Sheep Head Hair Removal Machine

The Sheep Head Hair Removal Machine, also known as the Sheep Head Dehairing Machine, is a specialized automated equipment designed specifically for efficient and thorough removal of hair and wool from sheep heads during slaughterhouse processing operations. This professional-grade machine addresses one of the most challenging aspects of sheep head processing—complete hair removal from the complex contours and crevices of animal heads—delivering clean, presentation-ready heads for further processing, inspection, or specialty product preparation.

Engineered with precision and built from high-quality stainless steel, this dehairing machine features an 800mm diameter rotating drum system that ensures comprehensive hair removal from all head surfaces including ears, snout, and facial areas. With a processing capacity of 40kg per hour and robust 400kg construction, this machine delivers consistent, reliable performance in demanding commercial slaughterhouse environments.

The compact yet powerful design (1180×1100×1300mm) makes it suitable for various facility layouts while maintaining the stability and durability required for continuous heavy-duty operation. Powered by 380V industrial voltage, this machine integrates seamlessly into existing slaughter lines, providing an automated solution that eliminates the labor-intensive and inconsistent results of manual dehairing methods.

Sheep head meat is a valued product in many markets worldwide, particularly in Middle Eastern, African, Asian, and Mediterranean cuisines. Proper hair removal is critical for product quality, food safety compliance, and consumer acceptance. This machine ensures thorough, hygienic dehairing that meets international food safety standards while maximizing the commercial value of sheep head products.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

Core Advantages

High Productivity

With a processing capacity of 40kg per hour, this machine significantly increases throughput compared to manual dehairing methods. This productivity level enables slaughterhouses to:

- Process multiple sheep heads efficiently and consistently

- Reduce processing time per head by up to 75%

- Eliminate labor bottlenecks in head processing operations

- Maintain steady production flow throughout operational hours

- Meet high-volume market demands for sheep head products

- Maximize daily output and profitability

The automated operation ensures continuous, reliable performance that dramatically outpaces manual methods while delivering superior and consistent dehairing quality.

Thorough Hair Removal

The machine’s specialized design ensures complete hair removal from challenging head areas:

- 800mm Diameter Drum: Large rotating drum provides comprehensive coverage and effective dehairing action

- Complex Contour Processing: Effectively removes hair from ears, snout, eye areas, and facial crevices

- Consistent Results: Automated operation delivers uniform dehairing quality across all heads

- Clean Finish: Produces presentation-ready heads suitable for retail or further processing

- Minimal Residual Hair: Thorough removal meets food safety and quality standards

This comprehensive dehairing capability is essential for producing high-quality sheep head products that meet consumer expectations and regulatory requirements.

Premium Stainless Steel Construction

Built entirely from high-quality stainless steel, the machine offers:

- Food-Grade Material: Full compliance with international food safety standards

- Exceptional Durability: Resistant to wear, impact, and continuous heavy-duty use

- Corrosion Resistance: Withstands harsh processing environments and frequent washing

- Easy Cleaning: Smooth surfaces facilitate thorough sanitization

- Hygienic Operation: Non-porous material prevents bacterial growth

- Professional Appearance: Maintains aesthetic quality throughout service life

- Long-Term Reliability: Minimal maintenance requirements and extended service life

Robust Mechanical Design

The machine’s substantial 400kg weight and solid construction provide:

- Operational Stability: Heavy construction eliminates vibration and movement during operation

- Consistent Performance: Stable platform ensures uniform dehairing results

- Durability: Robust build withstands continuous commercial use

- Safety: Secure, stable operation protects workers and equipment

- Longevity: Heavy-duty construction ensures years of reliable service

Large Capacity Drum System

The 800mm diameter drum is specifically engineered for sheep head processing:

- Optimal Size: Large diameter accommodates multiple heads simultaneously

- Effective Action: Provides sufficient tumbling and friction for thorough dehairing

- Gentle Processing: Removes hair without damaging delicate head tissues

- Efficient Design: Maximizes contact between heads and dehairing surfaces

- Consistent Results: Uniform drum rotation ensures even processing

Compact Yet Powerful

Despite its robust construction and high capacity, the machine maintains a space-efficient footprint:

- Dimensions: 1180×1100×1300mm (L×W×H)

- Suitable for various facility layouts and space constraints

- Easy integration into existing slaughter lines

- Optimal height for ergonomic loading and unloading

- Professional industrial design

Industrial Power System

Powered by reliable 380V industrial voltage:

