Integrated Egg Processing Production Line Solution

I. Project Overview and Design Philosophy

This solution aims to address the core pain points of traditional egg processing, which relies on manual labor, resulting in low efficiency and inconsistent hygiene standards. We propose a continuous production line using modular, fully automated equipment that handles eggs from intake to packaged finished products. The design adheres to the principles of “Cleaning, Visualization, Precision, and High Efficiency,” ensuring each egg undergoes standardized cleaning, inspection, processing, and sorting to significantly enhance product added value and market competitiveness.

II. Core Production Process Flow

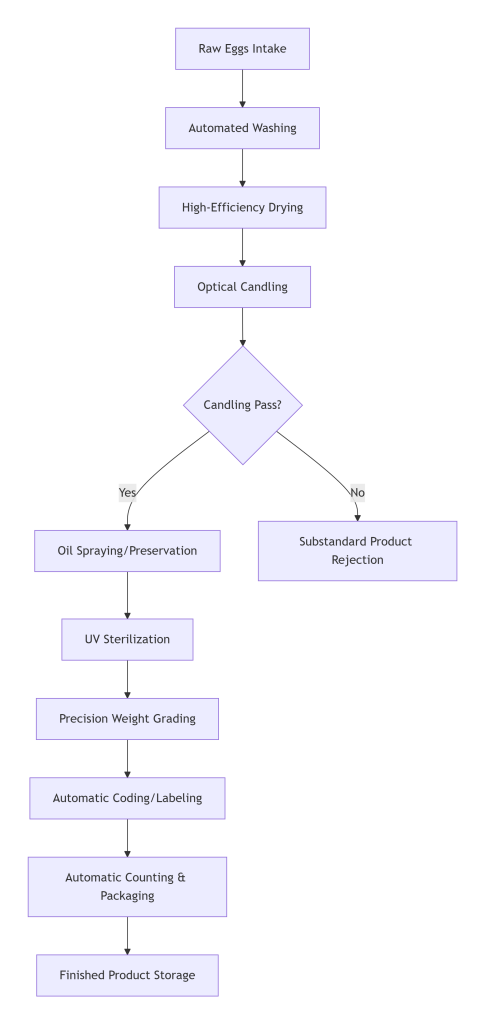

The flowchart below clearly illustrates the complete closed-loop process from raw material to finished product:

III. Core Equipment Configuration List

Based on the document, the main line modules are recommended as follows:

| Module Name | Recommended Equipment | Core Function & Technical Parameters | Solution Value |

|---|---|---|---|

| 1. Washing Module | 6/8/12 Row Egg Cleaning Line | 304 stainless steel body, combines multi-stage brushing and spraying to remove feces, blood spots, etc. Capacity: 20,000-30,000 eggs/hour. | Enables large-scale, harmless cleaning with low breakage rate. |

| 2. Drying & Candling Module | Integrated Washing-Drying-Candling Line | Rapid drying with hot air, integrated optical inspection system to automatically detect cracks, mixed yolks, and blood spots. | Ensures dry, hygienic eggs and achieves 100% online visual quality screening, replacing manual candling. |

| 3. Preservation & Sterilization Module | Oil Spraying & UV Sterilization Unit | Sprays food-grade mineral oil to form a protective film; UV tunnel for secondary surface sterilization. | Significantly extends shelf life, enhances hygiene and safety standards, meeting “clean egg” requirements. |

| 4. Grading & Sorting Module | 6-Row Electronic Sorting Machine | High-precision weight sensing (error ±0.2g), PLC-controlled, can sort into 3-4 grades. Capacity: 20,000-30,000 eggs/hour. | Precise weight-based grading enables product standardization and differential pricing, far surpassing manual efficiency. |

| 5. Marking & Packaging Module | Coding Machine & Automatic Packaging Line | Can print production date, batch, logo; automatic counting, tray loading (e.g., 30 eggs/tray), wrapping or boxing. | Meets regulatory requirements, enhances brand image, automates packaging, and saves labor. |

IV. Summary of Core Solution Advantages

- End-to-End Automation & High Efficiency: Seamless connection from washing to packaging, with maximum single-line capacity reaching 30,000 eggs/hour, greatly reducing labor costs and intensity.

- Superior Hygiene & Quality Assurance: Entire line uses food-grade 304 stainless steel, complying with HACCP hygienic design principles. Integrates multiple processes like washing, sterilization, and candling to ensure safe, high-quality finished products.

- High Flexibility & Intelligence: Supports customized capacity (single-row to twelve-row) and process combinations. Core sorting equipment uses PLC control systems for high precision, stable operation, and traceable data.

- Significant Return on Investment: Integrated design reduces inter-process losses and breakage rates. The produced “clean eggs” or “branded eggs” have high added value and can quickly meet the demands of supermarkets and food processing enterprises.

V. npw Support and Services

- Customization Capability: Can provide non-standard customization based on your specific capacity, site, and product type (regular fresh eggs, clean eggs, eggs for boiled processing).

- Quality Commitment: Key equipment components utilize reputable brands to ensure stability.

- Service Guarantee: Provides comprehensive support from installation and commissioning, operator training, to after-sales maintenance, ensuring stable production line operation.