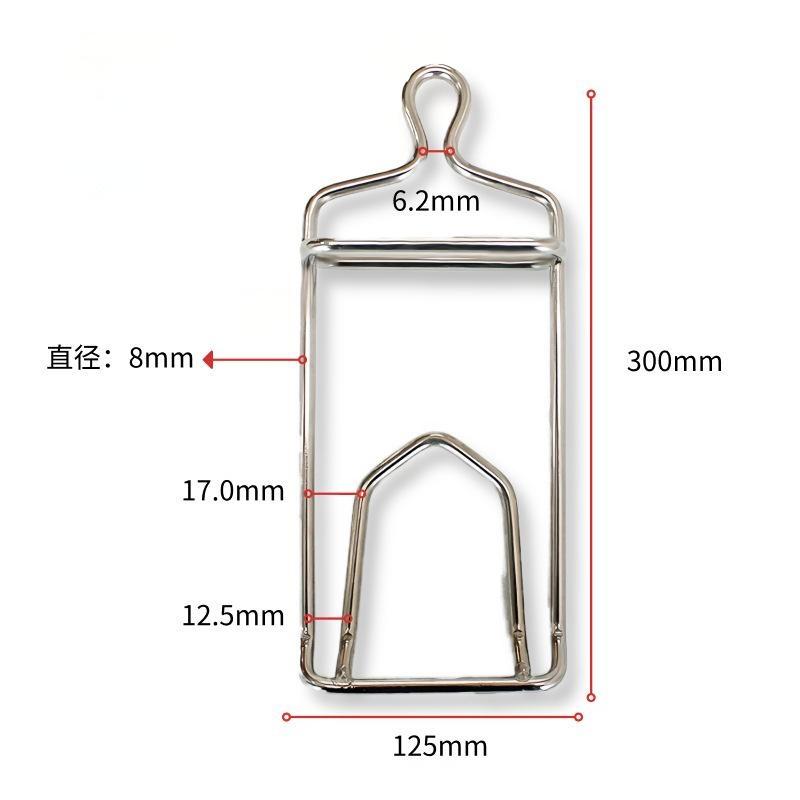

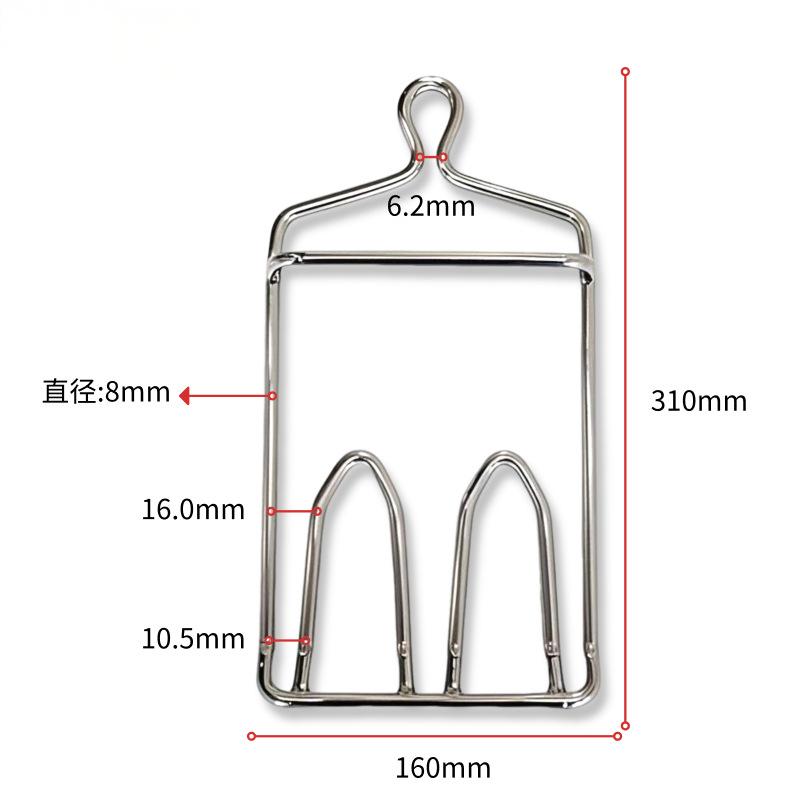

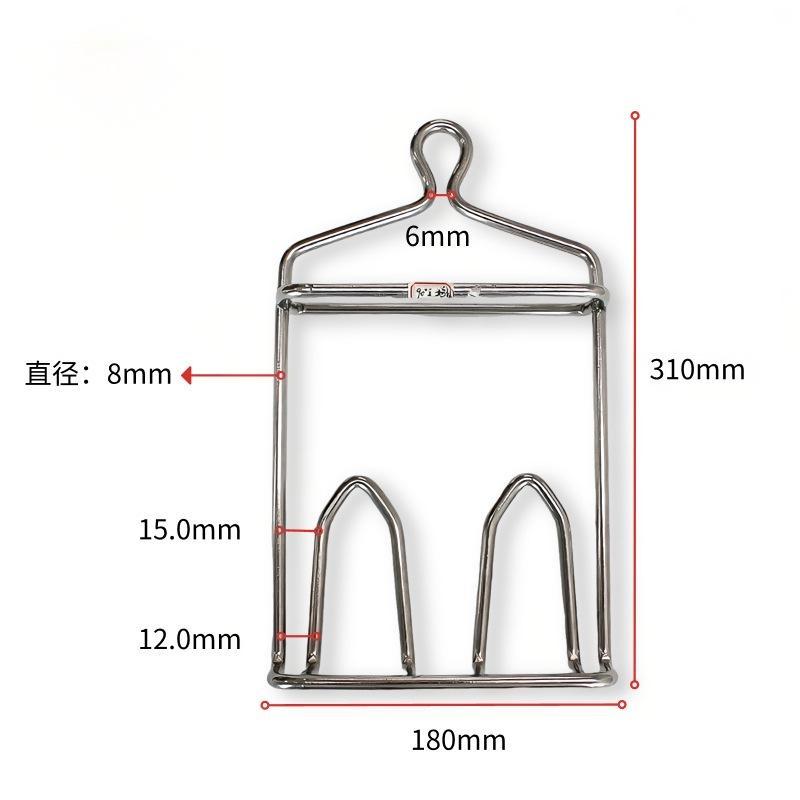

