Introduction: A Professional Partner for Modernizing Africa’s Poultry Industry

NPW, a poultry slaughtering equipment manufacturer with 16 years of professional experience, has a deep understanding of the unique needs and challenges in the development of the poultry industry across African countries. Our comprehensive slaughterhouse solution, tailored for the African market, integrates innovative technology, localized adaptation, and full-lifecycle services, aiming to provide African clients with efficient, reliable, and economical modern poultry processing equipment support.

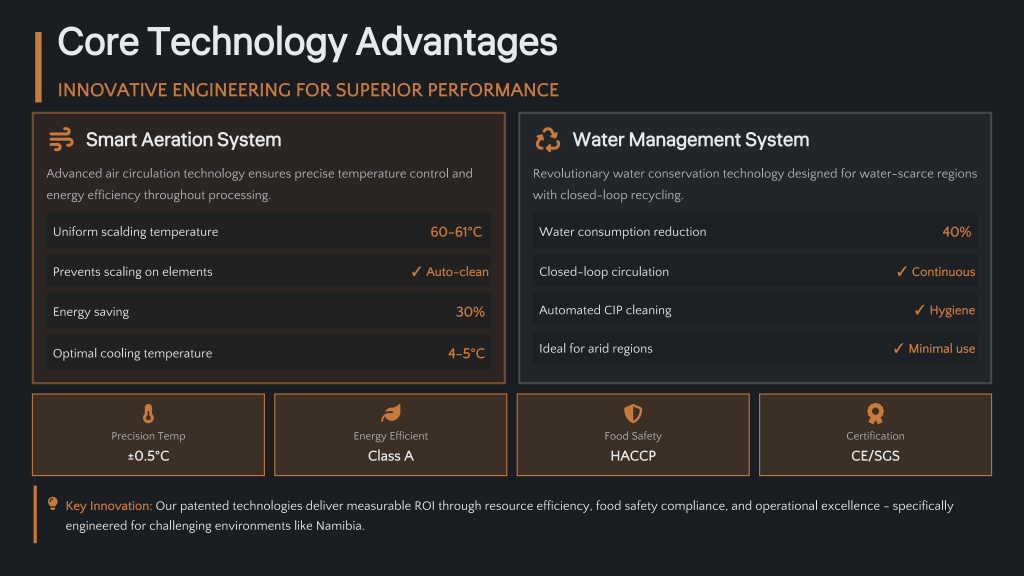

1. Core Technological Advantages: Tailored for African Conditions

Intelligent Aeration and Water Circulation System

- Utilizes patented aeration technology to ensure uniform and stable scalding temperature (60-63°C), adaptable to different poultry processing needs.

- Water-saving design increases water recycling efficiency by 40%, particularly suitable for water-scarce regions.

- Anti-corrosion stainless steel material withstands high temperature and humidity environments, extending equipment lifespan by 30%.

Diversified Energy Configuration

- Supports multiple heating methods (electricity, gas, oil), adapting to the current energy supply situation in various African regions.

