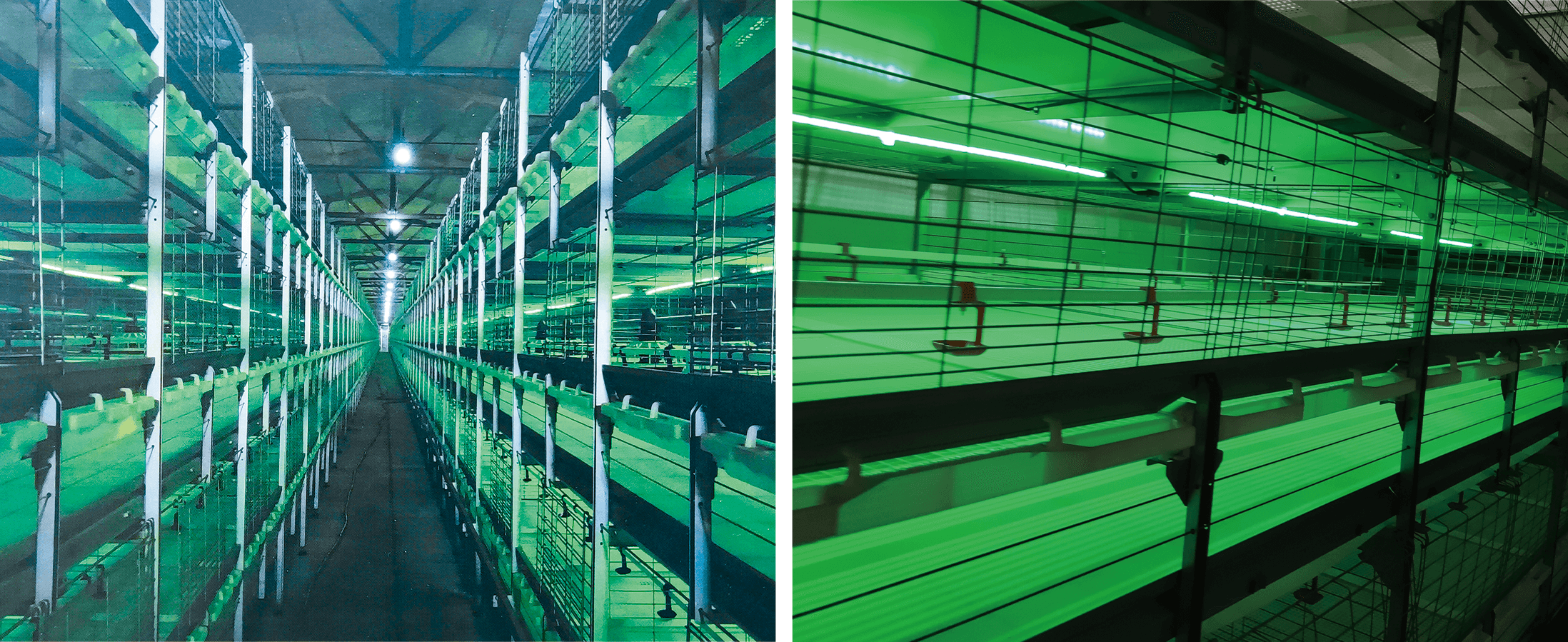

Product Name: Automatic Broiler Cage Equipment

Applicable Industries: Poultry Farms

Use: Broiler Chicken

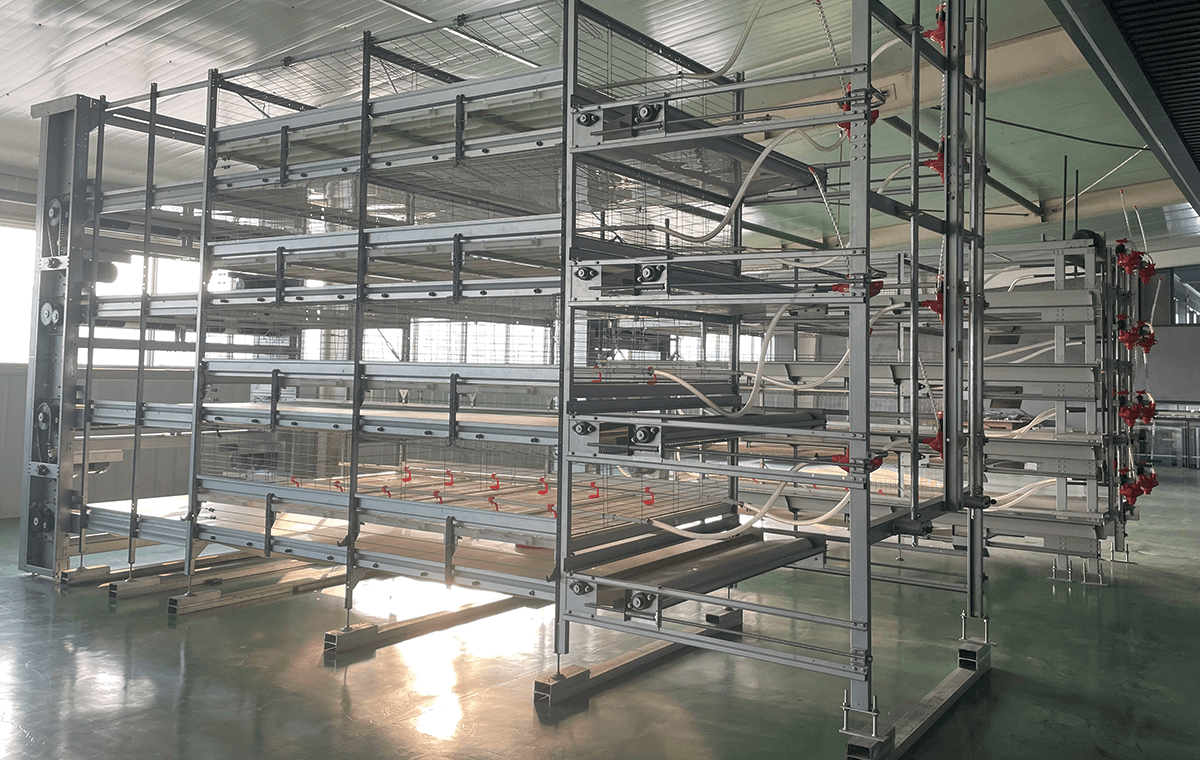

Material:Hot Dip Galvanized Steel

