A trusted choice for Zimbabwean customers: Customized 500BPH compact slaughter line successfully launched.

NPW has recently successfully delivered a customized 500BPH compact poultry slaughter line to its Zimbabwean client. The equipment has passed the final inspection, been carefully packaged, and officially dispatched to Harare. This project perfectly demonstrates the full-process professional services ranging from in-depth negotiations and precision manufacturing to comprehensive delivery, which is another powerful testament to NPW’s dedication to deepening its presence in the international market and its customer-centric approach.

From Demand to Trust: An On-Site Visit Across Ten Thousand Miles

This cooperation originated from the Zimbabwean client’s urgent need to improve their slaughtering and processing efficiency and hygiene standards. After initial contact and receiving our technical proposal, the client decided to pay a personal visit for an on-site inspection.

During the visit, the client went deep into the production workshop, observed the operation status of similar compact slaughter lines in detail, and conducted in-depth exchanges with our technical team on topics of their concern, including production efficiency, equipment durability, hygienic design, and subsequent maintenance.

The client spoke highly of our company’s equipment for its sophisticated manufacturing, innovative space-saving design, and transparent production process. Based on this inspection built on firsthand observation and in-depth mutual trust, the client confirmed on-site the customized solution tailored to its production capacity (500BPH) and site characteristics, and gladly placed the order.

From Order to Finished Product: Full-Process Transparent Collaborative Production

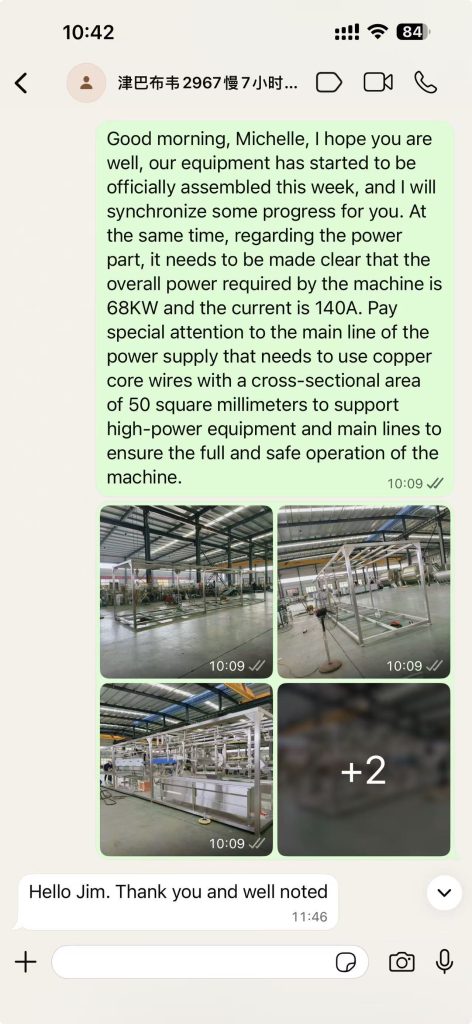

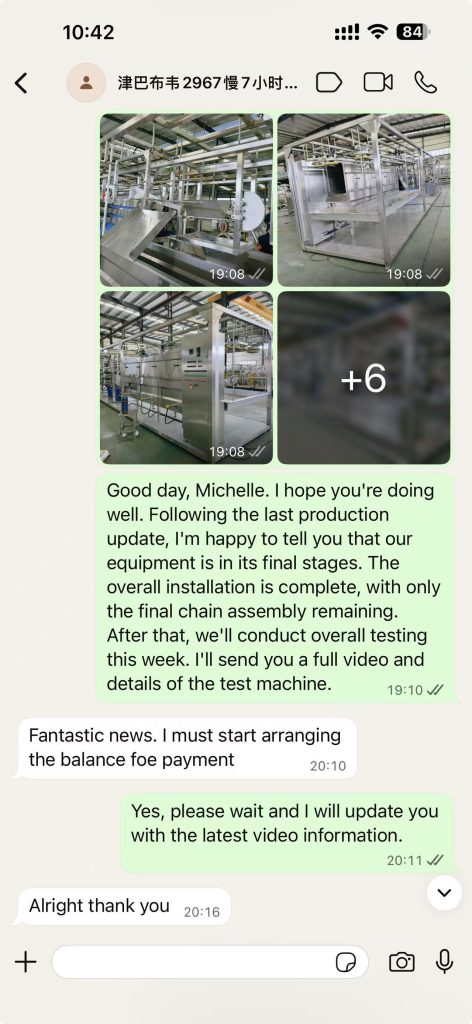

After the order is confirmed, the project immediately enters the precision manufacturing phase. We fully understand that trust stems from transparency. To this end, we have established an exclusive project communication mechanism:

