Poultry Carcass Auxiliary Cutting Workstation

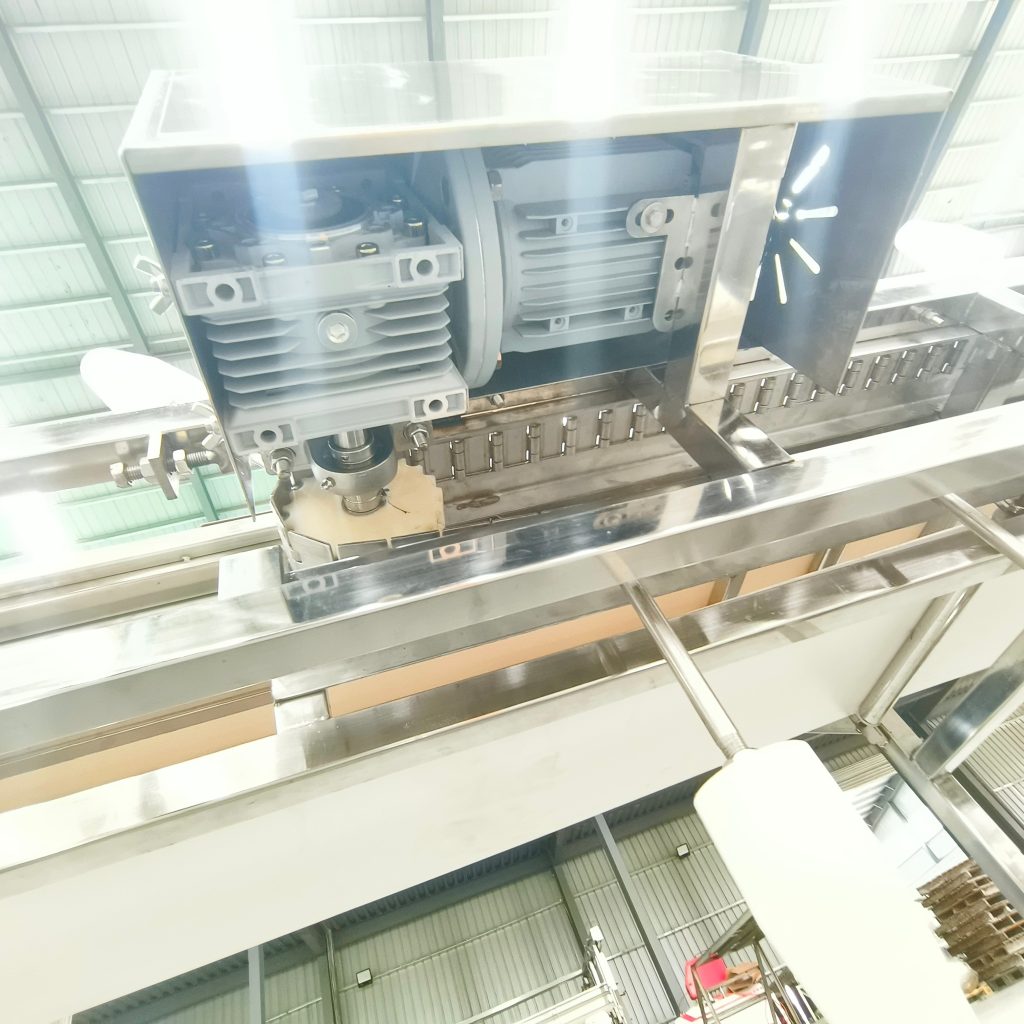

This machine is mainly composed of a frame, splitting cones, a conveyor chain, support rails, pressure plates, a reducer, and other components. The conveyor chain has a pitch of 38.1 mm, with one splitting cone installed every 8 links. The splitting cones are mounted on top of the conveyor chain and move along with it.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Product Name: Poultry Carcass Cone-Style Stacking Segmentation Line