Tiers:3-4 Tiers

Certification:ISO 9001,SONCAP

Life Time:15-20 Years

Save time

Bird-harvesting>6000 birds/hr

Save Feed

Feed-to-meat Ratio 1.4:1

Long Lifespan

15-20 years

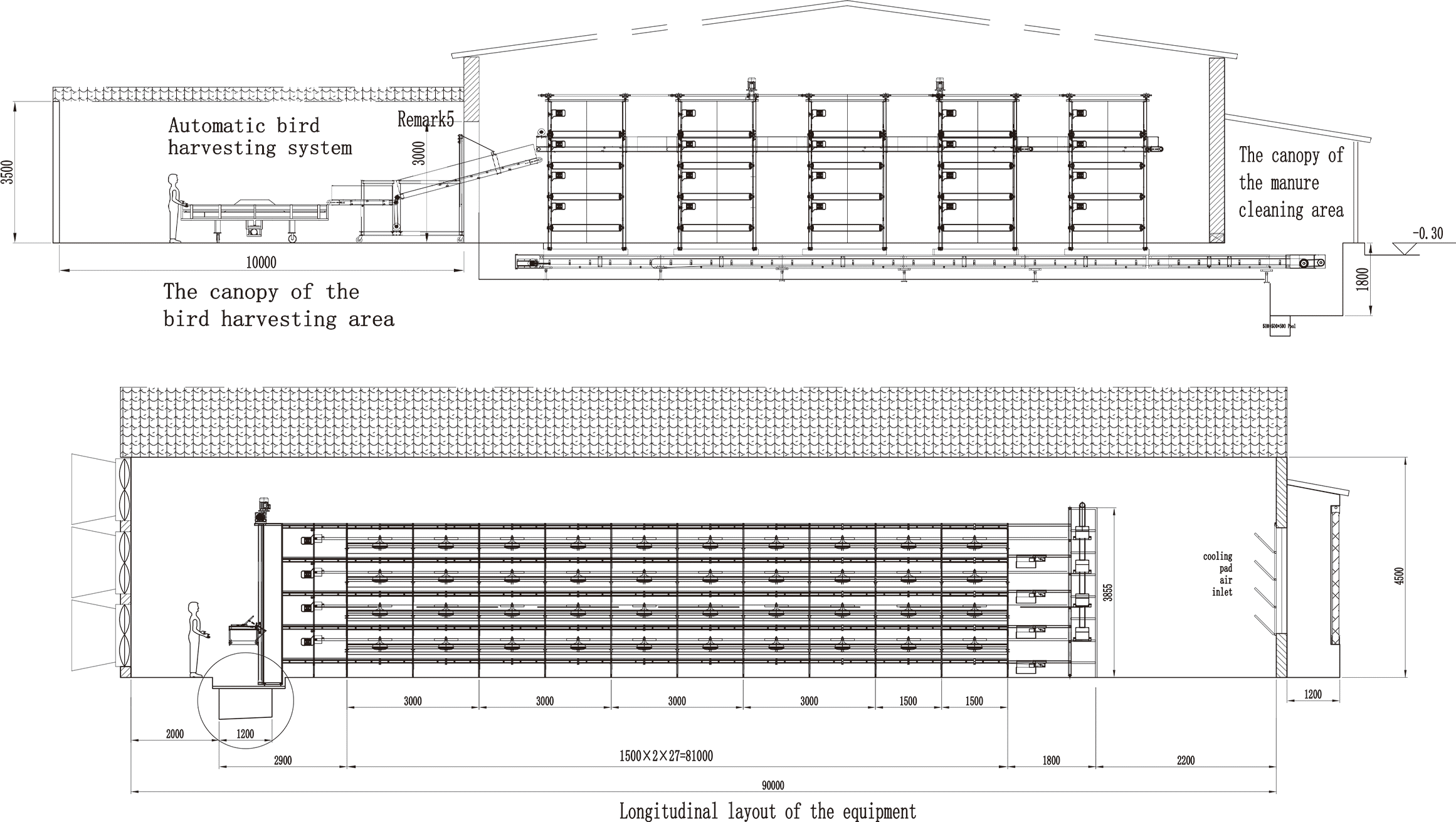

Automatic Harvesting Broiler Cage Drawing