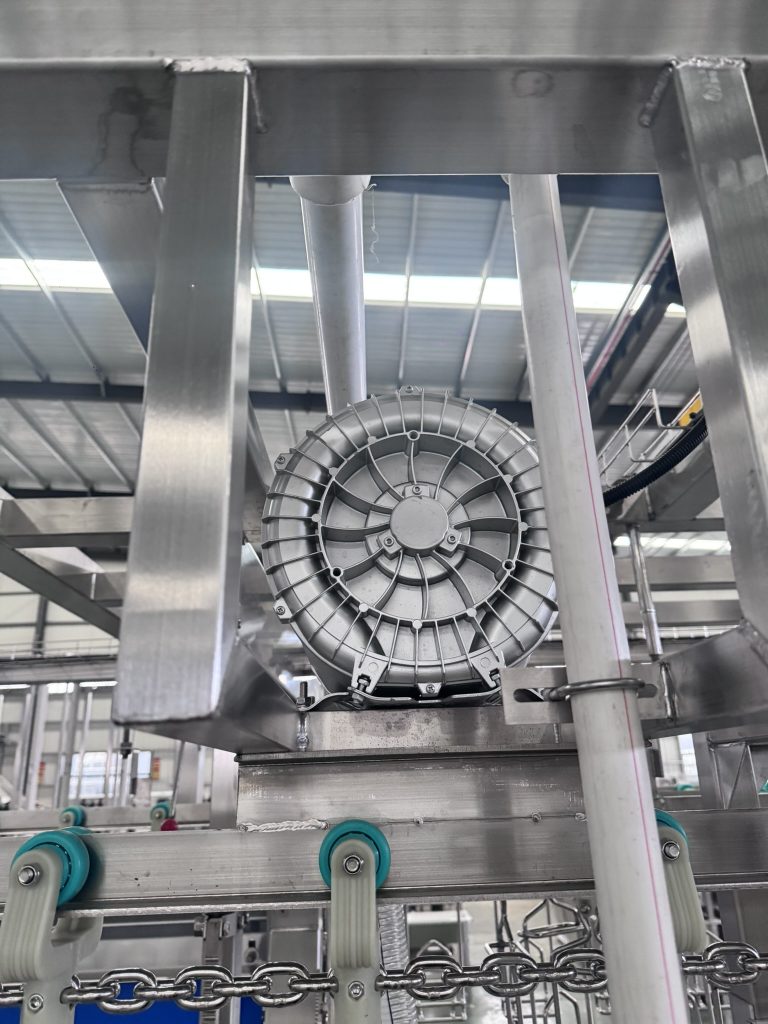

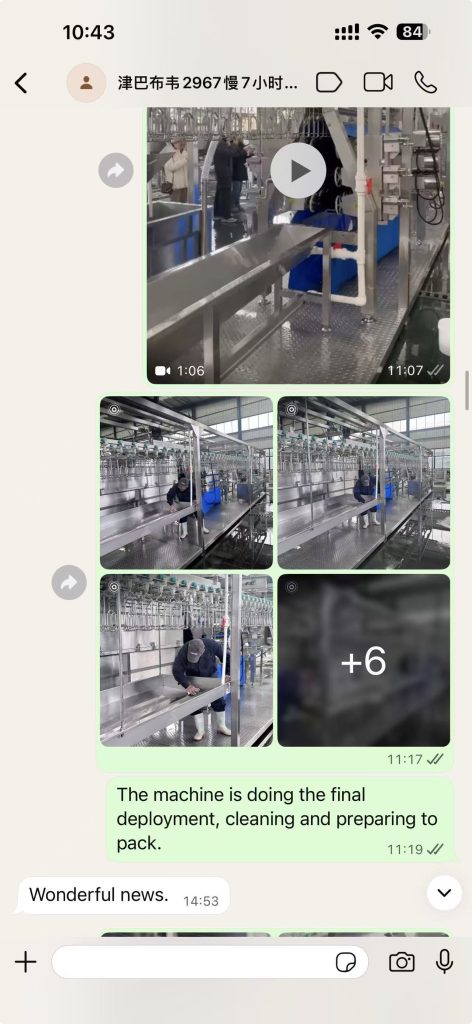

Synchronization of Key Milestones: From frame welding, assembly of critical components to final assembly and commissioning, we provide customers with intuitive updates via photos and videos upon the completion of each important production milestone.

In-Process Quality Inspection: Customers “participated remotely” in our quality inspection process. As requested, we conducted focused shooting and detailed explanations for key aspects including the material of core components, surface treatment processes, and assembly accuracy of moving mechanisms, ensuring that customers have a clear understanding of all production details.

From Equipment Completion to Shipment: Service Extension Beyond Expectations

After the equipment was fully assembled and passed rigorous in-house testing, we did not stop at a simple delivery.

Comprehensive Pre-Shipment Preparation: In addition to all the standard accessories, we also prepared an extra set of wearing parts as a complimentary gift based on local working conditions, so as to minimize potential downtime during the customer’s subsequent operations.

Robust Protective Packaging: For long-distance international maritime transportation, our packaging engineers designed a professional reinforcement solution. The main body of the equipment was given rust-proof packaging, while key electrical control components and precision parts were independently protected with custom wooden cases, ensuring that the equipment could arrive safely at the other side of the globe.

What we sell is not just equipment, but a reliable partnership from start to finish. “From the moment the customer steps into our factory, our goal is to make him fully confident in this investment. This successful cooperation has proven our capabilities in providing customized solutions and delivering international projects.”

This customized 500BPH compact slaughter line is expected to arrive in Zimbabwe in 50 days. NPW’s technical engineers will provide remote guidance and can arrange on-site installation and commissioning support according to the customer’s needs to ensure the smooth commissioning of the equipment.

Qingdao NPW Plastic Co., Ltd. is a leading supplier specializing in the R&D and manufacturing of intelligent poultry slaughtering and deep-processing equipment. We are committed to providing global customers with cost-effective, highly reliable customized slaughtering equipment solutions. Our products are exported to more than 30 countries and regions, and we support turnkey project solutions for slaughterhouses.