I. Product Overview

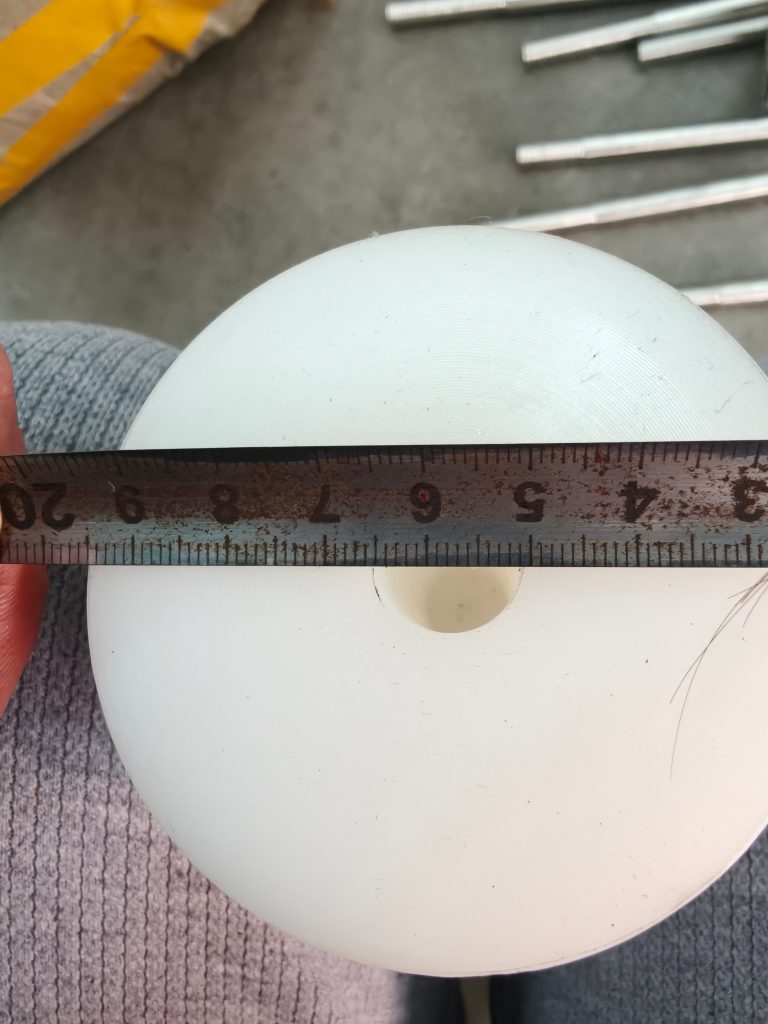

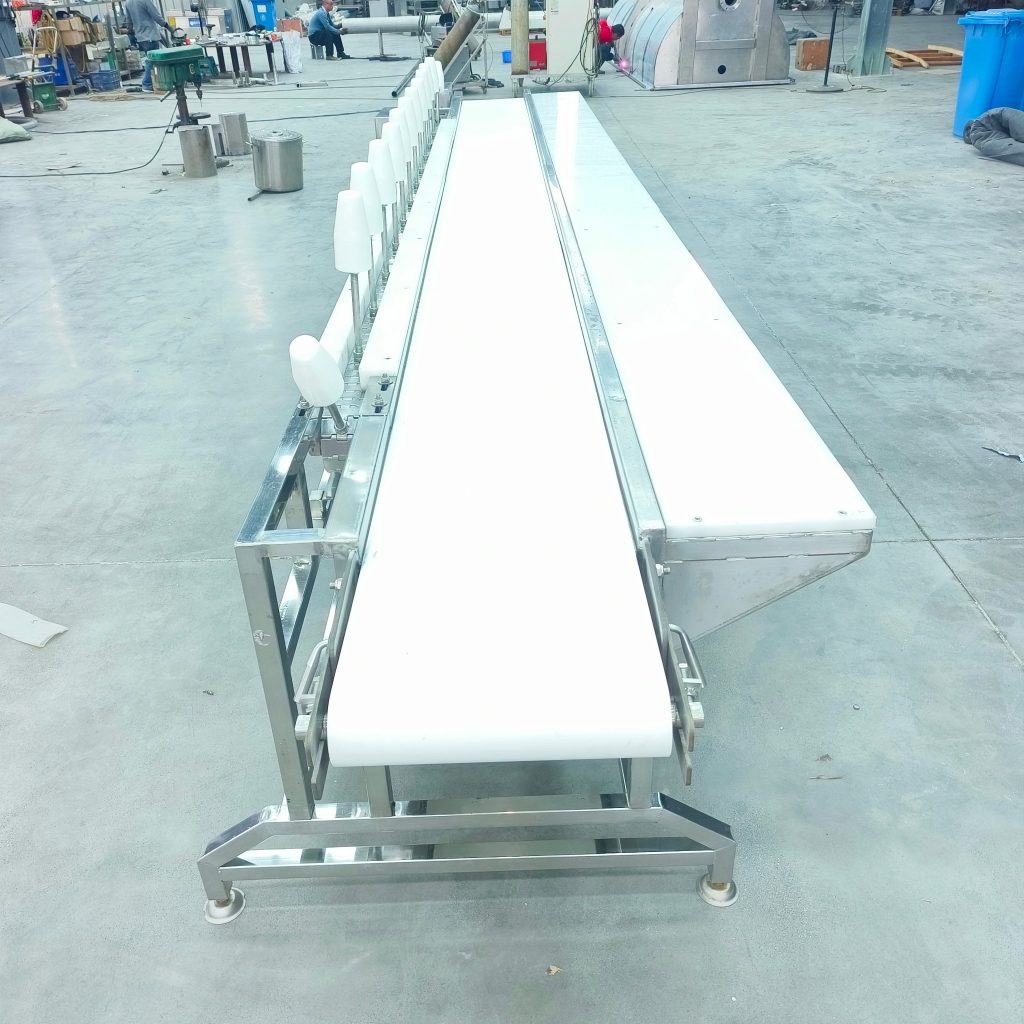

This equipment is an innovative fixed assembly line worktable for poultry carcass segmentation, featuring a “cone-style stacking” design. It is a human-machine collaborative auxiliary workstation specially designed for poultry slaughtering and cutting processes.Unlike traditional hanging methods, this system directly upright inserts chicken, duck, goose, and other poultry carcasses onto nylon segmentation cones at fixed workstations, creating a stable, adjustable “stacked” posture. The carcasses move with the conveying system, passing sequentially through each workstation, where operators perform efficient and precise segmentation on the immobilized carcasses. The equipment supports full customization, with a standard model size of Length 5000 × Width 705 × Height 1200 mm. It is a revolutionary solution for achieving standardized, assembly-line segmentation operations.

II. Design Structure and Working Principle

- Core Structure:

- Frame and Tabletop: Constructed from high-strength 304 stainless steel profiles, integrating a sturdy work surface that is corrosion-resistant and easy to clean.

