——Integrated with 3000 BPH Automated Slaughtering Line and Environmental Support Systems

1 Project Overview

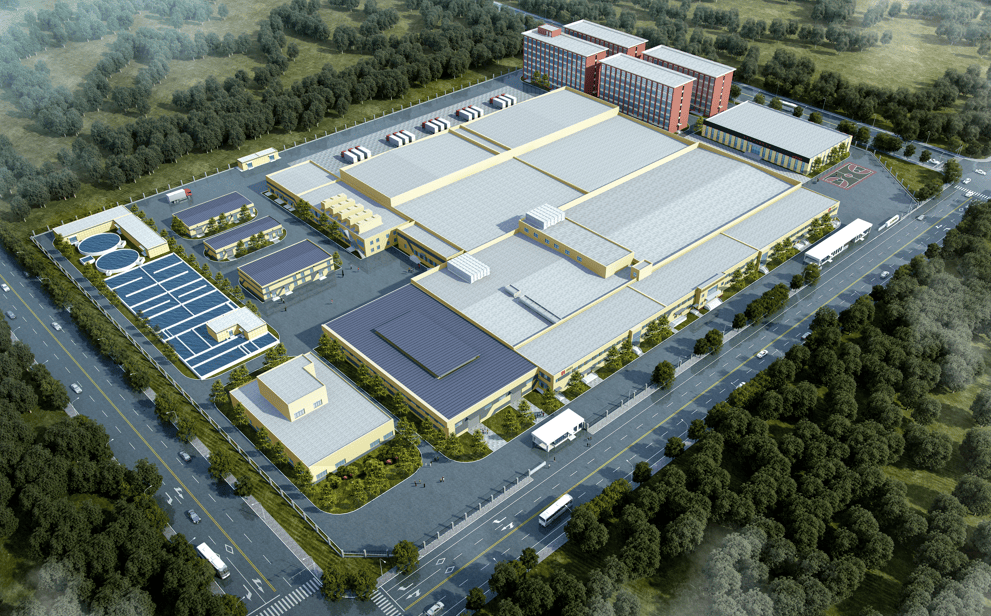

This solution, designed by Qingdao NPW Plastic Co., Ltd., features a fully automated broiler slaughtering line with a capacity of 3000 birds per hour. It is tailored for the efficient, hygienic, and standardized processing of whitefeathered broilers. The entire line adopts modular design, utilizes foodgrade stainless steel construction, and integrates automated control systems. It aims to establish a poultry processing base in Gabon that meets international hygiene standards with high output and low energy consumption.

2 Poultry Market Opportunity and Project Economic Analysis in Gabon

2.1 Market Opportunities

Rapid Demand Growth: Accelerated urbanization in Gabon and increasing consumer demand for highquality animal protein present significant market potential for poultry meat as a costeffective protein source.

Import Substitution Potential: The Gabonese market currently relies partly on imported poultry meat. Localized production can reduce logistics costs, ensure supply stability, and benefit from local policy support.

Industrial Upgrade Opportunity: Introducing modern, highhygienestandard slaughtering and processing systems can propel Gabon’s poultry industry from primary farming to highvalueadded processing, aligning with national agricultural product processing development strategies. The Gabonese government has announced a ban on chicken imports effective January 2027 to promote food selfsufficiency. This policy will significantly impact future market supply and price dynamics.

2.2 Output Value Estimation (Based on 3000 BPH Production Line)

Daily Production: Operating on a 20hour work schedule, daily processing capacity is 60,000 broilers (3000 birds/hour × 20 hours).

Average Carcass Weight: Based on an average live broiler weight of 2.5 kg and a 75% dressing yield, the average carcass weight is approximately 1.875 kg.

Daily Carcass Meat Output: 60,000 birds × 1.875 kg = 112,500 kg (112.5 tons).

Monthly Output Value Estimation (based on 25 production days):

Monthly Carcass Meat Output: 112.5 tons/day × 25 days = 2,812.5 tons.

Note: Actual output value can be further increased based on the proportion of further processing (e.g., breast, leg quarters, wings).

3 Technical Advantages and Process Role of Core Slaughter Line Equipment

3.1 Stunning and Bleeding System

Components: Stunning Machine, Bleeding Trough

Technical Advantages:

The stunning machine features a 304 stainless steel frame, a fiberglass water tank, and a manual voltage regulator, ensuring humane stunning that meets animal welfare standards.