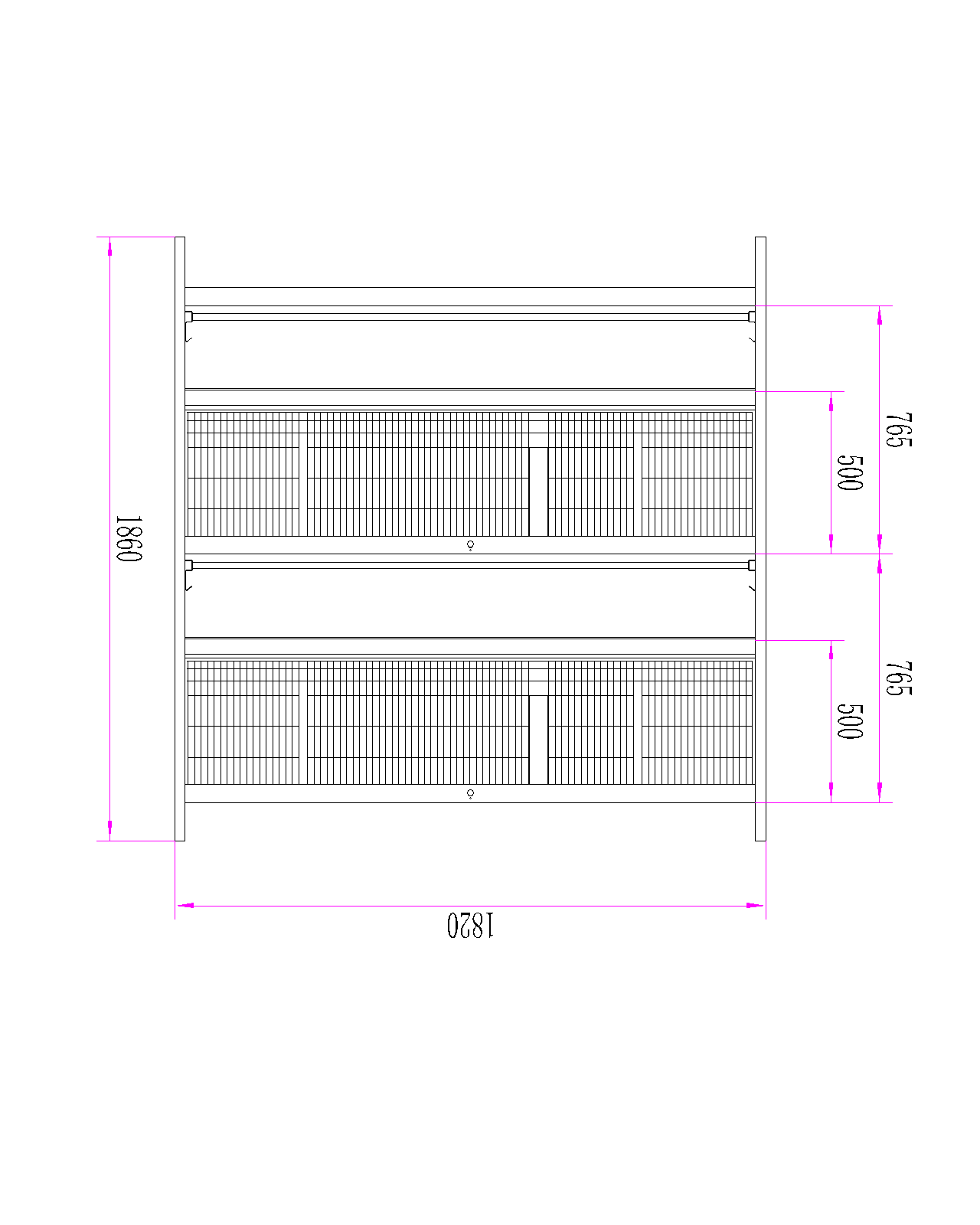

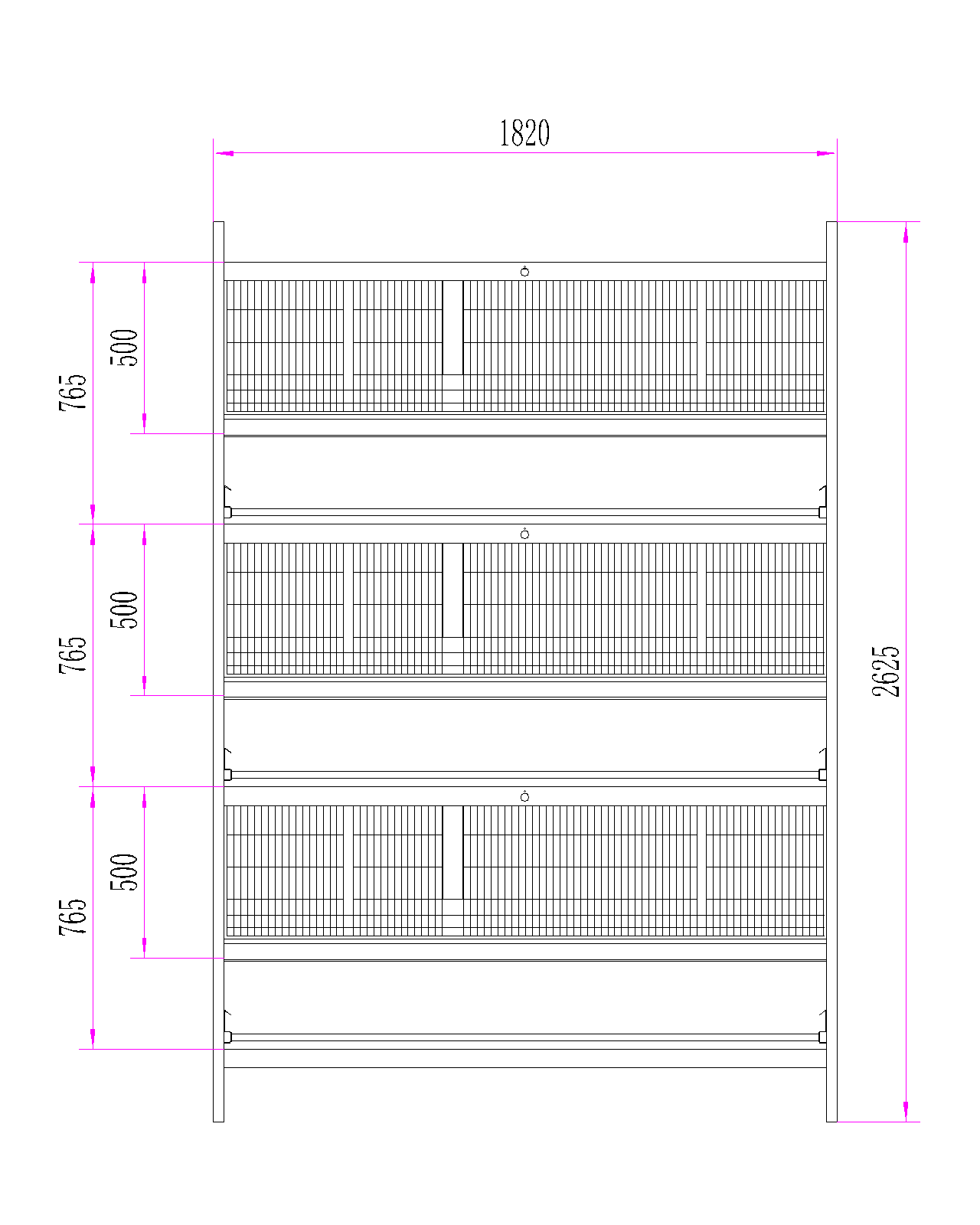

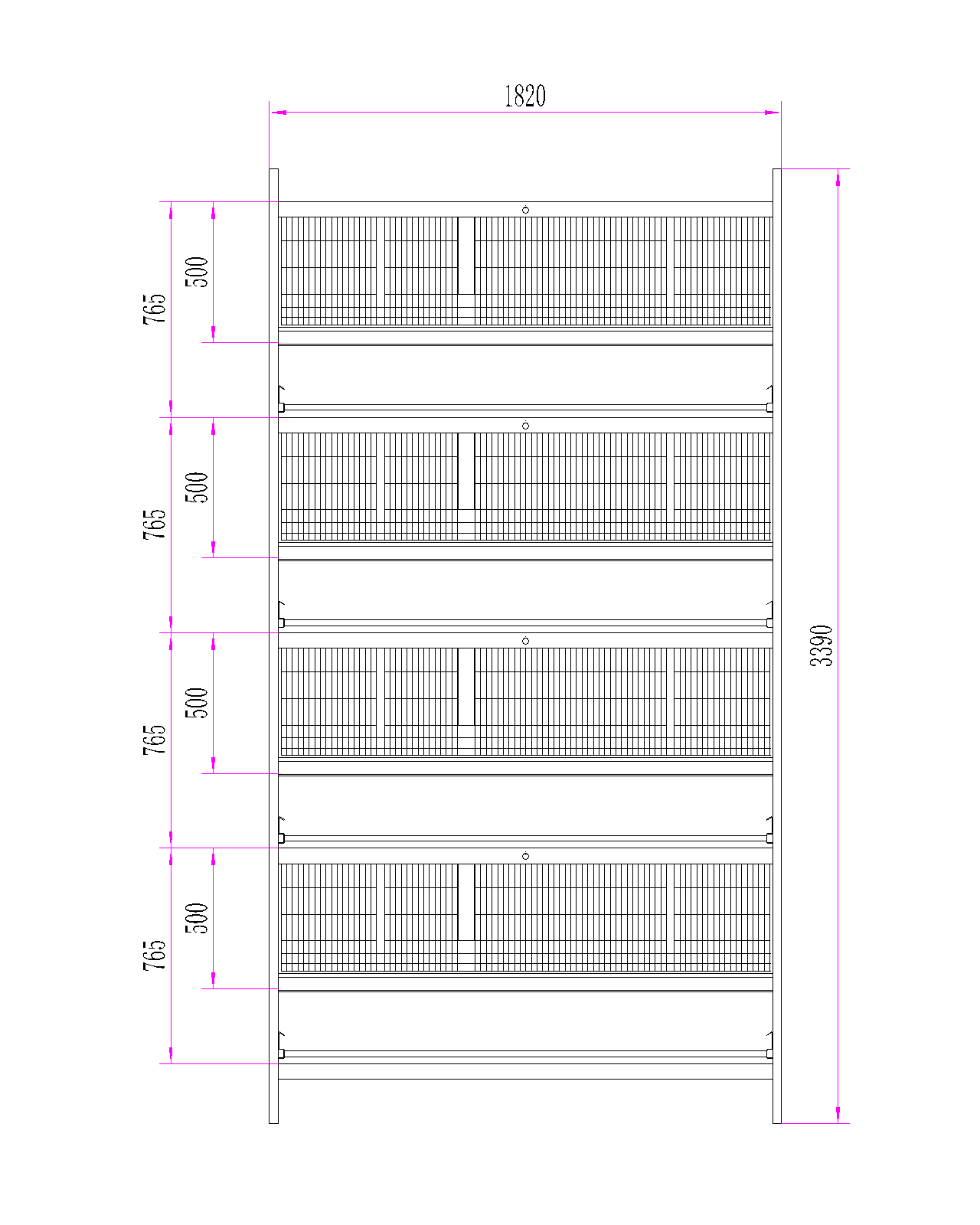

cage size

| Building size recommend | |||||||||

| Recommend building size | Chicken Quantity | ||||||||

| 90m*17.3m*4.5m (4-tier cage) | 81000(1.8kg bird) | ||||||||

| 80m*14.5m*4.2m (3-tier cage) | 41400(1.8kg bird) | ||||||||

| Cage information | |||||||||

| Cell Size | Length 3000mm, width 1820mm, height 500mm | ||||||||

| Raising Area | 364cm² | ||||||||

| Broiler Quantity per Cell | 150 birds/cell(<1.8kg) | ||||||||

Product Advantage

1. Cage mesh + frame

- Cage size: perfectly fitted to match the number of birds (raising density:50kg/㎡).