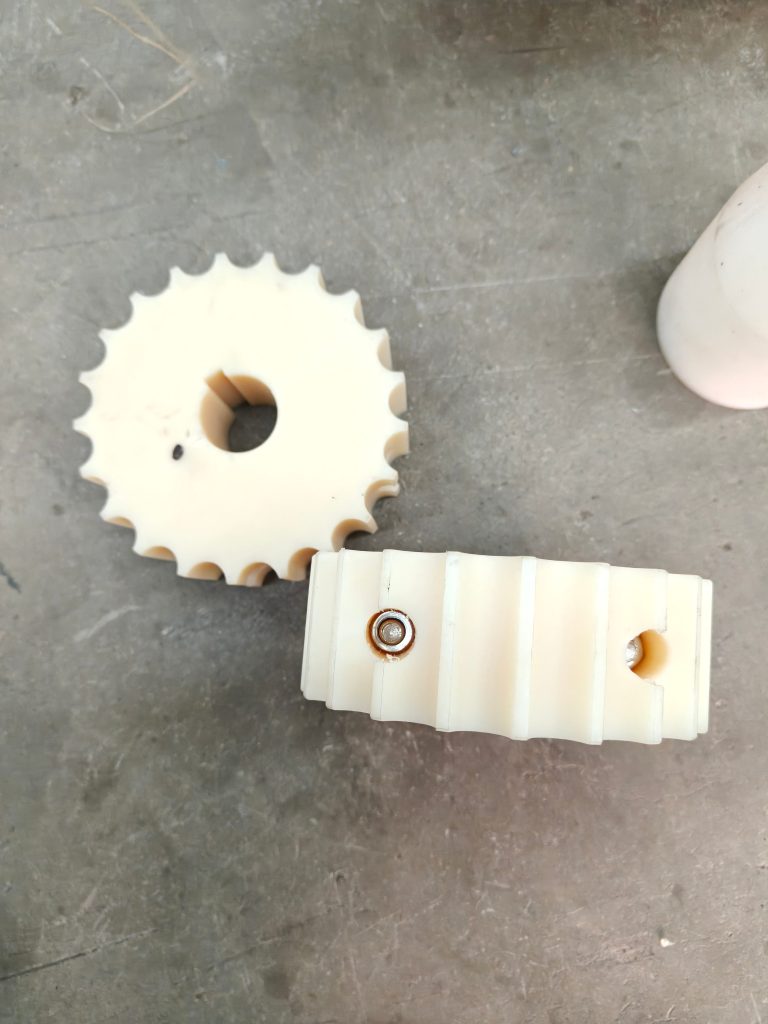

- Segmentation Cone Array: The core fixing component. Cones are precision-cast from food-grade nylon and installed at fixed intervals on the conveyor chain’s carrier plates. The cone design is for directly receiving and supporting the carcass pelvis or thoracic cavity, maintaining an upright working posture.

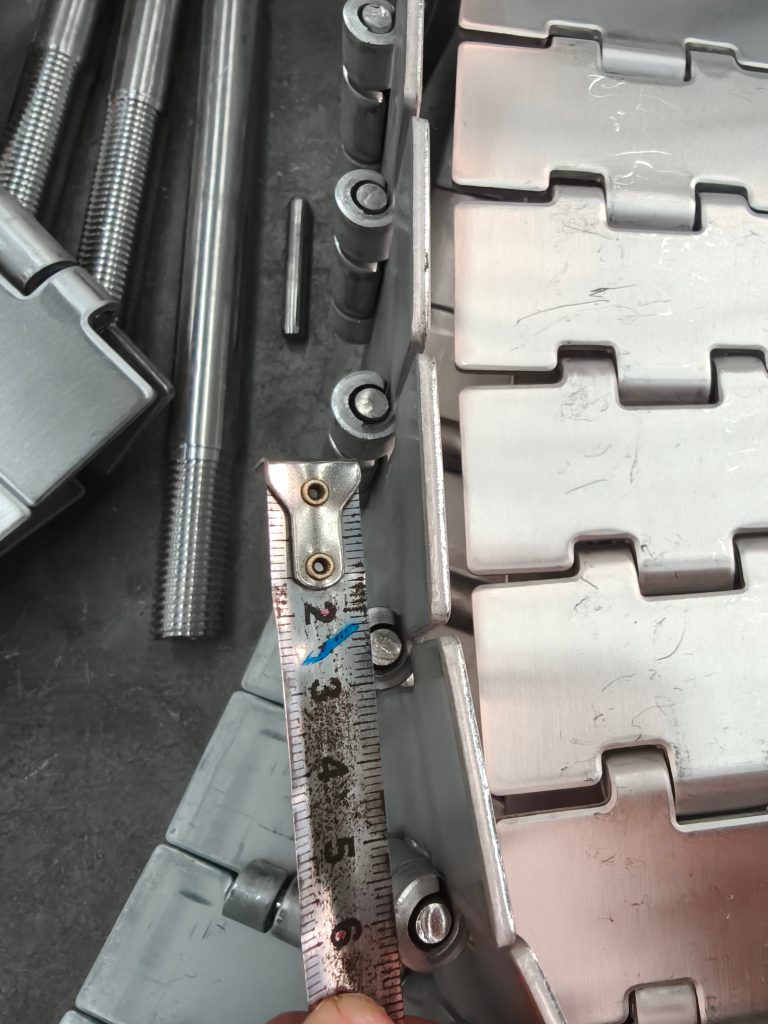

- Conveyor Chain System: Stainless steel conveyor chain with a 38.1 mm pitch. The segmentation cones are mounted on the chain plates (or carrier plates) and move intermittently or continuously with the chain.