The bleeding trough is a onepiece 304 stainless steel structure (7200×2400×800mm) with a sloped design for efficient blood collection, maintaining a clean work area.

Process Role: Humane stunning improves meat quality; thorough bleeding ensures good meat color and shelf life, laying the foundation for subsequent processes.

3.2 Scalding and Defeathering System

Components: Scalding Machine, Automatic Temperature Control System, Rough/Fine Defeathering Machines

Technical Advantages:

The scalding machine uses a Ushaped structure with internal water circulation and steam heating, allowing precise scalding time control (90 seconds) for uniform feather loosening.

Both the rough defeatherer (40wheel) and fine defeatherer (72wheel) feature split designs with multiple 2.2KW motors, achieving high feather removal rates with minimal damage to the carcass.

Process Role: Thoroughly removes feathers, maintains intact and smooth skin, enhancing product appearance grade.

3.3 Head/Foot Processing and Hook Cleaning

Components: Automatic Head Cutter, Automatic Foot Cutter, Detaching Device, Hook Cleaning Machine

Technical Advantages:

Head and foot cutters use stainless steel bodies and specialized blades for clean cuts and reduced product loss.

The hook cleaning machine features highpressure spray jets and dualmotor drive to automatically remove residues, preventing crosscontamination.

Process Role: Automates head and foot separation, maintains line hygiene, and reduces manual cleaning labor.

3.4 Precooling System

Components: Spiral Precooler, Variable Frequency Drive (VFD) Control System, Independent Power Distribution Box

Technical Advantages:

The precooling tank is made of 304 stainless steel, featuring multiple largecapacity spiral precoolers with an effective length of 5000mm and a water recirculation system for fast cooling and water conservation.

VFD control allows adjustment of water flow and rotation speed to adapt to seasonal water temperature variations.

Process Role: Rapidly reduces carcass core temperature below 4°C, inhibiting bacterial growth and extending shelf life.

3.5 Cutting and Packaging Section

Components: Chicken Cutting Machine, Automatic Vacuum Packaging Machine

Technical Advantages:

The cutting machine has a stainless steel structure (1.1KW power) suitable for standardized cutting of parts like legs, wings, and breasts.

The vacuum packaging machine uses a rolling vacuum chamber with a vacuum degree ≤1.0kPa, offering high sealing strength suitable for frozen and chilled packaging.

Process Role: Increases product added value, enables portioned packaging to meet diverse market demands.

3.6 Drive and Control System

Components: Main Drive Unit, Tensioning Device, Support Wheel Sets, Frequency Converter, Main Power Distribution Box

Technical Advantages:

The drive system uses national standard motors and stainless steel gears for smooth, lownoise operation.

The distribution box is equipped with Chint electrical components, is waterproof and dustproof, and supports multicircuit independent control.

Process Role: Ensures synchronized and stable operation of the entire line, enabling sectionspecific speed adjustment and energy consumption management.

4 Design and Value of Supporting Integrated Facilities

To ensure efficient operation of the slaughter line and achieve environmentally sustainable development, this project design includes the following key supporting facilities:

4.1 Cold Storage System (5day production buffer, max storage 560 tons)

Design Capacity: Designed for approximately 560 tons (5 days’ output), including Blast Freezers (35°C) and Refrigerated Storage (18°C).

Core Value:

Ensures stable product storage and regulates market supply, avoiding price fluctuation risks.

Meets precooling requirements for export transport, expanding sales radius to neighboring countries.

Provides raw material buffer for subsequent deep processing (e.g., further processed cooked products).

4.2 Wastewater Treatment System (300 tons/day, meeting agricultural irrigation standards)

Treatment Process: Utilizes a combined process of “Screening + Flotation + Anaerobic + Aerobic + Advanced Disinfection”.

Core Value:

Treats 300 tons of slaughterhouse wastewater daily, with effluent meeting Gabon’s agricultural irrigation water standards, allowing direct reuse for site landscaping or surrounding farmland irrigation, achieving water resource recycling.

Significantly reduces environmental compliance risks, builds a responsible corporate image, and aligns with ESG requirements of international financing institutions.

Treated sludge can be used as raw material for organic fertilizer, creating additional revenue.

4.3 Waste Incineration System (For slaughter byproducts)

Treatment Objects: Feathers, inedible viscera, dead birds, and other solid waste.

Technical Features: Employs hightemperature pyrolysis incinerators with flue gas treatment for compliant emissions.

