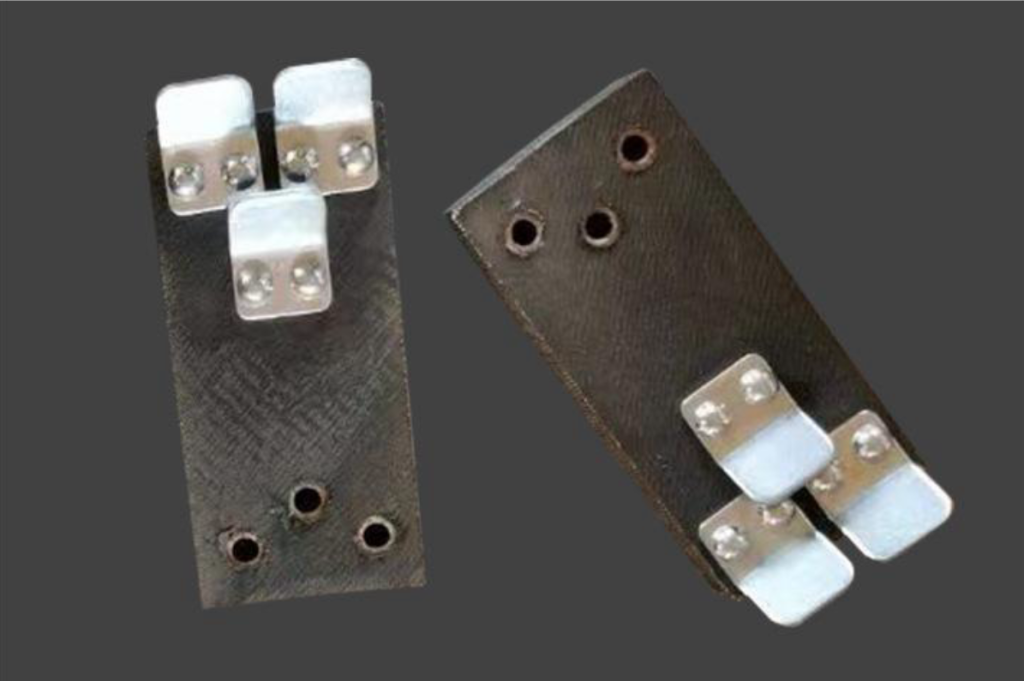

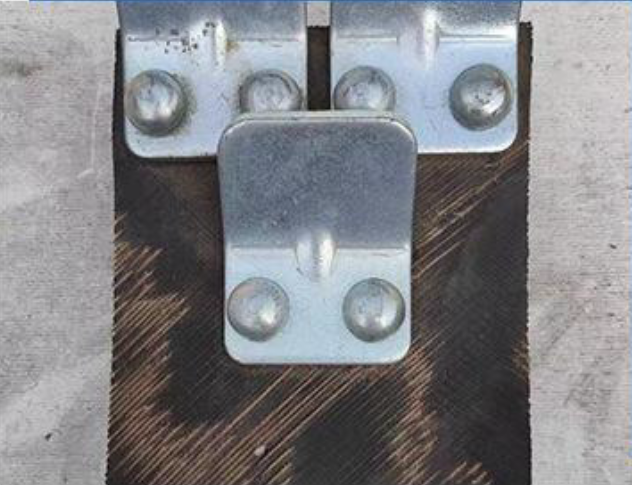

Dehairing Block for Dehairing Machine

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

1. Selection of Rubber Blocks for Dehairing Sections

Initial Dehairing Section: Select rubber blocks with slightly higher hardness and larger diameter for primary dehairing.

Fine Dehairing/Polishing Section: Select rubber blocks with slightly lower hardness and textured heads to remove residual fine hairs and polish the epidermis.

2. Maintenance and Replacement Recommendations

Regular Inspection: Check the rubber blocks for cracks, severe deformation, or excessive wear every shift (replace if the length is reduced by more than 15%).

Group Replacement: It is recommended to replace the rubber blocks in groups in the same area (e.g., one dehairing disk) to maintain force balance and uniform dehairing effect.

Cleaning & Maintenance: Rinse with warm water and neutral detergent daily; avoid using strong acids and alkalis, which can extend the service life by more than 30%.

If needed, I can assist in organizing the above parameters into a Specification Sheet or RFQ (Request for Quotation) format.