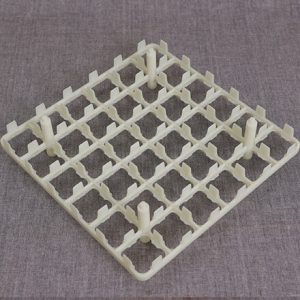

Plastic Chicken Transport Crate for Farms

Properly designed chicken transport crates protect the feet of poultry. Small holes in the crates and a smooth bottom avoid clamping and possible injury of poultry. There is also good ventilation. Easy installation. The bottom and top of crates match together so there is no sliding of parts and the birds may be transported safely. Our crates have a longer lifespan than most, up to five years. 100% pure PE material, not a recycled material. Crates feature a thicker middle support and thicker corner compression resistance.

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

They are easy to open and remove the chickens.

They have big sliding doors on a track design that saves time.

Easy to carry and move.

They save space because they fold.

Specifications of Chicken Crates

| Type 1 – made of two pieces | ||||||||||

| No. | Size | Weight/kg | Door size | Material | Suit for | Quantity chicken | ||||

| 1 | 750×550×270 | 4 | 26*33 | Polypropylene plastic | Adult chicken | 13 | ||||

| 2 | 750×550×270 | 4.4 | 26*33 | 13 | ||||||

| 3 | 750×550×270 | 4.85 | 26*33 | 13 | ||||||

| 4 | 750×550×270 | 5 | 26*33 | 13 | ||||||

| Type 2-made from six pieces | ||||||||||

| No. | Size | Weight/kg | Door size | Material | Suit for | Quantity chicken | ||||

| 1 | 750×550×190 | 4.75 | 29×32 | Polypropylene plastic | Pigeon, baby chick | 13 | ||||

| 2 | 750×550×230 | 5 | 29×32 | younth chicken | 13 | |||||

| 3 | 750×550×270 | 5.25 | 29×32 | old chicken | 13 | |||||

| 4 | 750×550×330 | 5.75 | 29×32 | Duck, goose chicken | 10 | |||||

| 5 | 950×550×250 | 7 | 29×32 | Duck, goose,chicken | 10 or12 | |||||

| Day old chicken transport cages | ||||||||||

| No. | Size | Weight/kg | Door size | Material | Suit for | Quantity chicken | ||||

| 1 | 690*495*140mm | 1.7 | 0 | PP | baby chick | 100 | ||||

| 2 | 690*495*160mm | 1.85 | 0 | baby chick | 100 | |||||

| Color and Logo could customized, only 200pcs will be OK. | ||||||||||