Core Value:

Achieves complete harmless treatment and volume reduction of waste (volume reduction rate >90%), eliminating sanitation hazards.

Recovered heat energy from incineration can be reused for the scalding process or plant heating, lowering energy costs.

A key facility for establishing a biosafe slaughterhouse, protecting the surrounding environment.

5 Summary of Complete Line Design Advantages

- Fully Automated Process Integration: Automated transfer via stainless steel rails and chains from stunning to precooling reduces manual handling, enhancing operational continuity and hygiene.

- Modular and Flexible Layout: Adaptable to actual workshop dimensions, supporting future capacity expansion or process addition.

- Energy Saving and Environmental Protection: Utilizes VFD drive systems and waterrecirculating precooling design to effectively reduce electricity and water consumption.

- Compliance with International Food Safety Standards: Full line uses 304 stainless steel contact surfaces for easy cleaning and corrosion resistance, with automatic monitoring for key temperaturecontrolled steps.

- Turnkey Complete Solution: Provides integrated design, supply, and integration services from main slaughter equipment to cold storage and environmental systems, ensuring perfect synergy.

- Clear Investment Return: Based on the output value estimation, the project offers promising profitability, aiding investors in achieving a quick return.

- Environmental Sustainability: The wastewater treatment and incineration systems transform the slaughterhouse from a “pollution source” into a resource recycling center, aligning with global green industry trends.

- Technological Localization Adaptation: All designs fully consider Gabon’s climate, power supply, water sources, and provide localized operational training.

6 Project Execution and Support

Delivery Lead Time: Production and delivery completed within 50 working days after receipt of the down payment.

Quality Warranty: Main structure of the entire line is covered by a 12month warranty; key motors and electrical components are covered by a repair warranty.

Technical Support: Provides installation guidance, operational training, and longterm technical consultation.

Packaging & Transportation: Uses standard export packaging suitable for longdistance sea freight, with assistance provided for container loading and customs declaration.

7 Conclusion

This solution, based on mature technology and highquality equipment, combined with market analysis and environmental support systems, aims to provide Gabon’s slaughterhouse project with a highefficiency, hygienic, reliable, and sustainable 3000 BPH broiler processing complete solution. We look forward to leveraging this production line to help elevate local poultry processing standards and market competitiveness, promoting the industrialization of agriculture and green industrial development in Gabon.

As operators of a medium-sized slaughterhouse in Gabon, we have been operating NPW’s broiler slaughtering line solution for over six months. What surprised us most was its compact, modular design, which perfectly adapted to our irregularly shaped factory space, achieving a stable capacity of 3,000 birds per hour within limited space—more than three times the efficiency of our previous system. In Gabon’s humid and hot climate, the equipment’s all-304 stainless steel construction and high-protection-level electrical control system withstood the test, with virtually no malfunctions due to corrosion or moisture. The production line achieves precise control at every stage, from stunning and defecation to pre-cooling. Our products have intact carcasses, clean skin and feathers, and stable core temperatures after pre-cooling, significantly extending shelf life and allowing us to successfully enter the local high-end fresh food and supermarket channels. Despite being an overseas customer, NPW engineers provided detailed on-site installation training and efficient remote support, giving us peace of mind during operations. This has been an investment that has provided exceptional value, completely transforming our production model and greatly enhancing our market competitiveness.

As a growing poultry processing company in Ethiopia, our investment in NPW’s broiler slaughtering line solution has been extremely successful. Previously, we were plagued by unreliable power supply, limited space, and a shortage of skilled maintenance personnel. NPW provided us with more than just equipment; they provided a reliable production system perfectly tailored to our local challenges.

The production line’s energy-efficient design is highly compatible with our power grid, and its compact layout is perfectly suited to our limited workshop space. More importantly, the use of corrosion-resistant stainless steel and high-protection electrical components throughout the line effectively withstands the impact of the local environment, ensuring continuous and stable production. The high level of automation has significantly reduced our reliance on skilled workers. After comprehensive training by NPW engineers, our local team is now proficient in operating and maintaining the entire line.

Since commissioning, our production capacity and product consistency have seen a qualitative leap. Clean and intact carcasses with excellent pre-cooling performance not only meet the needs of local high-end hotels and restaurants but also lay a solid foundation for our future expansion into neighboring countries. NPW’s solutions have truly helped us build a modern and sustainable competitive advantage in this high-potential market.