- Consistent, reliable power delivery

- Suitable for commercial slaughterhouse electrical systems

- Energy-efficient operation

- Smooth motor performance under continuous use

- Long motor service life

Technical Features

Large Diameter Drum System

- 800mm diameter rotating drum

- Optimized for sheep head dimensions

- Effective tumbling and dehairing action

- Durable drum construction

- Easy access for cleaning and maintenance

Impressive Processing Capacity

- 40kg per hour standard capacity

- Process multiple sheep heads per cycle

- Consistent output throughout operational hours

- Suitable for commercial-scale operations

- Scalable integration into complete slaughter lines

Heavy-Duty Construction

- 400kg weight ensures operational stability

- High-quality stainless steel throughout

- Precision-engineered components

- Minimal wear and tear

- Designed for continuous heavy-duty operation

Space-Efficient Design

- Compact footprint: 1180×1100×1300mm

- Vertical design maximizes floor space utilization

- Easy access for operation and maintenance

- Suitable for facilities with space constraints

- Professional industrial appearance

Reliable Power System

- 380V industrial voltage

- Efficient motor performance

- Smooth operation under continuous use

- Minimal vibration and noise

- Long-term reliability

Application Scenarios

This sheep head dehairing machine is ideal for:

Commercial Sheep Slaughterhouses

- Large-scale lamb and mutton processing facilities

- High-volume sheep processing operations

- Multi-species slaughter plants with sheep lines

- Export-oriented meat processing facilities

- Halal and Kosher certified processing plants

Specialty Head Meat Processing

- Dedicated sheep head processing operations

- Specialty meat product manufacturers

- Ethnic food processing facilities

- Traditional cuisine product preparation

- Value-added by-product processing

Complete Slaughter Line Integration

- Seamless integration with head removal equipment

- Compatible with washing and sanitizing systems

- Coordinates with inspection stations

- Works efficiently with packaging operations

- Facilitates downstream processing

Regional Market Processing

- Middle Eastern market processors

- African cuisine product facilities

- Asian specialty meat operations

- Mediterranean food processors

- Traditional delicacy manufacturers

Operational Benefits

Enhanced Productivity

- Process 40kg of sheep heads per hour

- Reduce manual labor requirements by up to 80%

- Eliminate time-consuming manual dehairing

- Increase overall processing efficiency

- Maximize daily throughput and profitability

Superior Quality Output

- Thorough, consistent hair removal

- Clean, presentation-ready heads

- Minimal residual hair

- Preserved tissue integrity

- Enhanced product appearance and value

Cost Efficiency

- Reduced labor costs through automation

- Lower operational expenses

- Minimal maintenance requirements

- Energy-efficient operation

- Long-term durability reduces replacement costs

- Increased product value through quality improvement

Improved Hygiene

- Stainless steel construction prevents contamination

- Easy cleaning and sanitization

- Reduced manual contact with products

- Compliance with food safety regulations

- Enhanced traceability and quality control

Food Safety Compliance

- Meets international food safety standards

- Facilitates HACCP compliance

- Supports regulatory inspection requirements

- Ensures product hygiene and quality

- Reduces contamination risks

Processing Capabilities

Sheep Head Dehairing

- Complete hair and wool removal from all head surfaces

- Effective processing of ears, snout, and facial areas

- Thorough cleaning of complex contours and crevices

- Suitable for various sheep breeds and sizes

- Consistent results across different head dimensions

Product Preparation

- Presentation-ready heads for retail markets

- Prepared heads for further processing

- Clean heads for specialty product manufacturing

- Ready for cooking or additional preparation

- Suitable for traditional cuisine applications

Quality Standards

- Meets consumer expectations for cleanliness

- Complies with food safety regulations

- Suitable for domestic and export markets

- Enhances product marketability

- Supports premium product positioning

Market Applications

Middle Eastern Markets

- Traditional dishes requiring sheep heads

- Halal certified product preparation

- Cultural cuisine requirements

- High-demand specialty products

African Markets

- Traditional delicacies and celebrations

- Cultural food preparations

- High-value specialty products

- Growing market demand

Asian Markets

- Traditional cuisine applications

- Specialty meat products

- Cultural food requirements

- Premium product segments

Mediterranean Markets

- Traditional recipes and dishes

- Specialty food preparations

- Cultural cuisine requirements

- Gourmet product applications

Quality Assurance & Support

Comprehensive Warranty

- 1-year warranty coverage on all components

- Quality guarantee on mechanical systems

- Replacement parts availability

- Technical support throughout warranty period

- Extended warranty options available

Professional Documentation

- Mechanical test reports provided

- Video factory inspection available before shipment

- Pre-shipment performance testing

- Complete quality documentation included

- Operation and maintenance manuals

- Safety guidelines and procedures

- Cleaning and sanitization protocols

Secure Packaging & Delivery

- Standard wooden case packaging

- Protection during international shipping

- Secure component arrangement

- Complete installation accessories included

- Safe delivery to your facility

- Professional packaging standards

Expert Manufacturing

- Professional production from Shandong, China

- Experienced engineering team

- Quality control at every production stage

- Proven manufacturing processes

- International quality standards

- ISO-compliant production facility

- Food machinery expertise

| Product Name | Sheep Head Hair Removal Machine / Sheep Head Dehairing Machine |