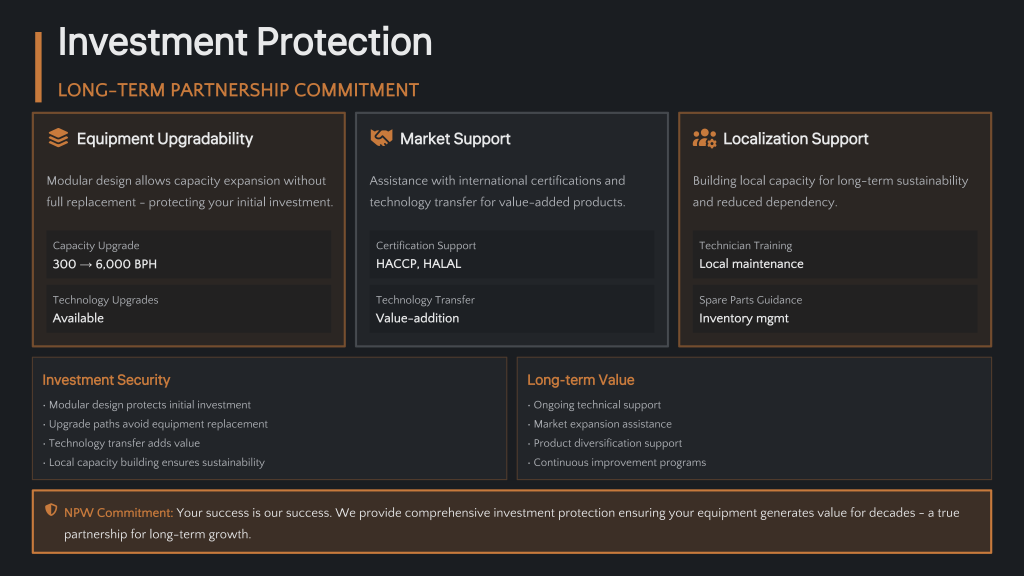

- Modular design allows for flexible expansion based on capacity needs, reducing initial investment by 35%.

- Intelligent temperature control system reduces energy consumption by 25-30% compared to traditional equipment.

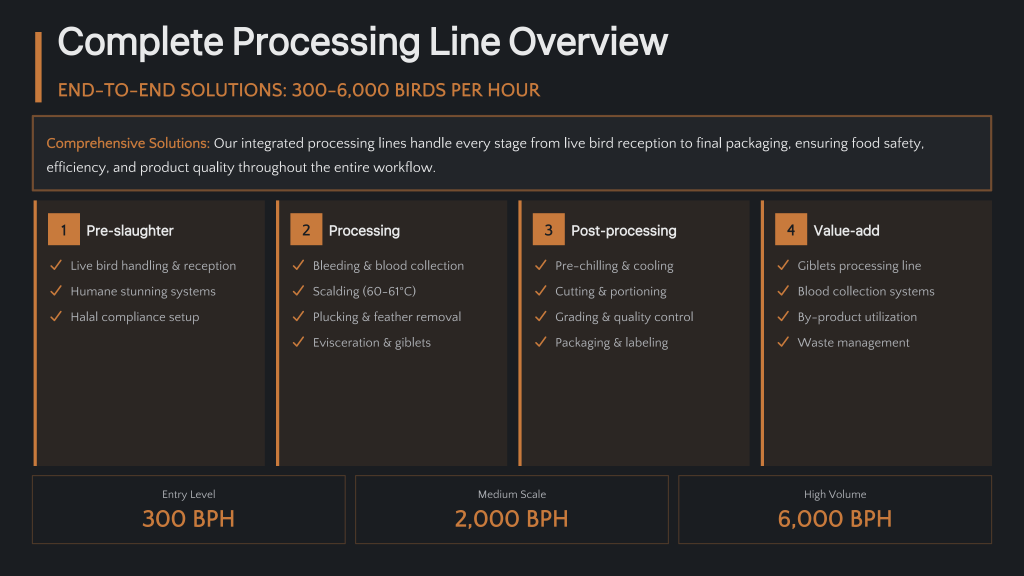

2. Complete Product Line Coverage: Meeting Needs of Different Scales

Compact Solution (500-2,000 birds/hour)

- Small footprint, quick installation, operational within 2 weeks.

- Suitable for small and medium-sized processors and farm-direct stores.

- Investment payback period of 12-18 months.

Medium-Scale Production Line (2,000-6,000 birds/hour)

- Modular design supports phased investment.

- Complies with EU and Middle East export standards.

- High degree of automation reduces labor costs by 50%.

Large Modern Slaughterhouse (6,000-12,000 birds/hour)

- Fully automated control enables digital management.

- Equipped with by-product deep processing equipment to enhance comprehensive benefits.

- Complete turnkey project services.

