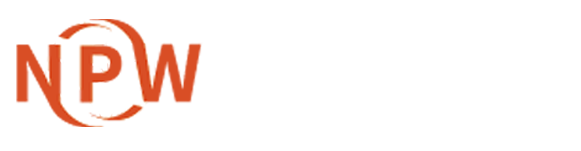

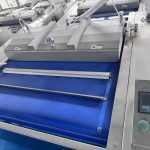

Rolling Vacuum Packaging Machine

External Dimensions: 1920*1630*960 mm Vacuum Chamber Dimensions: 540*1220*115 mm Sealing Length: 1100 mm Maximum Bag Length (Single Seal): 420 mm Maximum Package Height (High Cover): 90 mm Working Rate: 2-10 cycles/min, approximately 4 bags per cycle Power Supply: 380V 50HZ Power: 5.5 KW Weight: 600 kg Ultimate Vacuum: < 1.0 kPa Belt Drive Motor: Parallel Indexer 0.75 KW

Contact Us for Pricing

Interested in this product? Contact us now for detailed pricing and product information.

GET A QUOTE NOWProduct Details

The "rolling vacuum packaging machine" is a continuous, high-efficiency commercial/industrial vacuum packaging equipment. It completes the sealing by rolling a circulating heating rod on the sealing line, enabling uninterrupted continuous operation, which is very suitable for large-scale, assembly line packaging needs.

- The core working principle of a continuous band (rolling) vacuum packaging machine involves an automated cycle: the vacuum chamber cover automatically lowers to form a sealed cavity, air is evacuated, a rolling heating bar moves forward to complete the seal, and then the cover lifts, allowing the operator to immediately proceed to the next package. This creates a highly efficient, continuous workflow.

- The primary advantage of this design is its remarkable efficiency. By eliminating the waiting time for lid opening and closing inherent in single-chamber machines, it enables the packaging of hundreds to thousands of bags per hour with skilled operation. This makes it ideally suited for high-volume industries such as pre-made meals, cooked foods, red-cooked meats, frozen foods, snacks, and medical devices.

- When selecting a machine, several key parameters are crucial. The sealing length (common sizes: 400mm, 450mm, 500mm) determines the maximum package width per cycle. The vacuum pump power (commercial range: 63-100 m³/h) dictates the evacuation speed and final vacuum level. Finally, a microcomputer control system is essential for precisely setting vacuum level, sealing time, and cooling time.

- Important purchasing considerations include: 1) Ensuring capacity match based on your required bags per minute/hour; 2) Using only specialized vacuum bags (nylon/polyethylene composite film), as ordinary plastic bags are not suitable; 3) Evaluating key components like the heating bar material and vacuum pump brand (e.g., Busch, Rietschle), which directly impact longevity and stability; and 4) Verifying safety and compliance features, including an emergency stop button and electrically safe construction.