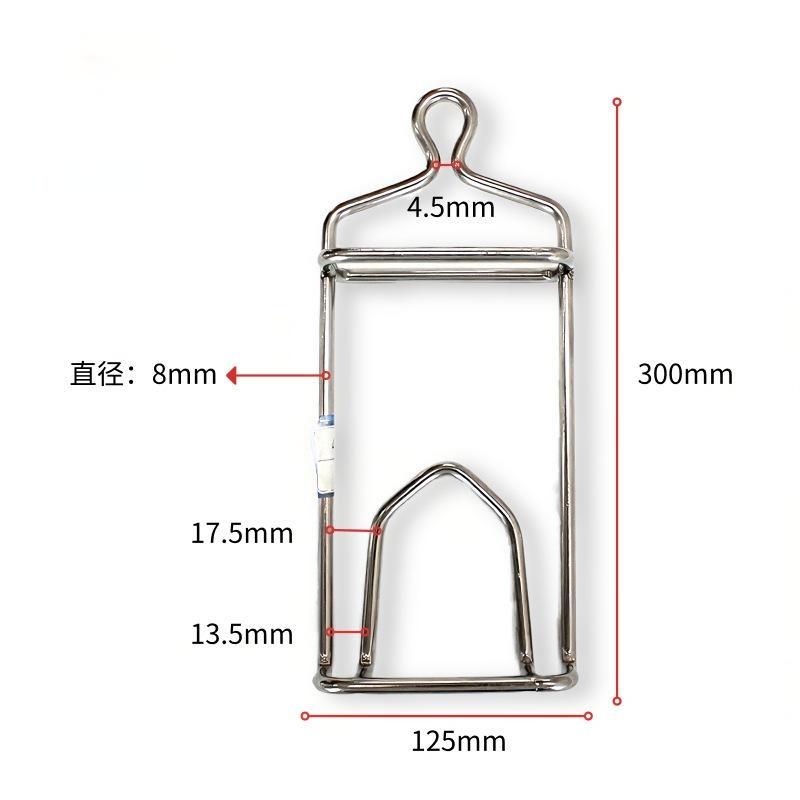

SINGLE ROTATION LANTERN HOOK 8MM (MATERIAL S201)

