Introduction: Water – The Lifeline of an Efficient Compact Slaughter Line

In modern poultry slaughter and processing, water is not merely a cleaning medium but a core element ensuring production efficiency, product hygiene, and equipment stability. A well-designed, logically laid-out integrated water circuit is key to realizing the “Plug-and-Play” concept for compact slaughter lines. This article provides an in-depth analysis of the water system configuration for compact lines, presenting a complete, efficient, and easily maintainable fluid handling solution—from supply and distribution to usage and discharge—ensuring customers can connect to the water source with minimal effort and commence highly efficient production immediately upon equipment installation.

I. Core Design Philosophy: Integrated and Modular Water Circuit Layout

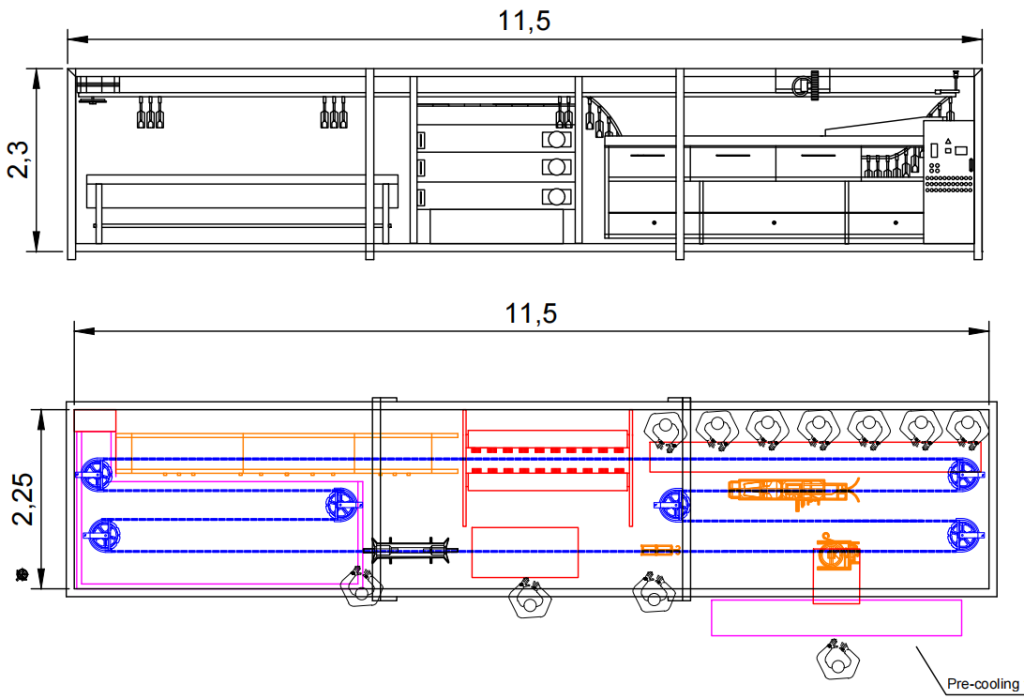

The water system of this compact slaughter line adopts an integrated design featuring unified top-side water supply and functional zoned bottom drainage. All pipelines are pre-connected, pressure-tested, and commissioned at the factory to ensure leak-free operation and precise flow direction. The modular layout allows each water-using unit to operate independently yet seamlessly connect, forming an efficient network for water utilization, reuse, and discharge.

II. Central Water Supply System: Single Point of Entry, Global Control

1. Water Inlet Location:

The system’s main water inlet is located on the upper section of the equipment frame, typically positioned above the pre-cooling tank, near the audible/visual alarm light. This elevated design offers advantages:

- Gravity-Assisted Distribution: Facilitates natural downward water distribution to various points, reducing reliance on pumping.

- Ease of Observation and Operation: Prominent location simplifies connection to the external source and installation of the main valve and filter.

- Safety: Located away from ground-level work areas, minimizing the risk of accidental impact.

2. Water Source and Pressure Requirements:

- Water Source: Connect to standard municipal potable water or treated clean process water.