- Drive and Speed Control System: Equipped with a 1.5 kW geared motor and a frequency converter (VFD) for power transmission and stepless speed regulation, allowing precise control of the production line cycle time.

- Support and Guidance System: Includes stainless steel support rails and side guide wheels to ensure smooth, stable, and wobble-free movement of the carrier plates and cones, guaranteeing segmentation accuracy.

- Working Principle:

Operators upright insert pre-processed poultry carcasses (e.g., after evisceration and washing) onto the segmentation cones at a stationary or slowly moving loading station, securing them. The carcasses then advance uniformly with the conveying system, passing sequentially by each fixed segmentation workstation along the line. Each operator specializes in one or a few segmentation actions (e.g., cutting wings, removing legs, extracting breast meat) performed on the stable, “stacked” carcass in front of them. The conveying speed is flexibly adjustable via the frequency converter to match the team’s work pace, enabling true assembly-line segmentation production.

Video Principle Demonstration

III. Technical Specifications

| Item | Parameter / Specification |

|---|---|

| Standard Equipment Dimensions | 5000 (L) × 705 (W) × 1200 (H) mm |

| Customization Info | Length, width, height, workstation spacing, and number of cones can be non-standard customized based on customer capacity and workshop layout. |

| Equipment Power | 1.5 kW |

| Speed Control Method | Variable Frequency Drive (VFD), Stepless Speed Regulation |

| Conveyor Chain Pitch | 38.1 mm |

| Segmentation Cone Configuration | Fixed spacing installation on carrier plates (density and layout customizable) |

| Material Specification | All main components are 304 stainless steel, except for the food-grade nylon segmentation cones. |

| Suitable Poultry Types | Common poultry carcasses like chicken, duck, goose (adaptable with different cone sizes) |

| Operation Posture | Carcass upright insertion, not hanging. |

Accessories Details Display of Poultry Slaughter & Cutting Collaborative Workstation

Support Rail

Conveyor Chain

Splitting Cone

Transmission Gear

Conveyor Chain

Link Shaft

Support Rail Disc

Support Rail

IV. Core Product Advantages

- Revolutionary Fixing Method: The “cone-style stacking” design provides upright, stable carcass fixation, completely freeing the operator’s hands to focus on segmentation, estimated to improve efficiency by 30%-50% compared to traditional hanging methods.

- Ergonomic Optimization: Worktable height is adjustable (custom option), positioning the carcass at the most comfortable posture and height for operation, significantly reducing worker back and waist strain.

- Enhanced Safety and Precision: No carcass wobble greatly reduces knife slippage risk, allows for more precise cutting, ensures high product consistency, and significantly lowers injury rates.

- Hygiene and Cleanability: All-stainless-steel main body, no complex overhead hangers, smooth tabletop with no dead angles, making cleaning and disinfection extremely easy.

- Flexible Customization & High Compatibility: Fully customizable from dimensions and workstation count to operating speed. Easily integrates with upstream and downstream processes, adaptable to production needs of any scale.

- Strong Cycle Time Control: VFD speed control allows precise adjustment of line speed based on the team’s overall proficiency, achieving optimal production capacity balance.

V. Application Scenarios

- Modern Slaughterhouses pursuing high efficiency and low labor strain: Replaces traditional hanging segmentation lines, achieving dual improvement in capacity and worker welfare.

- Further processing plants producing high-value cut products (e.g., chicken fillets, duck breast): Stable carcass posture ensures high cutting precision and yield.