.jpg)

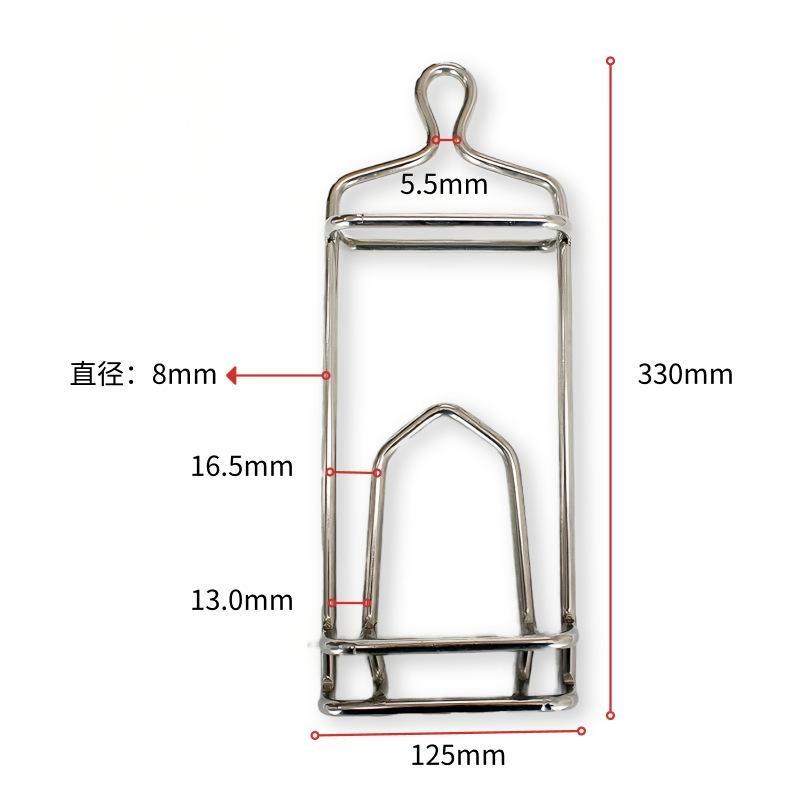

SINGLE ROTATION LANTERN HOOK 8MM (MATERIAL S304)

.jpg)