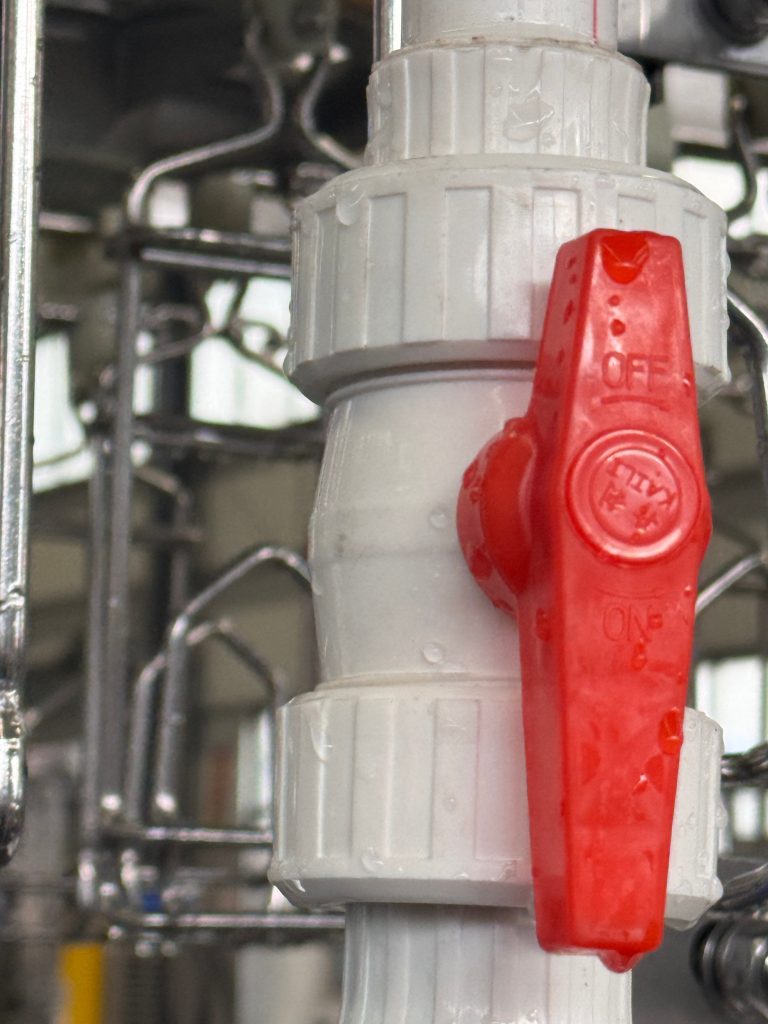

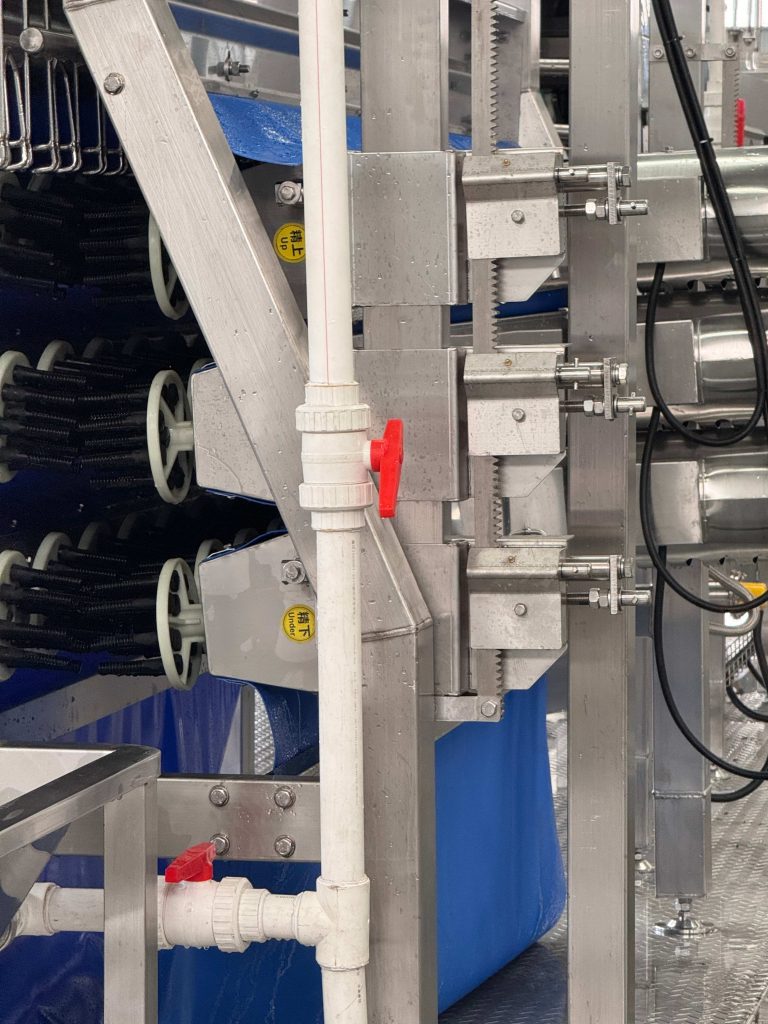

- Water Pressure: Standard mains water pressure (typically 0.2-0.4 MPa) is sufficient. The system integrates internal pressure-reducing and stabilizing valves to accommodate fluctuations, ensuring stable flow at all endpoints.

3. Main Supply Pipeline:

A plastic main pipeline branches from the central inlet, running through the equipment structure. Through branch pipes and solenoid/pneumatic valves, it accurately distributes water to six core process units.

III. Detailed Analysis of Core Water Usage Units: Function, Supply, and Design

The water circuit serves six key stages of the slaughter process, each designed for efficiency and hygiene.

| No. | Water Usage Unit | Core Function | Water Source/Supply Method | Key Design Features |