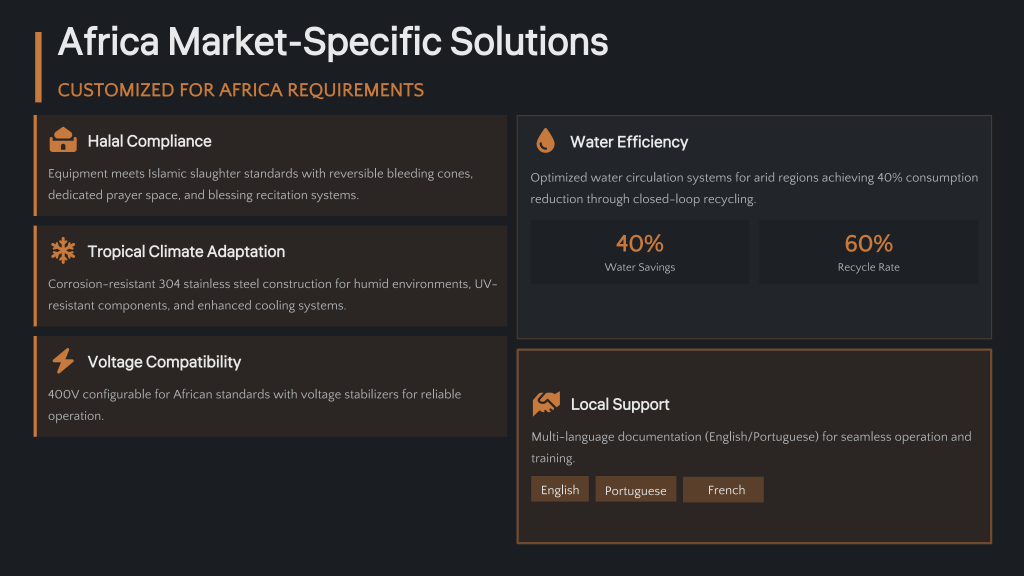

3. Specialized Design Adaptations for the African Market

Climate Adaptability

- Enhanced anti-rust treatment for high-salinity coastal areas.

- Efficient heat dissipation system ensures stable operation in high-temperature environments.

- Insect and dust proof design ensures a food-safe production environment.

Localized Service Support

- Provides technical documentation in multiple languages (English, French, Portuguese).

- Establishes local spare parts centers for 24-hour delivery of common parts.

- Biannual scheduled inspections for preventive maintenance ensuring continuous production.

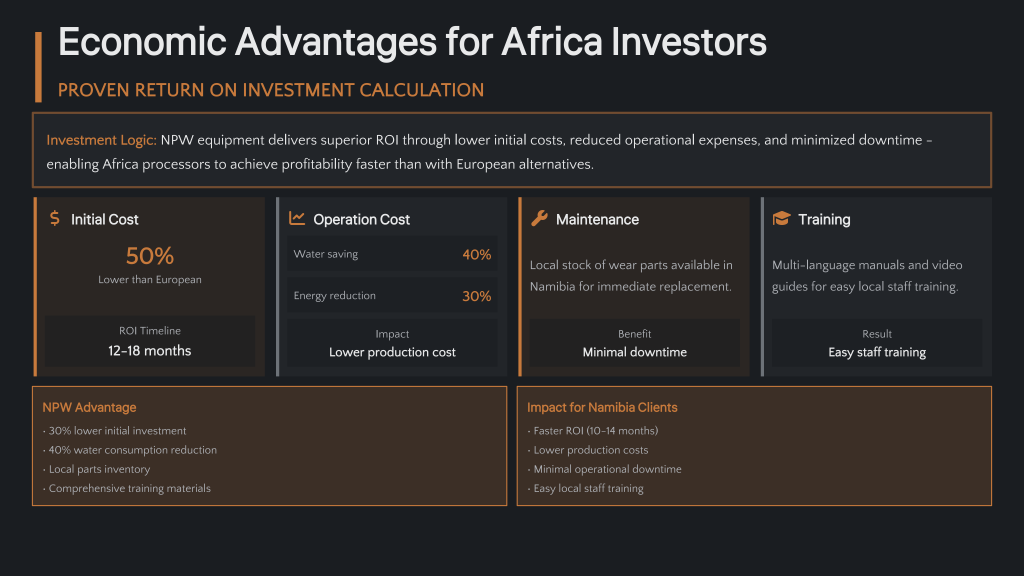

4. Economic Benefit Analysis: Tangible Return on Investment

Taking a standard 2,000 birds/hour production line as an example:

- Investment Cost: 40% lower than comparable European equipment, 3x longer lifespan than locally manufactured equipment.