- Central kitchens and standardized prepared food factories: Guarantees absolute uniformity in cut specifications across different batches.

- Upgrading existing production lines: Can directly replace old segmentation table sections, enhancing automation and standardization at that stage.

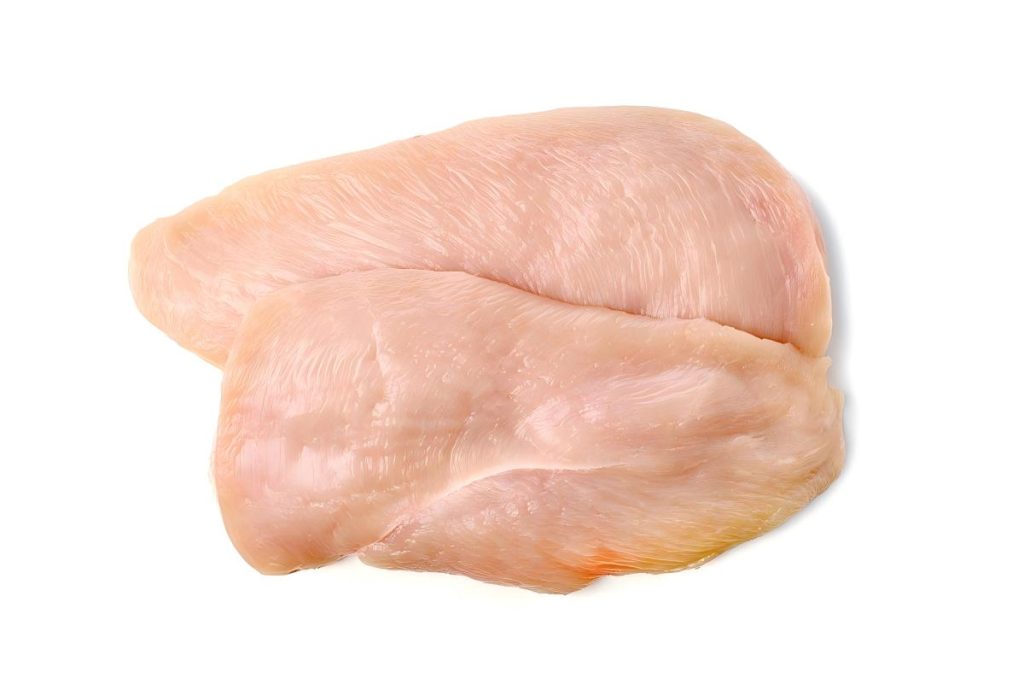

Broiler Products from the Auxiliary Manual Cutting System

Whole Chicken Wings

Chicken Necks

Chicken Breast

Chicken Thighs

Chicken Drumsticks

Customer Usage Scenarios

VI. Selection and Customization Service

We provide in-depth customization to ensure the equipment perfectly fits your process:

- Dimension and Layout Customization: Tailor equipment length, width, height, and workstation arrangement based on workshop floor space and assembly line planning.

- Capacity and Cycle Time Customization: Match your target daily/hourly throughput by adjusting the number of workstations, their spacing, and line speed.

- Functional Module Customization: Optional integrated wastewater collection trough, pneumatic-assisted cutting tool holders, automatic carcass loading mechanism (feeding assist), finished product automatic unloading chute, etc.

- Process Adaptation Customization: Optimize workstation sequence and tool configuration based on your specific segmentation process (e.g., leg removal first or breast first).

The cutting workstation can be customized according to requirements.

VII. Conclusion

This “Cone-Style Stacking Segmentation Line” represents a major innovation in traditional poultry segmentation methods. By upright fixing and inserting the carcass, it addresses inherent issues of traditional hanging methods such as poor stability, efficiency bottlenecks, and high labor intensity. While providing a standard, high-efficiency solution, the equipment boasts comprehensive customization capabilities. It is a key piece of equipment for poultry processing enterprises striving for higher efficiency, superior quality, and more humane management.