- Surface treatment: hot galvanized with uniform 275g zinc coating, good anti-corrosion quality.

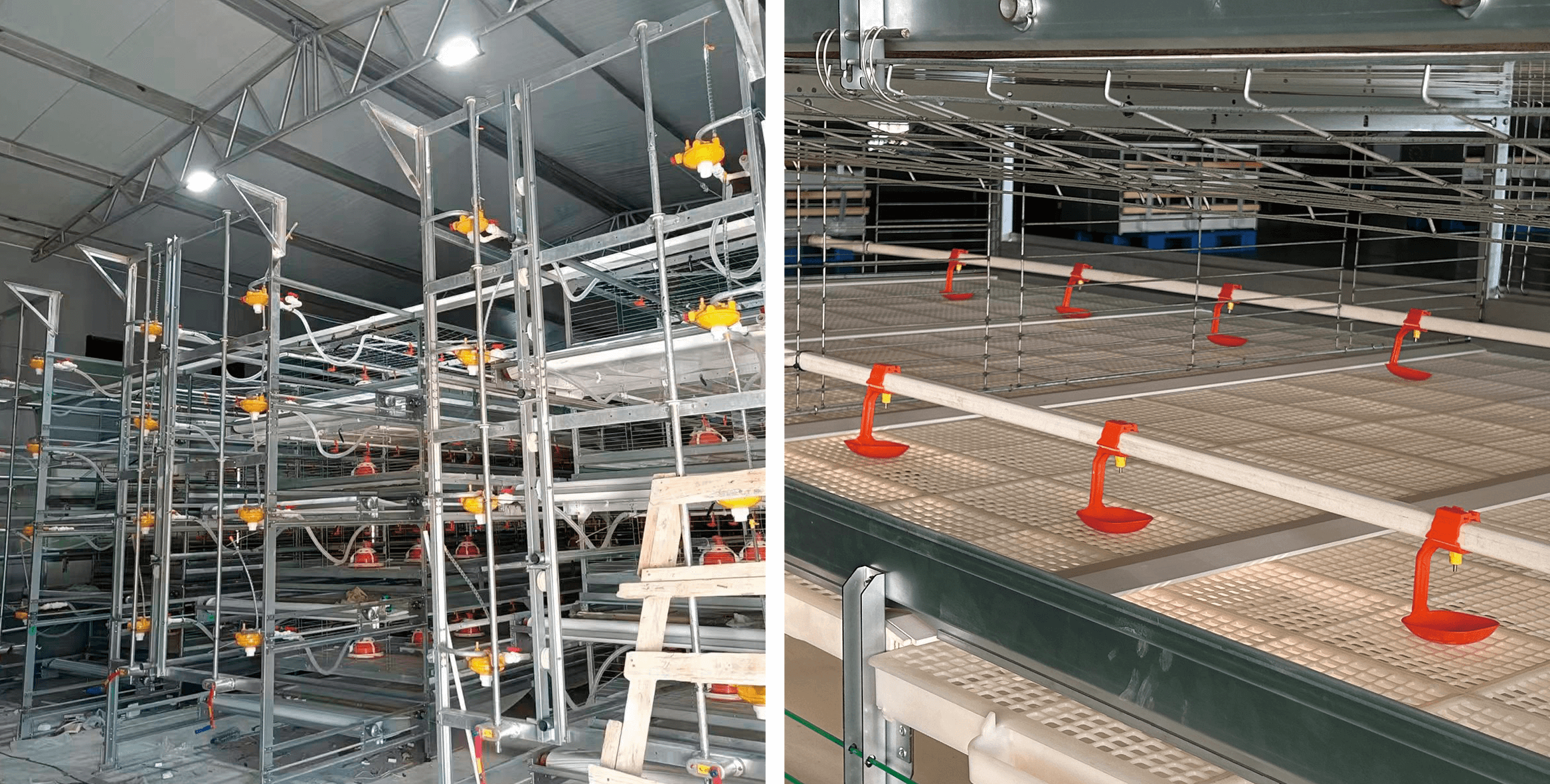

2. Automatic feeding

- Silo: weighing device is included for daily records of feed consumption.