| Application | Sheep |

| Capacity | 40kg/Hour |

| Material | High-Quality Stainless Steel |

| Dimensions (L×W×H) | 1180×1100×1300mm |

| Weight | 400kg |

| Drum Diameter | 800mm |

| Voltage | 380V |

| Core Component | Other |

| Core Selling Point | High Productivity |

| Warranty Period | 1 Year |

| Place of Origin | Shandong, China |

| Mechanical Test Report | Available |

| Video Factory Inspection | Available |

| Packaging | Standard Wooden Case |

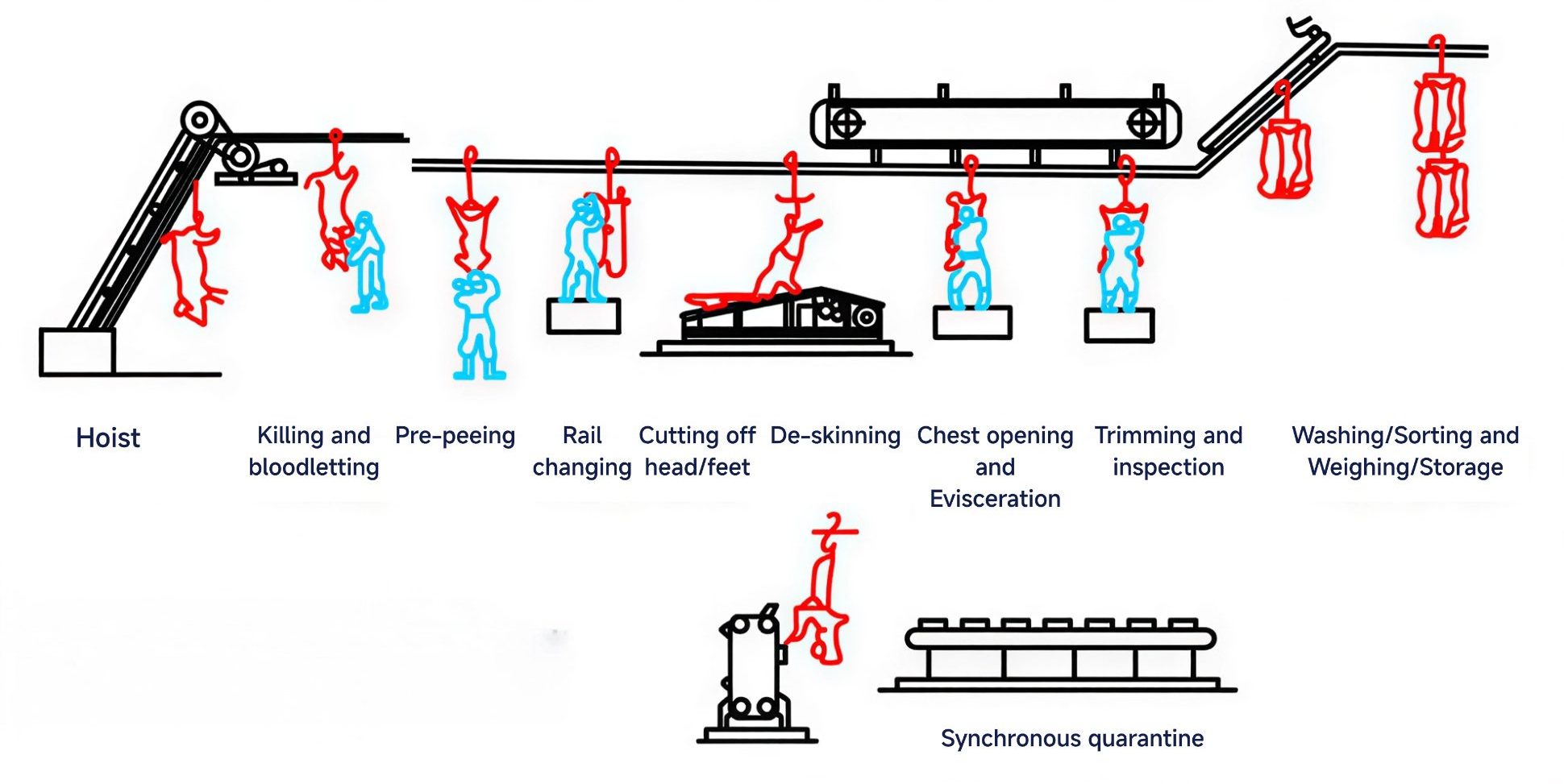

TECHNOLOGY FLOW SHEET FOR SHEEP SLAUGHTERING AND PROCESSING