|---|---|---|---|---|

| 1 | Stunner | Supplies the water bath stunner tub, creating a conductive circuit for humane stunning. | Supplied via a dedicated branch pipe from the main line; flow rate is adjustable. | Provides continuous, stable supply. Features a large drainage outlet directly below connected to the drain channel for rapid wastewater removal post-stunning. |

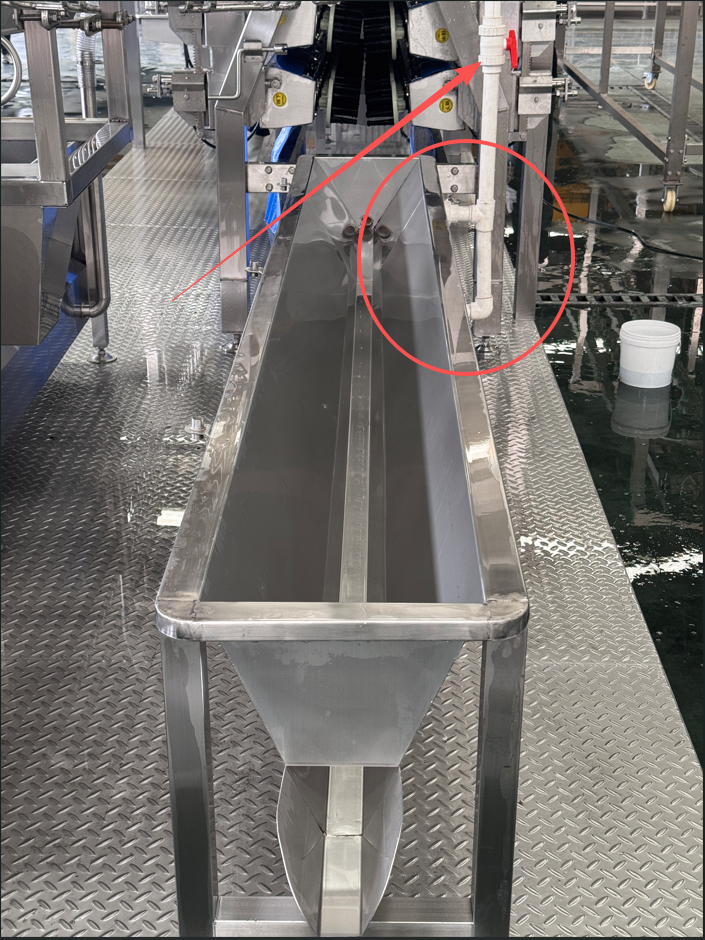

| 2 | Bleeding Trough | Rinses carcasses on the bleeding rail, diluting and transporting blood. | Equipped with multiple spray heads supplied evenly from a branch pipe. | The trough bottom has a dedicated drainage/blood outlet connectable to a blood collection line for separate collection and environmentally sound handling, adding significant value. |

