Installation Instructions for Mobile Compact Poultry Slaughter Line

*Please keep this manual properly.

*Please read this manual carefully before use.

*Please operate according to the requirements of this manual.

*If the equipment fails, please handle it according to the requirements of this manual.

Ⅰ. Overview

The compact chicken slaughtering line is a small slaughtering line suitable for 300-800 broilers per hour. It is characterized by easy installation, a compact structure, and high cost performance. It is constructed from stainless steel and integrates the complete process from hanging and stunning to scalding, feather removal, evisceration, and carcass pre-cooling. With its comprehensive functionality, it is the ideal choice for small-batch slaughtering operations.

Ⅱ. Product Model and Main Parameters

| Item | Specification |

|---|---|

| Equipment Dimensions | 11500 x 2250 x 2300 mm |

| Total Power | 67.5 kW |

| Power Supply | 380V / 50Hz / 3P |

Ⅲ. Main Technical Parameters

| Parameter | Value / Description |

|---|---|

| Type of Birds | Broiler Chicken |

| Live Bird Weight | 2.0 – 2.5 kg |

| Capacity | 300 – 800 Birds per Hour (Bph) |

| Bleeding Time | 3.5 – 4 minutes (Effective line length: 12 m) |

| Line Speed & Pitch | 2.58 meters/min; Hanging pitch: 203.2 mm |

| Scalding Type & Time | Air-agitated water bath; Approx. 90 seconds |

| Scalding Temperature | 62 – 64°C |

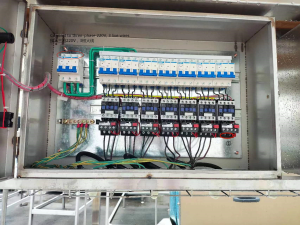

Ⅳ. Wiring Instructions

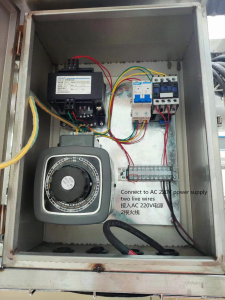

1. Stunning Machine Control Box

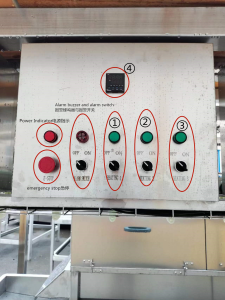

2. Scalding Machine Temperature Control Box

① No.1 heating switch and heating indicator light

② No.2 heating switch and heating indicator light

③ No.3 heating switch and heating indicator light

④ Temperature controller: Adjust temperature and differential on this panel.

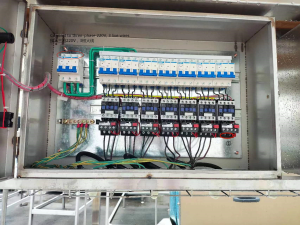

3. Plucking Machine and Blower Control Box

① For access to splitting saw and pre-cooling tank circuits.

4. Frequency Converter Control Box

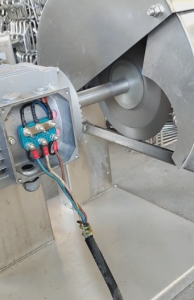

5. Split Saw Wiring Instruction

(Refer to device diagram.)

6. Pre-cooling Tank Wiring

For the other pre-cooling tank, refer to the wiring of the unit already installed.

7. Connect to Water Source

Ⅴ. Use and Operation

1. Pre-start Preparation (At least 1 hour before operation)

Turn on the electric heating pipes in the scalding machine to heat the water to 64°C.

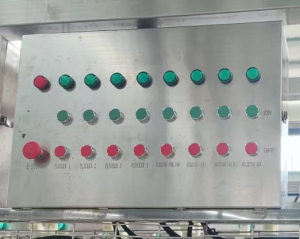

2. Start-up Sequence

2.1. Press the slaughtering line switch. Slowly run the chain to the required speed (check chain tension before starting).

2.2. Press the scalding machine blower button to start the blower.

2.3. Press the vertical plucking machine buttons in sequence to start the feather removers.

2.4. Press the pre-cooling tank blower button to start the blower.

2.5. Press the stunning machine button switch (Voltage range: 120-150V).

2.6. Connect to the water source.

Ⅵ. Safe Use Rules

1. Starting the Slaughtering Line Chain:

-

Open the power control box and verify all connections to the frequency converter. Turn on the main power only after confirmation.

-

Slowly rotate the frequency converter knob clockwise to gradually accelerate the chain to the required speed.

2. Stopping the Chain:

-

After production, slowly rotate the frequency converter knob counterclockwise until the chain stops completely.

-

Open the power control box, cut off the branch power supply, then the main power switch.

3. Important Notes:

-

After a temporary stop, wait at least 10-15 minutes before restarting the frequency converter.

-

Do not modify any settings on the frequency converter.

-

Do not hang hooks upside down on the chain to prevent derailment.

-

Do not rinse motors or the distribution box with water; use a rag only.

4. Hazard Prevention:

-

Keep hands and body parts away from the chain track during operation.

-

Do not stand under a moving chain.

-

All operators must receive safety training. Post warning signs. In case of injury, shut down the machine immediately to assist.