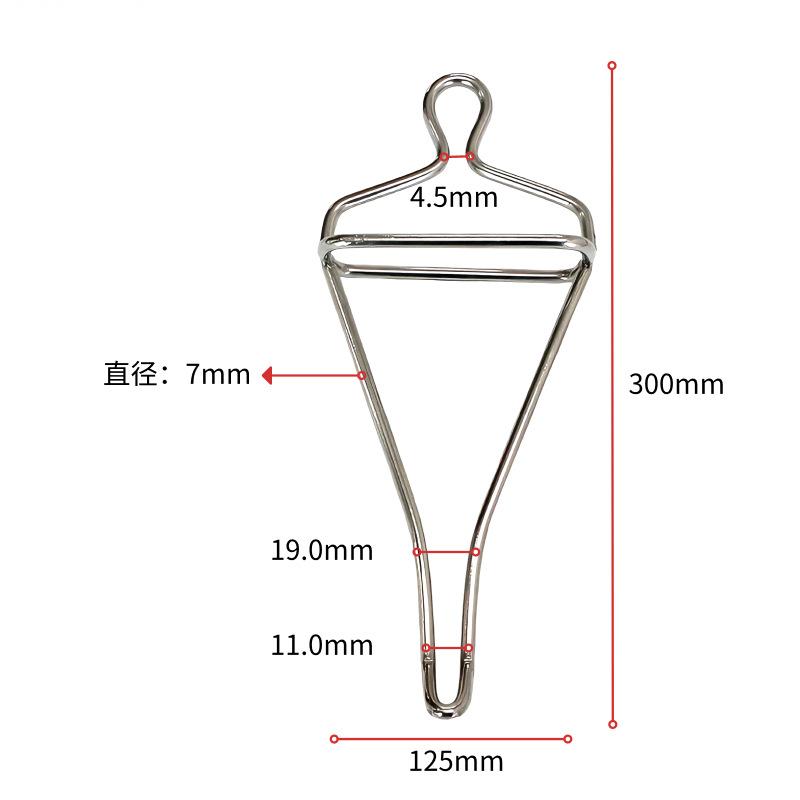

NECK-HANGING LANTERN HOOK 7MM (MATERIAL S201)

.jpg)

NECK-HANGING LANTERN HOOK 7MM (MATERIAL S304)

.jpg)

WING-HANGING LANTERN HOOK 7MM (MATERIAL S201)

.jpg)

WING-HANGING LANTERN HOOK 7MM (MATERIAL S304)

.jpg)