- Pan feeding: The height is adjustable to feed chickens at different ages.

- Feed sensor: IFM®.

- Feed pipe: hot galvanized.

- Spiral: imported from South Africa.

- This mechanism guarantees a uniform distribution of feed over the whole system.

3. Automatic drinking

- Lifting system for every water dispenser allows chickens to drink at the correct height.

- Two different water supply lines are placed in each cage with 12 pcs drinkers.

- 360°water supply of the nipples.

- Supply Doser, filter, and pressure gauge.

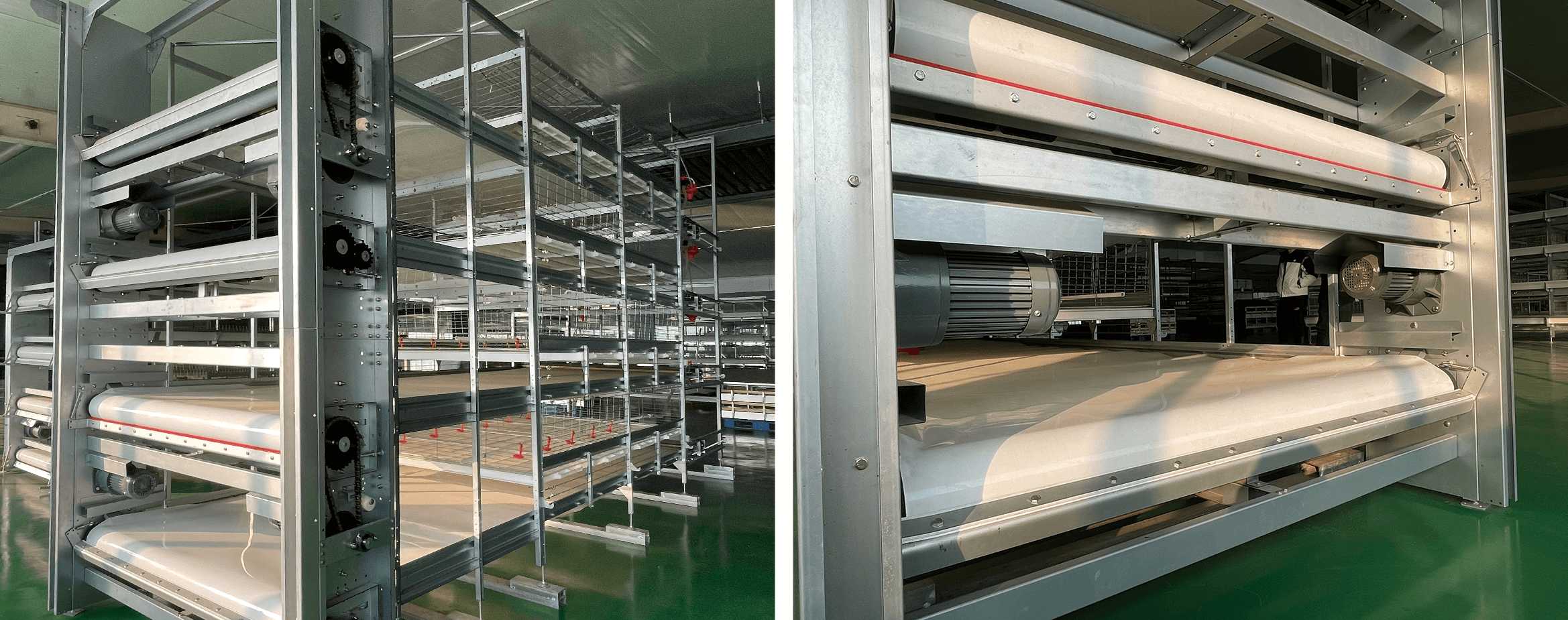

4. Automatic manure cleaning

- PP belt, 1.2mm thickness.

- Conveying speed: 3m/min.

5. Automatic bird-harvesting

- Plastic slat floor: PP raw material, soft and strong, hurt chicken breasts and feet; Easily pulled out.

- Flexible bird-harvesting time: Qualified chickens are taken out first. Chickens below the slaughter weight can continue to be raised for 1-2 days.

- lifting system at the final part can transport chickens from each tier outside the house.

