The chicken farm exhaust fan is an indispensable component of mechanical ventilation systems. In poultry and livestock housing facilities, it serves as the driving force behind the air exchange process, ensuring a healthy environment for the animals. When designing a mechanical ventilation system, selecting the right fans is the first and most critical step—prioritizing performance-tested and energy-efficient models is essential.

Key Factors of Poultry Farm Ventilation

A well-functioning ventilation system is vital for poultry houses, as it supplies fresh air to sustain life and maintains optimal conditions for the flock.

Ventilation reduces high temperatures, humidity, and air contamination to levels tolerable for confined chickens. It enables high-density livestock and poultry farming, improves overall welfare, and can lower the total building cost per unit of housed animals. As a core part of this system, exhaust fans play a must-include role in ensuring effective air exchange.

Principles of Poultry Ventilation with Exhaust Fans

Enclosed poultry buildings require a reliable air replacement system to prevent harmful changes in air composition. Without proper ventilation, concentrations of carbon dioxide, ammonia, and other toxic gases can rise to dangerous levels. The table below outlines critical and desired gas levels in poultry houses, based on research:

| Common gas levels in poultry houses | |||

| Gas | Symbol | Lethal | Desirable |

| Carbon Dioxide | CO2 | Above 30% | Below 1% |

| Methane | CH4 | Above 5% | Below 1% |

| Ammonia | NH3 | Above 500 ppm | Below 40 ppm |

| Hydrogen Sulfide | H2S | Above 500 ppm | Below 40 ppm |

| Oxygen | O2 | Below 6% | Above 16% |

Exhaust fans remove harmful gases and undesirable odors, supply oxygen to sustain life, and dilute airborne pathogens to levels safe for bird health.

There are two primary types of ventilation systems: natural airflow and mechanical (fan-driven). To balance chicken comfort with cost efficiency across varying climatic conditions, these systems are sometimes combined.

How to Measure Fan Capacity and Size for Poultry Farms?

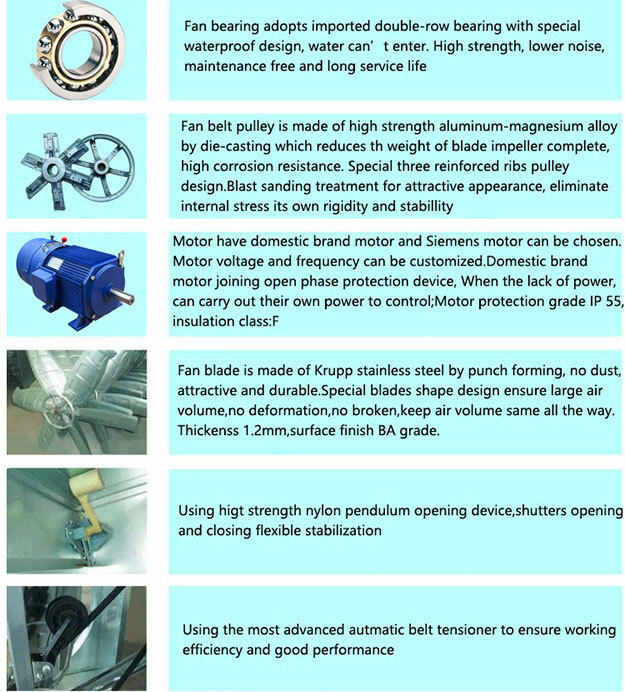

A fan’s airflow capacity depends on multiple factors: blade shape, blade diameter, motor horsepower (hp), blade speed (rpm), shroud design, and attachments like louvers. Fan capacity is measured in cubic feet per minute (cfm)—the volume of air moved per minute.

For efficient, affordable exhaust fans tailored to any poultry farm size or type, Qingdao NPW Plastic Co., Ltd. offers reliable solutions. Explore our range to find the perfect fit for your ventilation needs.

Prioritizing Energy Efficiency in Exhaust Fans

When selecting fans for animal ventilation, energy efficiency—expressed as airflow per unit of input energy (cfm/watt)—is a key consideration. Third-party testing helps evaluate this performance: for example, the University of Illinois’ Bio-environmental and Structural Systems Laboratory (BESS) tested 36-inch diameter fans and found significant variations in efficiency (8.3 to 18.6 cfm/watt at 1/10″ static pressure) and airflow (6,400 to 13,000 cfm).

Qingdao NPW Plastic Co., Ltd.’s poultry exhaust fans are engineered to meet these efficiency standards, with dimensions adjustable to suit any chicken farm layout.

Installation Considerations for Exhaust Fan Systems

To ensure optimal performance, keep these points in mind during installation:

- Design the system to account for the area’s extreme climatic conditions.

- Follow design specifications when installing ventilation equipment.

- Balance the system for the building’s intended capacity (i.e., full bird population).

- Insulate the structure based on local weather and intended use; use durable insulation to prevent rapid deterioration.

- Adjust the ventilation system seasonally and clean it regularly.

- Provide supplemental heating or cooling for extreme climates.

- Schedule periodic maintenance for all equipment (fans and controls).

- Maintain good management practices for poultry, the building, and the ventilation system.

- Install standby generators or alarm systems to address power failures.

Exhaust Fan System Maintenance

Fans in animal housing are exposed to dust, moisture, and dirt, which accumulate on blades, louvers, and shrouds. While dirt on blades has minimal impact, clogged louvers and guards can reduce airflow by up to 40%. To prevent this:

- Clean and lubricate louvers and guards regularly. Use graphite lubricant to minimize dirt buildup.

- Remove louvers from continuously running fans (if safe) to avoid airflow restrictions, but keep guards in place to prevent injury to humans or animals.

In facilities with manure pits, corrosive gases can damage equipment. Choose fans with non-corrosive housings (e.g., fiberglass) for pit exhausts. Protect controls (switches or microprocessors) with watertight, dust-tight electrical boxes to shield them from corrosive environments. For more details on wiring in corrosive settings, refer to the Farm Buildings Wiring Handbook (available from the University of Minnesota Agricultural Engineering Extension).

Qingdao NPW Plastic Co., Ltd. is committed to providing high-quality exhaust fans and ventilation solutions for poultry farms, ensuring optimal air quality, animal welfare, and operational efficiency. Contact us to learn more about our products and services.

Can you provide some examples of energy-efficient exhaust fans for chicken farms?

How do I choose the right size of exhaust fan for my chicken farm?

What are the maintenance requirements for chicken farm exhaust fans?