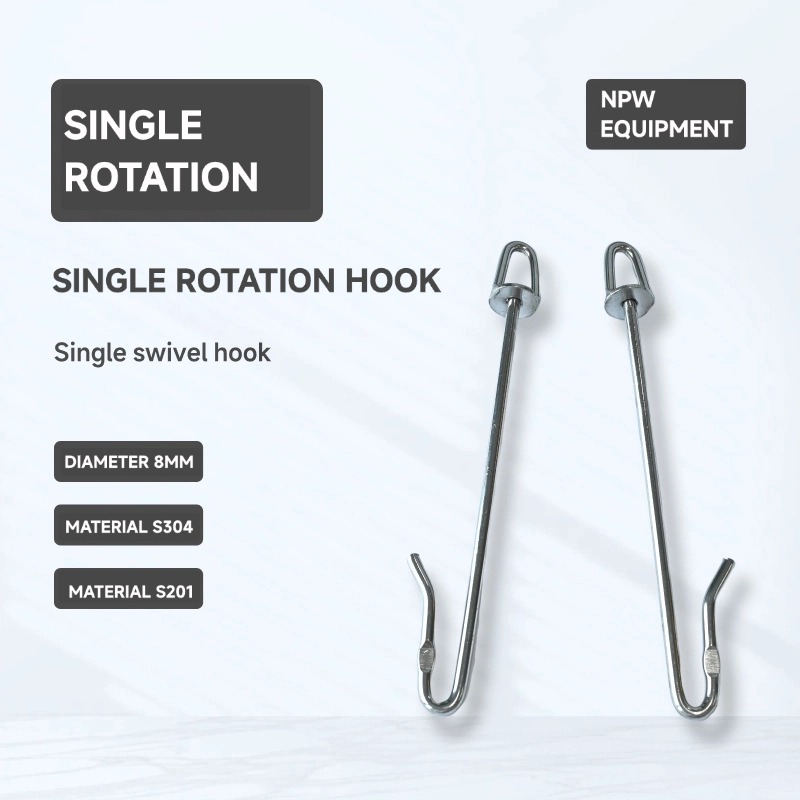

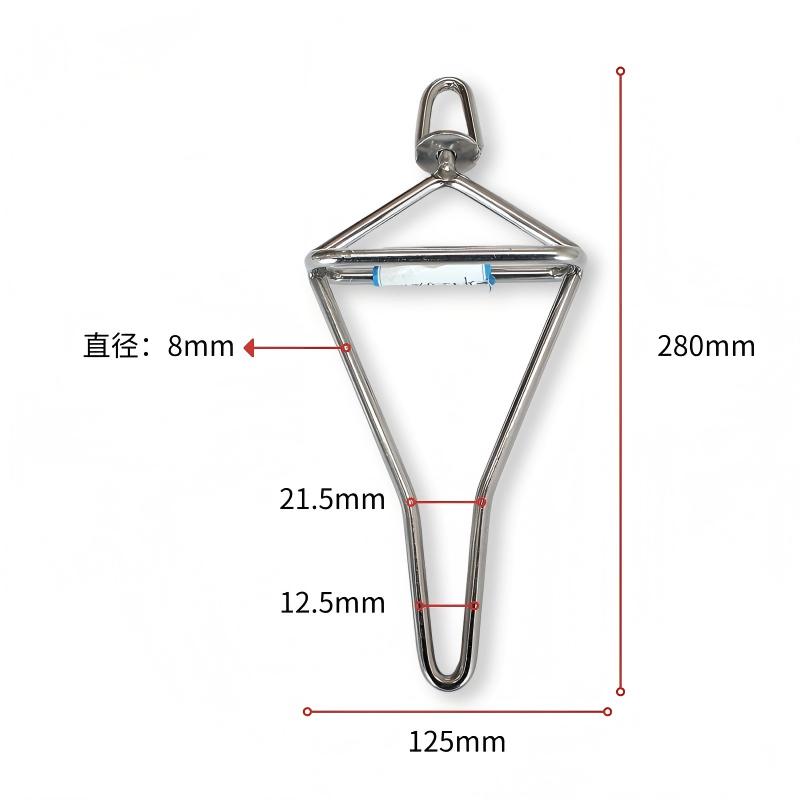

SINGLE ROTATION HOOK 8MM (MATERIAL S201)

.jpg)

SINGLE ROTATION HOOK 8MM (MATERIAL S304)

.jpg)

45° PIGEON HOOK 6MM (MATERIAL S201)

-1.jpg)

45° PIGEON HOOK 6MM (MATERIAL S304)

III. Core Product Advantages

- Safe, Reliable, and Rugged

- Manufactured using an integral forming process for a stable structure. With a breaking force ≥ 8kN, it ensures no breakage occurs during high-speed operation or under sudden load, guaranteeing production safety and continuity.

- Precision Fit for Smooth Operation

- Specifically designed for 8# slaughter conveyor chains. The connecting part features precise tolerances for smooth hanging and unhooking, effectively reducing chain jams and wear, thereby lowering equipment failure rates.

- Universal Compatibility for All Poultry Types

- The unique design accommodates various bird sizes, from quails to geese. There is no need to frequently change hooks for different poultry types, simplifying equipment management and spare parts inventory.

- Hygienic, Easy to Clean, and Compliant

- Both materials provide a smooth surface finish with no sanitary dead angles. They withstand repeated washing with high-pressure hot water and food-grade disinfectants, are easy to keep clean, and comply with food safety management system requirements like HACCP.

IV. Selection and Procurement Advice

- For Pursuing Ultimate Cost-Effectiveness in Standard Conditions: The 201 Stainless Steel Hook is recommended. It performs reliably in conventional chicken and duck slaughter lines and is an ideal choice for controlling initial investment costs.

- For Emphasizing Long-Term Asset Value in Demanding Environments: The 304 Stainless Steel Hook is highly recommended. Its superior corrosion resistance makes it especially suitable for processing waterfowl, frequently used modern Production Line, or factories targeting exports or facing strict audits. It significantly reduces replacement frequency due to rust, offering better long-term economics.

As a “standard joint” for slaughter lines, this product is available in sufficient stock, and customized services can be provided. Please feel free to inquire for procurement based on your production line planning.