- Operational Cost: 40% water saving, 30% energy saving, 50% reduction in labor costs.

- Maintenance Cost: Modular design, key component lifespan over 5 years.

- Comprehensive Benefits: Investment payback period of 18-24 months, annual return rate exceeds 30% post-investment.

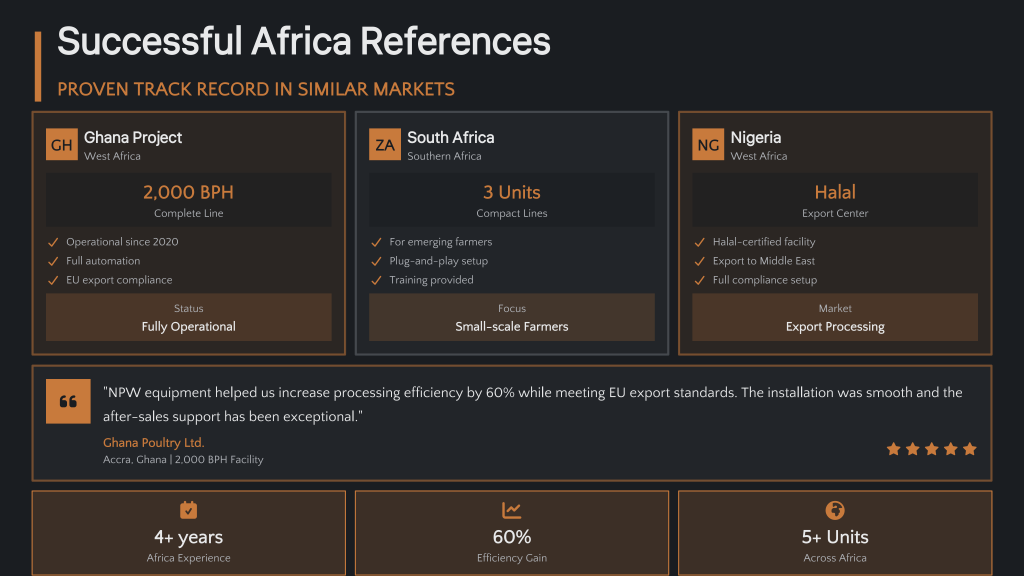

5. Success Case Studies

Ghana Project: A 2,000 birds/hour line operational since 2019, products exported to the EU.

Nigeria: A Halal-certified production line built in 2020, meeting local high-end market demand.

South Africa: Provided compact solutions for multiple SMEs, facilitating industry upgrading.

Kenya: A modern slaughterhouse completed in 2021, serving as a demonstration project in East Africa.

“After choosing NPW equipment, our processing efficiency increased by 60%, product quality met export standards, and market competitiveness significantly enhanced.” — Feedback from a Ghanaian client.

