Segment Overview

The packaging and palletizing segment serves as the “final guardian” of the egg processing line, representing a crucial stage in product commercialization. Through fully automatic palletizing technology and intelligent packaging systems, this segment efficiently and accurately loads processed eggs into trays, providing optimal conditions for storage, transportation, and sales.

Detailed Process Description

Automatic Palletizing Process

Quality eggs processed through previous stages are conveyed via transmission belts to positioning mechanisms. Robotic systems automatically pick up eggs and intelligently flip them, ensuring precise positioning with the small end facing downward. Subsequently, the robotic hands automatically open cardboard packaging boxes, gently load eggs into designated positions, and complete sealing operations.

Packaging Integration Process

Palletized eggs are transported through conveyor systems to subsequent processes, achieving seamless connectivity. The packaged egg trays are automatically stacked, ready to enter cold chain systems or for direct distribution to sales terminals.

Returnable Container Cleaning Process

Containers used in the packaging process are automatically conveyed into cleaning stations. High-pressure spray systems perform comprehensive reciprocating cleaning, ensuring hygiene standards. Some systems can be equipped with optional air-drying or baking functions for immediate reuse.

Core Equipment Detailed Explanation

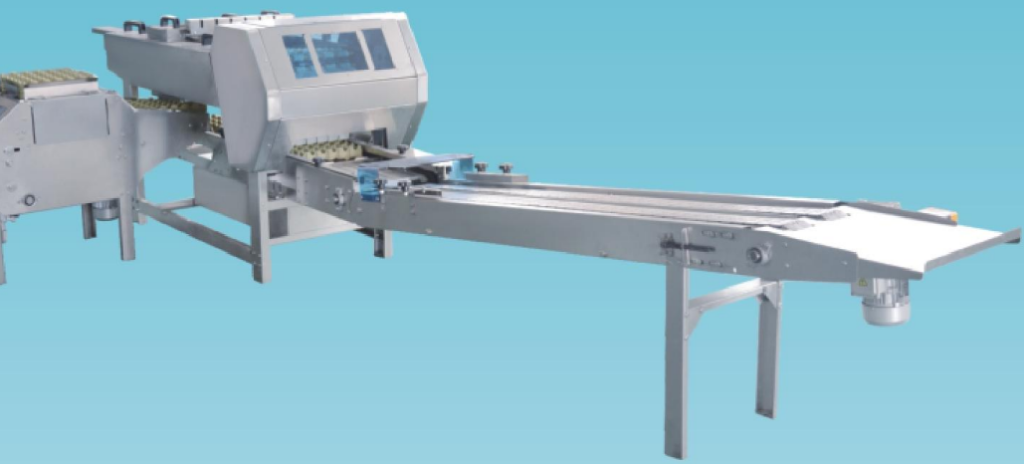

Automatic Egg Palletizing Machine

Equipment Model: Fully Automatic Palletizing System

Dimensions: 4200×1500×900mm

Efficiency: 15,000-30,000 eggs/hour

Equipment Functional Features

- Intelligent Positioning System:

- Advanced sensor technology enables automatic egg queuing and sorting

- Robotic precision positioning ensures small-end-down tray loading

- Automatic adjustment mechanisms adapt to different egg specifications

- Packaging Execution System:

- Integrated automated operations: box opening, egg loading, and sealing

- Standardized loading of 30 eggs per tray

- Modular combination structure facilitates maintenance and replacement

- Control System:

- LCD touchscreen control and display interface

- Electrical plug-in connections for easy transfer and maintenance

- Real-time production data monitoring with remote query capability

Returnable Container Washing Machine

Application Range: Cleaning various food containers and boxes

Cleaning Method: High-pressure reciprocating spray cleaning

Optional Functions: Air-drying, baking devices

Equipment Functional Features

- Cleaning System:

- Adjustable high-pressure spray devices with customizable water pressure

- Comprehensive coverage design without cleaning dead angles

- Automatic water filtration ensures cleaning效果

- Conveyor System:

- Automated conveyor belts for continuous operation

- Multi-specification adaptation for different container types

- Energy-saving design reduces operating costs

- Intelligent Control:

- Programmable logic control system

- Automatic fault diagnosis and alarm functions

- Real-time energy consumption monitoring and optimization

In-depth Analysis of Technical Advantages

1. Revolutionary Production Efficiency Improvement

The automatic palletizer achieves a maximum capacity of 30,000 eggs/hour, equivalent to the productivity of 20 skilled workers. Continuous operation mode breaks efficiency bottlenecks in traditional packaging segments, enabling truly large-scale production.

2. Significant Packaging Quality Enhancement

- Standardized Palletizing: Standardized loading of 30 eggs per tray ensures product consistency

- Precision Positioning: Scientific small-end-down placement reduces transportation breakage rates

- Hygiene Assurance: Fully automated operation prevents human contamination, improving product hygiene standards

3. Leading Intelligent Control Level

Equipment utilizes advanced PLC control systems with intelligent features including:

- Adaptive Adjustment: Automatic egg specification recognition and palletizing parameter adjustment

- Data Traceability: Real-time production data recording supporting quality tracing

- Remote Operation: Network connectivity enabling predictive maintenance

4. Significant Comprehensive Cost Advantages

- Labor Costs: Over 70% reduction in packaging segment labor input

- Consumable Costs: 30% improvement in standardized packaging material utilization

- Maintenance Costs: Modular design reduces maintenance difficulty and costs

Innovative Technology Highlights

Machine Vision Positioning Technology

Palletizers integrate high-precision vision systems capable of real-time egg posture and specification recognition. Intelligent algorithms optimize grasping paths, ensuring palletizing accuracy exceeds 99.9%.

Flexible Packaging System

Equipment supports multiple packaging specification switches, adapting to different market requirements through parameter adjustments, significantly enhancing production line adaptability and flexibility.

Energy-saving and Environmental Design

- Energy Optimization: High-efficiency motors and intelligent start-stop technology reduce energy consumption by 40%

- Water Resource Recycling: Cleaning machines equipped with water circulation systems achieve 60% water savings

- Eco-friendly Materials: All contact components comply with food-grade environmental standards

Quality Assurance System

Hygiene and Safety Control

- Entire machine constructed from 304 stainless steel meeting food-grade hygiene standards

- Enclosed design prevents external contamination

- Automatic CIP cleaning systems ensure equipment hygiene

Operational Stability Assurance

- Key components use imported brands ensuring equipment reliability

- Multiple safety protection devices guarantee operational safety

- Real-time monitoring systems promptly detect and address abnormalities

Practical Application Results

Production Efficiency Data

In actual production environments, this packaging and palletizing segment demonstrates exceptional performance:

- Palletizing Accuracy: Exceeds 99.5%

- Equipment Utilization Rate: Averages over 85%

- Mean Time Between Failures: Over 2000 hours

Economic Benefit Analysis

Case study of a medium-sized egg processing enterprise after implementing this packaging system:

- Labor Costs: Annual savings of approximately ¥300,000

- Efficiency Improvement: Daily processing capacity increased from 100,000 to 250,000 eggs

- Quality Enhancement: Packaging breakage rate reduced from 3% to 0.5%

- Investment Return: Payback period within 18 months

Customer Value Realization

- Brand Image Enhancement: Standardized packaging strengthens product market competitiveness

- Supply Chain Optimization: Perfect integration with downstream sales channel requirements

- Quality Traceability Strengthening: Provides data support for product tracing

The successful implementation of this packaging and palletizing segment not only achieves automation upgrading of the final egg processing stage but also creates significant economic benefits and market competitiveness for enterprises, making it an indispensable key link for modern egg processing businesses.