Segment Overview

The sorting and inspection segment serves as the “quality gatekeeper” of the egg processing line, responsible for accurately screening high-quality products from cleaned eggs. Utilizing advanced optical inspection and weight grading technologies, this segment ensures comprehensive quality control of both internal and external egg characteristics, guaranteeing that only compliant eggs proceed to subsequent processing stages.

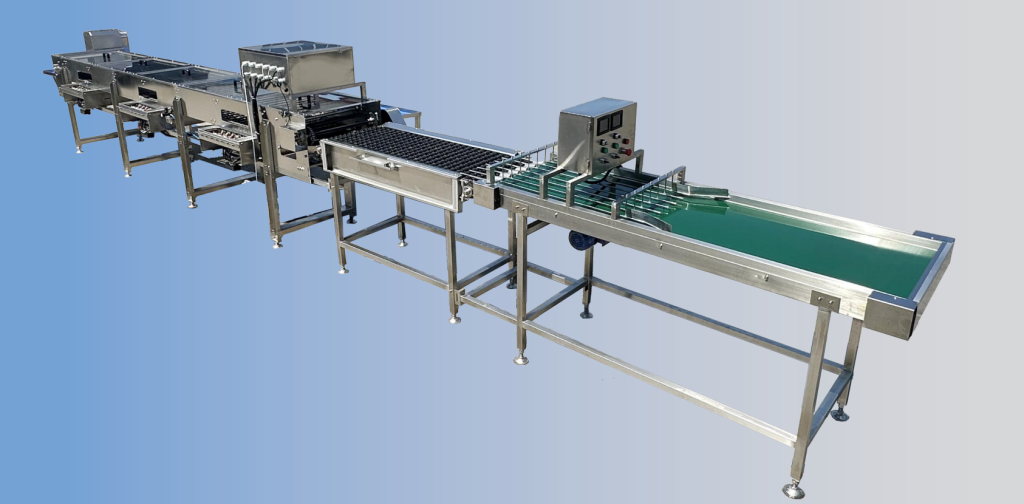

Detailed Process Description

Optical Inspection Process

After cleaning and drying, eggs first enter the optical inspection area. Eggs move uniformly along the conveyor belt through a professional LED lighting system, allowing operators to clearly observe internal conditions through transmitted light. This process effectively identifies abnormal eggs including cracked eggs, dark-spotted eggs, scattered yolk eggs, and double-yolk eggs.

Weight Grading Process

Qualified eggs passing optical inspection proceed to the weight grading stage. Eggs are automatically queued and sorted via a new self-clearing egg conveyor before entering a high-precision weighing system. After precise weighing, each egg is automatically directed to different output channels based on preset weight classifications.

Graded Output Process

Following grading completion, eggs from each classification are transported to designated areas, preparing them for subsequent processes such as coding, oil spraying, and packaging. The entire workflow achieves full automation, minimizing manual intervention to the greatest extent.

Core Equipment Detailed Explanation

Optical Egg Inspector

Model: TD-3 Optical Egg Inspector

Dimensions: 2550×420×680mm

Efficiency: 3000-10000 pieces/hour (adjustable)

Functional Features

- Optical Detection System:

- Utilizes professional LED candling technology with uniform, gentle lighting

- Supports detection of various defects including cracked, dark-spotted, and scattered yolk eggs

- Features visual inspection interface with intuitive operation

- Conveyor System:

- Three-row roller conveying design ensures smooth egg transportation

- Food-grade PVC conveyor belts meet hygiene standards

- Variable frequency speed regulation adapts to different production rhythms

- Control System:

- 220V voltage, 400W power consumption, energy efficient

- Integrated all-in-one design, plug-and-play functionality

- Continuous operation design suitable for large-scale production

Electronic Weight Grader

Specifications: Three-row/Six-row Electronic Sorting Machine

Dimensions: 8900×1500×1300mm

Sorting Efficiency: 20000-30000 pieces/hour

Functional Features

- Weighing System:

- Incorporates German HBM high-precision sensors

- Grading accuracy with ±0.2g error margin

- Supports classification into 3 grades plus substandard category

- Control System:

- PLC automated control unit ensures operational stability

- Xinje brand electrical control system with user-friendly interface

- 7-inch touchscreen for flexible parameter adjustments

- Execution System:

- Genuine Airtac solenoid valves ensure rapid response

- Modular sorting mechanism facilitates easy maintenance

- Two-section design enables convenient installation and transportation

In-depth Analysis of Technical Advantages

1. Industry-leading Detection Accuracy

The optical inspector employs advanced LED transmission technology, clearly displaying internal egg conditions with up to 99% detection accuracy. The weight grader equipped with German HBM sensors achieves weighing precision of ±0.2g, far exceeding manual sorting capabilities.

2. Significant Production Efficiency Improvement

- High-speed Sorting: Maximum processing capacity of 30,000 pieces/hour, over 10 times faster than manual sorting

- Continuous Operation: Supports 24-hour uninterrupted operation suitable for large-scale production

- High Automation Level: Reduces manual intervention and labor intensity

3. Intelligent Control Advantages

PLC control system integration provides intelligent features including:

- Automatic Alarm Function: Real-time monitoring of equipment status with automatic anomaly alerts

- Data Statistics Function: Automatic recording of production data including sorting quantities and grade proportions

- Parameter Memory Function: Saves optimal working parameters for one-touch recall

4. Strong Adaptability and Scalability

Equipment supports multiple configurations to meet diverse customer requirements:

- Three-row/Six-row Configurations: Flexible selection based on production volume needs

- Adjustable Grades: Supports 2-6 grade settings adaptable to various market standards

- Egg Compatibility: Suitable for various egg types including chicken, duck, and preserved eggs

Innovative Technology Highlights

Intelligent Sorting Algorithm

Incorporates advanced adaptive sorting algorithms that automatically optimize sorting parameters based on egg characteristics, ensuring optimal sorting performance under varying production conditions.

Modular Design Philosophy

Modular design approach with relatively independent functional units facilitates maintenance and upgrades. Electrical control system features plug-in connections for convenient transportation and repair.

User-friendly Operation Experience

7-inch touchscreen interface with clean, intuitive design supports Chinese-English language switching. Operators can master operations after minimal training. Real-time equipment status display with clear fault information prompts.

Quality Assurance System

Precision Guarantee Measures

- Regular calibration mechanisms ensure long-term weighing accuracy stability

- Redundant sensor design with backup for critical components

- Automatic temperature compensation adapts to environmental changes

Hygiene and Safety Standards

- Entire machine constructed from 304 stainless steel for easy cleaning and disinfection

- Food-grade contact surfaces comply with hygiene requirements

- Enclosed design prevents contamination

Practical Application Results

In production practice, this sorting and inspection segment demonstrates exceptional performance:

- Low Breakage Rate: Automated processing minimizes human-induced damage

- Accurate Sorting: Clear grade differentiation meets high-end market requirements

- Energy Efficient: Total power consumption only 2.2kW with low energy consumption

- Easy Maintenance: Modular design reduces maintenance costs

Case Example: A large egg processing enterprise implementing this sorting and inspection system achieved:

- Daily processing capacity increased from 50,000 to 200,000 pieces

- Labor costs reduced by 70%

- Premium product rate improved from 85% to 98%

- Customer complaint rate decreased by 90%

The successful implementation of this sorting and inspection segment not only enhances product quality and consistency but also creates significant economic benefits for enterprises, making it an indispensable core component of modern egg processing operations.