| 3 | Scalding Tank | Maintains a constant hot water temperature for relaxing feathers. | Besides the main supply, features an automatic replenishment system. | Incorporates automatic float valve control: Interlocked with the heating system, it automatically refills when the level drops below the set point, preventing dry heating absolutely, protecting heating elements, and ensuring temperature stability. The drain is at the tank bottom near the bleeding trough end. |

| 4 | Vertical Defeathering Machine | Continuously sprays during plucking to moisten carcasses, rinse off feathers, and reduce friction heat. | An internal annular spray pipe with multiple points ensures even spraying. | Spray water mixed with plucked feathers flows directly out of an open outlet at the machine’s bottom into the drain channel below. Simple design, low clogging risk. |

| 5 | Viscera Handling Table | Rinses and handles eviscerated offal, keeping the table clean. | Equipped with a flexible hose and handheld spray gun above the table; includes a rinsing sink below. | Rinse water and offal debris are channeled via the table’s sloped surface and dedicated waste outlet into the offal handling system or drain pipe. |

| 6 | Cooling Tank (Pre-cooler) | Washes and cools carcasses after head/feet removal. | The tank is filled with flowing chilled water for immersion cooling. | Features an independent drain valve at the bottom for thorough daily cleaning, draining, or water change. |

1.Stunner

2.Bleeding Trough

3.Scalding Tank

4.Vertical Defeathering Machine

5.Viscera Handling Table

6.Cooling Tank (Pre-cooler)

IV. Zoned Drainage and Environmental Treatment System

The drainage system design is crucial for workshop hygiene, ease of cleaning, and environmental compliance.

1. Drainage Design Principles:

- Separation of Clean and Dirty Water: Blood from the bleeding trough should be collected separately via a dedicated pipe for high-value use or specialized treatment.

- Segregation by Contaminant Type: Wastewater containing solids like feathers and viscera fragments (e.g., from defeatherers, viscera tables) should be separated from general rinse water (e.g., from stunners, floor washing) or receive preliminary filtration before discharge.

- Rapid Removal: All drain points are designed for quick, complete removal of wastewater by gravity, preventing accumulation.

2. Drainage Connections and Workshop Requirements:

- As highlighted in the user’s outline, dedicated, sloped drainage channels or underground pipes must be installed beneath each drainage unit of the equipment.

- Strongly Recommended: Install secondary or tertiary stainless steel filter baskets/screens at channel inlets to effectively intercept larger solids like feathers and meat fragments, preventing downstream pipe blockages.

- The final workshop effluent must be directed to the factory’s wastewater treatment plant for treatment before discharge, complying with regulations.

V. Installation, Operation, and Maintenance Key Points

1. On-Site Installation Preparation (Client Side):

- Ensure stable water supply pressure and water quality meets food processing standards.

- Strictly follow the equipment layout diagram to construct a comprehensive drainage network beneath the equipment; this is the prerequisite for “plug-and-play.”

- Provide independent power connections for heating units like the scalding tank.

2. Daily Operation:

- Check the main water valve and all water points for normal function before start-up.

- Closely monitor the scalding tank water level and automatic refill function for responsiveness.

- At the end of each shift, open all drain valves to completely empty water from the equipment.

3. Maintenance:

- Regularly clean the water inlet filter.

- Inspect all pipe connections for leaks.

- Clean solid waste from the drain channel filter screens.

- Periodically calibrate the scalding tank’s automatic float valve and temperature control system.

Conclusion

The water circuit of a compact poultry slaughter line is far more than simple piping; it is a precision engineering system integrating process needs, hygienic design, energy conservation, and user-friendly operation. Its principles of integrated design, automatic control (e.g., scalding tank refill), and separation of waste streams not only achieve the customer’s goal of “connect water and power to run” but fundamentally ensure production continuity, product safety, and operational economy. Scientific drainage infrastructure and regular maintenance will work synergistically with this excellent water system, jointly supporting a highly efficient, clean, and sustainable modern slaughter production line.

COMPACT POULTRY SLAUGHTER LINE

VIEW DETAILED MODEL INFORMATION FOR THE COMPACT POULTRY SLAUGHTER LINE.