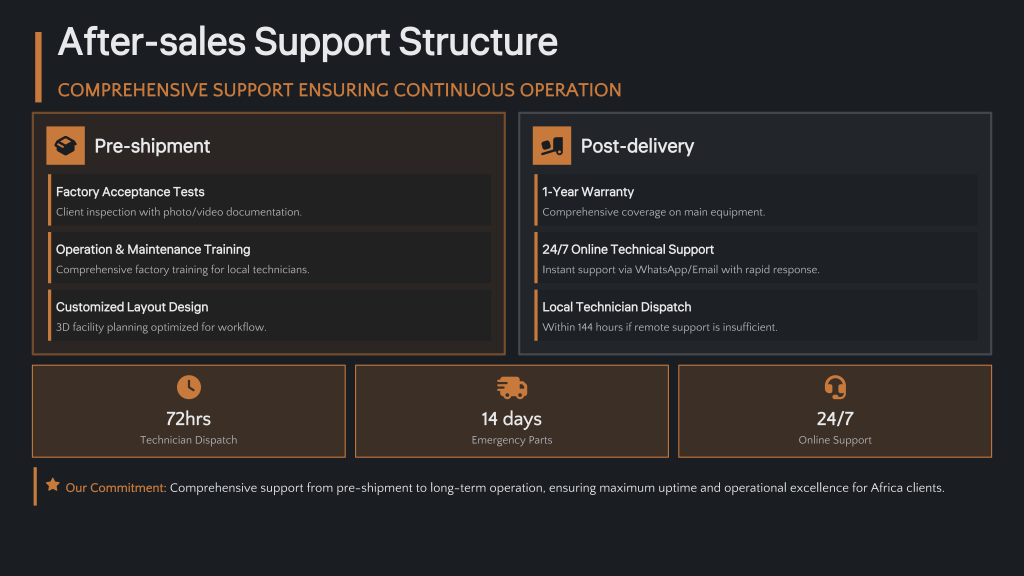

6. Comprehensive Service Guarantee

Pre-Sales Service

- Free on-site inspection and process solution design.

- Personalized equipment selection and configuration.

- Investment return analysis report.

In-Process Support

- Pre-delivery training at the factory.

- Installation and commissioning guidance.

- Systematic training for operators.

After-Sales Guarantee

- 3-year warranty, lifelong service.

- 24/7 remote technical support.

- Regular software upgrade services.

7. Commitment to Sustainable Development

Environmentally Friendly

- Wastewater recycling treatment system, discharges meet local standards.

- Noise control technology, boundary noise below 55 dB.

- Energy-saving design reduces carbon emissions by 25%.

Social Responsibility

- Creates local employment opportunities.

- Enhances employee skills through technical training.

- Supports the development of the local industrial chain.

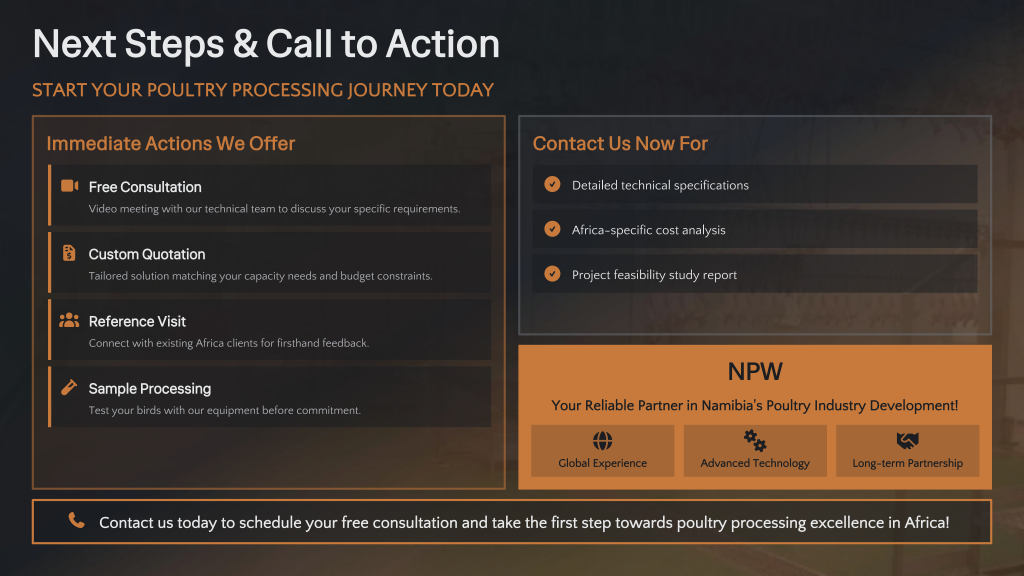

Conclusion: Partner with NPW to Create a New Era for African Poultry Processing

NPW has always adhered to a customer demand-oriented approach and is committed to providing African clients with advanced, practical, and fully supported slaughtering and processing solutions through continuous technological innovation and a comprehensive service system. We look forward to establishing long-term cooperative relationships with more African enterprises to jointly promote the development of Africa’s poultry industry towards modernization, standardization, and internationalization.

Act Now, Start the Journey of Cooperation

Inquiries are welcome for:

- Personalized solution design.

- Arrangement for on-site equipment inspection.

- Detailed investment analysis report.

Contact us to inject new momentum into your business development