- Bird-harvesting speed: about 6000 birds per hour.

- PVC conveying belt with 600mm width.

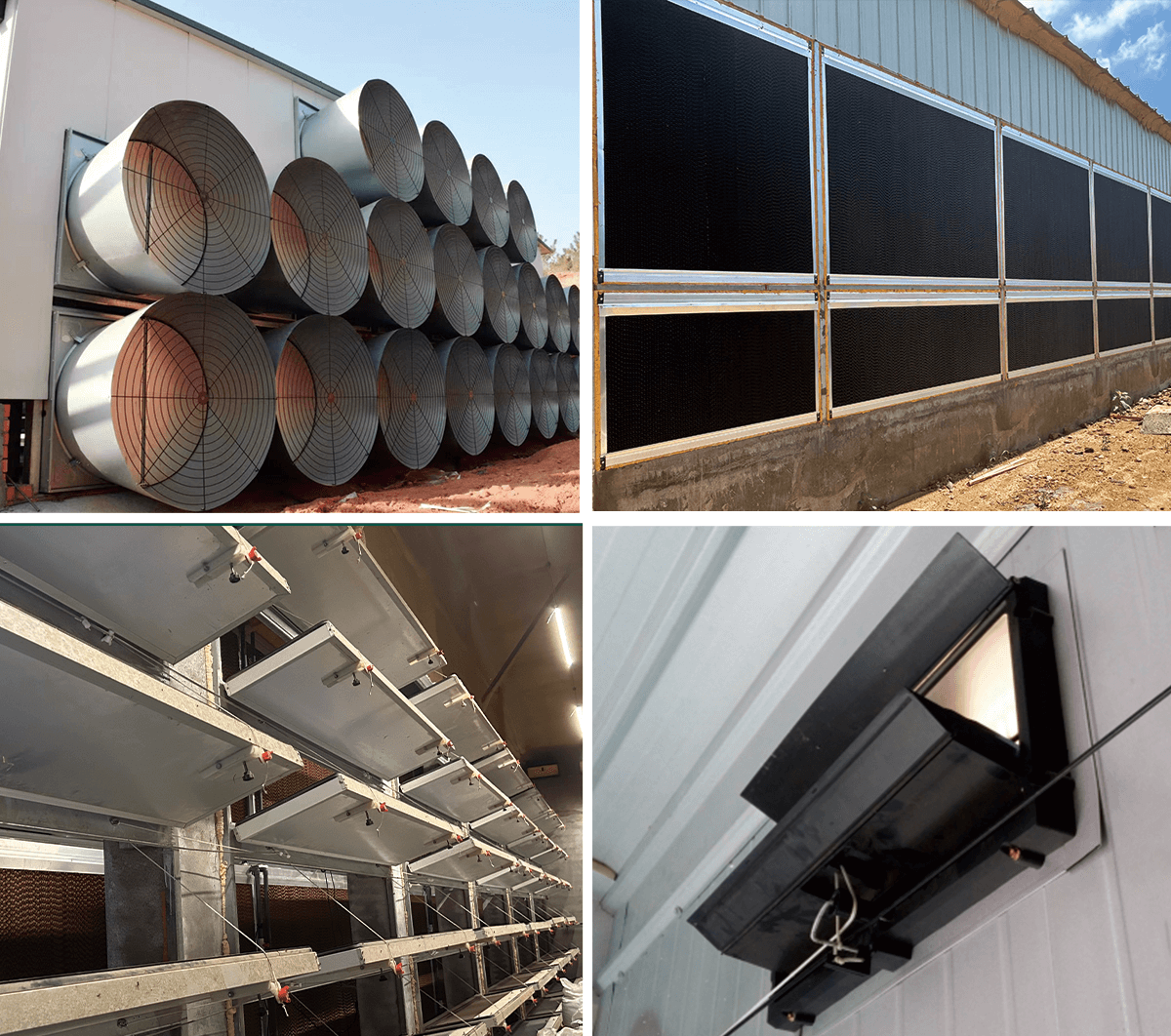

6. Automatic ventilation

- Cone fan: pass dynamic balance test.

- Cooling pad: with anti-rat mesh.

- Air-inlet window: with anti-bird mesh.

- Deflector: prevent cold air on chickens directly, avoid cold stress.

- Different heating methods can be designed: gas type, water type, diesel type

7. Automatic lighting

- Lights are specially for broiler chickens

- Uniform lighting, no flicker

8. Prefab chicken house

- Customized prefab steel structure chicken house based on local environment