Ⅶ. Troubleshooting

| Fault | Analysis | Solution |

|---|---|---|

| Hanger jumps/jams | Loose/elongated chain | Adjust tension / Replace chain |

| Frequency converter overload | Chain blockage, bad support wheel bearing, damaged reducer | Clear blockage / Replace bearing / Replace reducer |

| Red head, bruising | Poor bleeding, stunning voltage too high | Adjust stunning machine voltage |

| Poor feather removal | Incorrect scalding temperature, incorrect plucker gap, worn rubber fingers | Adjust scalding temperature, Adjust plucker gap, Replace rubber fingers |

Ⅷ. Inspection and Maintenance Schedule

| Content / Item | Daily | Weekly | Monthly | Quarterly | Yearly |

|---|---|---|---|---|---|

| Inspection | Clean all equipment with high-pressure water. Crucial: Clean scalding tank heating tubes. | Check chain tension. | Oil vertical plucker adjustment device. | Check condition of rubber fingers. | Check motor, reducer, and blower operation. |

| Maintenance | Grease 3-4 bearing chambers (2ml each). Cycle through all bearings monthly. | Oil adjustment screws. | Apply 5ml lithium grease to rack and lifter. | Maintain bearing seats; replace if necessary. |

This compact slaughter line is perfect for my slaughterhouse construction plan.

We compared several small slaughtering lines on the market and ultimately chose this model. After using it for six months, three things impressed us most: First, it’s stable, working continuously for hours without malfunctioning; second, it’s worry-free, with timely training and after-sales support from the manufacturer; and third, it’s flexible, allowing us to adjust the slaughtering pace according to order volume. For colleagues processing hundreds of thousands of animals annually, I would recommend it without hesitation.

We primarily supply high-end fresh food supermarkets, which have extremely high requirements for carcass appearance and hygiene standards. The hair removal and evisceration processes on this production line are exceptional, with a hair removal rate consistently above 95% and a very low breakage rate. The equipment is constructed entirely of stainless steel, making cleaning and disinfection very convenient, which ensures our products consistently have excellent microbiological indicators. For over a year, it has operated stably with virtually no downtime due to equipment malfunctions, guaranteeing our order fulfillment.

As the owner of a small poultry processing plant, the compact slaughter line is a game-changer for us. It takes up little space but is incredibly efficient, processing 500 birds per hour, which perfectly meets our peak demand. Most importantly, it offers exceptional value for money, with a much shorter return on investment period than we anticipated. The level of automation is just right, eliminating the need for a complex operations team and significantly reducing labor costs.

“Our facility is small, but our orders are demanding. We were initially worried that this compact production line was just a ‘scaled-down’ version, lacking power and stability. But this 500BPH line completely changed my mind. From hanging the chickens to pre-cooling, the process is incredibly smooth. What we’re most satisfied with is that it occupies 30% less space than the old equipment, yet our daily slaughter volume has nearly doubled. The Chinese team installed and debugged it very quickly and even made adjustments based on our local power conditions. Now, after six months of operation, there have been almost no major downtime issues; it’s a ‘heroic unit’ in our factory.”

“We were building a new factory from scratch, so we needed a turnkey project. This company not only provided the core slaughtering line, but also took care of everything from the initial process design and workshop layout to equipment production, installation, commissioning, and even worker training. During production, although we couldn’t visit in person, we received photos and videos of the production progress every week, seeing our equipment assembled step by step. This transparency gave us peace of mind. When it was finally delivered, even the spare parts and special tools were neatly packed. Now that the factory is in operation smoothly, they are indeed a reliable partner.”

“We need to apply for export registration, which has extremely high requirements for the hygiene standards and traceability of the equipment. The all-stainless steel material and smooth, seamless design of this line allowed us to pass the official review on the first try. Its synchronous hygiene inspection system and numberable racks perfectly meet the key traceability requirement of ‘one-to-one correspondence between carcass and internal organs.’ Although it’s called a compact line, there is no compromise on food safety design, which is a key part of our obtaining export qualifications.”

“As newcomers to the industry, our biggest fear was the complexity of the equipment and the slow installation and commissioning. The supplier not only sent engineers to install it on-site, but also adjusted the parameters of the scalding system according to the hard water temperature in our area, and taught us how to maintain it. The automation level of the production line is just right, and it does not require many professional workers to operate. After a week of training, we can basically get started. It took less than two weeks from installation to production. This efficient delivery and localized support greatly reduced our entry barrier.”

“We manufacture for multiple breeding cooperatives, operating continuously for more than 10 hours a day. The stability of the equipment is our lifeline. This compact production line has been running for almost a year, and the core transmission and control systems have never failed us. More importantly, the process parameters for scalding and hair removal are very stable, which directly ensures the beautiful appearance of the carcasses and the yield. Compared with our old equipment, the average yield is about 1.5 percentage points higher. Just this alone can recoup a significant portion of the investment in just over a year.”

“Our processing plant is located in the suburbs, where land rent is expensive and space is precious. The most impressive thing about this compact line is that it is small but complete. From hanging chickens and slaughtering to pre-cooling, the entire process is completed on a line less than 20 meters long. It occupies only half the space of the old production line, but the production capacity of 500 chickens per hour is not reduced at all. The design is very compact, but the maintenance passage is reasonably reserved, and daily cleaning and maintenance are not troublesome. For small and medium-sized factories like ours that want to upgrade but are afraid of not having enough space, it is a real ‘godsend’ equipment.”